(BAT) Reference Document for the Production of Chlor-alkali ...

(BAT) Reference Document for the Production of Chlor-alkali ... (BAT) Reference Document for the Production of Chlor-alkali ...

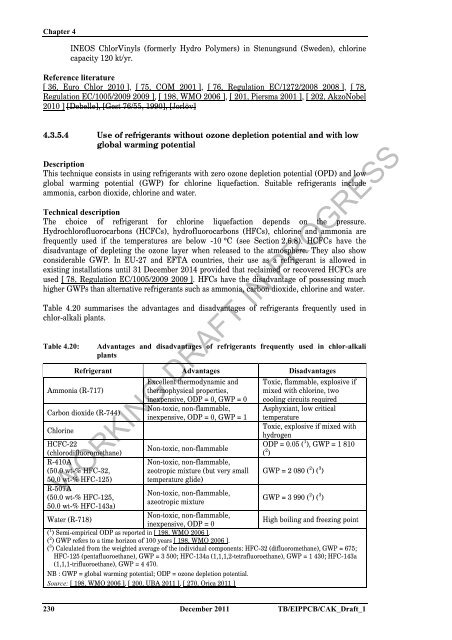

Chapter 4 INEOS ChlorVinyls (formerly Hydro Polymers) in Stenungsund (Sweden), chlorine capacity 120 kt/yr. Reference literature [ 36, Euro Chlor 2010 ], [ 75, COM 2001 ], [ 76, Regulation EC/1272/2008 2008 ], [ 78, Regulation EC/1005/2009 2009 ], [ 198, WMO 2006 ], [ 201, Piersma 2001 ], [ 202, AkzoNobel 2010 ] [Debelle], [Gest 76/55, 1990], [Jorlöv] 4.3.5.4 Use of refrigerants without ozone depletion potential and with low global warming potential Description This technique consists in using refrigerants with zero ozone depletion potential (OPD) and low global warming potential (GWP) for chlorine liquefaction. Suitable refrigerants include ammonia, carbon dioxide, chlorine and water. Technical description The choice of refrigerant for chlorine liquefaction depends on the pressure. Hydrochlorofluorocarbons (HCFCs), hydrofluorocarbons (HFCs), chlorine and ammonia are frequently used if the temperatures are below -10 °C (see Section 2.6.8). HCFCs have the disadvantage of depleting the ozone layer when released to the atmosphere. They also show considerable GWP. In EU-27 and EFTA countries, their use as a refrigerant is allowed in existing installations until 31 December 2014 provided that reclaimed or recovered HCFCs are used [ 78, Regulation EC/1005/2009 2009 ]. HFCs have the disadvantage of possessing much higher GWPs than alternative refrigerants such as ammonia, carbon dioxide, chlorine and water. Table 4.20 summarises the advantages and disadvantages of refrigerants frequently used in chlor-alkali plants. Table 4.20: Advantages and disadvantages of refrigerants frequently used in chlor-alkali plants Refrigerant Advantages Disadvantages Excellent thermodynamic and Toxic, flammable, explosive if Ammonia (R-717) thermophysical properties, mixed with chlorine, two inexpensive, ODP = 0, GWP = 0 cooling circuits required Carbon dioxide (R-744) Non-toxic, non-flammable, inexpensive, ODP = 0, GWP = 1 Asphyxiant, low critical temperature Chlorine Toxic, explosive if mixed with hydrogen HCFC-22 (chlorodifluoromethane) Non-toxic, non-flammable ODP = 0.05 ( 1 ), GWP = 1 810 ( 2 ) R-410A Non-toxic, non-flammable, (50.0 wt-% HFC-32, zeotropic mixture (but very small GWP = 2 080 ( 50.0 wt-% HFC-125) temperature glide) 2 ) ( 3 ) R-507A (50.0 wt-% HFC-125, 50.0 wt-% HFC-143a) Non-toxic, non-flammable, azeotropic mixture GWP = 3 990 ( 2 ) ( 3 ) Non-toxic, non-flammable, Water (R-718) inexpensive, ODP = 0 ( High boiling and freezing point 1 ) Semi-empirical ODP as reported in [ 198, WMO 2006 ]. ( 2 ) GWP refers to a time horizon of 100 years [ 198, WMO 2006 ]. ( 3 ) Calculated from the weighted average of the individual components: HFC-32 (difluoromethane), GWP = 675; HFC-125 (pentafluoroethane), GWP = 3 500; HFC-134a (1,1,1,2-tetrafluoroethane), GWP = 1 430; HFC-143a (1,1,1-trifluoroethane), GWP = 4 470. NB : GWP = global warming potential; ODP = ozone depletion potential. Source: [ 198, WMO 2006 ], [ 200, UBA 2011 ], [ 270, Orica 2011 ] WORKING DRAFT IN PROGRESS 230 December 2011 TB/EIPPCB/CAK_Draft_1

