Analiza ulja

Analiza ulja

Analiza ulja

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

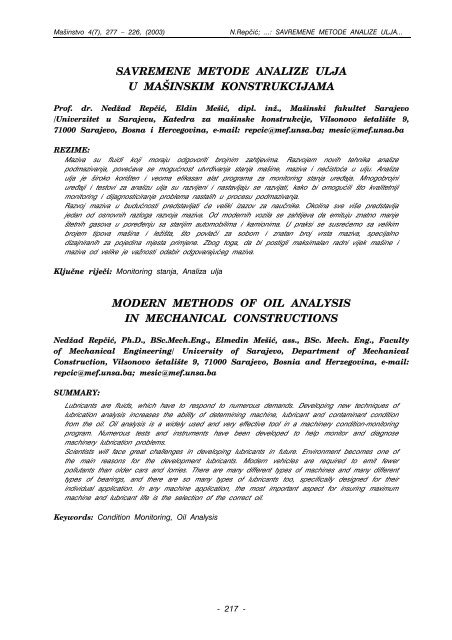

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...SAVREMENE METODE ANALIZE ULJAU MA[INSKIM KONSTRUKCIJAMAProf. dr. Ned`ad Rep~i}, Eldin Me{i}, dipl. in`., Ma{inski fakultet Sarajevo/Univerzitet u Sarajevu, Katedra za ma{inske konstrukcije, Vilsonovo {etali{te 9,71000 Sarajevo, Bosna i Hercegovina, e-mail: repcic@mef.unsa.ba; mesic@mef.unsa.baREZIME:Maziva su fluidi koji moraju odgovoriti brojnim zahtjevima. Razvojem novih tehnika analizepodmazivanja, pove}ava se mogu}nost utvr|ivanja stanja ma{ine, maziva i ne~isto}a u ulju. <strong>Analiza</strong><strong>ulja</strong> je {iroko kori{ten i veoma efikasan alat programa za monitoring stanja ure|aja. Mnogobrojniure|aji i testovi za analizu <strong>ulja</strong> su razvijeni i nastavljaju se razvijati, kako bi omogu}ili {to kvalitetnijimonitoring i dijagnosticiranje problema nastalih u procesu podmazivanja.Razvoj maziva u budu}nosti predstavljati }e veliki izazov za nau~nike. Okolina sve vi{e predstavljajedan od osnovnih razloga razvoja maziva. Od modernih vozila se zahtijeva da emituju znatno manje{tetnih gasova u pore|enju sa starijim automobilima i kamionima. U praksi se susre}emo sa velikimbrojem tipova ma{ina i le`i{ta, {to povla~i za sobom i znatan broj vrsta maziva, specijalnodizajniranih za pojedina mjesta primjene . Zbog toga, da bi postigli maksimalan radni vijek ma{ine imaziva od velike je va`nosti odabir odgovaraju}eg maziva.Klju~ne rije~i: Monitoring stanja, <strong>Analiza</strong> <strong>ulja</strong>MODERN METHODS OF OIL ANALYSISIN MECHANICAL CONSTRUCTIONSNed`ad Rep~i}, Ph.D., BSc.Mech.Eng., Elmedin Me{i}, ass., BSc. Mech. Eng., Facultyof Mechanical Engineering/ University of Sarajevo, Department of MechanicalConstruction, Vilsonovo {etali{te 9, 71000 Sarajevo, Bosnia and Herzegovina, e-mail:repcic@mef.unsa.ba; mesic@mef.unsa.baSUMMARY:Lubricants are fluids, which have to respond to numerous demands. Developing new techniques oflubrication analysis increases the ability of determining machine, lubricant and contaminant conditionfrom the oil. Oil analysis is a widely used and very effective tool in a machinery condition-monitoringprogram. Numerous tests and instruments have been developed to help monitor and diagnosemachinery lubrication problems.Scientists will face great challenges in developing lubricants in future. Environment becomes one ofthe main reasons for the development lubricants. Modern vehicles are required to emit fewerpollutants than older cars and lorries. There are many different types of machines and many differenttypes of bearings, and there are so many types of lubricants too, specifically designed for theirindividual application. In any machine application, the most important aspect for insuring maximummachine and lubricant life is the selection of the correct oil.Keywords: Condition Monitoring, Oil Analysis- 217 -

