System Design Guidelines - Viessmann

System Design Guidelines - Viessmann

System Design Guidelines - Viessmann

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>System</strong> <strong>Design</strong> <strong>Guidelines</strong><br />

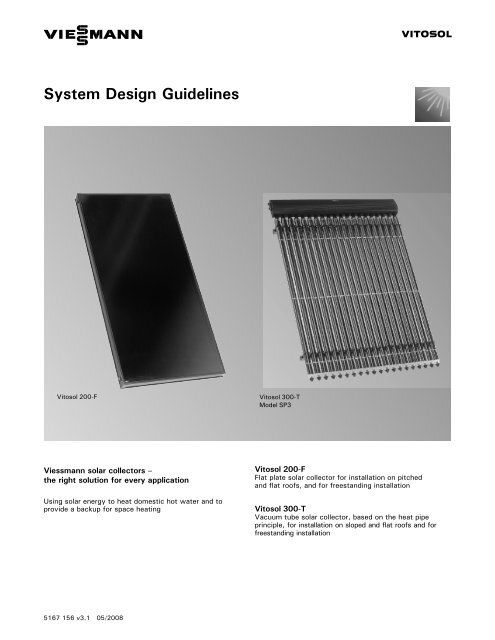

Vitosol 200-F Vitosol 300-T<br />

Model SP3<br />

<strong>Viessmann</strong> solar collectors –<br />

the right solution for every application<br />

Using solar energy to heat domestic hot water and to<br />

provide a backup for space heating<br />

5167 156 v3.1 05/2008<br />

Vitosol 200-F<br />

Flat plate solar collector for installation on pitched<br />

and flat roofs, and for freestanding installation<br />

VITOSOL<br />

Vitosol 300-T<br />

Vacuum tube solar collector, based on the heat pipe<br />

principle, for installation on sloped and flat roofs and for<br />

freestanding installation

Safety, Installation and Warranty Requirements<br />

2<br />

Safety, Installation and Warranty Requirements<br />

Please ensure that these instructions are read and understood before commencing installation. Failure to comply with the<br />

instructions listed below and details printed in this manual can cause product/property damage, severe personal injury, and/or<br />

loss of life. Ensure all requirements below are understood and fulfilled (including detailed information found in manual<br />

subsections).<br />

H Licensed professional heating<br />

contractor<br />

The installation, adjustment, service,<br />

and maintenance of this equipment<br />

must be performed by a licensed<br />

professional heating contractor.<br />

" Please see section<br />

entitled “Important<br />

Regulatory and<br />

Installation<br />

Requirements”.<br />

H Product documentation<br />

Read all applicable documentation<br />

before commencing installation. Store<br />

documentation near boiler in a readily<br />

accessible location for reference in<br />

the future by service personnel.<br />

" For a listing of<br />

applicable literature,<br />

please see section<br />

entitled “Important<br />

Regulatory and Safety<br />

Requirements”.<br />

H Advice to owner<br />

Once the installation work is<br />

complete, the heating contractor must<br />

familiarize the system<br />

operator/ultimate owner with all<br />

equipment, as well as safety<br />

precautions/requirements, shut-down<br />

procedure, and the need for<br />

professional service annually.<br />

H Warranty<br />

Information contained in<br />

this and related product<br />

documentation must be<br />

read and followed. Failure<br />

to do so renders warranty<br />

null and void.<br />

H Grounding/lightning protection of the<br />

solar system<br />

In the lower part of the building,<br />

install an electrical conductor on the<br />

solar circuit’s piping system in<br />

compliance with local regulations.<br />

Connection of the solar system to a<br />

new or existing lightning protection or<br />

the provision of local grounding should<br />

only be carried out by a licensed<br />

professional, who must take into<br />

account the prevailing conditions on<br />

site.<br />

CAUTION<br />

Observe maximum load and distance<br />

from edge before installing the<br />

substructure to the roof. If necessary,<br />

consult with a structural engineer to<br />

determine if the structure is suitable<br />

for installing solar collectors. The<br />

collectors must be securely mounted<br />

so that the mountings can withstand<br />

intense wind conditions and local<br />

snow loads.<br />

CAUTION<br />

Gloves and eye protection must be<br />

worn when handling solar panels.<br />

CAUTION<br />

Solar panel connection pipes and<br />

solar heating fluid can become hot<br />

enough to cause severe burns.<br />

Extreme caution must be taken if<br />

panels have been in a stagnant<br />

condition (no flow of fluid).<br />

CAUTION<br />

Avoid scratching or sudden shocks to<br />

glass cover of the solar panel.<br />

CAUTION<br />

Never step on collectors or solder in<br />

close proximity to the glass surface<br />

of the solar panel.<br />

H Applicability<br />

Vitosol solar collectors are designed<br />

for use in closed loop heating systems<br />

for domestic hot water heating, space<br />

heating and pool heating via a heat<br />

exchanger. The use of <strong>Viessmann</strong><br />

heat transfer medium “Tyfocor-HTL”<br />

is strongly recommended.<br />

IMPORTANT<br />

Pool water or potable water cannot be<br />

pumped directly through the Vitosol<br />

collectors. Damage to collectors caused<br />

by corrosion, freezing or scaling will<br />

void warranty.<br />

5167 156 v3.1

5167 156 v3.1<br />

Contents<br />

Contents Page<br />

Safety Safety Instructions<br />

Important Regulatory and Installation Requirements<br />

General Information About these Instructions<br />

Product Information<br />

Important Regulatory and Installation Requirements<br />

Basic Principles of Solar Technology Subsidies, Permits and Insurance ................................... 7<br />

Solar Energy ...................................................... 7<br />

HExploiting solar energy ............................................ 7<br />

H Solar radiation ................................................... 8<br />

H Global radiation .................................................. 8<br />

H Exploiting solar energy with collectors .............................. 9<br />

H Influence of alignment, inclination and shade on energy yield ......... 10<br />

H Inclination and orientation of collectors ............................. 11<br />

H Angle of inclination ............................................... 11<br />

Overall <strong>System</strong> Optimisation ....................................... 12<br />

Specification Construction and Function of Collectors ............................. 13<br />

H Vitosol 200-F – flat panel collector ................................. 13<br />

H Vitosol 300-T – vacuum tube collector based on the heat pipe principle 14<br />

Collector Efficiency ................................................ 16<br />

Solar coverage .................................................... 17<br />

Collector Installation and Mounting Details ........................... 18<br />

H Installation options for different collector types ..................... 18<br />

H Vitosol 200-F flat panel collector .................................. 18<br />

H Support weight requirements - Vitosol 300-T ........................ 24<br />

General Installation Instructions ..................................... 26<br />

Notes on Planning and Operation Calculating the Required Absorber Surface Area ...................... 27<br />

H Calculating the absorber surface area and DHW cylinder capacity ..... 27<br />

H Calculating the absorber surface area for space heating .............. 28<br />

Sizing Pipe Diameters and Circulation Pump .......................... 31<br />

H Sizing pipe diameters ............................................ 34<br />

H Installation examples for Vitosol 200-F, models SV2 and SH2 ........ 35<br />

H Collector pressure drop information ................................ 34<br />

H Sizing pipe circulation pump ...................................... 35<br />

H Technical information on the Solar-Divicon .......................... 36<br />

Safety Equipment ................................................. 38<br />

H Liquid capacity of solar heating system components ................. 37<br />

H Diaphragm expansion vessel ...................................... 39<br />

H Technical data for the expansion tank .............................. 43<br />

H Pressure relief valve ............................................. 41<br />

H High limit safety cut-out .......................................... 41<br />

H Thermostatic mixing valve ........................................ 42<br />

Accessories ...................................................... 43<br />

3

Contents<br />

Contents (continued) Page<br />

<strong>System</strong> <strong>Design</strong>s General Information ................................................ 44<br />

H How to implement the installation ................................. 44<br />

<strong>System</strong> <strong>Design</strong> 1 .................................................. 45<br />

H Dual-mode DHW heating with Vitocell-B 100 or Vitocell-B 300<br />

DHW tanks ..................................................... 45<br />

<strong>System</strong> <strong>Design</strong> 2 .................................................. 47<br />

H Dual-mode DHW heating and space heating backup<br />

with heating water storage tank ................................... 47<br />

<strong>System</strong> <strong>Design</strong> 3 .................................................. 50<br />

H Dual-mode DHW heating with two DHW tanks ...................... 50<br />

<strong>System</strong> <strong>Design</strong> 4 .................................................. 53<br />