{Please TWG provide more information.} Achieved environmental benefits The achieved environmental benefits of this technique include: prevention of emissions of ozone-depleting substances; prevention of emissions of substances with high global warming potential. Chapter 4 Environmental performance and operational data At the Dow plant in Stade (Germany) chlorine is used as refrigerant [ 199, Bezirksregierung Lüneburg 1997 ]. At the Orica plants in Melbourne and Sydney (Australia), the chlorine gas is liquefied by carbon dioxide evaporating at -45 °C and the carbon dioxide is in turn recondensed by an ammonia refrigeration unit operating at -52.6 °C saturated suction temperature and 40 °C condensing temperature. Because ammonia and chlorine are so reactive, they are physically separated from each other in the plant and in the refrigeration system. The ammonia refrigeration system is designed to provide cooling to a carbon dioxide thermosiphon loop which then provides cooling to the chlorine liquefaction process. The advantage of the thermosiphon system is that there are no moving parts or additional energy inputs. The brake horsepower of the refrigeration system ranges from 4.4 – 4.5 per tonne of refrigeration. The liquefied chlorine is stored at -41 °C and atmospheric pressure [ 270, Orica 2011 ]. Cross-media effects {Please TWG provide information.} Technical considerations relevant to applicability {Please TWG provide information.} Economics {Please TWG provide information.} Driving force for implementation The driving force for implementation of this technique is environmental legislation. Example plants Dow in Stade (Germany), chlorine capacity 1585 kt/yr, use of chlorine as refrigerant [ 199, Bezirksregierung Lüneburg 1997 ]; Orica in Melbourne (Australia), chlorine capacity 31 kt/yr, use of carbon dioxide and ammonia as refrigerants [ 238, Clews 2001 ]; Orica in Sydney (Australia), chlorine capacity 31 kt/yr, use of carbon dioxide and ammonia as refrigerants [ 238, Clews 2001 ]. Reference literature [ 78, Regulation EC/1005/2009 2009 ], [ 198, WMO 2006 ], [ 199, Bezirksregierung Lüneburg 1997 ], [ 200, UBA 2011 ], [ 238, Clews 2001 ], [ 270, Orica 2011 ] WORKING DRAFT IN PROGRESS 4.3.6 Techniques to reduce emissions to water 4.3.6.1 Techniques to reduce emissions of sulphate 4.3.6.1.1 Overview In addition to the technique described in the following Section 4.3.6.2.2, the recycling or reuse of spent sulphuric acid from chlorine drying (see Section 4.3.7) and the use of non-sulphur-containing reducing agents to reduce emissions of free oxidants (see Sections 4.3.6.3.3 to 4.3.6.3.6) also reduce sulphate emissions. TB/EIPPCB/CAK_Draft_1 December 2011 231

- Page 195 and 196: Chapter 4 4.2.3 Conversion of asbes

- Page 197 and 198: Chapter 4 directly from the cells.