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...1. UVODMaziva su od velikog zna~aja u `ivotu modernog~ovjeka. <strong>Analiza</strong> <strong>ulja</strong> je {iroko zastupljen i efikasanalat u programu za monitoring stanja nekema{inske konstrukcije. Mnogobrojni ure|aji itestovi za analizu <strong>ulja</strong> su razvijeni i nastavljaju serazvijati, kako bi omogu}ili {to kvalitetniji monitoringi dijagnosticiranje problema nastalih u procesupodmazivanja.Razvojem ra~unara i opreme, moderni programanalize <strong>ulja</strong> postaje jednostavan za provo|enje.Mnoge kompanije koriste softvere za analizu <strong>ulja</strong>.U zadnje vrijeme se mnogo govori o razvoju novihtehnika za analizu podmazivanja i pove}anjusposobnosti odre|ivanja stanja ma{ine, maziva ine~isto}a u ulju.1. INTRODUCTIONLubricants are important in modern life. Carlubricants perform four major functions: control ofengine friction and wear, protection of engine fromrusting, cooling of the pistons, and protection ofthe engine oil stored in the sump fromcombustion gases. Oil analysis is widely used and avery effective tool in a machinery condition-monitoringprogram. Numerous tests and instruments have beendeveloped to help monitor and diagnose machinerylubrication problems. With increased computer andinstrumentation capacity, a modern oil analysisprogram is both easy to manage and provides a highreturn of maintenance investments. Many companiesare using oil analysis software to track their equipmentdata. A great deal has been written about thedevelopment of new techniques for lubrication analysisand enhancing the ability to determine machine,lubricant, and contaminant condition from oil.2. MONITORING STANJA KROZTESTOVE ANALIZE ULJAPostoji veliki broj razli~itih testova unutar analize<strong>ulja</strong> koji se koriste u procijeni njegovog stanja.Testovi moraju pokriti tri oblasti od interesa: stanjema{ine, stanje ne~isto}a u mazivu i stanje maziva.Termin ''analiza <strong>ulja</strong>'' prihva}en u industriji mo`ese shvatiti na na~in da je primarna oblast odinteresa analiza stanja maziva, dok je u stvarnosti,to u stvari monitoring stanja ma{ine.Sa aspekta stanja ma{ine posebnu pa`nju trebaobratiti na pojavu i trend promjene broja metalnih~estica u ulju. Drugi fokus bi bilo stanje maziva,gdje je pa`nju potrebno obratiti na znakove kojiupu}uju na promjenu viskoznosti, pove}aneoksidacije i tro{enja aditiva. Tre}i fokus bi bilostanje ne~isto}a u ulju, gdje je potrebno pa`njuobratiti na brojnost ~estica, sadr`aj vode i metalnihne~isto}a. Teoretski, analize <strong>ulja</strong> podijeljene su utri klase. U stvarnosti sve tri klase monitoringastanja su me|usobno povezane i moraju seposmatrati kao cjelina. Tako na primjer, pove}anjeviskoznosti mo`e biti naznaka procesa oksidacijemaziva. Me|utim, to mo`e biti pogre{an zaklju~ak,ako nema pokazatelja trenda pove}anja oksidacijedobivenih preko analize vrijednosti kiselinskog broja(Acid Number-AN) i infracrvene analize na principuFurijerove transformacije (FT-IR).I pod najboljim uvjetima rada, mazivo }e vjerojatnodegradirati. Vr{e}i monitoring stanja maziva, umogu}nosti smo izvr{iti osvje`enje ili zamjenu mazivaprije nego {to nastupe ozbiljnija o{te}enja ma{ine.Ako je o{te}enje primije}eno tokom rada, zbogne~isto}a u ulju ili problema vezanih za mazivo,stanje ma{ine se mo`e nadzirati i odmah izvr{itiprekid njenog rada u cilju smanjenja o{te}enja.2. CONDITION MONITORINGTHROUGH OIL ANALYSIS TESTSThere are many different types of oil analysis teststhat are used to evaluate lubricants. The testsmust cover three areas: machine condition,contamination condition, and lubricant condition.The industry-accepted term oil analysis can implythat the primary area of interest is the condition ofthe lubricant. But in reality, monitoring the machinecondition is primary.From the machine condition aspect, the specific focuswould be to look for the presence and trending ofany wear metals. The second focus would be thelubricant condition. From that aspect, the focus wouldbe to look at the evidence of viscosity change,increase in oxidation, and signs of additive depletion.The third focus would be the contaminant condition.Emphasis should be placed on particle counts, watercontent, and contaminant metals.Theoretically, oil analyses are divided into threeclasses. In reality, all three condition-monitoringclasses are interrelated and must be consideredas a whole. For example, an increase in viscositycould be an indication that a lubricant is oxidizing.But oxidation could be an incorrect conclusion, ifthere is no indication of an increasing oxidationtrend either by acid number (AN) values or FourierTransform-Infrared (FT-IR) analysis.Even under the best of conditions, a lubricant willprobably degrade. By monitoring its condition, actionscan be implemented to refresh or replace thelubricant before serious machine damage begins.If damage is noticed in the course of operation, dueto contaminant, or lubricant problems, the machinecondition can be monitored and the machine may beshut down immediately to minimize damage.- 218 -

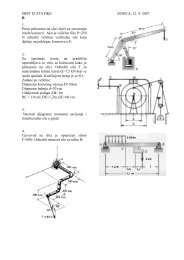

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...Druga mogu}nost je da se, u zavisnosti odsituacije, produ`i rad ma{ine do prve pogodneprilike za njeno isklju~enje.Postoje dva tipa alarma tj. upozorenja kori{tenih uanalizi <strong>ulja</strong>: apsolutni i statisti~ki alarm. Efikasnaanaliza <strong>ulja</strong> po~iva na kombinaciji oba tipa.Slika 1. predstavlja jedan primjer kombinacije alarma[1]. Granica upozorenja predstavlja apsolutni alarm.Statisti~ki trend, uzima u obzir promjenljivost, koja jeposljedica uzorkovanja <strong>ulja</strong>, zaprljanja <strong>ulja</strong> i sl.,predstavlja standardnu devijaciju (odstupanje).Odstupanje od ove normalne promjenljivostisignalizira pojavu ozbiljnijih problema. Ovoodstupanje predstavlja prvi znak za poduzimanjemjera u cilju rje{avanja nastalog problema. Kako setrend odstupanja pribli`ava granici upozorenjapotrebno je poduzeti mjere kao {to je zamjena ilipre~i{}avanje <strong>ulja</strong> ili pregled ma{ine.Another possibility would be to extend themachine runtime to a suitable shutdownopportunity, depending on the situation.There are the two types of alarming methodologiesthat are employed in oil analysis: absolute andstatistical alarms. Effective oil analysis relies on thecombination of both types of alarms. The followingillustration (Figure 1.) is an example of the alarmcombination [1]. The warning limit is the absolutealarm. Statistical trending, taking into account thevariability based on the sampling, contamination,etc. will develop the standard deviations.Departure from this normal variability signals thatgenuine problems are occurring. This is theearliest possible time to take action and resolveproblems. Failing this, as the trend approaches itswarning limit, action such as changing or cleaningthe oil, or inspection of the unit is required.Test sa isušivanjem <strong>ulja</strong>Granica upozorenja testaRad uređaja h/kmZahtijeva sepoduzimanje mjeraProjektovanitrend rastaPreporučuje sepoduzimanje mjeraNormalna rezultujućavarijabilnostSlika 1. Kombinacija apsolutnog i statisti~kog alarmaFigure 1. Combination of Absolute and Statistical AlarmsTest mo`e obuhvatiti kontrolu sadr`aja metalnih~estica, kontrolu viskoznosti ili neke drugeparametre. Oblast normalne promjenljivosti uzima uobzir male varijacije nastale uslijed analiti~keta~nosti, homogenosti uzorka, itd. Uspostavljanjestatisti~kih alarma, koji obezbje|uju najranijemogu}e upozorenje, bez la`nih alarma, je te{koostvariti. Faktori kao {to su dodavanje ili zamjena<strong>ulja</strong>, zamjena filtera i tehnika uzorkovanja uti~u nata~nost rezultata.The test used could be iron content, viscosity orother parameters. The normal result variabilityrange takes into account minor variations causedby analytical accuracy, sample homogeneity, etc.As the trend approaches the warning limit, someaction must be taken, either cleaning the oil orinspecting the equipment. Establishing statisticalalarms, which provide the earliest possible warningwithout false alarms, is a difficult task. Factorssuch as adding or changing oil, filter changes,sampling technique can distort the results.- 219 -