H Dual-mode DHW and swimming pool water heating ................. 53<br />

<strong>System</strong> <strong>Design</strong> Extensions .......................................... 56<br />

H <strong>System</strong> with bypass circuit ....................................... 56<br />

H Bypass circuit with solar cell ...................................... 56<br />

H <strong>System</strong> with energy-saving mode .................................. 57<br />

Appendix Calculation Example Based on the <strong>Viessmann</strong> ”ESOP” Program ........ 58<br />

H Solar heating systm with dual-coil DHW tank ....................... 58<br />

Glossary ......................................................... 60<br />

4<br />

5167 156 v3.1

5167 156 v3.1<br />

Safety<br />

Important Regulatory and Installation Requirements<br />

Codes<br />

The installation of solar heating<br />

systems might be governed by<br />

individual local rules and regulations for<br />

this type of product, which must be<br />

observed. The installation of this unit<br />

shall be in accordance with local codes.<br />

Always use latest editions of codes.<br />

Mechanical room<br />

Ensure the mechanical room complies<br />

with the requirements of the system<br />

design guideline and/or technical data<br />

manual.<br />

Thesolarstoragetankmustbeinstalled<br />

in a mechanical room which is never<br />

subject to freezing temperatures.<br />

If not in use and danger of freezing<br />

exists in the mechanical room, ensure<br />

water in tank is drained.<br />

Workingontheequipment<br />

The installation, adjustment, service,<br />

and maintenance of this equipment<br />

must be done by a licensed professional<br />

heating contractor who is qualified and<br />

experienced in the installation, service,<br />

and maintenance of solar heating<br />

systems. There are no user serviceable<br />

parts on this equipment.<br />

Ensure main power supply to<br />

equipment, the heating system, and all<br />

external controls has been deactivated.<br />

Take precautions in both instances to<br />

avoid accidental activation of power<br />

during service work.<br />

Technical literature<br />

Literature applicable to all aspects of<br />

the Vitosol:<br />

- Technical Data Manual<br />

- Installation Instructions<br />

- Start-up/Service Instructions<br />

- Operating Instructions<br />

and User’s Information Manual<br />

- <strong>System</strong> <strong>Design</strong> <strong>Guidelines</strong><br />

Please carefully read this manual prior<br />

to attempting installation. Any<br />

warranty is null and void if these<br />

instructions are not followed.<br />

This product must be installed<br />

observing not only the necessary<br />

product literature (see list), but also<br />

all local, provincial/state plumbing and<br />

building codes, as they apply to this<br />

product and all periphery equipment.<br />

For information regarding other<br />

<strong>Viessmann</strong> <strong>System</strong> Technology<br />

componentry, please reference<br />

documentation of the respective<br />

product.<br />

We offer frequent installation and<br />

service seminars to familiarize our<br />

partners with our products. Please<br />

inquire.<br />

The completeness and functionality of<br />

field supplied electrical controls and<br />

components must be verified by the<br />

heating contractor. These include<br />

pumps, valves, air vents, thermostats,<br />

temperature and pressure relief<br />

controls, etc.<br />

Leave all literature at the installation<br />

site and advise the system<br />

operator/ultimate owner where the<br />

literature can be found. Contact<br />

<strong>Viessmann</strong> for additional copies.<br />

5

General Information<br />

6<br />

About these Instructions<br />

Take note of all symbols and notations intended to draw attention to potential hazards or important product<br />

information. These include ”WARNING”, ”CAUTION”, and ”IMPORTANT”. See below.<br />

