You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SPUR GEARSGEAR NOMENCLATUREENGINEERING INFORMATIONADDENDUM (a) is the height by which a tooth projectsbeyond the pitch circle or pitch line.BASE DIAMETER (D b ) is the diameter of the base cylinderfrom which the involute portion of a tooth profile is generated.BACKLASH (B) is the amount by which the width of a toothspace exceeds the thickness of the engaging tooth on thepitch circles. As actually indicated by measuring devices,backlash may be determined variously in the transverse, normal,or axial-planes, and either in the direction of the pitch circlesor on the line of action. Such measurements should becorrected to corresponding values on transverse pitch circlesfor general comparisons.BORE LENGTH is the total length through a gear, sprocket, orcoupling bore.CIRCULAR PITCH (p) is the distance along the pitch circle orpitch line between corresponding profiles of adjacent teeth.CIRCULAR THICKNESS (t) is the length of arc between thetwo sides of a gear tooth on the pitch circle, unless otherwisespecified.CLEARANCE-OPERATING (c) is the amount by which thededendum in a given gear exceeds the addendum of its matinggear.CONTACT RATIO (m c ) in general, the number of angularpitches through which a tooth surface rotates from the beginningto the end of contact.DEDENDUM (b) is the depth of a tooth space below the pitchline. It is normally greater than the addendum of the matinggear to provide clearance.DIAMETRAL PITCH (P) is the ratio of the number of teeth tothe pitch diameter.GEAR is a machine part with gear teeth. When two gearsrun together, the one with the larger number of teeth is calledthe gear.HUB DIAMETER is outside diameter of a gear, sprocket orcoupling hub.HUB PROJECTION is the distance the hub extends beyondthe gear face.INVOLUTE TEETH of spur gears, helical gears and wormsare those in which the active portion of the profile in the transverseplane is the involute of a circle.LONG- AND SHORT-ADDENDUM TEETH are those ofengaging gears (on a standard designed center distance) oneof which has a long addendum and the other has a shortaddendum.KEYWAY is the machined groove running the length of thebore. A similar groove is machined in the shaft and a key fitsinto this opening.NORMAL DIAMETRAL PITCH (P n ) is the value of thediametral pitch as calculated in the normal plane of a helicalgear or worm.NORMAL PLANE is the plane normal to the tooth surface at apitch point and perpendicular to the pitch plane. For a helicalgear this plane can be normal to one tooth at a point layingin the plane surface. At such point, the normal plane containsthe line normal to the tooth surface and this is normal to thepitch circle.NORMAL PRESSURE ANGLE (ø n ) in a normal plane of helicaltooth.OUTSIDE DIAMETER (D o ) is the diameter of the addendum(outside) circle.FACE WIDTH (F) is the length of the teeth in an axial plane.FILLET RADIUS (r f ) is the radius of the fillet curve at the baseof the gear tooth.FULL DEPTH TEETH are those in which the working depthequals 2.000 divided by the normal diametral pitch.Gear Catalog 137

ENGINEERING INFORMATIONSPUR GEARSGEAR NOMENCLATURE (Continued)PITCH CIRCLE is the circle derived from a number of teethand a specified diametral or circular pitch. Circle on whichspacing or tooth profiles is established and from which thetooth proportions are constructed.PITCH CYLINDER is the cylinder of diameter equal to thepitch circle.PINION is a machine part with gear teeth. When two gearsrun together, the one with the smaller number of teeth is calledthe pinion.PITCH DIAMETER (D) is the diameter of the pitch circle. Inparallel shaft gears, the pitch diameters can be determineddirectly from the center distance and the number of teeth.PRESSURE ANGLE (ø) is the angle at a pitch point betweenthe line of pressure which is normal to the tooth surface, and theplane tangent to the pitch surface. In involute teeth, pressureangle is often described also as the angle between the line ofaction and the line tangent to the pitch circle. Standard pressureangles are established in connection with standard gear-toothproportions.ROOT DIAMETER (Dr) is the diameter at the base of the toothspace.PRESSURE ANGLE—OPERATING (ør) is determined by thecenter distance at which the gears operate. It is the pressureangle at the operating pitch diameter.TIP RELIEF is an arbitrary modification of a tooth profilewhereby a small amount of material is removed near the tip ofthe gear tooth.UNDERCUT is a condition in generated gear teeth when anypart of the fillet curve lies inside a line drawn tangent to theworking profile at its point of juncture with the fillet.WHOLE DEPTH (ht) is the total depth of a tooth space, equalto addendum plus dedendum, equal to the working depth plusvariance.WORKING DEPTH (hk) is the depth of engagement of twogears; that is, the sum of their addendums.TOOTH PARTSPINIONPINIONPITCH CIRCLELINE OF ACTIONPRESSUREANGLEWORKINGDEPTHCIRCULAR TOOTHTHICKNESSOUTSIDEDIA.CLEARANCEDEDENDUMTOOTH PROFILE(INVOLUTE)BASE CIRCLEPITCH CIRCLEWHOLE DEPTHADDENDUMROOT (TOOTH)FILLETCENTERDISTANCEROOTDIA.CIRCULARPITCHGEAR138 Gear Catalog

SPUR GEARSINVOLUTE FORMENGINEERING INFORMATIONGear teeth could be manufactured with a wide variety ofshapes and profiles. The involute profile is the most commonlyused system for gearing today, and all Boston spur and helicalgears are of involute form.An involute is a curve that is traced by a point on a taut cordunwinding from a circle, which is called a BASE CIRCLE. Theinvolute is a form of spiral, the curvature of which becomesstraighter as it is drawn from a base circle and eventuallywould become a straight line if drawn far enough.An involute drawn from a larger base circle will be less curved(straighter) than one drawn from a smaller base circle.Similarly, the involute tooth profile of smaller gears is considerablycurved, on larger gears is less curved (straighter), and isstraight on a rack, which is essentially an infinitely large gear.INVOLUTE – CIRCLE AINVOLUTECIRCLE A– CIRCLE BCI R C L EBInvolute gear tooth forms and standard tooth proportions arespecified in terms of a basic rack which has straight-sidedteeth, for involute systems.20 TEETH 48 TEETH RACKGear Catalog 139