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...Kori{tenjem programa za analizu <strong>ulja</strong> u slu~ajumotornih <strong>ulja</strong>, osigurava se nekoliko prednosti:smanjenje neplaniranog vremena otkaza vozila,pobolj{anje pouzdanosti vozila {to je od koristiprilikom organizovanja efikasnog plana odr`avanja,produ`enje radnog vijeka motora, optimiziranjeintervala zamjene <strong>ulja</strong> i smanjenje tro{kovaodr`avanja vozila.Sljede}i testovi su naj~e{}e kori{teni testoviprilikom monitoringa stanja ma{ine od kojih se kodnekih prepli}u tri interesne oblasti.Using Oil Analysis programs for engine oils hasseveral benefits: reduction of unscheduled vehicledowntime, improvement of vehicle reliability, helpin organizing effectiveness of maintenanceschedules, extension of engine life, optimization ofoil change intervals and reduction of cost ofvehicle maintenance.The following tests are the most used in conditionmonitoring. With some of them, the three areas ofinterest may overlap.2.1 Spektrometrijska analizaSpektrometrijska analiza je tehnika za utvr|ivanje ikvantificiranje metalnih ~estica nastalih habanjem,zaprljanjem i sl. Uzorak <strong>ulja</strong> se pobu|uje tako dasvaki element emituje ili apsorbuje odre|enukoli~inu energije {to ukazuje na koncentracijuelemenata u ulju.Rezultati predstavljaju koncentraciju svih rastvorenihmetala i ~estica. Oprema za spektrometrijskuanalizu danas predstavlja standardnu opremulaboratorija za analizu <strong>ulja</strong>, koja obezbje|ujeinformaciju o stanju ma{ine, zaprljanju i habanjurelativno brzo i ta~no.2.1 Spectrometric AnalysisSpectrometric analysis is a technique for detectingand quantifying metallic particulates in used oilarising from wear, contamination and additivepackages. The oil sample is energized to make eachelement emit or absorb a quantifiable amount ofenergy, which indicates the element’s concentrationin the oil. The results represent the concentration ofall dissolved metals and particles. The equipment forspectrometric analysis is the standard equipment foroil analysis laboratories today. It provides informationon machine, contamination and wear conditionrelatively quickly and accurately.Efikasnostdetekcije [%]SpektroskopijaRotrod FilterFerografijaVeličina čestica [µm]Slika 2. Efikasnost detekcijeFigure 2. Detection efficiencySpektroskopija je manje-vi{e ''slijepa'' za ve}e Spectroscopy is more-or-less blind to the larger particles~estice u uzorku <strong>ulja</strong>, ta~nije za ~estice ve}e od in an oil sample, more precisely, to particles greater10 µm u pre~niku, a koje su pokazatelj pojave than 10 µm in diameter, which are more indicative ofizrazito pove}anog habanja. (sl. 2) [2]. Nekoliko an abnormal wear mode (Figure 2.) [2]. Most severevrsta habanja (kao {to su: habanje kao posljedica wear modes (such as spalling, severe sliding wear, andraspadanja materijala pod uticajem toplote, nekoliko cutting wear) generate large particles, which gokliznih habanja i rezno habanje) generira velike undetected by spectroscopy. Large contaminant particles~estice koje se ne mogu otkriti spektroskopijom. are also missed by spectroscopy. The particle size atVeli~ina ~estice pri kojoj spektrometri po~inju da which spectrometers begin to lose their detection abilitygube sposobnost detekcije zavisi od brojnih faktora depends on a number of factors including spectrometerkao {to su vrsta i tip spektrometra, ali gledaju}i and type, but it is generally agreed that spectrometersgeneralno spektrometri gube sposobnost detekcije lose their ability to detect particles in the 1 to 10~estica pre~nika izme|u 1 i 10 µm. Ovo je glavni micrometer range. That is a major limitation of thenedostatak spektrometrijske analize.spectrometric analysis. Particle detection efficiency ispoor for particles 5 microns in size or greater. Thetechnique is accurate to 10%, although with newequipment it is within 3% [2].- 220 -