Product Information<br />

WARNING<br />

Indicates an imminently hazardous<br />

situation which, if not avoided, could<br />

result in substantial product/property<br />

damage, serious injury or loss of life.<br />

CAUTION<br />

Indicates an imminently hazardous<br />

situation which, if not avoided, may<br />

result in minor injury or<br />

product/property damage.<br />

IMPORTANT<br />

Warnings draw your attention to the<br />

presence of potential hazards or<br />

important product information.<br />

Cautions draw your attention to the<br />

presence of potential hazards or<br />

important product information.<br />

Helpful hints for installation, operation<br />

or maintenance which pertain to the<br />

product.<br />

This symbol indicates that additional,<br />

pertinent information is to be found in<br />

the adjacent column.<br />

This symbol indicates that other<br />

instructions must be referenced.<br />

Vitosol 200-F, Models SV2, SH2<br />

Flat panel solar collector with 25 ft. 2 /<br />

2.3 m 2 collector area.<br />

Max. stagnation temperature 430°F /<br />

221°C<br />

Max. operating pressure 87 psig /<br />

6bar<br />

Vitosol 300-T, SP3 Series<br />

Vacuum tube solar collector with 22<br />

and 32 ft. 2 /2and3m 2 collector area.<br />

Max. stagnation temperature 302°F /<br />

150°C<br />

Max. operating pressure 87 psig /<br />

6bar<br />

5167 156 v3.1

5167 156 v3.1<br />

Subsidies, Permits and Insurance<br />

Solar Energy<br />

Exploiting solar energy<br />

Solar heating systems for DHW or<br />

swimming pool heating are subsidised<br />

by many regional and local authorities.<br />

Request information about subsidies<br />

from your local authority.<br />

Further information is available from our<br />

sales offices.<br />

The sun has provided the earth with<br />

light and heat for billions of years.<br />

Without it, our existence on earth<br />

would be impossible.<br />

We have been using the sun’s heat<br />

since time immemorial. In summer, it<br />

heats our buildings directly, while in<br />

winter we make use of solar energy<br />

stored in the form of wood, coal, oil and<br />

gas, to provide heat for our buildings<br />

and domestic hot water.<br />

To protect fuel reserves, the heating<br />

industry has committed itself to finding<br />

more responsible ways of handling<br />

these precious resources, which have<br />

accumulated naturally over millions of<br />

years.<br />

One rational way of achieving this aim is<br />

to make direct use of solar energy by<br />

means of collectors.<br />

Basic Principles of Solar Technology<br />

Your local planning office will be able to<br />

advise you about whether solar heating<br />

systems need planning permission.<br />

<strong>Viessmann</strong> solar collectors are tested<br />

for impact resistance, incl. hail impact,<br />

in accordance with DIN EN 12975-2.<br />

Nevertheless, we would recommend<br />

you include the collectors in your<br />

building insurance, to protect you from<br />

losses arising from any extraordinary<br />

natural phenomenon. Our warranty<br />

excludes such losses.<br />

Thanks to the use of highly<br />

sophisticated collectors and a perfectly<br />

matched overall system, the economic<br />

use of solar energy is no longer a<br />

futuristic vision, but a proven everyday<br />

reality.<br />

Considering that fuel prices will<br />

continue to rise in the years ahead,<br />

investing in a solar heating system can<br />

be viewed as a ”genuine” investment in<br />

the future.<br />

7

Basic Principles of Solar Technology<br />

2<br />

Solar irradiation in Wh/(m x d)<br />

8<br />

Solar Energy (continued)<br />

Solar radiation<br />

Diffused celestial radiation<br />

Direct solar radiation<br />

Wind, rain, snow, convection<br />

Convection losses<br />

Conduction losses<br />

Global radiation<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

RT<br />

Heat radiation of the absorber<br />

Heat radiation of the glass cover<br />

Useful collector output<br />

Reflection<br />

RT Return<br />

S Supply<br />

S<br />

direct<br />

radiation<br />

diffused<br />

radiation<br />

0<br />

Jan. Feb. March April May June July Aug. Sept. Oct. Nov. Dec.<br />

Solar radiation represents a flow of<br />

energy irradiated uniformly in all<br />

directions by the sun. Of that energy,<br />

an output of 429 Btu/h/ft. 2 or<br />

1.36 kW/m 2 , the so-called solar<br />

constant, hits the outer earth’s<br />

atmosphere.<br />

After penetrating the earth’s<br />

atmosphere, the solar radiation is<br />

reduced by reflection, dispersion and<br />

absorption by dust particles and<br />

gaseous molecules. That portion of this<br />

radiation which passes unimpeded<br />

through the atmosphere to strike the<br />

earth’s surface is known as direct<br />

radiation.<br />

The portion of the solar radiation which<br />

is reflected and/or absorbed by dust<br />

particles and gas molecules and<br />

irradiated back strikes the earth’s<br />

surface indirectly is known as diffused<br />

radiation.<br />

The total radiation striking the earth’s<br />

surface is the global radiation Eg, i.e.,<br />

global radiation = direct radiation +<br />

diffused radiation.<br />

In the latitudes of North America, the<br />

typical global radiation under optimum<br />

conditions (clear, cloudless sky at midday)<br />

amounts to a max. of 317<br />

Btu/h/ft. 2 or 1 000 W/m 2 .<br />

With solar collectors, as much as 75 %<br />

of this global radiation can be utilised,<br />

depending on the type of collector.<br />

5167 156 v3.1

5167 156 v3.1<br />

Solar Energy (continued)<br />

Exploiting solar energy using solar collectors<br />

The useful energy which a collector can<br />

absorb depends on several factors.<br />

The main factor is the total solar energy<br />

available.<br />

Annual global radiation in Canada<br />

Annual global radiation in the United States<br />

The amount of global energy varies<br />

from location to location (see maps<br />

below).<br />

Basic Principles of Solar Technology<br />

The type of collector, as well as its<br />

inclination and orientation, are also very<br />

important (see page 10). If the solar<br />

installation is to be operated<br />

economically, careful dimensioning of<br />

the system components is also<br />

essential.<br />

Btu/ft2 2.5-3kwh/m<br />

/day<br />

2 /day 787-945<br />

3-3.3kwh/m2 /day 945-1040<br />

3.3 - 3.6 kwh/m2 /day 1040-1134<br />

3.6 - 3.9 kwh/m2 /day 1134-1228<br />

3.9 - 4.2 kwh/m2 /day 1228-1323<br />

4.2 - 4.4 kwh/m2 /day 1323-1386<br />

4.4 - 4.7 kwh/m2 /day 1386-1481<br />

>4.7kwh/m2 /day >1481<br />

Btu/ft 2 /day<br />

3-4kwh/m 2 /day 945-1260<br />

4-5kwh/m 2 /day 1260-1575<br />

5-6kwh/m 2 /day 1575-1890<br />

6-7kwh/m 2 /day 1890-2205<br />

Note: Average mean daily global radiation on a south-facing surface tilted at an angle equal to the latitude of the location.<br />

9

Basic Principles of Solar Technology<br />

Solar Energy (continued)<br />

Influence of alignment, inclination and shade on energy yield<br />

Example:<br />

30°; 45° south-west<br />

10<br />

West<br />

North<br />

South<br />

East<br />

Annual<br />

irradiation<br />

in %<br />

Angle of<br />

inclination<br />

Optimum alignment and inclination<br />

The solar generator provides the highest<br />

annual solar yield for a DHW system<br />

whenfacingsouthwithaninclinationof<br />

approx. 30 to 35 degrees<br />

to the horizontal plane. However, the<br />

installation of a solar heating system is<br />

still viable even when the installation<br />

deviates quite significantly from the<br />

above (south-westerly to south-easterly<br />

alignment, 25 to 55 degrees<br />

inclination).<br />

The graph illustrates the loss of yield<br />

resulting from an installation of the<br />

collector array which is less than<br />

perfect. The graph also indicates that a<br />

shallower inclination is more favourable,<br />

if the collector surface cannot be<br />

pointed south. A solar heating system<br />

with a 30º inclination and an alignment<br />

of 45º south-westerly still achieves<br />

95% of its optimum yield. Even with an<br />

east-westerly alignment, you can still<br />

expect 85% with a roof inclination<br />

between 25º and 40º.<br />

A more steeply sloped installation<br />

would be more favourable in winter, but<br />

the system achieves two thirds of its<br />

yield during the summer months. On the<br />

other hand, an angle of inclination less<br />

than 20 degrees should be avoided,<br />

otherwise the solar generator will<br />

become too contaminated, or<br />

snowcovered.<br />

Installing the collector array on different<br />

roofs requires complex hydraulic<br />

interconnections between the individual<br />

collectors.<br />

Every array is equipped with a separate<br />

collector temperature sensor and a<br />

separate pump line.<br />

The increase in energy yield is therefore<br />

offset by the higher installation costs,<br />

resulting in a significantly reduced<br />

cost:benefit ratio.<br />

Shade reduces energy yield<br />

Position and size the collector array so<br />

that the influence of neighbouring<br />

structures, trees, power lines, etc.,<br />

which throw shadows over the array, is<br />

minimised. Also consider how<br />

neighbouring properties will be likely to<br />

develop over a period of 20 years, as<br />

regards additional buildings, plants and<br />

saplings.<br />

5167 156 v3.1

5167 156 v3.1<br />

Solar Energy (continued)<br />

Inclination and orientation of collectors<br />

Angle of inclination<br />

Example:<br />

Deviation from south: 15º east<br />

IMPORTANT<br />

The angle of inclination for Vitosol<br />

300-T collectors must be at least 25º in<br />

order to guarantee circulation of the<br />

evaporator liquid in the heat pipe<br />

Collector plane<br />

Azimuth angle<br />

Basic Principles of Solar Technology<br />

To achieve optimum energy absorption,<br />

the collectors must be oriented towards<br />

the sun.<br />

The angle of inclination and the azimuth<br />

angle are the dimensions used to<br />

determine the orientation of the<br />

collectors.<br />

Angle of inclination α<br />

The angle of inclination a is the angle<br />

between the horizontal and the collector<br />

plane.<br />

For pitched roof installations, the angle of<br />

inclination is determined by the slope of the<br />

roof.<br />

The largest amount of energy can be<br />

captured by the collector’s absorber when<br />

the collector plane is aligned at right<br />

angles to the irradiation of the sun.<br />

Because the angle of irradiation depends<br />

on the time of day and the time of year,<br />

the collector plane should be aligned<br />

according to the position of the sun during<br />

the phase of maximum energy supply.<br />

In practice, angles of inclination of<br />

between 30 and 45º have proven to be<br />

ideal.<br />

For most installations in North America,<br />

for example, an angle of inclination of<br />

between 25 and 70º is advantageous,<br />

depending on the period of use.<br />

Lower angles of inclination are better for<br />

applications where more energy is<br />

required in the summer months (i.e. pool<br />

heating). Higher angles of inclination are<br />

better for applications where more energy<br />

is required in the winter months.<br />

Capturing the maximum amount of energy<br />

throughout the year can be achieved using<br />

an angle of inclination equal to the latitude<br />

of the building site. This is ideal for<br />

domestic hot water heating applications.<br />

Azimuth angle<br />

The azimuth angle describes the deviation<br />

of the collector plane from south; the<br />

collector plane aligned to the south is the<br />

azimuth angle = 0º.<br />

Because solar irradiation is at its most<br />

intensive at midday, the collector plane<br />

should be oriented as closely as possible<br />

to the south. However, deviations from<br />

south up to 45º south-east or south-west<br />

have minimal impact on annual energy<br />

production.<br />

11

Basic Principles of Solar Technology<br />

Overall <strong>System</strong> Optimization<br />

A high-quality solar collector cannot by<br />

itself guarantee the optimum operation<br />

of a solar installation. This depends<br />

more on the complete system solution<br />

as a whole.<br />

<strong>Viessmann</strong> supplies all the components<br />

required for a solar heating system:<br />

12<br />

DHW<br />

I<br />

Solar collector<br />

Solar-Divicon (pumping station)<br />

Overflow container<br />

Expansion vessel<br />

Solar manual filling pump<br />

<strong>System</strong> fill manifold valve<br />

H a control unit that is tailored to the<br />

individual solar heating system,<br />

H a DHW tank incorporating a solar heat<br />

exchanger low inside the tank,<br />

H a preassembled pump station with all<br />

necessary hydraulic components,<br />

H design details aimed at achieving<br />

fast-responding control and therefore<br />

maximum yields from the solar<br />

heating system.<br />

DCW<br />

Brass elbow c/w sensor well<br />

Dual-mode DHW tank<br />

I Tank temperature sensor<br />

Air separator<br />

Solar control unit<br />

Flexible connection pipe<br />

S R<br />

Correctly designed solar heating<br />

systems with well matched system<br />

components can cover 50 to 80 % of<br />

the annual energy demand for DHW<br />

heating in detached and semi-detached<br />

houses.<br />

We will be pleased to assist you with<br />

the design of solar heating systems.<br />

The elements of a solar heating system<br />

areshowninthediagram.<br />

Collector temperature sensor<br />

Fast air-vent, c/w shutoff valve *1<br />

R Return to collector<br />

S Supply from collector<br />

*1 Install at least one air-vent valve (quick-acting air-vent valve or a manual vent valve, see page 43) at the highest point of<br />