SPUR GEARSENGINEERING INFORMATIONDIAMETRAL PITCH SYSTEMAll stock gears are made in accordance with the diametralpitch system. The diametral pitch of a gear is the number ofteeth in the gear for each inch of pitch diameter. Therefore, thediametral pitch determines the size of the gear tooth.PRESSURE ANGLEPressure angle is the angle at a pitch point between the line ofpressure which is normal to the tooth surface, and the plane tangentto the pitch surface. The pressure angle, as defined in thiscatalog, refers to the angle when the gears are mounted on theirstandard center distances.Boston Gear manufactures both 14-1/2° and 20° PA, involute,full depth system gears. While 20°PA is generally recognizedas having higher load carrying capacity, 14-1/2°PA gears haveextensive use. The lower pressure angle results in lesschange in backlash due to center distance variation and concentricityerrors. It also provides a higher contact ratio andconsequent smoother, quieter operation provided that undercutof teeth is not present.TOOTH DIMENSIONSFor convenience, Tooth Proportions of various standarddiametral pitches of Spur Gears are given below.Thicknessof Tooth Depth to beCircular on Pitch Cut in GearDiametral Pitch Line (Inches) AddendumPitch (Inches) (Inches) (Hobbed Gears) (Inches)3 1.0472 .5236 .7190 .33334 .7854 .3927 .5393 .25005 .6283 .3142 .4314 .20006 .5236 .2618 .3565 .16678 .3927 .1963 .2696 .125010 .3142 .1571 .2157 .100012 .2618 .1309 .1798 .083316 .1963 .0982 .1348 .062520 .1571 .0785 .1120 .050024 .1309 .0654 .0937 .041732 .0982 .0491 .0708 .031248 .0654 .0327 .0478 .020864 .0491 .0245 .0364 .0156140 Gear Catalog

SPUR GEARSENGINEERING INFORMATIONBACKLASHStock spur gears are cut to operate at standard center distances.The standard center distance being defined by:Standard Center Distance =Pinion PD + Gear PD2When mounted at this center distance, stock spur gears willhave the following average backlash:Diametral Backlash Diametral BacklashPitch (Inches) Pitch (Inches)3 .013 8-9 .0054 .010 10-13 .0045 .008 14-32 .0036 .007 33-64 .00257 .006An increase or decrease in center distance will cause anincrease or decrease in backlash.Since, in practice, some deviation from the theoretical standardcenter distance is inevitable and will alter the backlash,such deviation should be as small as possible. For most applications,it would be acceptable to limit the deviation to anincrease over the nominal center distance of one half the averagebacklash. Varying the center distance may afford a practicalmeans of varying the backlash to a limited extent.The approximate relationship between center distance andbacklash change of 14-1/2° and 20° pressure angle gears isshown below:For 14-1/2°–Change in Center Distance = 1.933 x Change in BacklashFor 20° –Change in Center Distance = 1.374 x Change in BacklashFrom this, it is apparent that a given change in center distance,14-1/2° gears will have a smaller change in backlashthan 20° gears. This fact should be considered in cases wherebacklash is critical.UNDERCUTWhen the number of teeth in a gear is small, the tip of the matinggear tooth may interfere with the lower portion of the tooth profile.To prevent this, the generating process removes material atthis point. This results in loss of a portion of the involute adjacentto the tooth base, reducing tooth contact and tooth strength.On 14-1/2°PA gears undercutting occurs where a number ofteeth is less than 32 and for 20°PA less than 18. Since thiscondition becomes more severe as tooth numbers decrease, itis recommended that the minimum number of teeth be 16 for14-1/2°PA and 13 for 20°PA.In a similar manner INTERNAL Spur Gear teeth may interferewhen the pinion gear is too near the size of its mating internalgear. The following may be used as a guide to assure properoperation of the gear set. For 14-1/2°PA, the difference intooth numbers between the gear and pinion should not be lessthan 15. For 20°PA the difference in tooth numbers should notbe less than 12.SPUR GEAR FORMULASFOR FULL DEPTH INVOLUTE TEETHTo Obtain Having FormulaCircular Pitch (p)P = 3.1416pDiametral Pitch (P) Number of Teeth (N) & P =NPitch Diameter (D) DNumber of Teeth (N) &Outside Diameter (D o ) P =N + 2 (Approx.)D oCircular Pitch (p) Diametral Pitch (P) p = 3.1416PNumber of Teeth (N) & D =NPitch Diameter (D) Diametral Pitch (P) POutside Diameter (D o ) & D = Do – 2Diametral Pitch (P)PBase Diameter (D b)Pitch Diameter (D) andPressure Angle (ø) Db = DcosøNumber of Teeth (N)Diametral Pitch (P) &Pitch Diameter (D)N = P x DTooth Thickness (t)Diametral Pitch (P) t = 1.5708@Pitch Diameter (D)PAddendum (a) Diametral Pitch (P) a = 1 POutsidePitch Diameter (D) &Diameter (D o ) Addendum (a)D o= D + 2aWhole Depth (h t )Diametral Pitch (P) h t= 2.2 + .002(20P & Finer) PWhole Depth (h t )Diametral Pitch (P) h t= 2.157(Courser than 20P)PWorking Depth (h k ) Addendum (a) h k = 2(a)Clearance (c)Whole Depth (h t )Addendum (a)c = h t– 2aDedendum (b)Whole Depth (h t ) &Addendum (a)b = h t– aOutside Radii, BaseContact Ratio (M c ) Radii, Center Distanceand Pressure Angle+C.P.M c = R o 2 – R 2 2 2M b + r o – r b – Csinø*c =Ppc cosøRoot Diameter (D r)Pitch Diameter (D)D r= D – 2band Dedendum (b)Center Distance (C)Pitch Diameter (D) or C = D 1 + D 2No. of Teeth and Pitch 2or N 1 + N 22P*R o= Outside Radius, Gearr o= Outside Radius, PinionR b= Base Circle Radius, Gearr b= Base Circle Radius, PinionpfPITCHLINEtr fabch khta = ADDENDUMb = DEDENDUMc = CLEARANCEh k = WORKING DEPTHh t = WHOLE DEPTHp = CIRCULAR PITCHr f = FILLET RADIUSt = CIRCULAR TOOTH THICKNESSf = PRESSURE ANGLEGear Catalog 141