- Page 199 and 200: 4.3 All Diaphragm and membrane cell

- Page 201 and 202: Chapter 4 non-standardised) will be

- Page 203 and 204: Chapter 4 removal of conductive com

- Page 205 and 206: Chapter 4 Cross-media effects Plant

- Page 207 and 208: Environmental performance and opera

- Page 209 and 210: Example plants Dow, Stade (Germany)

- Page 211 and 212: Chapter 4 current density resulting

- Page 213 and 214: Chapter 4 modifications to auxiliar

- Page 215 and 216: Table 4.14: Cost calculation for th

- Page 217 and 218: Chapter 4 membrane lifetimes range

- Page 219 and 220: Chapter 4 Cross-media effects Some

- Page 221 and 222: Chapter 4 The drawback of using fer

- Page 223 and 224: Chapter 4 evaporation unit integrat

- Page 225 and 226: Chapter 4 Environmental performance

- Page 227 and 228: Chapter 4 Technical description The

- Page 229 and 230: Chapter 4 Table 4.17: Monitoring te

- Page 231 and 232: Chapter 4 Environmental performance

- Page 233 and 234: Environmental performance and opera

- Page 235 and 236: Chapter 4 Prevention of chlorine re

- Page 237 and 238: Chapter 4 Good pipework design to m

- Page 239 and 240: Chapter 4 was the solution at that

- Page 241 and 242: differential pressure at inlet and

- Page 243 and 244: Chapter 4 chlorine scrubber, immedi

- Page 245: Chapter 4 Achieved environmental be

- Page 249 and 250: environmental legislation; generati

- Page 251 and 252: Chapter 4 Table 4.21: Examples of o

- Page 253 and 254: Chapter 4 Driving force for impleme

- Page 255 and 256: 4.3.6.3.4 Catalytic decomposition r

- Page 257 and 258: Chapter 4 In both cases, the spent

- Page 259 and 260: Chapter 4 Example plants Thermal de

- Page 261 and 262: Chapter 4 migration of hydroxide io

- Page 263 and 264: eduction of chlorate emissions; red

- Page 265 and 266: Example plants Solvin in Antwerp-Li

- Page 267 and 268: eduction of costs related to equipm

- Page 269 and 270: Chapter 4 Off-site reconcentration

- Page 271 and 272: Chapter 4 b) closing of doors and w

- Page 273 and 274: 4.4 Membrane cell plants 4.4.1 High

- Page 275 and 276: 4.5.3 Containment Chapter 4 Descrip

- Page 277 and 278: Chapter 4 Sections 4.5.4.2 and 4.5.

- Page 279 and 280: Chapter 4 At this site, mercury con

- Page 281 and 282: Chapter 4 However, the soil washing

- Page 283 and 284: 5 BEST AVAILABLE TECHNIQUES Scope

- Page 285 and 286: General considerations In these BAT

- Page 287 and 288: 5.2 Decommissioning of mercury cell

- Page 289 and 290: 5.3 Environmental management system

- Page 291 and 292: Chapter 5 The BAT-associated enviro

- Page 293 and 294: Chapter 5 6. In order to reduce ene

- Page 295 and 296: 5.6 Monitoring of emissions Chapter

Chapter 4<br />

INEOS <strong>Chlor</strong>Vinyls (<strong>for</strong>merly Hydro Polymers) in Stenungsund (Sweden), chlorine<br />

capacity 120 kt/yr.<br />

<strong>Reference</strong> literature<br />

[ 36, Euro <strong>Chlor</strong> 2010 ], [ 75, COM 2001 ], [ 76, Regulation EC/1272/2008 2008 ], [ 78,<br />

Regulation EC/1005/2009 2009 ], [ 198, WMO 2006 ], [ 201, Piersma 2001 ], [ 202, AkzoNobel<br />

2010 ] [Debelle], [Gest 76/55, 1990], [Jorlöv]<br />

4.3.5.4 Use <strong>of</strong> refrigerants without ozone depletion potential and with low<br />

global warming potential<br />

Description<br />

This technique consists in using refrigerants with zero ozone depletion potential (OPD) and low<br />

global warming potential (GWP) <strong>for</strong> chlorine liquefaction. Suitable refrigerants include<br />

ammonia, carbon dioxide, chlorine and water.<br />

Technical description<br />

The choice <strong>of</strong> refrigerant <strong>for</strong> chlorine liquefaction depends on <strong>the</strong> pressure.<br />

