linear thermal expansion procedure

linear thermal expansion procedure

linear thermal expansion procedure

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PHYS 1111L/2211LLinear Thermal ExpansionObjectiveTo investigate <strong>thermal</strong> <strong>expansion</strong> and to calculate coefficients of <strong>linear</strong> <strong>thermal</strong><strong>expansion</strong> of different metals.BackgroundYou already know that many materials expand when heated. How much amaterial expands when it is heated depends on several factors:• The difference in temperature (makes sense that the hotter you heat something,the more it expands)• The original length (a longer rod will expand more than a shorter one)• A quantity called the coefficient of <strong>linear</strong> <strong>thermal</strong> <strong>expansion</strong>, which is acharacteristic of each individual materialWe summarize this concept in an equation that gives the <strong>expansion</strong> of a rod ∆L asa function of these three factors:∆L = αL∆TIn this equation α is the coefficient, L is the original length, and ∆T is thedifference in temperature (T final – T initial ).In this lab, we shall measure the length of a metal rod at room temperature. Weshall then blow steam through the rod to heat it and make it expand. We shallmeasure the <strong>expansion</strong> of the rod and the final temperature. From these we shallcalculate the coefficient and compare our value to the accepted one. We shall dothis for three different metal rods.EquipmentThermal <strong>expansion</strong> apparatusMetal tubes: aluminum, copper, and steelMultimeterLinear Thermal Expansion 11/13 1

PHYS 1111L/2211LTwo banana-banana wires (one red, one black)Steam generatorFriction blockTubingShallow foil panHeatproof glovesAlligator clip or hose clampProcedureWARNING: boiling water is HOT! So is steam! Wear heatproof gloves, stayout of the steam flow, and be careful not to burn yourself or your lab partner!NOTE: do not handle metal tubes with bare hands. Handle with papertowels when cool, or with heatproof gloves when hot.1. Fill the steam generator about ¾ full with hot water. Put the rubber stopper onthe top.2. Measure the length of one of the tubes at room temperature. Measure from theinner edge of the stainless steel pin to the inner edge of the angle bracket (seeFigure 1).3. Mount the tube in the apparatus as shown in Figure 2. Set the pin in the slotand tighten the thumbscrew gently until the tube does not move. Compress thespring arm on the dial gauge so that it rests against the angle bracket and canexpand as the tube expands.Linear Thermal Expansion 11/13 2

PHYS 1111L/2211L4. Loosen the thumbscrew in the middle of the tube and insert the thermistor lug.Tighten the screw to secure the lug. [NOTE: the lug is the actual sensor here.You’re measuring the resistance of the lug, not the tube. Make sure the lugmakes good contact with the tube surface, so that we can reasonably assumethe lug and the tube are at the same temperature.]5. Wrap the foam insulation around the thermistor lug.6. Insert two banana wires into the green jacks in the base of the apparatus – itdoes not matter which one. Insert the other ends of the banana wires into thejacks in the multimeters. Red in VΩ, black in COM.7. Attach a piece of tubing between the steam generator and the end of the metaltube farther from the dial gauge. Put another short piece of tubing on the othersteam generator port and clamp it off.8. Put a friction block under that end of the apparatus to raise it up a bit.9. Put a shallow foil pan under the other end of the tube (near the gauge) to catchwater that drains out of the tube. See the diagram below.Linear Thermal Expansion 11/13 3

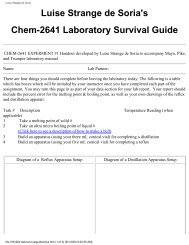

PHYS 1111L/2211L10. Turn the outer ring of the dial gauge so that the big needle is aligned with thezero reading.11. Turn on the multimeter (one of the Ω scales) and record the resistance whilethe tube is at room temperature. You may switch scales as you like in order toget a more precise reading. You may want to start on the 200k scale (where200,000 ohms is the highest you can read) and then switch to the 20k scalelater as the tube warms up and the resistance goes down. (Note: for example,if you read 104.5 on the 200k scale, that means 104.5 thousand ohms, or104,500.)12. Turn on the steam generator. Wait a few minutes for the water to boil andsteam to flow through the tube.13. After steam begins flowing, watch the needle on the dial gauge (NOTEWHICH DIRECTION IT IS GOING!) and the reading on the multimeter(which corresponds to the temperature). Feel free to change the scales on themultimeter as necessary.14. When the temperature stabilizes, record first the multimeter readings and thenthe <strong>expansion</strong> of the tube ∆L. (Each increment on the outer dial is 0.01 mm.∆L is the difference between the initial and final readings – or, how manyincrements the needle has moved times 0.01 mm.) NOTE: the manufacturerrecommends that you record the MAXIMUM ∆L and the MINIMUM resistanceon the multimeter.15. Shut off the steam generator. Don heatproof gloves, disconnect the tube andthe thermistor lug, and set the tube aside to cool.16. Repeat the entire <strong>procedure</strong> for the other two tubes.Data Analysis1. Calculate the temperature corresponding to each multimeter reading. Useeither the table on the apparatus or the one included in this writeup (same table).2. Calculate the temperature change ∆T = T final – T initial . Remember T initial shouldbe the room temperature reading.Linear Thermal Expansion 11/13 4

PHYS 1111L/2211L3. Calculate the coefficient of <strong>linear</strong> <strong>expansion</strong> α using the formula:α =∆LL∆Twhere L is the initial length of the tube, measured at room temperature. Besure to watch your units; ∆L and L need to be in the same units.4. Look up the accepted values for the <strong>expansion</strong> coefficient for aluminum,copper, and steel, and calculate a percent error for each of your values.Questions1. Why do we wrap foam insulation around the thermistor lug?2. If you drill a hole in the center of a square metal plate, and then heat the metalplate, does the hole get larger or smaller? Explain.3. Look up and write down the <strong>thermal</strong> <strong>expansion</strong> coefficients for quartz and forzinc. Now suppose you want to build a high-precision telescope with a mirrorthat must be capable of keeping its exact size and shape under many differentweather conditions. You can choose quartz, zinc, or one of the three metalsyou tested samples of today. Which will you choose, and why?4. Suppose you have a bimetallic strip made of aluminum and steel, as below.What will happen to the shape of the strip as you heat it? Describe or draw.5. (2211L only) Do questions 3, 5, and 6 in Cioffari.Linear Thermal Expansion 11/13 5

PHYS 1111L/2211LData TablesMaterial Original Length L, mm R initial (resistance),ohms (Ω)AluminumCopperSteelT initial , °C(room temp)Material ∆L, mm R final , Ω T final , °C ∆T, °C α % errorAluminumCopperSteelLinear Thermal Expansion 11/13 6