SPUR GEARSENGINEERING INFORMATIONLEWIS FORMULA (Barth Revision)Gear failure can occur due to tooth breakage (tooth stress) orsurface failure (surface durability) as a result of fatigue andwear. Strength is determined in terms of tooth-beam stressesfor static and dynamic conditions, following well established formulaand procedures. Satisfactory results may be obtained bythe use of Barth’s Revision to the Lewis Formula, which considersbeam strength but not wear. The formula is satisfactory forcommercial gears at Pitch Circle velocities of up to 1500 FPM. Itis this formula that is the basis for all Boston Spur Gear ratings.METALLIC SPUR GEARSW = SFYPW= Tooth Load, Lbs. (along the Pitch Line)S = Safe Material Stress (static) Lbs. per Sq. In. (Table II)F = Face Width, In.Y = Tooth Form Factor (Table I)P = Diametral PitchD = Pitch DiameterV = Pitch Line Velocity, Ft. per Min. = .262 x D x RPMFor NON-METALLIC GEARS, the modified Lewis Formulashown below may be used with (S) values of 6000 PSI forPhenolic Laminated material.W = SFYP600600 + V150200 + V + .25TABLE II–VALUES OF SAFE STATIC STRESS (s)Material(s) Lb. per Sq. In.Plastic ........................................................................ 5000Bronze ........................................................................ 10000Cast Iron ..................................................................... 12000.20 Carbon (Untreated)................................... 20000.20 Carbon (Case-hardened).......................... 25000Steel .40 Carbon (Untreated)................................... 25000Carbon (Heat-treated)............................... 30000{.40 C. Alloy (Heat-treated) .............................. 40000Max. allowable torque (T) that should be imposed on a gearwill be the safe tooth load (W) multiplied by D or T = W x D2 2The safe horsepower capacity of the gear (at a given RPM) canbe calculated from HP = T x RPM or directly from (W) and (V);HP =WV33,000For a known HP, T =63,02563025 x HPRPMTABLE I TOOTH FORM FACTOR (Y)14-1/2° Full 20° FullNumber of Teeth Depth Involute Depth Involute10 0.176 0.20111 0.192 0.22612 0.210 0.24513 0.223 0.26414 0.236 0.27615 0.245 0.28916 0.255 0.29517 0.264 0.30218 0.270 0.30819 0.277 0.31420 0.283 0.32022 0.292 0.33024 0.302 0.33726 0.308 0.34428 0.314 0.35230 0.318 0.35832 0.322 0.36434 0.325 0.37036 0.329 0.37738 0.332 0.38340 0.336 0.38945 0.340 0.39950 0.346 0.40855 0.352 0.41560 0.355 0.42165 0.358 0.42570 0.360 0.42975 0.361 0.43380 0.363 0.43690 0.366 0.442100 0.368 0.446150 0.375 0.458200 0.378 0.463300 0.382 0.471Rack 0.390 0.484142 Gear Catalog

HELICAL GEARSENGINEERING INFORMATIONGEAR NOMENCLATUREThe <strong>information</strong> contained in the Spur Gear section is alsopertinent to Helical Gears with the addition of the following:HELIX ANGLE (y) is the angle between any helix and an elementof its cylinder. In helical gears, it is at the pitch diameterunless otherwise specified.LEAD (L) is the axial advance of a helix for one complete turn,as in the threads of cylindrical worms and teeth of helicalgears.NORMAL DIAMETRAL PITCH (P n ) is the Diametral Pitch ascalculated in the normal plane.HAND – Helical Gears of the same hand operate at rightangles, see Fig. 1Helical Gears of opposite hands run on parallelshafts. Fig. 2HELIX ANGLE—NORMALPLANEHELIXANGLEYAXIAL PLANEpnpp = AXIAL CIRCULAR PITCHpn = NORMAL CIRCULAR PITCHTWORIGHT-HANDHELICAL GEARSTWOLEFT-HANDHELICAL GEARSLEFT-HAND ANDRIGHT-HANDHELICAL GEARSFigure 1LEFT HAND HELICAL GEARThe teeth of a LEFT HANDHelical Gear lean to the leftwhen the gear is placed flat ona horizontal surface.Figure 2RIGHT HAND HELICAL GEARThe teeth of a RIGHT HANDHelical Gear lean to the rightwhen the gear is placed flat ona horizontal surface.All Boston Helicals are cut to the Diametral Pitch system,resulting in a Normal Pitch which is lower in number than theDiametral Pitch.INVOLUTE—The Helical tooth form is involute in the plane ofrotation and can be developed in a manner similar to that ofthe Spur Gear. However, unlike the Spur Gear, which may beviewed as two-dimensional, the Helical Gear must be viewedas three-dimensional to show change in axial features.Helical gears offer additional benefits relative to Spur Gears,those being:• Improved tooth strength due to the elongated helical wraparound.• Increased contact ratio due to the axial tooth overlap.• Helical Gears thus tend to have greater load carrying capacitythan Spur Gears of similar size.• Due to the above, smoother operating characteristics areapparent.Gear Catalog 143

