Cold splicing of fabric ply conveyor belts with the contact adhesive ...

Cold splicing of fabric ply conveyor belts with the contact adhesive ...

Cold splicing of fabric ply conveyor belts with the contact adhesive ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

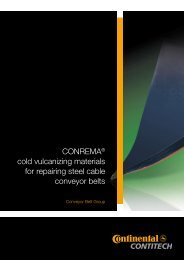

<strong>Cold</strong> <strong>splicing</strong> <strong>of</strong> <strong>fabric</strong> <strong>ply</strong> <strong>conveyor</strong><strong>belts</strong> <strong>with</strong> <strong>the</strong> <strong>contact</strong> <strong>adhesive</strong>CONTI SECUR ® BFA© 2004 by ContiTech TransportbandsystemeGmbH, Nor<strong>the</strong>im. All rights reserved.ContiTech - Division <strong>of</strong> Continental AG

Splicing <strong>of</strong> <strong>conveyor</strong> <strong>belts</strong> <strong>with</strong> more than two <strong>fabric</strong> pliesThe stepped cuts in <strong>the</strong> <strong>fabric</strong> produce a loss in strength in <strong>the</strong>se splices calculatedas one <strong>ply</strong>.Examples:3 <strong>ply</strong> belt will lose 33 % <strong>of</strong> <strong>the</strong> strength in <strong>the</strong> splice (2 steps).4 <strong>ply</strong> belt will lose 25 % <strong>of</strong> <strong>the</strong> strength in <strong>the</strong> splice (3 steps).5 <strong>ply</strong> belt will lose 20%. <strong>of</strong> <strong>the</strong> strength in <strong>the</strong> splice (4 steps).For certain belt types, <strong>the</strong> minimum step length Is <strong>of</strong> splice length Ic and <strong>the</strong>number <strong>of</strong> steps ns can be found in Table 1.Example:Belt type: 1000/3Strength <strong>of</strong> 1 <strong>ply</strong>: 333 N / mm (1000 divided by 3)Minimum Step length for this value: 300 mm (Table 1)Splice length: Is = 300 • (3 – 1) = 600 mmStep DirectionIf <strong>the</strong> scraper are working hard, <strong>the</strong> splice should be made in that way, that <strong>the</strong>scraper is not scraping against, but moving <strong>with</strong> <strong>the</strong> stepped design.Running againstRunning <strong>with</strong> <strong>the</strong> stepsTable 1Recommended minimum step and splice lengths for <strong>conveyor</strong> <strong>belts</strong> <strong>with</strong> morethan 2 pliesBelt strengthN/mmStrength<strong>of</strong> 1 <strong>ply</strong>N/mmMin.step lengthls mmSplice lengthlc mm400/3 200 400 2500/3 200 400 2125 to 160500/4 200 600 3630/4200 600 3No. <strong>of</strong> stepsns800/4 250 750 31000/4 250 750 3200 to 2501000/5 250 1000 41250/5250 1000 41250/4 300 900 31600/4 300 900 3315 to 4001600/5 300 1200 42000/5300 1200 42000/4 300 1050 32500/4 350 1400 3500 to 6302500/5 350 1400 43150/5350 1400 4ContiTech - Division <strong>of</strong> Continental AG

Cut <strong>the</strong> belt <strong>with</strong> a trailing angle. The angled join prevents <strong>the</strong> join from beingstressed over <strong>the</strong> entire width <strong>of</strong> <strong>the</strong> belt when it bends around <strong>the</strong> pulleys andidlers.Great angle > less stress. An angle <strong>of</strong> 16°40 has proven to be a standard(0,3 x belt width).• Folding back <strong>the</strong> belt• Preparation <strong>of</strong> <strong>the</strong> seam• Roughen interfaces between <strong>the</strong> covers and rubber edges• Remove <strong>the</strong> dust <strong>with</strong> a brush, no solventChoose step length. Mark <strong>the</strong> step- and splice length. Look to Table 1.© 2004 by ContiTech TransportbandsystemeGmbH, Nor<strong>the</strong>im. All rights reserved.ContiTech - Division <strong>of</strong> Continental AG