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...<strong>Analiza</strong> <strong>ulja</strong> spektrografijom je na{la dobru primjenukod motora sa unutra{njim sagorijevanjem ihidrauli~nih sistema, jer su pohabane ~esticenaj~e{}e sitne. Ove male ~estice se ravnomjernorasporede u uzorku <strong>ulja</strong> i lako sagore uspektrometru, tako da operator ima jasno o~itanje.Spectrographic oil analysis works well for internalcombustion engines and hydraulic systems becausethe wear particles are usually small. These smallparticles disperse evenly in the oil sample. They alsoburn readily in the spectrometer; therefore, theoperator gets a good reading.2. 2 Analiti~ka ferografijaAnaliti~ka ferografija je tehnika koja odvajapohabane magnetne ~estice iz <strong>ulja</strong>. Ove ~esticese slije`u na staklenu povr{inu poznatu kaoferogram. Mikroskopsko ispitivanje omogu}ava daodredimo tip habanja, a vjerovatno i izvor habanjau ma{ini. Analiti~ka ferografija je jedan izuzetanindikator izrazito pove}anog habanja dijelova odneobojenih metala, ali je neprikladna u slu~ajuhabanja dijelova od obojenih metala.Test je od izuzetne koristi kod ve} uspostavljenogprocesa habanja. Rezultati uklju~uju izvje{taj oveli~ini, morfologiji i koli~ini ~estica od neobojenihmetala i ne~isto}a.Ferografija je dosta rasprostranjena tehnologijaanalize pohabanih ~estica. Predstavlja dijagnosti~koprognoziraju}utehniku koja nudi jedan pogodanna~in ta~nog procjenjivanja on-line stanjapodmazivanih dijelova u kontaktu bez isklju~ivanjama{ine. Jedna automatizovana verzija ove tehnikeje DR (Direct Read) Ferografija koja mjeri odnoskrupnih i sitnih ~estica u ostacima uljnog uzorka.Mala koli~ina uzorka se razrje|uje rastvara~em ipu{ta da te~e kroz malu kapilarnu cijev koja sekre}e kroz magnetno polje. Dva opti~ka senzorasu neovisno jedan od drugog postavljeni na ulaz ineznatno usmjereni niz kapilarnu cijev mjere}igusto}u ~estica neobojenih metala sabranih naoba mjesta. Ovi podaci se mogu koristiti priodre|ivanju koncentracije pohabanih ~estica iindeksa ozbiljnosti situacije.Kada se je DR ferogram pojavio sedamdesetihgodina, do`ivio je veliki uspjeh, zahvaljuju}isposobno{}u otkrivanja kako velikih tako i malih~estica neobojenih metala u ulju, kao isposobno{}u odre|ivanja njihovog odnosa kojikarakteri{e pojavu pove}anog habanja kod ma{inasa rotacionim dijelovima. DR ferografija je i daljebazirana na magnetnom odvajanju, tako da se ovajprincip ne mo`e koristiti u slu~aju ~estica odobojenih metala bilo koje veli~ine, kao i u slu~ajuanorganskih nemetalnih ~estica (pijesak, ne~isto}e,i sl.). Ovaj nedostatak dolazi do izra`aja posebnokod monitoringa opreme sa kriti~nim dijelovima odobojenih metala. Zbog toga, tradicionalnaspektroskopija, ostaje sastavni dio analize <strong>ulja</strong>upravo zbog sposobnosti da otkrije sitne ~esticeobojenih metala.2.2 Analytical FerrographyAnalytical ferrography is a techniquewhichseparates magnetic wear particles from oil. Thoseparticles settle on a glass slide known as aferrogram. Microscopic examination enables todetermine the wear mode and probable sources ofwear in the machine. Analytical ferrography is anexceptional indicator of abnormal ferrous wear andit is inadequate for nonferrous wear. The test ismost useful for an established wear trend. Resultsinclude report of size, morphology, and quantity offerrous wear, and contaminant particle.Ferrography is a rapidly expanding technology ofwear particle analysis. It is a diagnosticandpredictive technique which offers a convenientmeans of accurately evaluating the online conditionof interacting lubricated components without havingto shut down the machine. An automated versionof this technique is DR (direct read) ferrography. Itmeasures the ratios of large and small debrisparticles in the sample. A small amount of sampleis diluted with solvent and flowed through a smallcapillary tube, which runs through the magneticfield. Iron-based particles are systematically (largestto smallest) separated by the magnetic field as thesample flows through the capillary tube. Twooptical sensors are respectively set at the entranceand slightly downstream of the capillary tube tomeasure the density of the iron particles collectedat each of the two points. This data may be usedto calculate the wear particle concentration andthe severity index.When the DR Ferrograph was introduced in the70’s, it met with immediate success because of itssensitivity to both large and small ferrous particlesin lubricating oil, and its capability of determiningthe ratio whereby abnormal wear could becharacterized in rotating machinery. DRFerrography is still based on magnetic separation,and this is a principle weakness when nonferrousmetal particles of any size are present in an oilsample, not to mention large nonmetallic inorganicparticles such as sand/dirt. This drawback isevident when monitoring equipment with criticalnonferrous components. Consequently, traditionalspectroscopy continues to remain an integral partof oil analysis because of the ability to detect finenonferrous debris.- 221 -