HELICAL GEARSENGINEERING INFORMATIONHELICAL GEAR FORMULASTo Obtain Having FormulaNumber of Teeth (N) &P = NTransverse Pitch Diameter (D) DDiametral Pitch (P) Normal Diametral Pitch (P n )P = P NCosyHelix Angle (y)Pitch Diameter (D)Number of Teeth (N) &D = NTransverse Diametral Pitch (P) PNormal Transverse Diametral Pitch (P) PN =PDiametral Pitch (P N ) & Helix Angle (y) CosyNormal CircularNormal Diametral Pitch (P N) t = 1.5708Tooth Thickness (t)P NTransverse Diametral Pitch (P)p = ¹Circular Pitch (p t ) (Transverse) t PNormalTransversep n= p tCosyCircular Pitch (p n ) Circular Pitch (p)Lead (L)Pitch Diameter andL = ¹DPitch Helix AngleTanyTRANSVERSE VS. NORMAL DIAMETRAL PITCH FORBOSTON 45° HELICAL GEARSPP NTransverseNormalDiametral PitchDiametral Pitch24 33.9420 28.2816 22.6312 16.9710 14.148 11.316 8.48HELICAL GEAR LEWIS FORMULAThe beam strength of Helical Gears operating on parallel shaftscan be calculated with the Lewis Formula revised to compensatefor the difference between Spur and Helical Gears, withmodified Tooth Form Factors Y.W = SFYP N600600 + VW= Tooth Load, Lbs. (along the Pitch Line)S = Safe Material Stress (static) Lbs. per Sq. In. (Table III)F = Face Width, InchesY =Tooth Form Factor (Table IV)P N= Normal Diametral Pitch(Refer to Conversion Chart)D = Pitch DiameterV = Pitch Line Velocity, Ft. Per Min. = .262 x D x RPMTABLE III–VALUES OF SAFE STATIC STRESS (S)Material(s) Lb. per Sq. In.Bronze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10000Cast Iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12000{.20 Carbon (Untreated) . . . . . . . . . . . . . . . . 20000.20 Carbon (Case-hardened) . . . . . . . . . . . 25000Steel .40 Carbon (Untreated) . . . . . . . . . . . . . . . . 25000.40 Carbon (Heat-treated) . . . . . . . . . . . . . . 30000.40 C. Alloy (Heat-treated) . . . . . . . . . . . . . 40000TABLE IV—VALUES OF TOOTH FORM FACTOR (Y)FOR 14-1/2°PA—45° HELIX ANGLE GEARNo. of Factor No. of FactorTeeth Y Teeth Y8 .295 25 .3619 .305 30 .36410 .314 32 .36512 .327 36 .36715 .339 40 .37016 .342 48 .37218 .345 50 .37320 .352 60 .37424 .358 72 .377HORSEPOWER AND TORQUEMax. allowable torque (T) that should be imposed on a gearwill be the safe tooth load (W) multiplied by D or T = W x D2 2The safe horsepower capacity of the gear (at a given RPM) canbe calculated from HP = T x RPM or directly from (W) and (V);HP =WV33,000For a known HP, T =63,02563025 x HPRPM144 Gear Catalog

HELICAL GEARSENGINEERING INFORMATIONWhen Helical gears are operated on other than Parallel shafts,the tooth load is concentrated at a point, with the result thatvery small loads produce very high pressures. The slidingvelocity is usually quite high and, combined with the concentratedpressure, may cause galling or excessive wear, especiallyif the teeth are not well lubricated. For these reasons,the tooth load which may be applied to such drives is very limitedand of uncertain value, and is perhaps best determined bytrial under actual operating conditions. If one of the gears ismade of bronze, the contact area and thereby the load carryingcapacity, may be increased, by allowing the gears to “runin”in their operating position, under loads which graduallyincrease to the maximum expected.THRUST LOADSAs a result of the design of the Helical Gear tooth, an axial orthrust load is developed. Bearings must be adequate toabsorb this load. The thrust load direction is indicated below.The magnitude of the thrust load is based on calculatedHorsepower.126,050 x HPAxial Thrust Load =RPM x Pitch DiameterBoston Helicals are all 45° Helix Angle, producing a tangentialforce equal in magnitude to the axial thrust load. A separatingforce is also imposed on the gear set based on calculatedHorsepower.Separating Load = Axial Thrust Load x .386Above formulae based on Boston 45° Helix Angle and 14-1/2°Normal Pressure Angle.DRIVERRIGHTHANDTHRUSTBEARINGDRIVERDRIVERLEFT-HANDTHRUSTBEARINGDRIVERDRIVERLEFT-HANDTHRUSTBEARINGDRIVERRIGHT-HANDSee page 118 for hardened and ground Thrust Washers.Gear Catalog 145

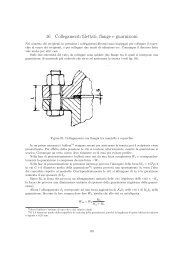

MITER AND BEVEL GEARSENGINEERING INFORMATIONStraight tooth bevel (and miter) gears are cut with generatedtooth form having a localized lengthwise tooth bearing knownas the “Coniflex” ® tooth form. The superiority of these gearsover straight bevels with full length tooth bearing, lies in thecontrol of tooth contact. The localization of contact permitsminor adjustment of the gears in assembly and allows forsome displacement due to deflection under operating loads,without concentration of the load on the end of the tooth. Thisresults in increased life and quieter operation.IncorrectIf Mounting Distance of one or both gears is made less thandimension specified, the teeth may bind. Excessive wear orbreakage can result. Drawing below shows gears mountedincorrectly with the Mounting Distance too short for one gear.PINION APEXON CENTERPINION APEX DEFLECTEDOR ASSEMBLED OFFCENTERMOUNTINGDISTANCETOO SMALLTOOTH BEARING CENTRALTOOTH BEARING SHIFTEDOFF CENTERBUT STILL SAFE(A)Boston Gear Bevel and Miter Gears will provide smooth, quietoperation and long life when properly mounted and lubricated.There are several important considerations in mounting thesegears.1. All standard stock bevel and miter gears must be mountedat right angles (90°) for proper tooth bearing.2. Mounting Distance (MD) is the distance from the end of thehub of one gear to the center line of its mating gear. Whenmounted at the MD specified, the gears will have a properbacklash and the ends of the gear teeth will be flush witheach other (see drawings).3. All bevel and miter gears develop radial and axial thrustloads when transmitting power. See page 148. Theseloads must be accommodated by the use of bearings.(B)ILLUSTRATION OF LOCALIZED TOOTH BEARINGIN STRAIGHT BEVEL CONIFLEX ® GEARSIncorrectIf Mounting Distance of either gear is made longer than dimensionspecified, as shown in drawing below, the gears will notbe in full mesh on a common pitch line and may have excessivebacklash. Excessive backlash or play, if great enough,can cause a sudden impulse or shock load in starting orreversing which might cause serious tooth damage.MOUNTINGDISTANCETOO GREATMOUNTINGDISTANCEMOUNTINGDISTANCEMOUNTINGDISTANCEMOUNTINGDISTANCE®Registered in the U.S. Patent Office.Gear Catalog 147