the system.<br />

T<br />

T<br />

T<br />

5167 156 v3.1

5167 156 v3.1<br />

Construction and Function of Collectors<br />

Vitosol 200-F flat panel collector<br />

Continuous profiled seal (vulcanised)<br />

Solar glass cover, 3.2 mm thick<br />

Meander-shaped copper pipe<br />

Copper absorber<br />

Melamine resin foam<br />

Technical Data Vitosol 200-F, SV2/SH2<br />

Model Gross Area Absorber<br />

Area<br />

Aperture<br />

Area<br />

Mineral fiber<br />

Aluminum frame sections<br />

Aluminum-zinc bottom panel<br />

Connection pipe<br />

Dimensions Weight<br />

m 2 ft 2 m 2 ft 2 m 2 ft 2 mm in kg lb<br />

SV2 2.51 27.0 2.32 25 2.33 25.1 1056x<br />

2380x90<br />

SH2 2.51 27.0 2.32 25 2.33 25.1 2380x90x<br />

1056<br />

41¾x<br />

93¾x3½<br />

93¾x41¾x<br />

x3½<br />

Specification<br />

Vitosol 200-F flat plate solar collector is<br />

available as:<br />

H Vertical version Model SV2 and<br />

horizontal version Model SH2, each<br />

offering 2.3 m 2 /25ft 2 absorber<br />

surface.<br />

The main component of Vitosol 100 is<br />

the Sol-Titanium coated copper<br />

absorber.<br />

It ensures high absorption of solar<br />

radiation and low emission of thermal<br />

radiation. A copper pipe through which<br />

the heat transfer medium flows is fitted<br />

to the absorber. The heat transfer<br />

medium channels the absorber heat<br />

through the copper pipe.<br />

The meander-shaped direct flow<br />

absorber of models SV2 and SH2<br />

provides an extremely even flow<br />

through each individual collector in the<br />

collector arrays.<br />

The absorber is surrounded by a highly<br />

insulated collector housing which<br />

minimises collector heat losses. The<br />

high quality thermal insulation provides<br />

temperature stability and is free from<br />

gas emissions.<br />

The cover comprises a solar glass panel.<br />

The glass has a very low iron content,<br />

thereby reducing reflection losses.<br />

The collector housing comprises a<br />

powder-coated aluminium frame<br />

(recycled aluminium), within which the<br />

solar glass panel is permanently sealed.<br />

Model SV2 and SH2<br />

Up to twelve collectors can be joined to<br />

form a single collector array. For this<br />

purpose, the standard delivery includes<br />

flexible connection pipes, sealed with<br />

O-rings.<br />

A general connection kit with clamping<br />

ring connections enables the collector<br />

array to be readily attached to the pipes<br />

of the solar circuit.<br />

The collector temperature sensor is<br />

installed in the solar circuit flow via a<br />

sensor well set.<br />

52 115<br />

52 115<br />

13

Specification<br />

Construction and Function of Collectors (continued)<br />

Vitosol 300-T vacuum tube collector<br />

14<br />

Evacuated glass tube<br />

Heat pipe<br />

Absorber<br />

Technical Data Vitosol 300-T, 2m 2 /3m 2<br />

Model Gross Area Absorber<br />

Area<br />

Aperture<br />

Area<br />

Condenser<br />

Double pipe heat exchanger<br />

Dimensions Weight<br />

m 2 ft 2 m 2 ft 2 m 2 ft 2 mm in kg lb<br />

2m 2 2.83 30.5 2.05 22 2.11 22.7 1419x<br />

1996x<br />

122<br />

3m 2 4.24 45.6 3.07 33 3.17 34.1 2126x<br />

1996x<br />

122<br />

55¾x<br />

78½x<br />

4¾<br />

83¾x<br />

78½x<br />

4¾<br />

45 99<br />

68 150<br />

Vitosol 300-T vacuum tube collectors<br />

areavailableintwotypes:<br />

20 tube version,<br />

30 tube version<br />

The tube shape gives the collector great<br />

stability and high impact resistence.<br />

Re-evacuation of the tubes is not<br />

necessary as the tubes have a<br />

permanent airtight seal.<br />

The vacuum in the glass tubes ensures<br />

optimum heat insulation. Convection<br />

losses between the glass tube and the<br />

absorber are almost completely<br />

eliminated. This enables the utilisation<br />

of even low radiation levels (diffused<br />

radiation). The performance of the<br />

collector does not drop off as<br />

significantly in cold weather as a flat<br />

plate collector. On average,<br />

approximately 30% to 50% higher<br />

annual solar energy gain than flat plate<br />

collectors can be expected.<br />

Built into each vacuum tube is a<br />

Sol-Titanium coated copper absorber. It<br />

is a highly selective surface that<br />

ensures high absorption of solar<br />

radiation and low emission of thermal<br />

radiation.<br />

A heat pipe filled with an evaporator<br />

liquid is arranged on the absorber. The<br />

heat pipe is connected to the condenser<br />

via a flexible coupling. The condenser is<br />

mounted in a double pipe heat<br />

exchanger.<br />

This involves a so-called ”dry<br />

connection”, i.e. pipes can be rotated or<br />

replaced even when the installation is<br />

filled and under pressure.<br />

Heat is transferred from the absorber to<br />

the heat pipe. This lets the liquid<br />

evaporate. The vapour then rises to the<br />

condenser.<br />

The heat is transferred to the passing<br />

heat transfer medium by the<br />

double-pipe heat exchanger containing<br />

the condenser which causes the vapour<br />

to condense. The condensate flows<br />

back into the heat pipe and the process<br />

is repeated.<br />

Please note:<br />

Theangleofinclinationmustbeatleast<br />

25º to guarantee circulation of the<br />

evaporator liquid inside the heat<br />

exchanger.<br />

5167 156 v3.1

5167 156 v3.1<br />

Construction and Function of Collectors (continued)<br />

Vitosol 300-T (continued)<br />

Legend<br />

102mm /<br />

4”<br />

Groove for retaining clip<br />

Specification<br />

Absorber surface areas of up to 6 m 2<br />

can be joined to form a single collector<br />

array. For this purpose, the standard<br />

delivery includes flexible connection<br />

pipes, sealed with O-rings.<br />

A connection kit with clamping ring<br />

connections enables the collector array<br />

to be readily connected to the pipes of<br />

the solar circuit.<br />

The collector temperature sensor is<br />

installed in a sensor mounting on the<br />

flow pipe in the connection housing of<br />

the collectors.<br />

15

Specification<br />

Collector Efficiency<br />

Some of the solar radiation striking the<br />

glassofthecollectorsis”lost”dueto<br />

reflection and absorption. The optical<br />

efficiency ηo takes these losses into<br />

account.<br />

When the collectors heat up, they<br />

transfer heat to the environment as the<br />

result of conduction, radiation and<br />

convection. These thermal losses are<br />

allowed for by the heat loss factors k1<br />

and k2 .<br />

16<br />

The heat loss factors and optical<br />

efficiency combine to form the collector<br />

efficiency curve which can be<br />

calculated on the basis of the following<br />

formula:<br />

η = ηo − k1 ⋅ ∆T<br />

− k2 ⋅<br />

Eg<br />

∆T2<br />

Eg<br />

Eg= radiation intensity (W/m 2 )<br />

∆ T=Temperature difference between<br />

ambient air and collector fluid ºC<br />

Collector type Opt. efficiency Heat loss factors Spec. thermal<br />

level<br />

capacity<br />

*1 i %<br />

kJ/( 2 ηo K)<br />

*1 in % k1 in<br />

W/(m2 · K)<br />

k2 in<br />

W/(m2 · K2 p y<br />

)<br />

kJ/(m2 · K)<br />

Vitosol 200-F 79.3<br />

3.95<br />

0.0122 6.4<br />

Vitosol 300-T 82.5<br />

1.19<br />

0.009 5.4<br />

*1 ηo basedonabsorberarea<br />

H<br />

0.9<br />

Efficiency<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

0 10 20 30 40 50 60 70 80 90 100<br />

Temperature difference in degrees C between ambient air and collector fluid<br />