Hydrochlor<strong>of</strong>luorocarbons (HCFCs), hydr<strong>of</strong>luorocarbons (HFCs), chlorine and ammonia are<br />

frequently used if <strong>the</strong> temperatures are below -10 °C (see Section 2.6.8). HCFCs have <strong>the</strong><br />

disadvantage <strong>of</strong> depleting <strong>the</strong> ozone layer when released to <strong>the</strong> atmosphere. They also show<br />

considerable GWP. In EU-27 and EFTA countries, <strong>the</strong>ir use as a refrigerant is allowed in<br />

existing installations until 31 December 2014 provided that reclaimed or recovered HCFCs are<br />

used [ 78, Regulation EC/1005/2009 2009 ]. HFCs have <strong>the</strong> disadvantage <strong>of</strong> possessing much<br />

higher GWPs than alternative refrigerants such as ammonia, carbon dioxide, chlorine and water.<br />

Table 4.20 summarises <strong>the</strong> advantages and disadvantages <strong>of</strong> refrigerants frequently used in<br />

chlor-<strong>alkali</strong> plants.<br />

Table 4.20: Advantages and disadvantages <strong>of</strong> refrigerants frequently used in chlor-<strong>alkali</strong><br />

plants<br />

Refrigerant Advantages Disadvantages<br />

Excellent <strong>the</strong>rmodynamic and Toxic, flammable, explosive if<br />

Ammonia (R-717)<br />

<strong>the</strong>rmophysical properties, mixed with chlorine, two<br />

inexpensive, ODP = 0, GWP = 0 cooling circuits required<br />

Carbon dioxide (R-744)<br />

Non-toxic, non-flammable,<br />

inexpensive, ODP = 0, GWP = 1<br />

Asphyxiant, low critical<br />

temperature<br />

<strong>Chlor</strong>ine<br />

Toxic, explosive if mixed with<br />

hydrogen<br />

HCFC-22<br />

(chlorodifluoromethane)<br />

Non-toxic, non-flammable<br />

ODP = 0.05 ( 1 ), GWP = 1 810<br />

( 2 )<br />

R-410A<br />

Non-toxic, non-flammable,<br />

(50.0 wt-% HFC-32, zeotropic mixture (but very small GWP = 2 080 (<br />

50.0 wt-% HFC-125) temperature glide)<br />

2 ) ( 3 )<br />

R-507A<br />

(50.0 wt-% HFC-125,<br />

50.0 wt-% HFC-143a)<br />

Non-toxic, non-flammable,<br />

azeotropic mixture<br />

GWP = 3 990 ( 2 ) ( 3 )<br />

Non-toxic, non-flammable,<br />

Water (R-718)<br />

inexpensive, ODP = 0<br />

(<br />

High boiling and freezing point<br />

1 ) Semi-empirical ODP as reported in [ 198, WMO 2006 ].<br />

( 2 ) GWP refers to a time horizon <strong>of</strong> 100 years [ 198, WMO 2006 ].<br />

( 3 ) Calculated from <strong>the</strong> weighted average <strong>of</strong> <strong>the</strong> individual components: HFC-32 (difluoromethane), GWP = 675;<br />

HFC-125 (pentafluoroethane), GWP = 3 500; HFC-134a (1,1,1,2-tetrafluoroethane), GWP = 1 430; HFC-143a<br />

(1,1,1-trifluoroethane), GWP = 4 470.<br />

NB : GWP = global warming potential; ODP = ozone depletion potential.<br />

Source: [ 198, WMO 2006 ], [ 200, UBA 2011 ], [ 270, Orica 2011 ]<br />

WORKING DRAFT IN PROGRESS<br />

230 December 2011 TB/EIPPCB/CAK_Draft_1