ENGINEERING INFORMATIONMITER AND BEVEL BEARSTOOTH STRENGTH (Straight Tooth)The beam strength of Miter and Bevel gears (straight tooth)may be calculated using the Lewis Formula revised to compensatefor the differences between Spur and Bevel gears. Severalfactors are often combined to make allowance for the toothtaper and the normal overhung mounting of Bevel gears.W = Tooth Load, Lbs. (along the Pitch Line)S = Safe Material Stress (static) Lbs. per Sq. In. (Table 1)F = Face Width, In.Y = Tooth Form Factor (Table I)P = Diametral PitchD = Pitch DiameterV = Pitch Line Velocity, Ft. per Min. = .262 x D x RPMTABLE I VALUES OF SAFE STATIC STRESS (s)TABLE II TOOTH FORM FACTOR (Y)HORSEPOWER AND TORQUEMax. allowable torque (T) that should be imposed on a gearwill be the safe tooth load (W) multiplied by D or T = W x D2 2The safe horsepower capacity of the gear (at a given RPM) canbe calculated from HP = T x RPM or directly from (W) and (V);HP =WV33,000For a known HP, T =W = SFYP63,02563025 x HPRPM600600 + V .75Material(s) Lb. per Sq. In.Plastic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5000Bronze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10000Cast Iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12000{.20 Carbon (Untreated) . . . . . . . . . . . . . . . . . . . . . . 20000.20 Carbon (Case-hardened) . . . . . . . . . . . . . . . . . . 25000Steel .40 Carbon (Untreated) . . . . . . . . . . . . . . . . . . . . . . 25000.40 Carbon (Heat-treated) . . . . . . . . . . . . . . . . . . . . 30000.40 C. Alloy (Heat-treated) . . . . . . . . . . . . . . . . . . . . 4000020°P.A.—LONG ADDENDUM PINIONS SHORT ADDENDUM GEARSNo.RatioTeeth 1 1.5 2 3 4 6Pinion Pin. Gear Pin. Gear Pin. Gear Pin. Gear Pin. Gear Pin. Gear12 — — — .345 .283 .355 .302 .358 .305 .361 .32414 — .349 .292 .367 .301 .377 .317 .380 .323 .405 .35216 .333 .367 .311 .386 .320 .396 .333 .402 .339 .443 .37718 .342 .383 .328 .402 .336 .415 .346 .427 .364 .474 .39920 .352 .402 .339 .418 .349 .427 .355 .456 .386 .500 .42124 .371 .424 .364 .443 .368 .471 .377 .506 .405 — —28 .386 .446 .383 .462 .386 .509 .396 .543 .421 — —32 .399 .462 .396 .487 .402 .540 .412 — — — —36 .408 .477 .408 .518 .415 .569 .424 — — — —40 .418 — — .543 .424 .594 .434 — — — —THRUSTThe axial thrust loads developed by straight tooth miter andbevel gears always tend to separate the gears.For Spiral Bevel and Miter Gears, the direction of axial thrustloads developed by the driven gears will depend upon thehand and direction of rotation. Stock Spiral Bevel pinions cutLeft Hand only, Gears Right Hand only.The magnitude of the thrust may be calculated from the formulaebelow, based on calculated HP, and an appropriateThrust Bearing selected.Straight Bevels and MitersGear Thrust =126,050 x HPx tan a cos bRPM x Pitch DiameterPinion Thrust =126,050 x HPx tan a sin bRPM x Pitch DiameterSpiral Bevels and MitersThrust values for Pinions and Gears are given for four possiblecombinations.R.H. SPIRALCLOCKWISEL.H. SPIRALC. CLOCKWISEL.H. SPIRALCLOCKWISER.H. SPIRALC. CLOCKWISET P =T G =T P =T G =a = Tooth Pressure Angleb = 1/2 Pitch AnglePitch Angle = tan ( N -1 PN G)g = Spiral Angle = 35°126,050 x HPRPM x D126,050 x HPRPM x D126,050 x HPRPM x D126,050 x HPRPM x Dtana sinbcosgtana cosbcosgtana sinbcosgtana cosbcosg– tang cosb+ tang sinb+ tang cosb+ tang sinb148 Gear Catalog

WORMS AND WORM GEARSENGINEERING INFORMATIONBoston standard stock Worms and Worm Gears are used forthe transmission of motion and/or power between non-intersectingshafts at right angles (90°). Worm Gear drives areconsidered the smoothest and quietest form of gearing whenproperly applied and maintained. They should be consideredfor the following requirements:HIGH RATIO SPEED REDUCTIONLIMITED SPACERIGHT ANGLE (NON-INTERSECTING) SHAFTSGOOD RESISTANCE TO BACK DRIVINGGeneral nomenclature having been applied to Spur andHelical gear types, may also be applied to Worm Gearing withthe addition of Worm Lead and Lead Angle, Number ofThreads (starts) and Worm Gear Throat diameter.THRUST LOADSAs is true with Helical and Bevel gearing, Worm gearing, whenoperating, produces Thrust loading. The Chart below indicatesthe direction of thrust of Worms and Worm Gears when theyare rotated as shown. To absorb this thrust loading, bearingsshould be located as indicated.DRIVENDRIVERTHRUST BEARINGRIGHT-HANDDRIVENDRIVERHOW TO TELL A LEFT-HANDOR RIGHT-HANDWORM OR WORM GEARDRIVENDRIVENDRIVENLEFT-HANDDRIVENDRIVERTHRUST BEARINGDRIVERDRIVENDRIVENThreads of LEFT-HAND lean to theLeft when standing on either end:EFFICIENCYThe efficiency of a worm gear drive depends on the lead angleof the worm. The angle decreases with increasing ratio andworm pitch diameter. For maximum efficiency the ratio shouldbe kept low.Threads of RIGHT-HAND lean to theRight when standing on either end:Due to the sliding action which occurs at the mesh of theWorm and Gear, the efficiency is dependent on the LeadAngle and the Coefficient of the contacting surface. A commonformula for estimating efficiency of a given Worm Gearreduction is:EFFICIENCY = E =Tang (1 – f tang)f + tangwhere g = Worm Lead Anglef = Coefficient of FrictionFor a Bronze Worm Gear and hardened Steel Worm, aCoefficient of Friction in the range of .03/.05 may be assumedfor estimated value only.Gear Catalog 149

