INDUSTRIAL CHOICE ALKYD ENAMEL - Rust-Oleum

INDUSTRIAL CHOICE ALKYD ENAMEL - Rust-Oleum

INDUSTRIAL CHOICE ALKYD ENAMEL - Rust-Oleum

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

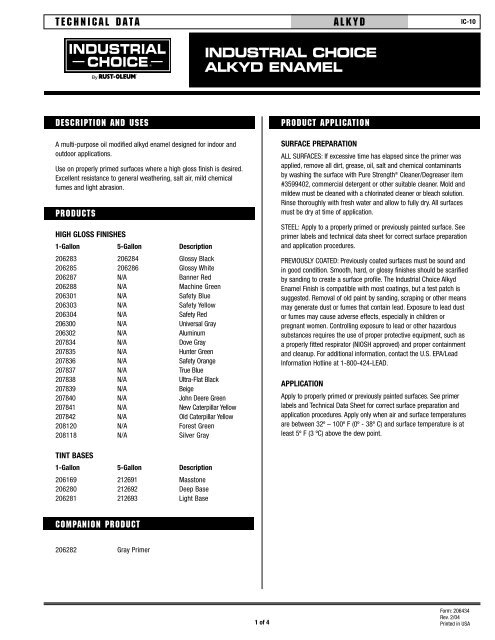

TECHNICAL DATA<strong>ALKYD</strong>IC-10<strong>INDUSTRIAL</strong> <strong>CHOICE</strong><strong>ALKYD</strong> <strong>ENAMEL</strong>DESCRIPTION AND USESPRODUCT APPLICATIONA multi-purpose oil modified alkyd enamel designed for indoor andoutdoor applications.Use on properly primed surfaces where a high gloss finish is desired.Excellent resistance to general weathering, salt air, mild chemicalfumes and light abrasion.PRODUCTSHIGH GLOSS FINISHES1-Gallon 5-Gallon Description206283 206284 Glossy Black206285 206286 Glossy White206287 N/A Banner Red206288 N/A Machine Green206301 N/A Safety Blue206303 N/A Safety Yellow206304 N/A Safety Red206300 N/A Universal Gray206302 N/A Aluminum207834 N/A Dove Gray207835 N/A Hunter Green207836 N/A Safety Orange207837 N/A True Blue207838 N/A Ultra-Flat Black207839 N/A Beige207840 N/A John Deere Green207841 N/A New Caterpillar Yellow207842 N/A Old Caterpillar Yellow208120 N/A Forest Green208118 N/A Silver GraySURFACE PREPARATIONALL SURFACES: If excessive time has elapsed since the primer wasapplied, remove all dirt, grease, oil, salt and chemical contaminantsby washing the surface with Pure Strength ® Cleaner/Degreaser item#3599402, commercial detergent or other suitable cleaner. Mold andmildew must be cleaned with a chlorinated cleaner or bleach solution.Rinse thoroughly with fresh water and allow to fully dry. All surfacesmust be dry at time of application.STEEL: Apply to a properly primed or previously painted surface. Seeprimer labels and technical data sheet for correct surface preparationand application procedures.PREVIOUSLY COATED: Previously coated surfaces must be sound andin good condition. Smooth, hard, or glossy finishes should be scarifiedby sanding to create a surface profile. The Industrial Choice AlkydEnamel Finish is compatible with most coatings, but a test patch issuggested. Removal of old paint by sanding, scraping or other meansmay generate dust or fumes that contain lead. Exposure to lead dustor fumes may cause adverse effects, especially in children orpregnant women. Controlling exposure to lead or other hazardoussubstances requires the use of proper protective equipment, such asa properly fitted respirator (NIOSH approved) and proper containmentand cleanup. For additional information, contact the U.S. EPA/LeadInformation Hotline at 1-800-424-LEAD.APPLICATIONApply to properly primed or previously painted surfaces. See primerlabels and Technical Data Sheet for correct surface preparation andapplication procedures. Apply only when air and surface temperaturesare between 32º – 100º F (0º - 38º C) and surface temperature is atleast 5º F (3 ºC) above the dew point.TINT BASES1-Gallon 5-Gallon Description206169 212691 Masstone206280 212692 Deep Base206281 212693 Light BaseCOMPANION PRODUCT206282 Gray Primer1 of 4Form: 206434Rev. 2/04Printed in USA

