(BAT) Reference Document for the Production of Chlor-alkali ...

(BAT) Reference Document for the Production of Chlor-alkali ...

(BAT) Reference Document for the Production of Chlor-alkali ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

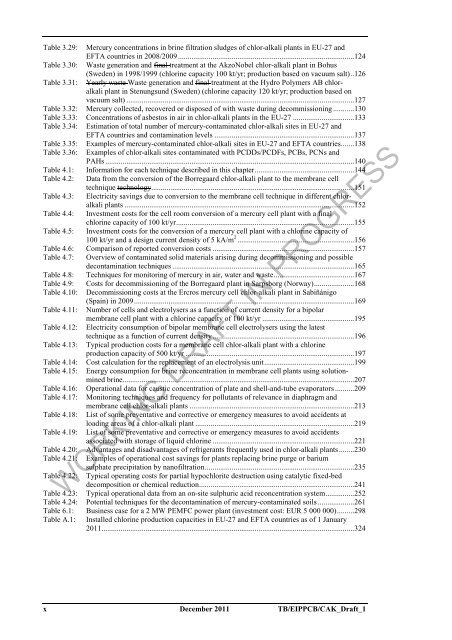

Table 3.29: Mercury concentrations in brine filtration sludges <strong>of</strong> chlor-<strong>alkali</strong> plants in EU-27 and<br />

EFTA countries in 2008/2009............................................................................................124<br />

Table 3.30: Waste generation and final treatment at <strong>the</strong> AkzoNobel chlor-<strong>alkali</strong> plant in Bohus<br />

(Sweden) in 1998/1999 (chlorine capacity 100 kt/yr; production based on vacuum salt)..126<br />

Table 3.31: Yearly waste Waste generation and final treatment at <strong>the</strong> Hydro Polymers AB chlor<strong>alkali</strong><br />

plant in Stenungsund (Sweden) (chlorine capacity 120 kt/yr; production based on<br />

vacuum salt) .......................................................................................................................127<br />

Table 3.32: Mercury collected, recovered or disposed <strong>of</strong> with waste during decommissioning ...........130<br />

Table 3.33: Concentrations <strong>of</strong> asbestos in air in chlor-<strong>alkali</strong> plants in <strong>the</strong> EU-27 ................................133<br />

Table 3.34: Estimation <strong>of</strong> total number <strong>of</strong> mercury-contaminated chlor-<strong>alkali</strong> sites in EU-27 and<br />

EFTA countries and contamination levels .........................................................................137<br />

Table 3.35: Examples <strong>of</strong> mercury-contaminated chlor-<strong>alkali</strong> sites in EU-27 and EFTA countries.......138<br />

Table 3.36: Examples <strong>of</strong> chlor-<strong>alkali</strong> sites contaminated with PCDDs/PCDFs, PCBs, PCNs and<br />

PAHs ..................................................................................................................................140<br />

Table 4.1: In<strong>for</strong>mation <strong>for</strong> each technique described in this chapter....................................................144<br />

Table 4.2: Data from <strong>the</strong> conversion <strong>of</strong> <strong>the</strong> Borregaard chlor-<strong>alkali</strong> plant to <strong>the</strong> membrane cell<br />

technique technology..........................................................................................................151<br />

Table 4.3: Electricity savings due to conversion to <strong>the</strong> membrane cell technique in different chlor<strong>alkali</strong><br />

plants ........................................................................................................................152<br />

Table 4.4: Investment costs <strong>for</strong> <strong>the</strong> cell room conversion <strong>of</strong> a mercury cell plant with a final<br />

chlorine capacity <strong>of</strong> 100 kt/yr.............................................................................................155<br />

Table 4.5: Investment costs <strong>for</strong> <strong>the</strong> conversion <strong>of</strong> a mercury cell plant with a chlorine capacity <strong>of</strong><br />

100 kt/yr and a design current density <strong>of</strong> 5 kA/m 2 .............................................................156<br />

Table 4.6: Comparison <strong>of</strong> reported conversion costs ..........................................................................157<br />

Table 4.7: Overview <strong>of</strong> contaminated solid materials arising during decommissioning and possible<br />

decontamination techniques ...............................................................................................165<br />

Table 4.8: Techniques <strong>for</strong> monitoring <strong>of</strong> mercury in air, water and waste..........................................167<br />

Table 4.9: Costs <strong>for</strong> decommissioning <strong>of</strong> <strong>the</strong> Borregaard plant in Sarpsborg (Norway).....................168<br />

Table 4.10: Decommissioning costs at <strong>the</strong> Ercros mercury cell chlor-<strong>alkali</strong> plant in Sabiñánigo<br />

(Spain) in 2009...................................................................................................................169<br />

Table 4.11: Number <strong>of</strong> cells and electrolysers as a function <strong>of</strong> current density <strong>for</strong> a bipolar<br />

membrane cell plant with a chlorine capacity <strong>of</strong> 100 kt/yr ................................................195<br />

Table 4.12: Electricity consumption <strong>of</strong> bipolar membrane cell electrolysers using <strong>the</strong> latest<br />

technique as a function <strong>of</strong> current density..........................................................................196<br />

Table 4.13: Typical production costs <strong>for</strong> a membrane cell chlor-<strong>alkali</strong> plant with a chlorine<br />

production capacity <strong>of</strong> 500 kt/yr ........................................................................................197<br />

Table 4.14: Cost calculation <strong>for</strong> <strong>the</strong> replacement <strong>of</strong> an electrolysis unit...............................................199<br />

Table 4.15: Energy consumption <strong>for</strong> brine reconcentration in membrane cell plants using solutionmined<br />

brine.........................................................................................................................207<br />

Table 4.16: Operational data <strong>for</strong> caustic concentration <strong>of</strong> plate and shell-and-tube evaporators ..........209<br />

Table 4.17: Monitoring techniques and frequency <strong>for</strong> pollutants <strong>of</strong> relevance in diaphragm and<br />

membrane cell chlor-<strong>alkali</strong> plants ......................................................................................213<br />

Table 4.18: List <strong>of</strong> some preventative and corrective or emergency measures to avoid accidents at<br />

loading areas <strong>of</strong> a chlor-<strong>alkali</strong> plant ...................................................................................219<br />

Table 4.19: List <strong>of</strong> some preventative and corrective or emergency measures to avoid accidents<br />

associated with storage <strong>of</strong> liquid chlorine ..........................................................................221<br />

Table 4.20: Advantages and disadvantages <strong>of</strong> refrigerants frequently used in chlor-<strong>alkali</strong> plants........230<br />

Table 4.21: Examples <strong>of</strong> operational cost savings <strong>for</strong> plants replacing brine purge or barium<br />

sulphate precipitation by nan<strong>of</strong>iltration..............................................................................235<br />

Table 4.22: Typical operating costs <strong>for</strong> partial hypochlorite destruction using catalytic fixed-bed<br />

decomposition or chemical reduction.................................................................................241<br />

WORKING DRAFT IN PROGRESS<br />

Table 4.23: Typical operational data from an on-site sulphuric acid reconcentration system...............252<br />

Table 4.24: Potential techniques <strong>for</strong> <strong>the</strong> decontamination <strong>of</strong> mercury-contaminated soils ...................261<br />

Table 6.1: Business case <strong>for</strong> a 2 MW PEMFC power plant (investment cost: EUR 5 000 000).........298<br />

Table A.1: Installed chlorine production capacities in EU-27 and EFTA countries as <strong>of</strong> 1 January<br />

2011....................................................................................................................................324<br />

x December 2011 TB/EIPPCB/CAK_Draft_1