WORMS AND WORM GEARSENGINEERING INFORMATIONWORM AND WORM GEAR FORMULASTo Obtain Having FormulaCircular Pitch (p) Diametral Pitch (P) p = 3.1416PDiametral Pitch (P) Circular Pitch (p) P = 3.1416pLead (of Worm) (L)Number of Threads inWorm & Circular Pitch (p)L = p(No. of Threads)Addendum (a) Diametral Pitch (P) a = 1 PPitch Diameter (D) Outside Diameter (d o ) &of Worm (D W ) Addendum (a)D W= d o– 2aPitch Diameter of Circular Pitch (p) &D G=N GpWorm Gear (D G ) Number of Teeth (N) 3.1416Center Distance Pitch DiameterBetween Worm & of Worm (d w) &CD = dw + DGWorm Gear (CD) Worm Gear (D2G)Whole Depth ofCircular Pitch (p)h T = .6866 pTeeth (h T) Diametral Pitch (P) h T= 2.157PBottom Diameterof Worm (Dr )Whole Depth (h T ) &Outside Diameter (d w )d r= d o– 2h TThroat Diameter Pitch Diameter of Wormof Worm Gear (D T ) Gear (D) & Addendum (a)D T = D G + 2aLead Angle of Pitch Diameter of Worm(D) LWorm (g)& The Lead (L)g = tan ( -1 3.1416d )RatioNo. of Teeth on Gear (N G )NRatio =Gand Number ofNo. of ThreadsThreads on WormGear O.D. (D O)Throat Dia. (D T )and Addendum (a)D O= D T+ .6aWORM GEAR BACK-DRIVINGThis is the converse of self-locking and refers to the ability ofthe worm gear to drive the worm. The same variables exist,making it difficult to predict. However, our experience indicatesthat for a hardened worm and bronze gear properly manufactured,mounted and lubricated, back-driving capability may beexpected, if the lead angle is greater than 11°. Again, no guaranteeis made and the customer should be so advised.RATINGThe high rate of sliding friction that takes place at the mesh ofthe Worm and Gear results in a more complex method of ratingthese Gears as opposed to the other Gear types. Materialfactors, friction factors and velocity factors must all be consideredand applied to reflect a realistic durability rating.SELF-LOCKING ABILITYThere is often some confusion as to the self-locking ability of aworm and gear set. Boston worm gear sets, under no conditionshould be considered to hold a load when at rest. Thestatement is made to cover the broad spectrum of variableseffecting self-locking characteristics of a particular gear set ina specific application. Theoretically, a worm gear will not backdrive if the friction angle is greater than the worm lead angle.However, the actual surface finish and lubrication may reducethis significantly. More important, vibration may cause motionat the point of mesh with further reduction in the friction angle.Generally speaking, if the worm lead angle is less than 5°,there is reasonable expectation of self-locking. Again, no guaranteeshould be made and customer should be advised. Ifsafety is involved, a positive brake should be used.150 Gear Catalog

COUPLINGSENGINEERING INFORMATIONUNIVERSAL JOINTSALIGNMENTAlignment of Boston couplings should be performed by the followingsteps to meet lateral and angular misalignment specificationsbelow.1. Align shafts and supports to give minimum lateral andangular misalignment.2. Assemble coupling halves to shaft.3. Slide couplings together and check lateral misalignmentusing straight edge and feeler gauge over coupling outsidediameter (On BF Series couplings, spider must beremoved.) This should be within specifications below.4. Lock couplings on shaft and check distance using feelergauges between drive lug on one half and space betweenon other coupling half. Rotate coupling and check gap at aminimum of 3 other coupling positions. The differencebetween any two readings should be within specificationsbelow.MOUNTINGA single universal joint (rotating at uniform speed) operating atan angle will introduce periodic variations of angular velocity tothe driven shaft. These cyclic speed fluctuations (two per revolution)cause vibration, higher shaft stresses and bearing loadswhich will be more severe with larger angles of operation.The detrimental effects of these rotational deviations can bereduced, and uniform speed restored by using two joints (andan intermediate shaft) to connect shafts at an angle or misalignedin a parallel direction.FEELER GAUGEFEELER GAUGELATERAL MISALIGNMENTANGULAR MISALIGNMENTFor connecting shafts in the same plane the joints should bearranged to operate at equal angles and with the bearing pinsof the yokes on the intermediate shaft in line with each other.MISALIGNMENT TOLERANCESCoupling Series Lateral AngularFC—Bronze Insert .001See ChartFC—Urethane Insert .002belowFC—Rubber Insert .002BF .002 1-1/2°BG (Shear Type) 1/32 2°FA .002 2°FCP (Plastic) .003 3°FC SERIES ANGULAR MISALIGNMENTChart reflects maximum angular misalignment of 1-1/2° forrubber, 1° for urethane and 1/2° for bronze.MAXIMUM READING DIFFERENTIALInsertSize Rubber Urethane BronzeFC12 .033 .022 .011FC15 .039 .026 .013FC20 .053 .035 .018FC25 .066 .044 .022FC30 .078 .052 .026FC38 .097 .065 .032FC45 .117 .078 .039LUBRICATIONPIN and BLOCK TYPEThese universal joints are not lubricated when shipped.Many applications are considered severe when in harsh environmentsand when a combination of speed, dirt contaminationand inaccessible locations make it impractical to maintainproper lubrication.It is in these instances when the Boot Kits become a desirablealternative. For satisfactory performance, all booted jointsshould be used with a LITH-EP-000 grease for an ambienttemperature range of 40° to 225°F.VOLUME OF LUBRICATION FOR BOOTED JOINTSVolume Volume VolumeSize (Ozs.) Size (Ozs.) Size (Ozs.)37 .4 100 2.0 250 25.050 .5 125 3.5 300 30.062 .75 150 4.5 400 50.175 1.0 175 7.087 1.5 200 15.0Note: Joints should be initially lubricated with a 90 weight oil before beingpacked with grease.FORGED AND CAST TYPEUniversal Joints are not lubricated when shipped.Lubricate these joints with a Lith EP-2 grease or equivalent.The center cross of these joints holds a generous supply oflubricant which is fed to the bearings by centrifugal action.Light-duty, low-angle operation may require only occasionallubrication. For high-angle, high-speed operation or in extremedirt or moist conditions, daily regreasing may be required.Gear Catalog 151