Cut <strong>the</strong> <strong>fabric</strong> plies <strong>with</strong> a <strong>ply</strong> cutter.Strip <strong>of</strong>f <strong>the</strong> first <strong>fabric</strong> <strong>ply</strong>.Stripping <strong>of</strong>f <strong>the</strong> last <strong>of</strong> <strong>the</strong> <strong>fabric</strong> plies.ContiTech - Division <strong>of</strong> Continental AG

• Check for <strong>the</strong> exact dimension• This is important after finishing <strong>the</strong> splice for <strong>the</strong> straight running <strong>of</strong> <strong>the</strong> belt• Smooth, if necessary <strong>the</strong> part <strong>of</strong> <strong>the</strong> skim rubber <strong>with</strong> a grinding disc• Remove <strong>the</strong> dust dry, don’t use a solvent• Coat <strong>the</strong> splice area <strong>with</strong> <strong>the</strong> activated CONTI SECUR® BFA• Depending <strong>of</strong> <strong>the</strong> strength <strong>of</strong> <strong>the</strong> <strong>fabric</strong> it’s necessary to decide how manycoats you have to ap<strong>ply</strong>• The <strong>fabric</strong> has to be complete covered <strong>with</strong> solution• Drying time see Table 2Table 2Number <strong>of</strong> coatsDrying time <strong>of</strong> <strong>the</strong> coats by roomtemperature1 st coat min. 30 min., max. 24 hours2 nd coat Back <strong>of</strong> hand test, max. 20 min.Or if it’s necessary to coat <strong>the</strong> splicesurface three times:1 st coat min. 30 min., max. 24 hours2 nd coat min. 30 min., max. 24 hours3 rd coat Back <strong>of</strong> hand test, max. 20 min.© 2004 by ContiTech TransportbandsystemeGmbH, Nor<strong>the</strong>im. All rights reserved.ContiTech - Division <strong>of</strong> Continental AG

• Fit toge<strong>the</strong>r <strong>the</strong> prepared surfaces and roll down <strong>the</strong> surface from <strong>the</strong> centreto <strong>the</strong> edges <strong>with</strong> a double rollerRemark: <strong>with</strong> this tool you will get <strong>the</strong> needed pressure into <strong>the</strong> splice.The pressure is absolute necessary for getting <strong>the</strong> adhesion between <strong>the</strong> plies.ContiTech - Division <strong>of</strong> Continental AG

• Coat <strong>the</strong> tacky back <strong>of</strong> <strong>the</strong> cover strip and <strong>the</strong> seam <strong>with</strong> <strong>the</strong> activatedCONTI SECUR® BFA• Drying time: 5 to 10 minutes• Fix and press down <strong>the</strong> CONREMA® cover strip• Edges projecting on ei<strong>the</strong>r side can be cut <strong>of</strong>f flush <strong>with</strong> <strong>the</strong> coverFinished splice.Don’t tension <strong>the</strong> belt before 2 to 5 hours after <strong>splicing</strong>.© 2004 by ContiTech TransportbandsystemeGmbH, Nor<strong>the</strong>im. All rights reserved.ContiTech - Division <strong>of</strong> Continental AG