TECHNICAL DATA<strong>INDUSTRIAL</strong> <strong>CHOICE</strong> <strong>ALKYD</strong> <strong>ENAMEL</strong>PRODUCT APPLICATION (contINUED)EQUIPMENT RECOMMENDATIONSBRUSH: Use a good quality natural or synthetic bristle brush.ROLLER: Use a good quality natural or synthetic cover. Use ashort nap roller for smooth surfaces, and a medium nap rollerfor rough surfaces.AIR-ATOMIZED SPRAY:Method Fluid Tip Fluid Delivery Atomizing PressurePressure 0.055 –.070 16 oz/min 25–60 psiSiphon 0.055 –.070 — 25–60 psiHVLP (various) 0.043 –.070 8–14 oz/min 60–90 psi**(10 psi maximum at tip)AIRLESS SPRAY:THINNINGFluid Pressure Fluid Tip Filter Mesh1600–2400 psi 0.013–.017 100BRUSH/ROLLER: Normally not required.AIR-ATOMIZED SPRAY: 333402 Thinner – Use up to 15% by volume.AIRLESS SPRAY: 333402 Thinner normally not required. If neededuse up to 5% by volume.Performance characteristicsCONICAL FLEXIBILITYMETHOD: ASTM D522RESULT: >33%GLOSS AT 60º FMETHOD: ASTM D523RESULT: 86 (color – white)ACCELERATED WEATHERING (% gloss retention)METHOD: ASTM D4587, QUV Type A bulb, 450 HoursRESULT: 81% retention (color – white)TABER ABRASIONMETHOD: ASTM D4060 500g load 1000 cyclesRESULT: 84 mg lossCYCLIC PROHESION Rating 1-10 10=bestMETHOD: ASTM D5894, 3 cycles, 1008 hoursRESULT: Rating 10 per ASTM D714 for blisteringRESULT: Rating 9 per ASTM D610 for rustingFor chemical and corrosion resistance see page 4 of the <strong>Rust</strong>-<strong>Oleum</strong>Industrial Brands Catalog Form #206275.CLEAN-UP633402 Thinner or Mineral spirits.2 of 4Form: 206434Rev. 2/04Printed in USA

TECHNICAL DATA<strong>INDUSTRIAL</strong> <strong>CHOICE</strong> <strong>ALKYD</strong> <strong>ENAMEL</strong>PHYSICAL PROPERTIESResin TypePigment TypeSolventsVolatile Organic Compounds<strong>ALKYD</strong> <strong>ENAMEL</strong>SOil Modified AlkydVaries with color, Calcium CarbonateAliphatic Hydrocarbons< 450 g/L (3.75 lbs./gal.) for all colors except Aluminum< 500 g/L (4.20 lbs./gal.) for AluminumWeight Per GallonSolidsPer GallonPer LiterBy WeightBy Volume7.6–9.3 lbs.0.9–1.1 Kg51–60%42–43%Recommended Dry Film Thickness(DFT) Per CoatWet Film to Achieve DFT(unthinned material)Theoretical Coverage at1 mil DFT (25 µ)Practical Coverage at RecommendedDFT (assumes 15% material loss)1.0–2.0 mils (25.0–50.0 µ)2.5 –4.5 mils (62.5–112.5 µ)670–690 sq. ft./gal. (16.5–17.0 m 2 /L)285–585 sq. ft./gal. (7.0–14.4 m 2 /L)Dry Times at 70º–80º F (21º– 27º C)and 50% RelativeHumidityTack-freeHandleRecoat2–4 hours5–9 hours24–48 hoursDry Heat Resistance 212º F (100º C)Shelf Life5 yearsSpecification and PerformanceAlternativesCan be used in USDA – regulated facilitiesbased on FSIS Directive 11,000.4 (Rev. 4), November 24, 1995.Safety InformationFlash PointContains104º F (40º C)Lead-freeWarning!COMBUSTIBLE LIQUID AND VAPOR. HARMFUL IF INHALED.MAY AFFECT BRAIN OR NERVOUS SYSTEM CAUSING DIZZINESS,HEADACHE OR NAUSEA. CAUSES RESPIRATORY TRACT, EYEAND SKIN IRRITATION. FOR <strong>INDUSTRIAL</strong> OR COMMERCIAL USEONLY. KEEP OUT OF REACH OF CHILDREN. SEE THE PRODUCTMATERIAL SAFETY DATA SHEET (MSDS) AND LABEL WARNINGSFOR ADDITIONAL SAFETY INFORMATION.Calculated values are shown and may vary slightly from the actual manufactured material.3 of 4Form: 206434Rev. 2/04Printed in USA

The technical data and suggestions for use contained herein are correct to the best of our knowledge, and offered in good faith. The statements of this literature do not constitutea warranty, express, or implied, as to the performance of these products. As conditions and use of our materials are beyond our control, we can guarantee these products onlyto conform to our standards of quality, and our liability, if any, will be limited to replacement of defective materials. All technical information is subject to change without notice.<strong>Rust</strong>-<strong>Oleum</strong> Corporation11 Hawthorn Parkway | Vernon Hills, Illinois 60061 | Phone: (847) 367-7700 | www.rustoleum.comAn RPM Company4 of 4Form: 206434Rev. 2/04Printed in USA