(BAT) Reference Document for the Production of Chlor-alkali ...

(BAT) Reference Document for the Production of Chlor-alkali ...

(BAT) Reference Document for the Production of Chlor-alkali ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 4<br />

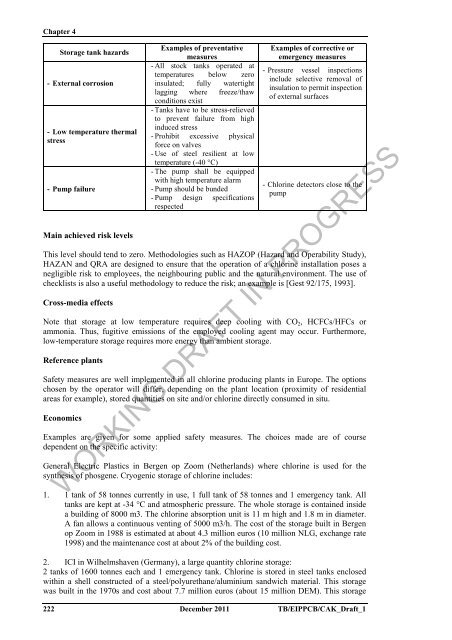

Storage tank hazards<br />

- External corrosion<br />

- Low temperature <strong>the</strong>rmal<br />

stress<br />

- Pump failure<br />

Main achieved risk levels<br />

Examples <strong>of</strong> preventative<br />

measures<br />

- All stock tanks operated at<br />

temperatures below zero<br />

insulated; fully watertight<br />

lagging where freeze/thaw<br />

conditions exist<br />

- Tanks have to be stress-relieved<br />

to prevent failure from high<br />

induced stress<br />

- Prohibit excessive physical<br />

<strong>for</strong>ce on valves<br />

- Use <strong>of</strong> steel resilient at low<br />

temperature (-40 °C)<br />

- The pump shall be equipped<br />

with high temperature alarm<br />

- Pump should be bunded<br />

- Pump design specifications<br />

respected<br />

Examples <strong>of</strong> corrective or<br />

emergency measures<br />

- Pressure vessel inspections<br />

include selective removal <strong>of</strong><br />

insulation to permit inspection<br />

<strong>of</strong> external surfaces<br />

- <strong>Chlor</strong>ine detectors close to <strong>the</strong><br />

pump<br />

This level should tend to zero. Methodologies such as HAZOP (Hazard and Operability Study),<br />

HAZAN and QRA are designed to ensure that <strong>the</strong> operation <strong>of</strong> a chlorine installation poses a<br />

negligible risk to employees, <strong>the</strong> neighbouring public and <strong>the</strong> natural environment. The use <strong>of</strong><br />

checklists is also a useful methodology to reduce <strong>the</strong> risk; an example is [Gest 92/175, 1993].<br />

Cross-media effects<br />

Note that storage at low temperature requires deep cooling with CO2, HCFCs/HFCs or<br />

ammonia. Thus, fugitive emissions <strong>of</strong> <strong>the</strong> employed cooling agent may occur. Fur<strong>the</strong>rmore,<br />

low-temperature storage requires more energy than ambient storage.<br />

<strong>Reference</strong> plants<br />

Safety measures are well implemented in all chlorine producing plants in Europe. The options<br />

chosen by <strong>the</strong> operator will differ, depending on <strong>the</strong> plant location (proximity <strong>of</strong> residential<br />

areas <strong>for</strong> example), stored quantities on site and/or chlorine directly consumed in situ.<br />

Economics<br />

Examples are given <strong>for</strong> some applied safety measures. The choices made are <strong>of</strong> course<br />

dependent on <strong>the</strong> specific activity:<br />

General Electric Plastics in Bergen op Zoom (Ne<strong>the</strong>rlands) where chlorine is used <strong>for</strong> <strong>the</strong><br />

syn<strong>the</strong>sis <strong>of</strong> phosgene. Cryogenic storage <strong>of</strong> chlorine includes:<br />

WORKING DRAFT IN PROGRESS<br />

1. 1 tank <strong>of</strong> 58 tonnes currently in use, 1 full tank <strong>of</strong> 58 tonnes and 1 emergency tank. All<br />

tanks are kept at -34 °C and atmospheric pressure. The whole storage is contained inside<br />

a building <strong>of</strong> 8000 m3. The chlorine absorption unit is 11 m high and 1.8 m in diameter.<br />

A fan allows a continuous venting <strong>of</strong> 5000 m3/h. The cost <strong>of</strong> <strong>the</strong> storage built in Bergen<br />

op Zoom in 1988 is estimated at about 4.3 million euros (10 million NLG, exchange rate<br />

1998) and <strong>the</strong> maintenance cost at about 2% <strong>of</strong> <strong>the</strong> building cost.<br />

2. ICI in Wilhelmshaven (Germany), a large quantity chlorine storage:<br />

2 tanks <strong>of</strong> 1600 tonnes each and 1 emergency tank. <strong>Chlor</strong>ine is stored in steel tanks enclosed<br />

within a shell constructed <strong>of</strong> a steel/polyurethane/aluminium sandwich material. This storage<br />

was built in <strong>the</strong> 1970s and cost about 7.7 million euros (about 15 million DEM). This storage<br />

222 December 2011 TB/EIPPCB/CAK_Draft_1