Vitosol 300-T<br />

Vitosol 200-F<br />

If the difference between the collector<br />

and ambient temperature is zero, the<br />

collector loses no heat to the<br />

environment, and the efficiency η is at<br />

its maximum level; this is known as the<br />

optical efficiency ηo.<br />

The thermal capacity is a measure of<br />

the thermal inertia of the collector, and<br />

shows the response behaviour of the<br />

collector when heating and cooling. A<br />

low thermal capacity is of advantage<br />

with wide ranging temparature and<br />

weather conditions typical in northerly<br />

climates.<br />

The table below lists comparative<br />

values for the optical efficiency and the<br />

heat loss factors as tested in European<br />

certification labs.<br />

Vitosol 200-F and 300-T are both<br />

tested and certified in North America to<br />

SRCC OG-100.<br />

5167 156 v3.1

5167 156 v3.1<br />

Solar Coverage<br />

Vitosol 200-F<br />

Absorber surface in m 2 Absorber surface in m 2<br />

0 13 26 40 53 66 79 92<br />

ltrs/day<br />

106 USG/day<br />

Vitosol 300-T<br />

DHW consumption<br />

DHW consumption<br />

Reference system<br />

100 litres/day<br />

300 litres/day<br />

400 litres/day<br />

Collector inclination 30°<br />

Collector inclination 60°<br />

Westerly orientation<br />

South-west orientation<br />

*1<br />

Vacuum tubes<br />

Hannover<br />

Freiburg<br />

USG/day<br />

0 13 26 40 53 66 79 92<br />

ltrs/day<br />

106 USG/day<br />

Influence of various parameters on solar coverage<br />

*1 For comparable absorber surface area.<br />

0 20 40 60 80<br />

Solar cover rate in %<br />

45<br />

45<br />

52<br />

56<br />

55<br />

62<br />

61<br />

61<br />

69<br />

76<br />

77<br />

Specification<br />

The solar coverage value indicates<br />

what percentage of the energy required<br />

annually for domestic hot water<br />

applications can be covered by the solar<br />

heating system.<br />

The absorber surface area should be<br />

sized so that the ”production” of<br />

surplus heat is just about avoided<br />

during the summer months.<br />

The higher the solar cover rate, the<br />

lower the efficiency, since a high cover<br />

rate has the effect of raising the<br />

temperature level of the solar circuit.<br />

This results in increased heat losses<br />

and lower seasonal efficiency.<br />

The diagrams show the coverage values<br />

that can be achieved with the various<br />

collector types, based on<br />

H the meteorological records for a<br />

typical location at 49° latitude,<br />

H south-facing roofs,<br />

H a roof pitch of 45º and<br />

H a DHW temperature of 113°F / 45ºC<br />

in the standby tank.<br />

This data represents approximate guide<br />

values.<br />

Note:<br />

Solar fractions will be higher for<br />

locations in southern parts of the USA<br />

due to higher levels of radiation.<br />

Reference system:<br />

H 4-person household with hot water<br />

consumption of 53 USG/day / 200<br />

litres/day<br />

H 2 Vitosol 200-F collectors, model<br />

SV2 and SH2<br />

H 45º roof inclination<br />

H South-facing roof orientation<br />

H Dual-mode DHW cylinder, 300 litres<br />

H Meteorological records for a typical<br />

location at 49° latitude<br />

The bars indicate the expected<br />

coverage values for deviations from the<br />

reference system.<br />

17

Specification<br />

Collector Installation and Mounting<br />

Installation options for different collector types<br />

Sloped roofs - rooftop installation<br />

Required roof area<br />

18<br />

<strong>Viessmann</strong> offers universal mounting<br />

systems to simplify installation. The<br />

mounting systems are suitable for<br />

virtually all forms of roofs, as well as<br />

installation on flat roofs or ground<br />

mounted free-standing installations.<br />

Fitting Collector type<br />

Pitched roofs A Vitosol 200-F, model SV2<br />

Vitosol 300-T<br />

B Vitosol 200-F, model SH2<br />

Flat roofs C Vitosol 200-F, model SV2, SH2<br />

Vitosol 300-T<br />

Freestanding installation D Vitosol 200-F, model SV2, SH2<br />

Vitosol 300-T<br />

Collector Type A mm A in B mm B in<br />

Vitosol 200-F,<br />

type SV2 2380 93 3/4 1056 + 16* 1 41 5/8 + 5/8* 1<br />

Vitosol 200-F,<br />

type SH2 1056 41 5/8 2380 + 16* 1 93 3/4 + 5/8* 1<br />

Vitosol 300-T,<br />

type SP3, 2m2 2031 80 1418 + 102* 1 55 3/4 + 4* 1<br />

Vitosol 300-T,<br />

type SP3, 3m2 2031 80 2127 + 102* 1 83 3/4 + 4* 1<br />

*1 Add this value for every additional collector.<br />

5167 156 v3.1

5167 156 v3.1<br />

Collector Installation and Mounting (continued)<br />

Vitosol 200-F flat panel collector<br />

Flat collectors are ideally suited for<br />

domestic hot water and swimming pool<br />

heating applications.<br />

Both vertical and horizontal types are<br />

suitable for installation on pitched roofs.<br />

The selection of method of installation<br />

is influenced by the structural<br />

characteristics of the building.<br />

Sloped Roofs Installation Details<br />

c<br />

Collector<br />

Lag bolt<br />

Mounting rail<br />

Roof bracket<br />

Model SH2 has been specially designed<br />

for installation on flat roofs and for<br />

freestanding installation.<br />

<strong>Viessmann</strong> offers a universal fastening<br />

system to simplify installation. The<br />

fastening system is suitable for virtually<br />

all forms of roof and roofing.<br />

Collector Dimension a b c<br />

Model SV2<br />

Model SH2<br />

a<br />

inches<br />

mm<br />

inches<br />

mm<br />

b<br />

93¾<br />

2 380<br />

41¾<br />

1 138<br />

74¾ - 82½<br />

1 900 - 2 100<br />

19½ - 35½<br />

500 - 900<br />

3½<br />

89<br />

3½<br />

89<br />

Specification<br />

Installation kits are available for<br />

installing collectors on flat roofs.<br />

An engineering evaluation is required to<br />

establish additional superimposed loads<br />

from wind or snow, as described in the<br />

local building code. Retain the services<br />

of a professional structural engineer to<br />

calculate additional live loads due to the<br />

installation of solar collectors on the<br />

roof.<br />

40<br />

10<br />

19

Specification<br />

Collector Installation and Mounting (continued)<br />

Flat roof installation<br />

The collectors should be installed with<br />

an angle of inclination of 35 º to 45 º if<br />

the load capacity of the roof allows<br />

this. Maintain a minimum distance of<br />

2m/6ft from the roof edge in all<br />

installations.<br />

Outsideofthisareayoumay<br />

experience significant increases in wind<br />

turbulance. The system will also be<br />

hard to access if modifications are<br />

required. If the roof size dictates a<br />

modification of the array distribution,<br />

ensure that arrays of the same size are<br />

created.<br />

Determining the collector row distance<br />

“z”<br />

When installing several collector rows in<br />

sequence, exact dimensions (dimension<br />

“z”) must be maintained to prevent<br />

unwanted shade.<br />

Determine angle of the sun β.<br />

Collector row distance ”z” (all<br />

dimensions in mm)<br />

20<br />

l<br />

α<br />

z = Collector row distance<br />

l = Collector height<br />

(see page 13 and 14)<br />

z<br />

β<br />

A collector system must be secured by<br />

additional weights against slippage and<br />

lifting (see table on the following page).<br />

Slippage is the movement of the<br />

collectors on the roof surface due to<br />

wind, because of insufficient friction<br />

between the roof surface and the<br />

collector system.<br />

H Collectors secured against slippage<br />

require more ballast weight, but no<br />

additional attachment to the roof or<br />

substructure.<br />

This should be chosen so that the<br />

midday sun on Dec. 12 can fall onto the<br />

collector without creating shade.<br />

In North America, this angle is<br />

dependent upon latitude and is between<br />

13 º (Edmonton) and 41 º (Miami).<br />

H Collectors secured against lifting<br />

require less ballast weight, but<br />

additional attachment to the roof or<br />

building structure with wires, cables<br />

or other sufficient means.<br />

Example<br />

Boston is located approx. 42.5 º latitude.<br />

Angle of the sun β= 90 º -23.5 º -latitude<br />

(23.5 º should be accepted as the<br />

constant)<br />

90 º -23.5 º -42.5 º =24 º<br />

l · sin (180º - ( α+ β ))<br />

z =<br />

sin β<br />

Vitosol 200-F, type SV2<br />

l = 2380mm<br />

α= 45 º β =24 º (Boston)<br />

2385mm 0 sin (180º - 69 º )<br />

z =<br />

sin 24º<br />

z = 5474mm<br />

Collector type Vitosol 200-F Vitosol 300-T<br />

Type SV2<br />

Angle of inclination α<br />

l<br />

α<br />

β<br />

α<br />

= Collector angle of inclination<br />

= Angle of the sun<br />

Type SH2<br />

Angle of inclination α<br />

Angle of inclination α<br />

Angle of sun β 35º 45º 35º 45º 35º 45º 55º<br />

15.0º 7059 7880 3140 3550 5991 6772 7349<br />

17.5º 6292 7035 2799 3130 5340 5970 6419<br />

20.0º 5712 6320 2541 2812 4848 5363 5716<br />

22.5º 5256 5758 2338 2561 4461 4886 5164<br />

25.0º 4887 5303 2174 2359 4148 4500 4716<br />

27.5º 4582 4926 2038 2191 3888 4180 4346<br />

Min. 6 ft/<br />

2m<br />

Roof edge<br />

Collector<br />

array<br />

Min. 6 ft/<br />

2m<br />

5167 156 v3.1

5167 156 v3.1<br />

Collector Installation and Mounting (continued)<br />

Vitosol 200-F flat panel collector (continued)<br />

Please refer to Vitosol 200-F Installation<br />

instructions for additional information on<br />

collector mounting on 5285 710.<br />

A<br />

An evaluation by a professional<br />

structural engineer is required to<br />

calculate additional live loads due to the<br />

installation of solar collectors on a roof.<br />

Vitosol 200-F, type SV2 and SH2<br />

Collector angle of inclination - 25 º or 45 º<br />

Ballast to be applied and maximum load on the substructures of flat roofs to DIN 1055<br />

Specification<br />

Collector angle of inclination 25º 45º<br />

Ballast against slippage* 1 Ballast against lifting* 1 Ballast against slippage Ballast against lifting<br />

Installation height above ground m up 8 20 up 8 20 up 8 20 up 8 20<br />

to to to to to to to to to to to to<br />

Ballast to be applied<br />

8 20 100 8 20 100 8 20 100 8 20 100<br />

Type SV2 kg 315 554 793 144 304 465 508 842 1213 128 224 346<br />

Type SH2 kg 323 561 800 155 315 476 492 845 1198 132 254 375<br />

* 1 See description on page 20.<br />

Collector supports<br />

The collector supports are pre-assembled. They consist of foot support A, bearing supports and adjustment pieces. The<br />

upper adjustment pieces contain holes for adjusting the angle of inclination.<br />

Connection cross ties are required for 1 to 6 collectors connected in a series.<br />

