It's about accurate seed placement - Kuhn North America

It's about accurate seed placement - Kuhn North America

It's about accurate seed placement - Kuhn North America

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

top<br />

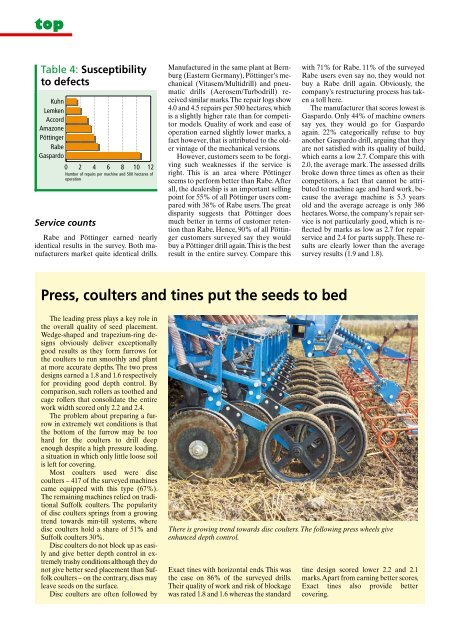

Table 4: Susceptibility<br />

to defects<br />

<strong>Kuhn</strong><br />

Lemken<br />

Accord<br />

Amazone<br />

Pöttinger<br />

Rabe<br />

Gaspardo<br />

Anzahl 0 2 4 6 8 10 12<br />

Number of repairs per machine and 500 hectares of<br />

Reparaturen je Maschine und<br />

operation<br />

500 ha Einsatzfläche<br />

Service counts<br />

Rabe and Pöttinger earned nearly<br />

identical results in the survey. Both manufacturers<br />

market quite identical drills.<br />

The leading press plays a key role in<br />

the overall quality of <strong>seed</strong> <strong>placement</strong>.<br />

Wedge-shaped and trapezium-ring designs<br />

obviously deliver exceptionally<br />

good results as they form furrows for<br />

the coulters to run smoothly and plant<br />

at more <strong>accurate</strong> depths. The two press<br />

designs earned a 1.8 and 1.6 respectively<br />

for providing good depth control. By<br />

comparison, such rollers as toothed and<br />

cage rollers that consolidate the entire<br />

work width scored only 2.2 and 2.4.<br />

The problem <strong>about</strong> preparing a furrow<br />

in extremely wet conditions is that<br />

the bottom of the furrow may be too<br />

hard for the coulters to drill deep<br />

enough despite a high pressure loading,<br />

a situation in which only little loose soil<br />

is left for covering.<br />

Most coulters used were disc<br />

coulters – 417 of the surveyed machines<br />

came equipped with this type (67%).<br />

The remaining machines relied on traditional<br />

Suffolk coulters. The popularity<br />

of disc coulters springs from a growing<br />

trend towards min-till systems, where<br />

disc coulters hold a share of 51% and<br />

Suffolk coulters 30%.<br />

Disc coulters do not block up as easily<br />

and give better depth control in extremely<br />

trashy conditions although they do<br />

not give better <strong>seed</strong> <strong>placement</strong> than Suffolk<br />

coulters – on the contrary, discs may<br />

leave <strong>seed</strong>s on the surface.<br />

Disc coulters are often followed by<br />

Manufactured in the same plant at Bernburg<br />

(Eastern Germany), Pöttinger’s mechanical<br />

(Vitasem/Multidrill) and pneumatic<br />

drills (Aerosem/Turbodrill) re-<br />

ceived similar marks. The repair logs show<br />

4.0 and 4.5 repairs per 500 hectares, which<br />

is a slightly higher rate than for competitor<br />

models. Quality of work and ease of<br />

operation earned slightly lower marks, a<br />

fact however, that is attributed to the older<br />

vintage of the mechanical versions.<br />

However, customers seem to be forgiving<br />

such weaknesses if the service is<br />

right. This is an area where Pöttinger<br />

seems to perform better than Rabe. After<br />

all, the dealership is an important selling<br />

point for 55% of all Pöttinger users compared<br />

with 38% of Rabe users. The great<br />

disparity suggests that Pöttinger does<br />

much better in terms of customer retention<br />

than Rabe. Hence, 90% of all Pöttinger<br />

customers surveyed say they would<br />

buy a Pöttinger drill again. This is the best<br />

result in the entire survey. Compare this<br />

Press, coulters and tines put the <strong>seed</strong>s to bed<br />

Exact tines with horizontal ends. This was<br />

the case on 86% of the surveyed drills.<br />

Their quality of work and risk of blockage<br />

was rated 1.8 and 1.6 whereas the standard<br />

with 71% for Rabe. 11% of the surveyed<br />

Rabe users even say no, they would not<br />

buy a Rabe drill again. Obviously, the<br />

company’s restructuring process has taken<br />

a toll here.<br />

The manufacturer that scores lowest is<br />

Gaspardo. Only 44% of machine owners<br />

say yes, they would go for Gaspardo<br />

again. 22% categorically refuse to buy<br />

another Gaspardo drill, arguing that they<br />

are not satisfied with its quality of build,<br />

which earns a low 2.7. Compare this with<br />

2.0, the average mark. The assessed drills<br />

broke down three times as often as their<br />

competitors, a fact that cannot be attributed<br />

to machine age and hard work, because<br />

the average machine is 5.3 years<br />

old and the average acreage is only 386<br />

hectares. Worse, the company’s repair service<br />

is not particularly good, which is reflected<br />

by marks as low as 2.7 for repair<br />

service and 2.4 for parts supply. These results<br />

are clearly lower than the average<br />

survey results (1.9 and 1.8).<br />

There is growing trend towards disc coulters. The following press wheels give<br />

enhanced depth control.<br />

tine design scored lower 2.2 and 2.1<br />

marks. Apart from earning better scores,<br />

Exact tines also provide better<br />

covering.