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...Kombinacija DR ferografije i spektrometra je do Until now, the combination of the DR andpojave Rotrode Filter Spektroskopije (RFS) bila spectrometer has been a popular method ofpopularna metoda ekranizacije uljnih uzoraka radi screening oil samples to detect abnormal wear.detekcije pove}anog habanja. Me|utim, ~ak i u However, even in combination, they remainkombinaciji, ove metode ne mogu otkriti krupnije insensitive to large nonferrous particles.~estice obojenih metala.2. 3 Rotrode Filter Spektroskopija (RFS)Rotrod filter spektroskopija je prvi put predstavljena1992. godine. Ova spektrometrijska tehnika detektujekrupne metalne ~estice i ne~isto}e u uljnom uzorku.Pre~nik ovih ~estica je do 25 µm. Ove krupne~estice su od posebnog zna~aja, jer predstavljajuprve indikatore pove}anog intenziteta habanja.RFS predstavlja jednu pobolj{anu spektroskopskumetodu analize kori{tenog <strong>ulja</strong> za monitoring stanjaodnosno predvi|anja potrebnog odr`avanja, bezograni~enja po veli~ini ili tipu ~estice kao uslu~aju kombinovane spektrohemijske metode i DRferografije. Superiornija je u odnosu na DRferografiju, jer ima mogu}nost detekcije ~esticakako neobojenih metala tako i obojenih, kao ine~isto}a. Efikasnost detekcije opada sa porastompre~nika ~estica iznad 25 µm.Metoda koristi spektrometar sa elektrodom u oblikurotacionog diska, poznat kao RDE (Rotating DiskEmission) spektrometar, koji obezbje|ujespektrografi~ku analizu <strong>ulja</strong> (SOA).RDE spektrometar sastoji se od karbonskog diskakoji je pritisnut na kraj rotiraju}eg vratila.Osjetljivost metode je odli~na. Koristi sevi{estepeni ure|aj tako da se vi{e uzoraka mo`efiltrirati istovremeno. Metoda je brza i ekonomi~na izahvaljuju}i prednostima koje posjeduje predstavljajedan mo}an predskaziva~ kvara opreme.Povi{en stepen habanja prouzrokuje zna~ajnopove}anje u koncentraciji i veli~ini pohabanih~estica. Koriste}i poroznu grafi~ku ''rotrodu'' kaofiltriraju}i medij krupne ~estice se apsorbuju ipodvrgavaju RDE spektroskopiji dobijaju}i vi{eelementnuanalizu uljnog uzorka. Prvenstveno semjeri koncentracija i veli~ina ovih apsorbovanihkrupnih ~estica nezavisno od sitnih i rastvorenih~estica ne~isto}a u uzorku. Kombinuju}i rezultateanalize krupnih ~estica sa konvencionalnom RDEanalizom rastvorenih i sitnih ~estica u uljnomuzorku mo`e se dobiti kompletna slika analizepohabanih ~estica odre|ene ma{ine.Rotrod filter spektroskopija je brza i efikasnametoda analize <strong>ulja</strong>. Dobiveni podaci se moguiskoristiti i za analizu ne~isto}a kojom se dobivasastav po elementima krupnih ~estica ne~isto}a(silikon). Prednost ove tehnike je i ta da se mo`eodrediti da li je neki element porijeklom odpakovanja aditiva (silikonski polimer protivpjenu{anja <strong>ulja</strong>) ili je u pitanju ~estice ne~isto}a(pijesak, i sl.).2.3 Rotrode Filter Spectroscopy (RFS)RFS was first introduced in 1992. This spectrometrictechnique detects coarse wear metals andcontaminants in a used oil sample. Diameter ofthose particles is up to 25 µm, but it excludes alladditives. The coarse particles are especiallyimportant. They are the first indicators of abnormalwear situations. RFS was developed to provide animproved spectroscopic method for analysis of usedoils for condition monitoring/predictive maintenancewithout the particle size or metal-type limitations ofthe combined spectrochemical and DR ferrographictechniques. It is superior to DR ferrography becauseit detects ferrous, nonferrous and contaminantelements. The detection efficiency of large materialgets poorer as particle size increases above 25 µmdiameter. Its accuracy range is within 15% [2].This method uses a rotating disc electrodespectrometer, known as an RDE spectrometer,which performs spectrographic oil analysis (SOA). Inthe RDE spectrometer, a carbon disc is pressedonto the end of a shaft, which rotates causing thedisc to rotate. The sensitivity of the method isexcellent. A multi-station fixture is used so that anumber of samples can be filtered at once. Theprocedure is fast and economical to perform. It isan ideal screening test for analytical ferrography.The technique has several advantages, which makeit a powerful predictor of equipment failure.Most abnormal wear modes cause a significantincrease in concentration and size of wear particles.Using porous graphite rotrodes as a filtering media,large particles are captured and subjected to RDE(Rotating Disk Emission) Spectroscopy to obtain amulti-elemental analysis. These captured coarseparticles are measured essentially independently of fineand dissolved particle contaminants in the sample.Removal of the used oil from the spectroscopicanalysis reduces the energy required to vaporize thesample. By combining such large particle results withconventional RDE analysis of the dissolved and fineparticles in the oil sample, a complete wear analysispicture for a machine of interest can be obtained.Rotrode Filter Spectroscopy is fast and efficient. Thedata is also excellent for contamination analysis. Itgives elemental composition of large contaminantparticles (silicon). The advantage of this is that itcan determine whether the element is sourced froman additive package (silicone polymer fordefoaming) or a contaminant (sand/dirt particles)- 222 -