A Foot support<br />

IMPORTANT<br />

Type SV2<br />

Foot support hole dimensions<br />

80<br />

11<br />

50<br />

75<br />

100 1620<br />

1795<br />

Type SH2<br />

Foot support hole dimensions<br />

80<br />

11<br />

50<br />

75<br />

100 722<br />

897<br />

21

Specification<br />

Collector Installation and Mounting (continued)<br />

Vitosol 200-F<br />

Installation on substructures<br />

22<br />

X<br />

Y<br />

X<br />

* 1 For calculating dimension “z”, see page 20<br />

Installation with ballast<br />

X<br />

Y<br />

X<br />

* 1 For calculating dimension “z”, see page 20<br />

A<br />

A<br />

Z* 1<br />

Z* 1<br />

A Connection cross ties<br />

A Connection cross ties<br />

Collector type x mm x in y mm y in<br />

SV2 590 23 1/4 481 19<br />

SH2 1920 75 5/8 481 19<br />

5167 156 v3.1

5167 156 v3.1<br />

Collector Installation and Mounting (continued)<br />

Vitosol 300-T sloped roof installation details<br />

1600mm /<br />

63”<br />

Collector<br />

Roof bracket<br />

Roof joist<br />

Collector installation rail with tube mountings<br />

Roof sheathing complete with shingles<br />

Lag bolt<br />

1650mm /<br />

65”<br />

230mm /<br />

9”<br />

340mm /<br />

13.4”<br />

2m 2 version 1419mm/55 3 /4” 102mm / 4” 3m 2 version 2126mm/83 3 /4”<br />

Deviations from south<br />

can be compensated by<br />

axial rotation of the<br />

vacuum tubes.<br />

Specification<br />

23

Specification<br />

Collector Installation and Mounting (continued)<br />

Flat roof support weight requirements - Vitosol 300-T<br />

Collector angle of inclination of 25º<br />

Weight of supports<br />

Installation height above ground ft.<br />

m<br />

Weight of supports<br />

* 1 See description on page 20.<br />

A<br />

24<br />

lbs per support A<br />

kg per support A<br />

lbs per support B<br />

kg per support B<br />

Secured against slippage* 1 Secured against lifting* 1<br />

up to 26<br />

up to 8<br />

2m2 Version<br />

168<br />

76<br />

225<br />

102<br />

3m 2<br />

Version<br />

256<br />

116<br />

342<br />

155<br />

Support A<br />

Support B<br />

Model 2m 2 Version 3m 2 Version<br />

Dimension X inches<br />

mm<br />

Dimension Y inches<br />

mm<br />

Surface area (X x Y) ft. 2<br />

m 2<br />

Weight of lbs<br />

collector kg<br />

B<br />

76¼<br />

1940<br />

56¾<br />

1440<br />

30<br />

2.80<br />

99<br />

45<br />

76¼<br />

1940<br />

84½<br />

2149<br />

44½<br />

4.15<br />

150<br />

68<br />

26 to 66<br />

8to20<br />

2m2 Version<br />

284<br />

129<br />

392<br />

178<br />

3m 2<br />

Version<br />

430<br />

195<br />

593<br />

269<br />

up to 26<br />

up to 8<br />

2m2 Version<br />

57<br />

26<br />

141<br />

64<br />

3m 2<br />

Version<br />

90<br />

41<br />

220<br />

100<br />

26 to 66<br />

8to20<br />

2m2 Version<br />

112<br />

51<br />

276<br />

125<br />

3m 2<br />

Version<br />

176<br />

80<br />

421<br />

191<br />

5167 156 v3.1

5167 156 v3.1<br />

Collector Installation and Mounting (continued)<br />

Flat roof support weight requirements - Vitosol 300-T (continued)<br />

Collector angle of inclination of 45º<br />

Weight of supports<br />

Installation height above ground ft.<br />

m<br />

Weight of supports<br />

A<br />

lbs per support A<br />

kg per support A<br />

lbs per support B<br />

kg per support B<br />

Secured against slippage Secured against lifting<br />

up to 26<br />

up to 8<br />

2m2 Version<br />

H20<br />

225<br />

102<br />

377<br />

171<br />

3m 2<br />

Version<br />

344<br />

156<br />

564<br />

256<br />

Support A<br />

Support B<br />

Model 2m 2 Version 3m 2 Version<br />

Dimension X inches<br />

mm<br />

Dimension Y inches<br />

mm<br />

Surface area (X x Y) ft. 2<br />

m 2<br />

Weight of lbs<br />

collectors kg<br />

B<br />

60¼<br />

1530<br />

56¾<br />

1440<br />

24<br />

2.20<br />

99<br />

45<br />

60¼<br />

1530<br />

84½<br />

2149<br />

35<br />

3.27<br />

150<br />

68<br />

26 to 66<br />

8to20<br />

2m2 Version<br />

390<br />

177<br />

633<br />

287<br />

3m 2<br />

Version<br />

586<br />

266<br />

948<br />

430<br />

up to 26<br />

up to 8<br />

2m2 Version<br />

--<br />

--<br />

161<br />

73<br />

3m 2<br />

Version<br />

--<br />

--<br />

245<br />

111<br />

Specification<br />

26 to 66<br />

8to20<br />

2m2 Version<br />

--<br />

--<br />

302<br />

137<br />

3m 2<br />

Version<br />

--<br />

--<br />

454<br />

206<br />

25

Specification<br />

General Installation Instructions<br />

26<br />

H Vitosol solar collectors are hailproof.<br />

Nevertheless we recommend to<br />

include bad weather and hail damage<br />

coverage into your home owners<br />

insurance package. Our warranty does<br />

not cover such damages.<br />

H Please observe local building code<br />

guidelines for maximum load<br />

restrictions on the substructure and<br />

for necessary distance to roof edge.<br />

H Make sure to remove snow off<br />

collectors if more than 20” / 50 cm<br />

have accumulated.<br />

H Mount collectors carefully, so that<br />

even during storm and bad weather<br />

mounting clamps can absorb any<br />

tension.<br />

H An access door or skylight should be<br />

provided in the roof in the vicinity of<br />

the collectors to facilitate inspection<br />

and maintenance work.<br />

H When there is a relatively large<br />

distance between the collector panel<br />

and the roof ridge, a snow board must<br />

be installed above the collector panel<br />

in regions where heavy snowfalls can<br />

be expected.<br />

H Filling the solar heating systems with<br />

<strong>Viessmann</strong> “Tyfocor-HTL” heat<br />

transfer medium is highly<br />

recommended. Other heat transfer<br />

fluids may be suitable if they have the<br />

same temperature range (-35ºC /<br />

-31ºF to 170ºC / 338ºF) and are<br />

non-toxic.<br />

H Use high temperature insulation<br />

materials. In pump idle mode and with<br />

strong solar irradiation, collectors<br />

could reach an idle temperature of<br />

over 200 º C / 392ºF. Protect pipe<br />

insulation and sensor cables against<br />

attack by birds and animals.<br />

H Grounding and lightning protection of<br />

the solar heating system<br />

An electrically conductive connection<br />

ofthepipeworksystemofthesolar<br />

circuit should be implemented in the<br />

lower part of the building in<br />

accordance with local regulations.<br />

Connection of the collector system to<br />

a new or existing lightning protection<br />

system or the provision of local<br />

grounding should only be carried out<br />

by a licensed professional, taking local<br />

conditions into account.<br />

5167 156 v3.1

5167 156 v3.1<br />

Calculating the Required Absorber Surface Area<br />

Calculating the absorber surface area and DHW tank capacity<br />

Absorber surface area<br />

Estimates based on meteorological<br />

conditions such as annual global<br />

radiation, cloud cover etc. are<br />

sufficiently accurate for practical<br />

purposes. In order to obtain a<br />

comprehensive summary of the solar<br />

coverage for domestic hot water<br />

heating, it is recommended that this<br />

estimate should form the basis of a<br />

calculation carried out using a solar<br />

computer simulation. <strong>Viessmann</strong> can<br />

provide design support and computer<br />

simulations upon request. Contact your<br />

local <strong>Viessmann</strong> sales representative.<br />

