Sierra Fixed Speed Oil Free Rotary Screw Air Compressor

Sierra Fixed Speed Oil Free Rotary Screw Air Compressor

Sierra Fixed Speed Oil Free Rotary Screw Air Compressor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

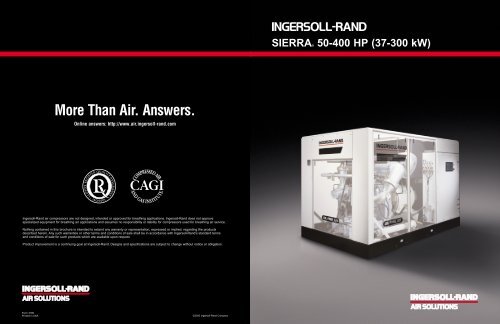

INGERSOLL-RANDSIERRA®50-400 HP (37-300 kW)More Than <strong>Air</strong>. Answers.Online answers: http://www.air.ingersoll-rand.comREGISTERQUALITY ASSURANCELLOYD’S•I S O 9 0 01Ingersoll-Rand air compressors are not designed, intended or approved for breathing applications. Ingersoll-Rand does not approvespecialized equipment for breathing air applications and assumes no responsibility or liability for compressors used for breathing air service.Nothing contained in this brochure is intended to extend any warranty or representation, expressed or implied, regarding the productsdescribed herein. Any such warranties or other terms and conditions of sale shall be in accordance with Ingersoll-Rand’s standard termsand conditions of sale for such products which are available upon request.Product improvement is a continuing goal at Ingersoll-Rand. Designs and specifications are subject to change without notice or obligation.Form 3189Printed in USA©2000 Ingersoll-Rand Company

Delivering Compressed<strong>Air</strong> Solutions For MoreThan 125 YearsFor more than a century, Ingersoll-Rand aircompressors have helped build dams, bridgesand tunnels; produce cars, appliances andelectrical equipment; and package foodsand pharmaceuticals.As more and more companies choseIngersoll-Rand air compressors, we answeredthe call for new technologies and updateddesigns, ensuring that our customers would getthe maximum benefits from their compressed air.Focused on Our CustomersIngersoll-Rand strives to deliver value toour customers in everything we do. We stayfocused on what you need, remaining true toour goal: to help you achieve the best resultspossible with your compressed air supply.MORE THAN125KNOWLEDGEABLE SALES STAFFTECHNOLOGY LEADERSHIPTECHNICAL ASSISTANCEIngersoll-Rand:Your <strong>Oil</strong>-<strong>Free</strong> ResourceIf you need oil-free air, Ingersoll-Rand ishere to help. We’ll listen to what you need.Then we’ll use our decades of leadership inthe oil-free market to help you design thebest oil-free system for your application.Today, we’re the only manufacturer that cansupply you with oil-free compressed air in allthree technologies: rotary screw, reciprocatingand centrifugal. And since each technologyhas its benefits, we can help you select theone that works best for your application.By maintaining solid relationships with ourcustomers, our dedicated sales staff anddistributor network relay changing requirementsto our engineering team. With this information,our engineers make design improvementsthat ensure that our customers get the qualitycompressed air they’ve asked for.If you want a single source supplier, you cancount on Ingersoll-Rand. Whether you needcompressed air systems, parts and service,or technical support, we will be there to helpyour system run at peak efficiency now andin the future.23

SIERRA: SuperiorTechnologyThe heart of the SIERRA oil-free rotaryscrew air compressor is our superior twostagecompression module. Our rotorsare precision-machined in a twenty-stepmanufacturing process that ensuresunmatched rotor profile accuracy andrepeatability. By using the highest qualitybearings and precision gearing to maintainexact alignment of the rotors, you are assuredof years of reliable, efficient service.Generously sized, anti-friction bearingseasily handle all expected loads to keepthe airend running smoothly. In the vitalsealing arrangement, the SIERRA usesdurable stainless steel for the air seals anda time-proven labyrinth design for the oilseals. This combination protects the rotorsfrom lubrication impurities while keeping theloss of air through leakage to an absoluteminimum, ensuring the continuous flow ofclean, oil-free compressed air.The precision gearing incorporated in thecompression module drive design optimizesboth speed and rotor timing, providingtrouble-free performance over a long life.And the improved lip seal on the bull geardrive input shaft eliminates any opportunityfor oil leakage into the SIERRA package.45