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...2.4 Infracrvena analiza (FT-IR) 2.4 Infrared Analysis (FT-IR)Infracrvena spektroskopija furijerovomtransformacijom (FT-IR) je spektrometrijksa tehnikaza detekciju organskih ne~isto}a, vode i produkatadegradacije <strong>ulja</strong> u uljnom uzorku. Vr{i se kontroladegradacije maziva (oksidacija, nitracija, sulfatacija,tro{enje aditiva) i te~nih ne~isto}a (voda, glikol,razbla`ivanje maziva gorivom).Tokom radnog vijeka maziva, akumuliraju seprodukti oksidacije, prouzrokuju} i degradiranje <strong>ulja</strong>i u ve}ini slu~ajeva lagani porast njegove kiselosti.Ako se oksidacija pojavi u ve}oj mjeri, mazivo }eprouzrokovati koroziju kriti~nih povr{ina ure|aja.Pove}anje oksidacije dovodi do ve}eg''oksidacionog broja''. Sli~no tome, ''nitracioni broj''ukazuje na nivo jedinjenja nitrogena u uljuprouzrokovanih vezivanjem atoma azota (~estapojava kod motora na prirodni gas). Pojave kao{to su bijeljenje <strong>ulja</strong>, talo`enje m<strong>ulja</strong>, ljepljivi klipniprsteni i za~epljenje filtera javljaju se u sistemimasa problemom oksidacije i/ili nitracije.FT-IR spektroskopija tako|er, utvr|uje zaprljanje <strong>ulja</strong>uslijed vode, glikol antifriza, naslaga~a|i,razbla`ivanja <strong>ulja</strong> gorivom. Postoje preporukeproizvo|a~a vezano za oksidacione brojeve i te~nene~isto}e.Fourier-Transform Infra-Red Spectroscopy is aspectrometric technique for detecting organiccontaminants, water and oil degradation productsin a used oil sample. It monitors lubricantdegradation (oxidation, nitration, sulfation, additivedepletion) and liquid contaminants (water, glycol,fuel dilution).During a lubricant’s service life, oxidation productsaccumulate, causing the oil to become degraded,and in most instances, slightly acidic. If oxidationbecomes severe, the lubricant will corrode theequipment’s critical surfaces. The greater the"oxidation number", the more oxidation is present.Similarly, the "nitration number" reflects the level ofnitrogen compounds in the oil resulting fromnitrogen fixation (common in natural gas fueledengines). Conditions such as varnishing, sludgedeposits, sticky rings, lacquering and filterplugging occur in systems with oxidation and/ornitration problems.FT-IR spectroscopy also indicates contamination dueto free water, glycol antifreeze, soot deposits andfuel dilution. There are guidelines issued foroxidation numbers and liquid contaminants bymanufacturers, but this is essentially a trending tool.2. 5 ViskoznostViskoznost je otpornost fluida te~enju i predstavljanajzna~ajniju fizi~ku osobinu maziva. Mazivo moraposjedovati odgovaraju}e karakteristike, kako biosiguralo adekvatno snabdijevanje podmazivanihpovr{ina u kontaktu pri razli~itim radnimtemperaturama. Fluid se stavlja u viskozimetar(kalibrirana kapilarna cijev za precizno mjerenjeprotoka izme|u dvije obilje`ene ta~ke na cijevi) ipredgrijava na zadanu temperaturu u ''viskoznojkadi'' koja je naj~e{}e napunjena uljem. Nakon {tose ulje zagrije na odre|enu temperaturu, uslijeddjelovanja gravitacije po~inje te}i kroz viskozimetar.Mjeri se vrijeme potrebno da ulje protekne izme|udvije kalibrirane ta~ke na cijevi.Smicanje maziva se javlja u slu~aju cijepanjanjegovih molekule na manje molekule. Ovo sede{ava iz dva osnovna razloga: toplota i pritisak izsistema. Indeks viskoznosti (VI) je mjera otporamaziva usitnjavanju njegovih molekula sa porastomtemperature. Predstavlja jednu va`nu osobinu mazivana ni`im temperaturama. Tako na primjer, zbogpumpabilnosti maziva zahtijeva se njegova manjaviskoznost, dok s druge strane zbog obezbje|enjapotrebne mo}i no{enja mazivnog filma na radnojtemperaturi, zahtijeva se njegova dovoljna gusto}a. Uslu~aju motornih <strong>ulja</strong>, ispunjenju ovih zahtjevauspje{no potpoma`u pobolj{iva~i indeksa viskoznostibazirani na polimerima.2.5 ViscosityViscosity is the resistance of a fluid to flow and themost important lubricant physical property.Lubricants must have suitable flow characteristics toinsure that an adequate supply reaches lubricatedparts at different operating temperatures. The fluid isplaced in a "viscometer" (a calibrated capillary tubefor precise flow measurement between two premarkedpoints on the tube) and pre-heated to agiven temperature in a "viscosity bath" (which isusually oil-filled). After the oil reaches the desiredviscosity temperature, gravity-influenced flow of theoil is initiated in the viscometer and timed betweentwo calibrated points. This time becomes thedeterminant for the result.Shearing of a lubricant occurs when its moleculesare split into yet smaller molecules. This canhappen from two basic processes: heat andpressure from the system. This can affect even thelubricant's base stock, although it more aptlyapplies to any viscosity-index improvers which mayhave been present during mechanical shearing,such as a ring scraping against a cylinder wall,trapping of lubricant molecules and cutting oflubricant molecules. Viscosity Index (VI) is ameasure of a lubricant's resistance to thinning astemperature increases.- 223 -