The cover rate determined by this<br />

program should be 50 to 60 % for<br />

relatively small systems (detached<br />

house), and at least 40 % for larger<br />

systems (apartment block).<br />

Guide values for estimating the required<br />

absorber surface area can be drawn<br />

from the table on page 30.<br />

The absorber surface area calculated on<br />

the basis of this table has proved to be<br />

accurate in practice.<br />

Typical Solar Storage and Collector Selection<br />

# People<br />

in household<br />

2<br />

3-4<br />

5-6<br />

Daily DHW Demand<br />

@ 50ºC/120ºF<br />

120L<br />

32 gal.<br />

180-240L<br />

48-63 gal.<br />

300-360L<br />

79-95 gal.<br />

The basis for designing a solar DHW<br />

heating system is the DHW daily<br />

demand. It can be estimated based on<br />

the following table:<br />

Residential<br />

properties *1<br />

High demands<br />

Average demands<br />

Low demands<br />

Solar Tank<br />

Capacity<br />

200L<br />

53 gal.<br />

300L<br />

79 gal.<br />

450L<br />

120 gal.<br />

DHW Demand<br />

Vp<br />

litres/(d · person)<br />

For DHW temps<br />

temps.<br />

45ºC 60ºC<br />

50 - 80 35-56<br />

30- 50 21-35<br />

15 - 30 11-21<br />

Notes on Planning and Operation<br />

DHW tank capacity (solar storage)<br />

The following values can be used as a<br />

basis for calculating the cylinder<br />

storage capacity:<br />

The total available solar DHW tank<br />

capacity (dual-coil tank or preheating<br />

tank) should be sized on the basis of<br />

1.5 to 2 times the daily requirements.<br />

For fluctuating DHW demand use larger<br />

storage (daily demand x2). For relatively<br />

constant demand use value 1.5.<br />

The minimum solar storage tank volume<br />

should be based on 50 liter/m 2 /<br />

1.25gal/ft 2 collector absorber area.<br />

Vitosol 200-F Flat Plate<br />

Collectors SH2/SV2<br />

1 1x2m 2<br />

2 1x3m 2<br />

Vitosol 300-T<br />

Tube Collectors<br />

3 1x2m 2+ 1x3m 2<br />

27

Notes on Planning and Operation<br />

Calculating the Required Absorber Surface Area<br />

<strong>System</strong> for space heating backup - DHW cylinder and collector<br />

Energy requirement or gain (%)<br />

100<br />

75<br />

50<br />

25<br />

0<br />

Jan.<br />

Feb.<br />

Mar.<br />

Apr.<br />

May<br />

Jun.<br />

Jul.<br />

Aug.<br />

Sep.<br />

Oct.<br />

Nov.<br />

Dec.<br />

A Space heating requirement for one house (typical construction)<br />

B Space heating requirement for one low energy house<br />

C Hot water requirement<br />

D Solar energy yield at 5 m 2 absorber surface (2 flat collectors)<br />

E Solar energy yield at 15 m 2 absorber surface (6 flat collectors)<br />

Concentrating exclusively on the central<br />

heating demand can lead to problematic<br />

oversizing of the system.<br />

For low energy houses (heat demand<br />

less than 50 kWh/(m 2 p.a.), solar<br />

coverage of 20 to 25% refers to the<br />

total energy demand, incl. provision for<br />

DHW heating.<br />

28<br />

E<br />

D<br />

A<br />

B<br />

C<br />

For buildings with a higher energy<br />

demand the coverage drops lower.<br />

Use the <strong>Viessmann</strong> ESOP calculation<br />

program when making sizing<br />

calculations.<br />

Max. connectable collector area when<br />

using Vitocell tanks must follow the<br />

chart on page 31.<br />

The period when the greatest amount of<br />

solar energy is available does not<br />

coincide with the time when the most<br />

heat is required.<br />

While the heat consumption for DHW<br />

heating is relatively constant<br />

throughout the year, only very little<br />

solar energy is available at the times<br />

when the heat demand for central<br />

heating is at its highest (see diagram).<br />

A relatively large absorber area is<br />

required to provide central heating<br />

backup. In summer, this can result in<br />

stagnation in the solar circuit. <strong>System</strong>s<br />

for heating backup require additional<br />

storage tanks and controls.<br />

The basis for sizing a solar heating<br />

system for central heating backup is the<br />

space heating demand of the building<br />

during spring, autumn and in winter, as<br />

well as the heating demand in summer<br />

(i.e. the demand for DHW heating).<br />

Heat demand in summer, e.g to avoid<br />

condensation in cellars, to use<br />

underfloor heating in bathrooms,<br />

increases the demand. For efficient<br />

operation of a solar central heating<br />

backup, the collector area should be 2<br />

to 2.5 times larger than the DHW heat<br />

demand in summer requires.<br />

To avoid excessive summer time<br />

temperature stagnation avoid using<br />

collector areas greater than 3 times<br />

whatwouldbeusedforDHW<br />

requirements only.<br />

5167 156 156 v3.1

5167 156 v3.1<br />

Calculating the Required Absorber Surface Area (continued)<br />

Swimming pool water heating system - heat exchanger and collector<br />

Open-air swimming pools<br />

Open-air swimming pools are mainly<br />

used between May and September [in<br />

northern USA]. The energy demand<br />

required depends mainly on the leakage<br />

rate, evaporation, loss (water must be<br />

replenished cold) and the transmission<br />

heat loss. Through using a cover, the<br />

evaporation and consequently the<br />

energy demand of the pool is reduced<br />

to a minimum. The largest energy input<br />

comes direct from the sun, which<br />

shines onto the pool surface. Therefore<br />

the pool has a ”natural” base<br />

temperature which can be shown in the<br />

adjacent diagram as an average pool<br />

temperature over the operating time.<br />

A solar heating system in no way alters<br />

this typical temperature pattern. The<br />

solar application leads to a definite<br />

increase in the base temperature.<br />

Subject to the ratio between the pool<br />

surface and the collector area, a<br />

different temperature can be reached.<br />

The adjacent diagram shows with<br />

which ratio of aperture or absorber area<br />

to the pool surface what average<br />

temperature increase can be reached.<br />

This ratio is independent of the collector<br />

type used due to the comparably low<br />

collector temperatures and the<br />

operating period (summer). For this<br />

reason, unglazed collectors are most<br />

often used for outdoor pools.<br />

Indoor swimming pools<br />

Indoor swimming pools generally have a<br />

higher target temperature than open-air<br />

pools and are used throughout the year.<br />

If, over the course of the year, a<br />

constant pool temperature is required,<br />

indoor swimming pools must be heated<br />

in dual-mode. To avoid sizing errors, the<br />

energy demand of the pool must be<br />

measured. For this, suspend heating the<br />

water for 48 hours and determine the<br />

temperature at the beginning and end of<br />

the test period. The daily energy<br />

demand can therefore be calculated<br />

from the temperature difference and the<br />

capacity of the pool. For new builds,<br />

the heat demand of the swimming pool<br />

must be calculated.<br />

Note<br />

Revising and maintaining the pool<br />

temperature at a higher base level using<br />

a conventional heating system does not<br />

alter this ratio. However, the pool will<br />

be heated up much more quickly.<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Jan Feb MarApr May Jun JulAug Sep Oct Nov Dec<br />