GENERALENGINEERING INFORMATIONMOUNTINGSPUR & HELICALFor proper functioning gears, gears must be accuratelyaligned and supported by a shaft and bearing system whichmaintains alignment under load. Deflection should not exceed.001 inch at the tooth mesh for general applications. The toleranceon Center Distance normally should be positive to avoidpossibility of gear teeth binding. Tolerance value is dependenton acceptable system backlash. As a guide for average application,this tolerance might vary from .002 for Boston Gear’sfine pitch gears to .005 for the coarsest pitch.WORMS AND WORM GEARIt is important that the mounting assures the central plane ofthe Worm gear passes essentially through the axis of theWorm. This can be accomplished by adjusting the Worm Gearaxially. Boston Worm Gears are cut to close tolerancing of theCenter Line of the Gear tooth to the flush side of the Gear.When properly mounted Worm Gears will become more efficientafter initial break-in period.HOW WORM GEARS “ADJUST” THEMSELVESThe gear in a worm gear reducer is made of a soft bronzematerial. Therefore, it can cold-work and wear-in to accommodateslight errors in misalignment.Evolution of Contact in a Worm GearEnteringsideWormrotationLeavingsideInitially, contact is concentratedon the leaving side ofthe worm.After several hours or runningunder load, gear hascold-worked to spread areaof contact.ALTERATIONSBoston Gear Service Centers are equipped to alter catalogsprockets (rebore, keyway, setscrew, etc.). For customers,choosing to make their own alterations, the guidelines listedbelow should be beneficial. Alterations to hardened gearsshould not be made without consultation with factory.In setting up for reboring the most important consideration isto preserve the accuracy of concentricity and lateral runoutprovided in the original product. There are several methods foraccomplishing this. One procedure is: mount the part on anarbor, machine hub diameter to provide a true running surface,remove from arbor and chuck on the hub diameter,check face and bore runout prior to reboring. As a basic rule ofthumb, the maximum bore should not exceed 60% of the HubDiameter and depending on Key size should be checked forminimum wall thickness. A minimum of one setscrew diameterover a keyway is considered adequate.Boston Gear offers a service for hardening stock sprockets.This added treatment can provide increased horsepower capacitywith resultant longer life and/or reduction in size and weight.Customers wishing to do the hardening operation should referto “Materials” below for <strong>information</strong>.LUBRICATIONThe use of a straight mineral oil is recommended for mostworm gear applications. This type of oil is applicable to gearsof all materials, including non-metallic materials.Mild E.P. (Extreme Pressure) lubricants may be used with Ironand Steel Gears. E.P. lubricants normally should be selectedof the same viscosity as straight mineral oil, E.P. lubricantsare not recommended for use with brass or bronze gears.SAE80 or 90 gear oil should be satisfactory for splash lubricatedgears. Where extremely high or low speed conditions areencountered, consult a lubricant manufacturer. Oil temperatureof 150°F should not be exceeded for continuous dutyapplications. Temperatures up to 200°F can be safely toleratedfor short periods of time.Many specialty lubricants have been recently developed tomeet the application demands of today’s markets, includingsynthetics and both high and low temperature oils and greases.In those instances where Bath or Drip Feed is not practical,a moly-Disulphide grease may be used successfully, forlow speed applications.After many hours of operation,contact has spread tocover the entire workingarea of the tooth.152 Gear Catalog

GENERALENGINEERING INFORMATIONMATERIALSBoston Gear stock steel gears are made from a .20 carbonsteel with no subsequent treatment. For those applicationsrequiring increased wearability. Case-hardening produces awear resistant, durable surface and a higher strength core.Carburizing and hardening is the most common process used.Several proprietary nitriding processes are available for producingan essentially distortion-free part with a relatively shallowbut wear-resistant case. Boston stock worms are made ofeither a .20 or .45 carbon steel. Selection of material is basedon size and whether furnished as hardened or untreated.Stock cast iron gears are manufactured from ASTM-CLASS30 cast iron to Boston Gear specifications. This provides afine-grained material with good wear-resistant properties.Bronze worm and helical gears are produced from severalalloys selected for bearing and strength properties. Phosphorbronze is used for helicals and some worm gears (12P andcoarser). Finer pitch worm gears are made from several differentgrades of bronze, dependent on size.Non-metallic spur Gears listed in this Catalog are made fromcotton reinforced phenolic normally referred to as Grade “C.”Plastic Gears listed are molded from either Delrin ® , Acetal orMinlon ® .STANDARD KEYWAYS AND SETSCREWSStandard RecommendedDiameter of Hole W d Setscrew5/16 to 7/16” 3/32” 3/64” 10-321/2 to 9/16 1/8 1/16 1/4-205/8 to 7/8 3/16 3/32 5/16-1815/16 to 1-1/4 1/4 1/8 3/8-161-5/16 to 1-3/8 5/16 5/32 7/16-141-7/16 to 1-3/4 3/8 3/16 1/2-131-13/16 to 2-1/4 1/2 1/4 9/16-122-5/16 to 2-3/4 5/8 5/16 5/8-112-13/16 to 3-1/4 3/4 3/8 3/4-103-5/16 to 3-3/4 7/8 7/16 7/8-93-13/16 to 4-1/2 1 1/2 1-84-9/16 to 5-1/2 1-1/4 7/16 1-1/8-75-9/16 to 6-1/2 1-1/2 1/2 1-1/4-6STYLESBoston Spur, Helical, and Worm Gears are carried in Plain,Web, or Spoke styles, as illustrated.PLAIN – AWEB – BWEB WITHLIGHTNING HOLES – CWdXDIA. OF HOLEOR DX'FORMULA:X = (D/2) 2 – (W/2) 2 + d + D/2X’ = 2X – DSPOKE – DEXAMPLE:Hole 1”; Keyway 1/4” wide by 1/8” deep.X = (1/2) 2 – (1/8) 2 + 1/8 + 1/2 = 1.109”X’ = 2.218 – 1.000 = 1.218”Gear Catalog 153