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...Viskoznost maziva znatno zavisi od njegoveklasifikacije ili gradacije kao i od stepenaoksidacije i zaprljanja tokom rada.Razlozi za pove}anje viskoznosti maziva le`e usljede}em: oksidacija maziva, kavitacija uslijedpjenu{anja maziva, rastvaranje maziva s vodom,punjenje sistema mazivom ve}e viskoznosti odpreporu~ene i zaprljanje maziva ~vrstim ~esticama.S druge strane, razlozi za smanjenje viskoznostimaziva su: zaprljanje maziva gorivom, usitnjavanjemolekula, zaprljanje maziva bez njegovograstvaranja s vodom, punjenje sistema mazivommanje viskoznosti od preporu~ene i uticaj sredstvaza hla|enje (erkodi{n sistemi).Ako se viskoznost maziva razlikuje vi{e od 10% odnominalne gradacije, proizvo|a~imazivapreporu~uju njegovu zamjenu. Tokom rada ivremena, o~ekuje se porast viskoznosti maziva.Smanjenje viskoznosti se smatra opasnijim odnjenog pove}anja. Stoga, je dozvoljena gornjagranica +20% iznad nominalne vrijednosti, a donja–10% ispod nominalne vrijednosti.2.6 Ukupni kiselinski broj (TAN)Ukupni kiselinski broj je neutralizacioni brojnamijenjen za mjerenje svih kiselinskih i kiselinsko-(KOH) i dodajeaktivnih materijala u mazivu uklju~uju}i jake i blagekiseline. To je titraciona metoda koja pokazujerelativnu kiselost maziva.Uzorak se razbla`uje razrje|iva~em i alkalnombazom, u obliku kalijum hidroksidau kontrolisanoj mjeri iz menzure dok se uzorak neneutralizira. Kalijum hidroksid je titrant.Neutralizacija se mjeri jedinicom volt ili pHfaktorom. Ta~ka po~etka neutralizacije se kre}eoko vrijednosti faktora pH 11. TAN se odre|uje naosnovu utro{ene koli~ine KOH.Jake kiseline imaju tendenciju da postanukorozivne i njihova koli~ina u mazivu mora seobavezno kontrolisati. Kiselinski broj koristi se kaopokazatelj oksidacione degradacije <strong>ulja</strong> tokom rada.Kada vrijednost TAN-a dosegne odre|eni definisaninivo za dato mazivo i za njegovo mjesto primjenepotrebno je izvr{iti zamjenu <strong>ulja</strong>. Neo~ekivaniporast vrijednosti TAN-a mo`e upu}ivati naabnormalne radne uslove (npr. pregrijavanje) {tozahtijeva istragu. Ve}ina proizvo|a~a maziva dajepreporu~ene vrijednosti TAN-a u katalozima.It is an important property in cold climates: onewants a low viscosity for pump-ability, but then wantsthe lubricant to remain thick enough to provide filmstrength at operating temperature. Polymer-based "VIimprovers" help accomplish this in motor oils. VI isof little use in used motor lubricant analysis. Theviscosities of lubricants vary depending on theirclassification or grade, as well as the degree ofoxidation and contamination in service.The reasons for increase in the viscosity are:lubricant oxidation, foaming/pump cavitation, emulsionwith water, wrong fill or make-up lubricant (higherviscosity than recommended), and solidscontamination. However, the reasons for the reductionin viscosity are: fuel or solvent contamination,molecular shearing, non-emulsified watercontamination, wrong fill or make-up lubricant (lowerviscosity than recommended), and refrigerant (airconditioningsystems). If viscosity of the lubricantdiffers by more than 10% from the nominal grade,the lubricant supplier recommends a change of oil.When the equipment is on a condition-monitoringprogram, more specific controls may be put inplace. Oil viscosity is expected to rise over timeand use, and loss of viscosity is considered to bemore serious than its increase. Therefore, aworking alarm range is +20%, -10%, i.e. not morethan 20% over nominal, and not less than 10%under the nominal grade. The accuracy of this testis very good, 0.5% [3].2.6 Total Acid Number (TAN)TAN is a neutralization number intended formeasuring all acidic and acid-acting materials inthe lubricant, including strong and weak acids. Itis a titration method designed to indicate therelative acidity in a lubricant.The sample is diluted with solvent and base(alkaline), in the form of potassium hydroxide(KOH), and added in controlled increments from aburette (a calibrated tube with a stopcock valve atthe bottom to allow gravity feed) until the sampleis neutralized. The KOH is the tyrant. Neutralizationis determined with a volt or pH meter. Theneutralization point usually occurs around pH 11.The TAN is calculated from the amount of KOHconsumed. Strong acids tend to be corrosive andare much more necessary to control.The acid number is used as a guide to follow theoxidative degeneration of oil in service. Oil changesare often indicated when the TAN value reaches apredetermined level for a given lubricant andapplication. An unexpected increase in TAN wouldbe indicative of abnormal operating conditions (e.g.overheating) that require investigation. Most lubricantsuppliers give TAN condemnation limits in thecatalogs. Accuracy of this test is within 15% [3].- 224 -

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...2.7 Ukupni bazni broj (TBN)TBN je neutralizacioni broj namijenjen za mjerenjesvih bazi~nih (alkalnih) materijala u mazivu.Suprotno od TAN, ovaj metoda titracije slu`i zaodre|ivanje rezerve alkalnosti maziva. Posmatraju}igeneralno, TBN predstavlja jedan pokazateljsposobnosti <strong>ulja</strong> da neutralizira {tetne kiselinskekoprodukte sagorijevanja gasova u motoru.Uzorak se razbla`uje razrje|iva~em i kiselinom(hlorovodoni~na ili perhlorna) i dodaje ukontrolisanoj mjeri iz menzure dok se uzorak neneutralizira. Kiselina je titrant. Neutralizacija se mjerina isti na~in kao i kod TAN-a, s tom razlikom data~ka po~etka neutralizacije se naj~e{}e javlja okovrijednosti pH 4. TBN se odre|uje na osnovuutro{ene koli~ine kiseline.Vrijednost TBN-a je najve}a kod novognekori{tenog <strong>ulja</strong>, a smanjuje se sa vremenomprovedenim u radu. Niska vrijednost TBN-a ukazujena skori kraj radnog vijeka <strong>ulja</strong>.TBN se naj~e{}e koristi kod motornih maziva.Kiseline nastale sagorijevanjem (sumporna kiselina)smanjuju vrijednost TBN-a.2. 8 Koli~ina vode i ~esticaVe}e zaga|enje <strong>ulja</strong> vodom mo`e se vizuelnoregistrovati. Prekomjerna koli~ina vode u sistemuslabi nosivu mo} maziva tj. sposobnost formiranjauljnog filma izme|u pokretnih dijelova {to rezultiraznatnim pove}anjem habanja, a time, uslijed trenja,do stvaranja znatne koli~ine toplote. Zaga|enje <strong>ulja</strong>vodom ne treba da pre|e 0,25% za ve}inuure|aja i ne vi{e od 100 ppm (broja dijelova umilionu dijelova posmatranog uzorka) za turbinskamaziva i maziva u kontrolnim sistemima.Postoji vi{e metoda koje se koriste za testiranje <strong>ulja</strong>od zaga|enja vlagom (FT-IR metoda na vodu,centrifugalna metoda, Karl Fischer) svaka sa razli~itimnivoom detekcije (1000 ppm ili 0,1% kod prve dvijemetode i 10 ppm ili 0,001% kod Karl Fischermetode). Utvr|ivanje koli~ine ~estica u ulju je metodakoja se koristi za odre|ivanje broja ~estica u fluidu injihovu klasifikaciju prema opsegu veli~ina definisanihpo ISO 4406 i NAS 1638 [3]. Postoji vi{e razli~itihtipova instrumentacije na tr`i{tu, prema raznolikostimjernih mehanizama, od opti~ko laserskih mjera~a dokontrolnih ure|aja na principu mjerenja zapu{enja pora.2.9 Primjenljivost testovaIndustrijska oprema zahtijeva kombinaciju gorenavedenih testova za monitoring stanja. Sljede}atabela predstavlja primjenljivost testova kod razli~itihindustrijskih ure|aja [4].2.7 Total Base Number (TBN)TBN is a neutralization number intended formeasuring all basic (alkaline) materials in the lube(acid-neutralizing components in the lubricantadditive package). The converse of the TAN, thistitration is used to determine the reserve alkalinityof a lubricant. The TBN is generally accepted asan indicator of the ability of the oil to neutralizeharmful acidic byproducts of engine combustion.The sample is diluted with solvent and acid(hydrochloric or perchloric) is added in controlledincrements from a burette until the sample isneutralized. The acid is the tyrant. Neutralization isdetermined with a volt or pH meter, and theneutralization point usually occurs around pH 4.The amount of acid consumed is recorded, andthe TBN calculated from that value.The TBN is highest when oil is new and decreaseswith its use. Low TBN normally indicates that the oilhas reached the end of its useful life. TBN is ameasure of the lubricant's alkaline reserve, and mostlyapplies to motor lubricants. If a lube contains noalkaline additives, there is little use to determine a TBN,as there will likely be none. Combustion acids attackTBN, e.g., sulfuric acid, decreasing as it consumes.2.8 Water and Particle CountWater can be detected visually if grosscontamination is present. Excessive water in asystem destroys a lubricant's ability to separateopposing moving parts, allowing severe wear tooccur with resulting high frictional heat. Watercontamination should not exceed 0.25 % for mostequipment, and not more than 100 ppm (parts permillion) for turbine lube and control systems.There are several methods used for testing themoisture contamination (crackle, FT-IR water,centrifuge, Karl Fischer) each with a different level ofdetection (1000 ppm or 0.1 % for first three methodsand 10 ppm or 0.001 % for Karl Fischer method).Particle Count is a method used to count andclassify particulate in a fluid according to acceptedsize ranges, usually to ISO 4406 and NAS 1638[3]. There are several different types ofinstrumentation on the market, utilizing a variety ofmeasurement mechanisms, from optical lasercounters to pore blockage monitors.2.9 Equipment ApplicationsIndustrial equipment needs a combination of theabove tests for condition monitoring. The followingtable is a summary of the test applicability [4].- 225 -

