The Avicel ® Advantage - FMC BioPolymer

The Avicel ® Advantage - FMC BioPolymer

The Avicel ® Advantage - FMC BioPolymer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

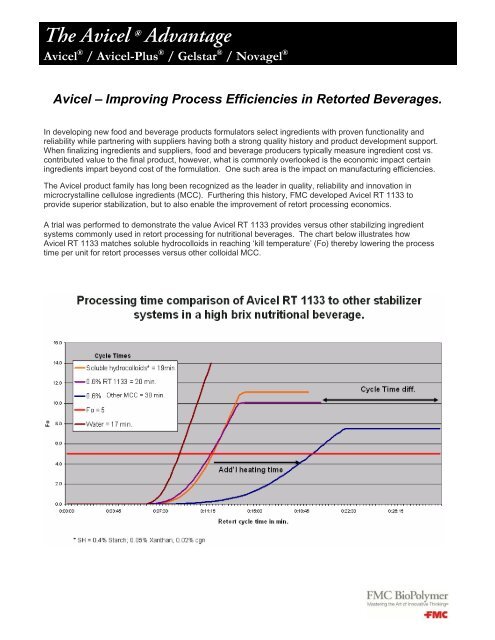

<strong>The</strong> <strong>Avicel</strong> <strong>®</strong> <strong>Advantage</strong><strong>Avicel</strong> <strong>®</strong> / <strong>Avicel</strong>-Plus <strong>®</strong> / Gelstar <strong>®</strong> / Novagel <strong>®</strong><strong>Avicel</strong> – Improving Process Efficiencies in Retorted Beverages.In developing new food and beverage products formulators select ingredients with proven functionality andreliability while partnering with suppliers having both a strong quality history and product development support.When finalizing ingredients and suppliers, food and beverage producers typically measure ingredient cost vs.contributed value to the final product, however, what is commonly overlooked is the economic impact certainingredients impart beyond cost of the formulation. One such area is the impact on manufacturing efficiencies.<strong>The</strong> <strong>Avicel</strong> product family has long been recognized as the leader in quality, reliability and innovation inmicrocrystalline cellulose ingredients (MCC). Furthering this history, <strong>FMC</strong> developed <strong>Avicel</strong> RT 1133 toprovide superior stabilization, but to also enable the improvement of retort processing economics.A trial was performed to demonstrate the value <strong>Avicel</strong> RT 1133 provides versus other stabilizing ingredientsystems commonly used in retort processing for nutritional beverages. <strong>The</strong> chart below illustrates how<strong>Avicel</strong> RT 1133 matches soluble hydrocolloids in reaching ‘kill temperature’ (Fo) thereby lowering the processtime per unit for retort processes versus other colloidal MCC.

<strong>The</strong> <strong>Avicel</strong> <strong>®</strong> <strong>Advantage</strong><strong>Avicel</strong> <strong>®</strong> / <strong>Avicel</strong>-Plus <strong>®</strong> / Gelstar <strong>®</strong> / Novagel <strong>®</strong>Each of the tested products was then also evaluated for stability by visual inspection over 12 month acceleratedstability testing. Products received a ‘Pass’ ranking if the product had less than several mm of separation in thefinished product. <strong>The</strong> table below illustrates the value of <strong>Avicel</strong> RT 1133 in providing superior stability in additionto processing savings.Retort Time from Process Start to110°BeverageViscosity(cps)% Retort CycleTime SavingsStability*Other MCC 250 --- Pass<strong>Avicel</strong><strong>®</strong> RT 1133 230 32 PassSolubleHydrocolloids(xanthan/starch)153 35 Fail* =Accelerated Stability (Simulating 6 to 12 months)With the criteria of producing a stable, high quality product, the following assumptions were used to determinewhat value <strong>Avicel</strong> RT 1133 provides to retort processors from a production efficiency perspective. Using anaverage retort cost of $0.04 per unit at a rate of 400 units per minute per line, <strong>Avicel</strong> RT 1133 can reduceprocessing costs by over $1.4 M for every 10% increase in productivity. Applying the time savings from the trial innutritional beverages, <strong>Avicel</strong> RT 1133 reduced process time by 32%, which translates to over $4 M in savings 1 !1 In some cases customers have realized increased production efficiencies by over 50% as compared to other<strong>Avicel</strong> family or microcrystalline cellulose products.

<strong>The</strong> <strong>Avicel</strong> <strong>®</strong> <strong>Advantage</strong><strong>Avicel</strong> <strong>®</strong> / <strong>Avicel</strong>-Plus <strong>®</strong> / Gelstar <strong>®</strong> / Novagel <strong>®</strong>In addition to measuring the production value created, a sensory evaluation was conducted by the National FoodLaboratory, Inc. 2 between <strong>Avicel</strong> RT 1133 and a soluble hydrocolloid system. Results of the sensory evaluationare shown in the table below.Quantitative Descriptive Evaluations of Chocolate Nutritional BeverageN=20 (10 panelists, 2 Evaluations Each)<strong>Avicel</strong> RT 1133 Xanthan / Starch Confidence LevelAppearanceDark Color 8.64 10.25 95%Mottled (surface) 1.62 4.07 95%AromaTotal Aroma 6.03 6.16 NSDChocolate 4.98 5.28 NSDTotal Dairy 3.12 3.11 NSDCooked 3.10 2.94 NSDFlavorTotal Flavor 7.52 7.44 NSDChocolate 6.25 6.32 NSDTotal Dairy 3.97 3.86 NSDCooked 4.02 4.06 NSDVitamin / Grain 2.87 2.86 NSDSweet 5.39 5.12 NSDBitter 0.38 0.43 NSDTextureViscosity 3.35 5.11 95%Slimy / Slick 0.44 0.93 95%Gritty (in Product) 1.72 2.17 95%Gritty Mouthfeel 2.96 3.43 NSDMouth Coating 2.72 3.33 95%AftertasteTotal Aftertaste 4.31 4.75 95%Cooked 2.66 2.65 NSDNSD – Not significantly different at confidence levels of 90% or higherScale Range = 0 to 15As the table indicates, there are many areas where <strong>Avicel</strong> RT 1133 is statistically different from the Xanthan /Starch / CGN blend. Not only does <strong>Avicel</strong> RT 1133 produce a highly stable product, it also provides a lessmottled, less gritty, less viscous, less slimy, lower mouth coating, and reduced aftertaste – in short, it produceda more refreshing and appealing product to consumers!In summary, <strong>Avicel</strong> RT 1133 contributes significant value through production efficiency savings, and moreimportantly provides a stable and more appealing product for consumers. To learn more about <strong>Avicel</strong> RT 1133and how it can benefit your next retort product application, or for technical assistance on any of the <strong>Avicel</strong> productfamily, we invite you to contact your local <strong>FMC</strong> <strong>BioPolymer</strong> representative, or our technical hotlineat 1-800-526-3649.2 <strong>The</strong> National Food Laboratory, Inc., www.<strong>The</strong>NFL.com