ENGINEERING INFORMATIONHOW TO FIGURE HORSEPOWER AND TORQUETO OBTAIN HAVING FORMULAVelocity (V)Pitch Diameter (D) ofFeet Per MinuteGear or Sprocket – Inches V = .2618 x D x RPM& Rev. Per Min. (RPM)Velocity (V) Ft. Per Min.Rev. Per Min. (RPM) & Pitch Diameter (D) of RPM = ————— VGear or Sprocket—Inches.2618 x DPitch Diameter (D) Velocity (V) Ft. Perof Gear or Sprocket Min. & Rev. Per Min. D = —————— V— Inches (RPM).2618 x RPMTorque (T) In. Lbs.Horsepower (HP)Horsepower (HP)Torque (T) In. Lbs.Force (W) Lbs.Force (W) Lbs. &Radius (R) InchesForce (W) Lbs. &Velocity (V) Ft. Per Min.Torque (T) In. Lbs. &Rev. Per Min. (RPM)Horsepower (HP)& Rev. Per Min. (RPM)Horsepower (HP) &Velocity (V) Ft. Per Min.Horsepower (HP) &Rev. Per Min. (RPM)Torque (T) In. Lbs.POWER is the rate of doing work.T = W x RHP = ———— W x V33000HP =T ———— x RPM63025T = ————— 63025 x HPRPMW = ————— 33000 x HPVRPM = ————— 63025 x HPTWORK is the exerting of a FORCE through a DISTANCE. ONEFOOT POUND is a unit of WORK. It is the WORK done in exerting aFORCE OF ONE POUND through a DISTANCE of ONE FOOT.THE AMOUNT OF WORK done (Foot Pounds) is the FORCE(Pounds) exerted multiplied by the DISTANCE (Feet) throughwhich the FORCE acts.THE AMOUNT OF POWER used (Foot Pounds per Minute) isthe WORK (Foot Pounds) done divided by the TIME (Minutes)required.WORK (Ft. Lbs.)POWER (Foot Pounds per Minute) = ————————TIME (Minutes)POWER is usually expressed in terms of HORSEPOWER.HORSEPOWER is POWER (Foot Pounds per Minute) dividedby 33000.POWER (Ft. Lbs. per Minute)HORSEPOWER (HP) = ————————————33000WORK (Ft. Pounds)= —————————33000 x TIME (Min.)FORCE (Lbs.) x DISTANCE (Feet)= ———————————————33000 x TIME (Min.)FORCE (Lbs.) x DISTANCE (Feet)= ———————————————33000 x TIME (Min.)1 hp = 36 lb-in. @ 1750 rpm1 hp = 3 lb-ft. @ 1750 rpmTorque (lb.-in.) x rpmhp = —————————63,02533,000 x 1HP = ————— = 1 HP33,000 x 1Cut on Dotted Linesand Keep for Quick ReferenceForce (lb) x Velocity (ft/min.)hp = ————————————33,000Velocity (ft/min.) = 0.262 x Dia. (in.) x rpmTorque (lb.-in) = Force (lb) x Radius (in.)hp x 63,025Torque (lb.-in.) = ——————rpmMechanical Output hp= ———— x 100%Efficiency Input hpOT (lb-in.) x Output rpmOutput hp = ——————————63,025OT = Input Torque x Ratio x EfficiencyOT = Output TorqueInput rpmOutput rpm = ————RatioFORCE (W)= 33,000 LBS.33,000LBS.APPLICATION FORMULASDISTANCE = 1 FT.TIME = 1 MIN.2 TKOHL = ———— DOHL = Overhung Load (lb)T = Shaft Torque (lb-in.)D = PD of Sprocket, Pinion or Pulley (in.)K = Overhung Load FactorOverhung Load Factors:Sprocket or Timing Belt . . . . . . . .1.00Pinion & Gear Drive . . . . . . . . . . .1.25Pulley & V-Belt Drive . . . . . . . . . .1.50Pulley & Flat Belt Drive . . . . . . . .2.50Variable Pitch Pulley . . . . . . . . . .3.50kW = hp x 0.7457in. = mm/25.4Temp. °C = (°F - 32) x 0.556Temp. °F = (°C x 1.8) + 32Torque (lb-in.) = 86.6 x kg•mTorque (lb-in.) = 8.85 x N•mTorque (lb-in.) = 88.5 x daN•mILLUSTRATION OF HORSEPOWERFORCE (W)1000 LBS. 1000LBS.DISTANCE = 33 FT.TIME = 1 MIN.1000 x 33HP = ———— = 1 HP33,000 x 1TORQUE (T) is the product of a FORCE (W) in pounds,times a RADIUS (R) in inches from the center of shaft (LeverArm) and is expressed in Inch Pounds.W300*R = 1"W150*R = 2"T=WR=300 x 1=300 In. Lbs. T=WR=150 x 2=300 In. Lbs.If the shaft is revolved, the FORCE (W) is moved through adistance, and WORK is done.2¹RWORK (Ft. Pounds) = W x —— x No. of Rev. of Shaft.12When this WORK is done in a specified TIME, POWER is used.2¹RPOWER (Ft. Pounds per Min.) = W x —— x RPM12Since (1) HORSEPOWER = 33,000 Foot Pounds per Minute2¹R RPM WxRxRPMHORSEPOWER (HP) = W x —— x ——— = ——————12 33,000 63,025but TORQUE (Inch Pounds) = FORCE (W) X RADIUS (R)TORQUE (T) x RPMTherefore HORSEPOWER (HP) = —————————63,025154 Gear Catalog