Ma{instvo 4(7), 277 – 226, (2003)N.Rep~i}; ...: SAVREMENE METODE ANALIZE ULJA...Tabela 1. Testovi za monitoring stanja industrijskih ure|ajaTable 1. Tests for Condition Monitoring of Industrial EquipmentTestovi za monitoring stanja – Tests for Condition MonitoringUre|ajEquipmentSpektro<strong>Analiza</strong>SpectroAnalysisTestviskoznostiViscosityFT-IRanalizaSpecifikacija~esticaParticle CountKarlFisherTAN TBN RFSMotori - Motors Z (R) Z (R) Z (R) Z (R)Ma{ine – EnginesZ (R) Z (R) Z (R) Z (R) P (A)Zup~asti prenosnici -GearboxesZ (R) Z (R) Z (R) Z (R)Le`i{ta – Bearning Z (R) Z (R) Z (R) P (A) Z (R)Hidrauli~niure|aji – HidraukicsZ (R) Z (R) Z (R) Z (R) P (A) P (A) Z (R)Turbine – Turbines Z (R) Z (R) Z (R) Z (R) Z (R) Z (R)Z (R)Kompresori -CompressorsZ (R) Z (R) Z (R) P (A) Z (R) Z (R)Z : Zahtijevani test P : Preporu~ ljiv test (osigurava dodatne informacije, naro~it o tokom rje{avanja problema)(R) Reqiured test(A) Advisable test, provides exstra details, particulary during problem solving3. ZAKLJU^AK 3. CONCLUSIONPrilikom upotrebe maziva bitno je odabrati ispravnomazivo i odr`avati ga ~istim, svje`im i bezprisustva vlage. U praksi, to povla~i za sobombrojne tehnologije i pravila koja osiguravajuispunjenje prethodnih uvjeta, a {to u znatnoj mjerizavisi od vrste aplikacije i njene specifi~nosti. Topodrazumijeva odabir ispravnog baznog <strong>ulja</strong>,ispravne viskoznosti i ispravnih aditiva zaodgovaraju}u namjenu. Tako|er, nu`no je voditira~una o zaprljanju <strong>ulja</strong> sa aspekta udjela vode i~estica {to mo`e imati izrazito {tetne efekte naradni vijek ma{ine i maziva.Ispravno odr`avanje maziva pove}ava radnusposobnost ma{ine, produ`ava njen radni vijek kaoi vijek maziva. Otkazi ma{ine su smanjeni kao itro{kovi opravke. Tako|er, umanjeni su tro{kovinabavke maziva i njegovog odlaganja.Lubrication best practices simply mean selectingthe correct lubricant, and then keeping it clean,dry, and cool. In reality, it involves numeroustechnologies and practices to ensure those idealsare met and will vary depending on theapplication and the specific issues involved.Lubrication best practices will maximize machineavailability, machine life, and lubricant life. Machinedowntime is minimized, as well as unit repaircosts and lubricant purchase and disposal costs.Implementing such an approach enhances thevalue of the oil analysis by improving the signal-tonoiseratio of the information captured in the oil.In any machine application, the most importantaspect for insuring maximum machine and lubricantlife is the selection of the correct oil. This processincludes choosing the correct base oil, the correctviscosity, and the correct additives for the application.Next in importance is keeping the oil clean and dry.Particle and water contamination can havedevastating effects on machine and lubricant life.4.LITERATURA - REFERENCES[1] A. A. Seireg, “Friction and Lubrication inMechanical Design”, Marcel Dekker, 1998[3] M Priest and C M Taylor, “Automobile enginetribology”, 2000[2] R I Taylor and R C Coy, “Improved fuel [4] A. J. Caines and R. F. Haycock, “Automotiveefficiency by lubricant design”, 2001 Lubricants Reference Book”, SAE, 1996- 226 -

![zavarivanje kao metod produ@enja @ivotnog vijeka ku]i[ta toplotnih ...](https://img.yumpu.com/36506092/1/184x260/zavarivanje-kao-metod-produenja-ivotnog-vijeka-kuita-toplotnih-.jpg?quality=85)