Average pool temperature in 0C25<br />

Average temperature increases<br />

in degrees C/day<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2<br />

Ratio-absorber area to the pool surface<br />

(open-air swimmimg pool)<br />

On a summer day (clear skies), a<br />

collector system used to heat a<br />

swimming pool in northern USA<br />

produces energy of approx. 4.5kWh/m2<br />

absorber area.<br />

Calculation example for Vitosol 200-F<br />

Pool surface: 36 m 2<br />

Average pool depth: 1.5m<br />

Pool capacity: 54m 3<br />

Temperature loss<br />

on 2 days: 2ºC<br />

Daily energy demand:<br />

kWh<br />

54m3⋅1K⋅1.16 = 62.6kWh<br />

Km 3<br />

Notes on Planning and Operation<br />

Collector area:<br />

Location Boston<br />

40m 2 Upper surface<br />

1.5m deep<br />

protected position<br />

covered at night<br />

62.6 kWh<br />

4.5 kWh/m 2<br />

This corresponds to 6 collectors.<br />

=13.9m 2<br />

For a first approximation (cost<br />

estimate), an average temperature loss<br />

of 1C/day can be used. With an average<br />

pool depth of 1.5m an energy demand<br />

of 1.74kWh/day is required to maintain<br />

the base temperature. It is therefore<br />

sensible to use approx. 0.4m 2 absorber<br />

area per m 2 of pool surface.<br />

29

Notes on Planning and Operation<br />

Calculating the Required Absorber Surface Area (continued)<br />

Guide values for sizing solar heating systems (continued)<br />

H Absorber surface area (data based on meteorological records for a site at 49° latitude)<br />

Application Required absorber<br />

surface area A 60 % 40 up to 50 %<br />

for coverage of Vitosol 200-F Vitosol 300-T Vitosol 200-F Vitosol 300-T<br />

DHW heating<br />

Detached & semi-detached<br />

houses<br />

Multi-occupancy dwellings<br />

30<br />

ft. 2 /person<br />

m 2 /person<br />

ft. 2 /person<br />

m 2 /person<br />

Information regarding the DHW cylinder<br />

When sizing the solar heating system,<br />

observe the max. aperture area which<br />

may be connected to the different DHW<br />

cylinders.<br />

At a design output of 600W/m 2 and a<br />

temperature difference between DHW<br />

temperature (at the height of the solar<br />

13 - 16<br />

1.2 - 1.5<br />

8.6 - 11.8<br />

0.8 - 1.1<br />

heat exchanger, lower indirect coil) and<br />

solar circuit return (lower than 10 º C),<br />

the max. number of collectors<br />

mentioned in the table (values apply to<br />

all <strong>Viessmann</strong> collectors) should not be<br />

exceeded.<br />

8.6 - 10.8<br />

0.8 - 1.0<br />

6.5 - 8.6<br />

0.6 - 0.8<br />

DHW Tank Capacity Max. connectable number of collectors<br />

Vitocell-B<br />

100/300<br />

Vitocell-B<br />

100/300<br />

Vitocell-V<br />

100/300<br />

10.8 - 13<br />

1.0 - 1.2<br />

6.5 - 8.6<br />

0.6 - 0.8<br />

6.5 - 8.6<br />

0.6 - 0.8<br />

4.3 - 6.5<br />

0.4 - 0.6<br />

If a higher system temperature range is<br />

acceptable, then the number of<br />

collectors can be no more than doubled.<br />

Vitosol 200-F Vitosol 300-T 2m 2 Vitosol 300-T 3m 2<br />

300 L/79 gal. 4 5 3<br />

450 L/120 gal. 7 7 5<br />

200 L/53 gal.<br />

300 L/79 gal.<br />

450 L/120 gal.<br />

3<br />

4<br />

7<br />

4<br />

5<br />

7<br />

3<br />

3<br />

5<br />

5167 156 156 v3.1

5167 156 v3.1<br />

Sizing Pipe Diameters and Circulation Pump<br />

Solar heating system operating modes<br />

Volume flow in the collector array<br />

Generally, very low flow rates are<br />

required for Vitosol collectors. This<br />

results in small pipe and pump<br />

requirements. There are different<br />

operating modes, which depend on the<br />

total area of collectors installed, and<br />

piping requirements.<br />

At the same irradiation level, and<br />

consequently the same collector output,<br />

a higher flow rate means a lower<br />

temperature spread in the collector<br />

circuit; a lower flow rate means a<br />

higher temperature spread. With a high<br />

temperature spread, the average<br />

collector temperature increases, i.e the<br />

operating efficiency of the collector<br />

drops accordingly. Therefore, with<br />

lower flow rates the use of electrical<br />

energy (pump size) reduces and a<br />

smaller size connection pipe is possible.<br />

To safeguard a safe flow rate and a<br />

turbulent flow, Vitosol flat-plate<br />

collectors require a flow rate of at least<br />

15 liters/(h . m 2 ) . Vitosol tube collectors<br />

require at least 25 liters/(h . m 2 ).<br />

Generally, when setting the collector<br />

volume flow, the necessary volume<br />

flow of the connected heat exchanger<br />

should also be taken into account.<br />

1. High-flow mode<br />

For solar heating systems up to<br />

270º ft. 2 /25m 2 absorber surface<br />

area, we recommend the high flow<br />

operation. This reduces the temperature<br />

spread between supply and return.<br />

The higher flow rate requires a slightly<br />

larger pipework size, and larger pump<br />

sizes.<br />

In the high-flow operating mode, the<br />

pipes can be sized on the basis of a<br />

flowrate of<br />

H Vitosol 200-F: approx. 40 liters/h per<br />

m 2 absorber surface area (approx.<br />

0.18 gpm/m 2 absorber surface area).<br />

H Vitosol 300-T: 60 liters/h per m 2<br />

absorber surface area<br />

(0.27 gpm/m 2 absorber surface area).<br />

2. Low-flow mode<br />

For large solar installations (larger than<br />

270 ft. 2 /25m 2 absorber surface area),<br />

low flow mode operation can be used..<br />

Advantages of the low-flow mode:<br />

H A high temperature level is reached<br />

quickly in the collector circuit.<br />

H The low flow rate in the collector<br />

circuit means that much smaller pipe<br />

sizes are required.<br />

H A smaller pump capacity is required<br />

resulting in lower electrical<br />

consumption.<br />

In the low-flow operating mode, the<br />

pipes can be sized on the basis of a<br />

flowrate of<br />

H Vitosol 200-F: approx. 15 liters/h per<br />

m 2 absorber surface area (approx.<br />

0.07 gpm/m 2 absorber surface area).<br />

H Vitosol 300-T: approx. 25 litrers/h per<br />

m 2 absorbed surface area (approx.<br />

0.11gpm/m 2 absorber surface area) .<br />

With both collector models, a uniform<br />

flow rate through all collectors is<br />

guaranteed if the <strong>Viessmann</strong> piping<br />

layout drawings are followed. To reduce<br />

the amount of installation work required<br />

for the piping, it is advisable to connect<br />

two rows of collectors with all piping<br />

connections on one side of the array.<br />

Pipe installation information<br />

To minimise the pressure drop through<br />

the piping of the solar heating systems,<br />

the flow velocity in the copper pipe<br />

should not exceed 3.5ft/s. We<br />