ContiTechSpecialist in rubber andplastics technologyContiTechTransportbandsysteme GmbHWe are a company <strong>of</strong> <strong>the</strong> ContiTech Group. 120years <strong>of</strong> experience in rubber processing and acomprehensive range <strong>of</strong> products and serviceshave made us <strong>the</strong> leading manufacturer <strong>of</strong> <strong>conveyor</strong><strong>belts</strong> and service materials that meet variousrequirements in every industry. The product rangeextends from textile and steel <strong>conveyor</strong> <strong>belts</strong> tospecial <strong>conveyor</strong> <strong>belts</strong> <strong>with</strong> a wide variety <strong>of</strong> accessories.Our products and services remain state-<strong>of</strong>-<strong>the</strong>-artthanks to continuous research and developmentbased on careful basic research. We evaluate ourongoing material investigations and practicaltesting in collaboration <strong>with</strong> our raw materialssuppliers. This gives rise to products that combinereliability and long life for every materials-handlingtask at an optimum cost/benefit ratio. We provideour customers <strong>with</strong> all-round service. It extends toconsultation in planning <strong>conveyor</strong>s and in-serviceproduct support.DisclaimerThe content <strong>of</strong> this document is provided for information only and <strong>with</strong>out responsibility. ContiTech TransportbandsystemeGmbH makes no representations about <strong>the</strong> accuracy, reliability, completeness or timeliness <strong>of</strong><strong>the</strong> information in this document. ContiTech Transportbandsysteme GmbH may, in its sole discretion, revise<strong>the</strong> information contained herein at any time <strong>with</strong>out notice.ContiTech Transportbandsysteme GmbH's obligations and responsibilities regarding its products aregoverned solely by <strong>the</strong> agreements under which <strong>the</strong>y are sold. Unless o<strong>the</strong>rwise agreed in writing, <strong>the</strong>information contained herein does not become part <strong>of</strong> <strong>the</strong>se agreements. This document does not containany guarantee or agreed quality <strong>of</strong> ContiTech Transportbandsysteme GmbH’s products or any warranty <strong>of</strong>merchantability, fitness for a particular purpose and non-infringement. ContiTech TransportbandsystemeGmbH may make changes in <strong>the</strong> products or services described at any time <strong>with</strong>out notice.This document is provided on an "as is" basis. To <strong>the</strong> extent permitted by law, ContiTech TransportbandsystemeGmbH makes no warranty, express or implied, and assumes no liability in connection <strong>with</strong> <strong>the</strong> use <strong>of</strong><strong>the</strong> information contained in this document. ContiTech Transportbandsysteme GmbH is not liable for anydirect, indirect, incidental, consequential or punitive damages arising out <strong>of</strong> <strong>the</strong> use <strong>of</strong> this document.Information contained herein is not intended to announce product availability anywhere in <strong>the</strong> world.ContiTechTransportbandsysteme GmbHWerk Nor<strong>the</strong>imBreslauer Straße 14D-37154 Nor<strong>the</strong>imPhone +49 (0) 55 51 / 7 02-207Fax +49 (0) 5551 / 7 02-504E-mail: transportbandsysteme@tbs.contitech.dewww.contitech.de/transportbandsystemeThe trademarks, service marks and logos displayed in this document are <strong>the</strong> property <strong>of</strong> ContiTech TransportbandsystemeGmbH and/or its affiliates. Nothing in this document should be construed as granting anylicense or right to <strong>the</strong> Trademarks. Without <strong>the</strong> express written consent <strong>of</strong> ContiTech TransportbandsystemeGmbH <strong>the</strong> use <strong>of</strong> <strong>the</strong> Trademarks is prohibited.All text, images, graphics and o<strong>the</strong>r materials in this document are subject to <strong>the</strong> copyright and o<strong>the</strong>r intellectualproperty rights <strong>of</strong> ContiTech Transportbandsysteme GmbH and/or its affiliates. ContiTech TransportbandsystemeGmbH owns <strong>the</strong> copyrights in <strong>the</strong> selection, coordination and arrangement <strong>of</strong> <strong>the</strong> materials inthis document. These materials may not be modified or copied for commercial use or distribution.Copyright © 2004 by ContiTech TransportbandsystemeGmbH, Nor<strong>the</strong>im. All rights reserved.ContiTech - Division <strong>of</strong> Continental AG