Download brochure - F. Zimmermann GmbH

Download brochure - F. Zimmermann GmbH

Download brochure - F. Zimmermann GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

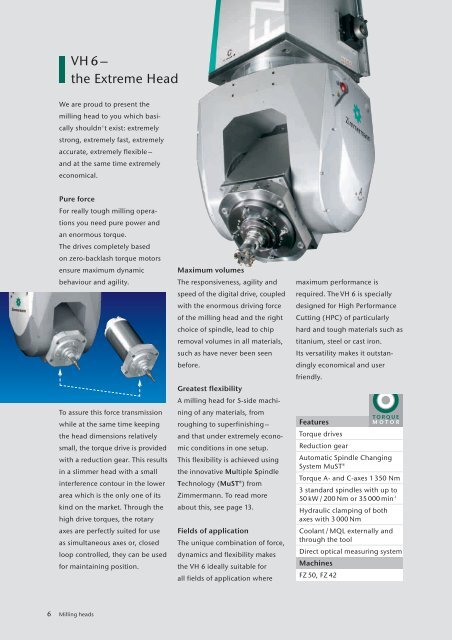

VH 6 –the Extreme HeadWe are proud to present themilling head to you which basicallyshouldn't exist: extremelystrong, extremely fast, extremelyaccurate, extremely flexible –and at the same time extremelyeconomical.Pure forceFor really tough milling operationsyou need pure power andan enormous torque.The drives completely basedon zero-backlash torque motorsensure maximum dynamicbehaviour and agility.To assure this force transmissionwhile at the same time keepingthe head dimensions relativelysmall, the torque drive is providedwith a reduction gear. This resultsin a slimmer head with a smallinterference contour in the lowerarea which is the only one of itskind on the market. Through thehigh drive torques, the rotaryaxes are perfectly suited for useas simultaneous axes or, closedloop controlled, they can be usedfor maintaining position.Maximum volumesThe responsiveness, agility andspeed of the digital drive, coupledwith the enormous driving forceof the milling head and the rightchoice of spindle, lead to chipremoval volumes in all materials,such as have never been seenbefore.Greatest flexibilityA milling head for 5-side machiningof any materials, fromroughing to superfinishing –and that under extremely economicconditions in one setup.This flexibility is achieved usingthe innovative Multiple SpindleTechnology (MuST ® ) from<strong>Zimmermann</strong>. To read moreabout this, see page 13.Fields of applicationThe unique combination of force,dynamics and flexibility makesthe VH 6 ideally suitable forall fields of application wheremaximum performance isrequired. The VH 6 is speciallydesigned for High PerformanceCutting (HPC) of particularlyhard and tough materials such astitanium, steel or cast iron.Its versatility makes it outstandinglyeconomical and userfriendly.FeaturesTorque drivesReduction gearMachinesFZ 50, FZ 42T ORQUEMOTORAutomatic Spindle ChangingSystem MuST ®Torque A- and C-axes 1 350 Nm3 standard spindles with up to50 kW / 200 Nm or 35 000 min -1Hydraulic clamping of bothaxes with 3 000 NmCoolant / MQL externally andthrough the toolDirect optical measuring system6 Milling heads