End View of RotorsSurface preparation createsminute crevices in our rotorsthat tightly grip the UltraCoatcoating. The result is the mostdurable performance on themarket, lowering our customers’energy costs and increasingthe life of the airend in theirSIERRA compressor.Rotor SurfaceRotor CoatingSolving The Need ForBetter <strong>Oil</strong>-<strong>Free</strong> PerformanceThe challenge: to give our customers an oil-freerotary compressor that operates at peakperformance throughout its lifetime. After a greatdeal of research, Ingersoll-Rand found that inferiorrotor coatings wear away over time, leaving therotors unprotected and susceptible to impuritiesin the air and to the effects of temperaturevariation. Eventually, this leads to reducedperformance or even compressor failure.After two years of modification and testing,Ingersoll-Rand chose the coating that consistentlyoutperformed all others in adhesion and durabilitytests: UltraCoat. Now, we use UltraCoat toprotect every SIERRA airend.To help our customers get the best performance,we didn’t limit our improvements to the coating.We selected stainless steel and aluminum forthe piping linking the intercooler with the stainlesssteel second-stage rotors. Condensation createdin the cooling process could not corrode thesematerials, eliminating the possibility of rust formationand carry-through, further lengthening the life ofthe coating and rotors.% of Capacity100%95%90%85%80%75%0 500 1,000 2,000 4,000 8,000 16,000 32,000UltraCoat Protection andPerformanceThe first step to full UltraCoat protection is thesuperior surface preparation of our rotors andhousings. As the images on the left show, ourcomponent surface treatments allow for thetightest possible grip for the coating. In the nextstep, UltraCoat is applied using robotics forthe thinnest, most even coat available.Then therotors and housings are heat-cured to solidifythe bond between the coating and the rotor orhousing surface.Competitive CoatingHours of OperationSIERRA ® UltraCoat10% Energy SavingsThe UltraCoat AdvantageWhen compared with other coatings,UltraCoat is a clear winner. Our customersget near-100% capacity and lower energycosts over a longer airend life.67

Intellisys Gives You TotalControl of YourCompressed <strong>Air</strong> DeliveryWhether you need eight hours of continuousduty compressed air or an intermittent supplyover a 24 hour period, Intellisys ® puts youin complete control.TOTAL CONTROL AT YOUR FINGERTIPSWith finger-touch control, an Intellisyscontroller provides quick, comprehensiveaccess to your compressed air system.EASY OPERATIONIntellisys is easy to learn and easy to operate.ADJUSTABLE OPERATING PARAMETERSTo satisfy your system requirements, youcan change your operating parametersquickly and easily.SIERRA OptionsThe SIERRA compressor comes with severaloptions to ensure that you get the rightmachine for your application. If there are anyspecial options or requirements you need,we’ll work with you to find a solution. Justcontact your local Ingersoll-Rand distributor.• Multiple unit sequencer• Remote communications capability• Automatic power outage restart option• Remote starter/no starter• TEFC motors*• Premium efficiency motorsTIMESAVING DIAGNOSTICSIntellisys provides fast diagnosis of systemdemand and displays a warning and/orstops the compressor if it exceeds operatingparameters. This will keep troubleshootingexpenses and downtime to a minimum.COMPREHENSIVE DATA DISPLAYAn easy-to-read, liquid crystal displayprovides you with critical details of yourcompressor’s operation, allowing you tomake fast adjustments when necessary.GIVING YOU COMPLETE FLEXIBILITYWith Intellisys, you are always in control.You can change your operating parametersto maintain the best performance level.• Heavy-duty, high-dust inlet filter• Duplex oil filters• Stainless steel oil piping• No aftercooler• Power phase monitor• NEMA 4 electrical option• Outdoor modification• Low-ambient temperature option• Sitemaster package for portable outdoorapplications• Piping for heat of compression dryer*Standard on 37kW-75kW 50 Hz machines.60 Hz SIERRA 50-400 HP Specifications<strong>Free</strong> <strong>Air</strong> Delivery - CFMNominal HP Model L Model H Model HH L W H Weight100 psig 125 psig 150 psig (in) (in) (in) (lbs)50 214 179 – 88.5 54 75.4 511160 266 229 – 88.5 54 75.4 536475 333 288 *268 88.5 54 75.4 5364100 419 407 *378 88.5 54 75.4 5500125 585 523 477 106 62.5 **93.3/72.5 **6437/6709150 690 690 565 106 62.5 **93.3/72.5 **6452/6724200 911 854 759 106 62.5 **93.3/72.5 **7099/7385250 1182 1070 905 120 76 **96/80 8820300 1398 1264 1112 120 76 **96/80 9090350 1600 1501 1330 120 76 **96/80 9610400 – – 1527 120 76 **96/80 961050 Hz SIERRA 37-300 kW Specifications<strong>Free</strong> <strong>Air</strong> Delivery - M 3 /min.Nominal kW Model SL Model SM Model SH L W H Weight7.0 BARg 8.5 BARg 10.0 BARg (mm) (mm) (mm) (kg)37 6.0 5.1 – 2248 1372 1914 **2387/241045 7.6 6.5 – 2248 1372 1914 **2497/252055 9.6 8.6 *7.7 2248 1372 1914 **2577/260075 12.5 11.6 *10.7 2248 1372 1914 **2682/270590 15.9 13.6 13.0 2692 1588 **2362/1841 **3040/3195110 19.4 18.0 15.3 2692 1588 **2362/1841 **3095/3250132 22.8 21.4 18.8 2692 1588 **2362/1841 **3274/3429150 25.9 24.6 22.1 2692 1588 **2362/1841 **3275/3430200 35.0 32.6 27.4 3048 1930 **2438/2032 4186250 45.2 41.5 35.5 3048 1930 **2438/2032 4306300 – – 43.3 3048 1930 **2438/2032 4366FAD (<strong>Free</strong> <strong>Air</strong> Delivery) CFM and M 3 /min. are full package performance ratings in accordance with CAGI/Pneurop acceptance test standardPN2CPTC2 or ISO 1217.*Available in water-cooled configuration only.**Specification given with air-cooled value first, then water-cooled.1011