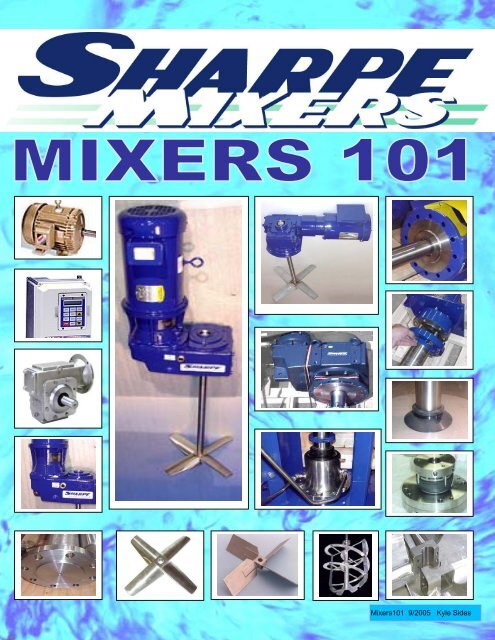

Sharpe Principles of mixing - Tri-Canada

Sharpe Principles of mixing - Tri-Canada

Sharpe Principles of mixing - Tri-Canada

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Motors- Primary purpose: Transmit power and torque to the mixers.Mounting Description Motor/Gearbox/CouplingC-Face MotorsStandard on most mixers. Mounts directly on gearbox C-Face input. Registered fit. Easy to install. Available <strong>of</strong>f theshelf for most motor enclosures. Can be mounted verticalor horizontal. Connects to the gearbox via motor coupling.Foot Mounted MotorsMounts to gearbox with a motor scoop. Used for highhorsepower (20 hp and above) or when a C-Face motor isnot available. Connect to gearbox with flexible motorcoupling. (Standard on V-Belt drives).TEFC Mill & Chem. Duty Washdown Duty Stainless SteelTotally Enclosed Fan Cooledmotors are designed for“General Purpose” operation.Available in 1 phase and 3phase power. Horsepowerrange <strong>of</strong> 1/8 HP through 150HP. 1750 rpm standard.Chemical Processingmotors are designedfor applicationsrequiring protection<strong>of</strong> the motors forsevere operatingconditions.Applications include foodprocessing, packaging,pharmaceuticals, orapplications wheremotors are regularlyexposed to high pressurewash down.All Stainless-Steelmotors (Paint Free)Meet all <strong>of</strong> therequirements <strong>of</strong>Washdown Duty witha stainless steelenclosure.Premium Efficient Explosion Pro<strong>of</strong> DC Motor Air MotorPremium EfficientMotors are designedto conserve energyand reduceoperating costs. Allthree phase motorsare Inverter Ready.XP motors are used in awide variety <strong>of</strong>applications wherehazardous fumes or dustmay be present. Thecustomer must definearea classification.Permanent magnetmotor. Variable speedrequires SCR controller.Standard 90 or 180 VoltDC power. Available inTEFC, XP and washdownenclosure.Air motors are goodcombination <strong>of</strong> speedcontrol and cost.Operating costs arehigher when compared toelectric motor.Recommend filter/lube kitVariable Speed Drives Primary purpose: Control the speed <strong>of</strong> the motorAC Controller -1 Phase (VFD) AC Controller –3 Phase (VFD) DC Control –1ph (SCR)¼ to 1 hp. The VFD Drive is avariable speed control in a NEMA-4X washdown enclosure. It isdesigned for 1ph, 110/220-voltinput and to work with 208-230 Volt3ph “inverter ready” motors. Easyto install and operate. The drivecan be mounted directly to motor ortank sidewall.1 hp to 20 hp. Adjustable speedInverter control for AC motor.Washdown duty NEMA 4X/12enclosures. Designed to work with3-phase inverter ready motors.Includes digital display, pushbutton control and programming.Wall or tank mounted. 3 phaseinput. Many options available.SCR controls are designedto operate with DCmotors. Available in Nema4x washdown dutyenclosure. ¼ hp to 3 hp.Do to its small compactdesign; the drive can bemounted directly to motor.Single-phase input.

Gearbox (Speed Reducer) Primary purpose: Reduce or Increase output shaft speed.Output Shaft OptionsHollow BoreHollow bore gearboxes are themost common and costeffectiveway to install a mixershaft onto a gearbox. Theshaft slides up in the drivewithout the need for shaftcoupling. Preferred when usingany type <strong>of</strong> tank seal.Solid ShaftSolid output shaftsallow the maximumgearbox shaft size.Requires a flanged orsplit style coupling tomount mixer shaft.Gearbox Type Description OptionsE-SeriesRight Angle Worm DrivesThe <strong>Sharpe</strong> Mixers’ compact E-Seriesworm gear drive is a very versatilehollow bore unit that is typically used in1/3 to 5 hp range with output speeds <strong>of</strong>5 to 350 rpm. The low pr<strong>of</strong>ile rightangle design can be tailored to meetmost top entry and side entry <strong>mixing</strong>applications up to 10,000 gallons. Ringbase, plate or flange mounted For openor closed tank applications. Available instandard corrosion resistant epoxycoated unit, white washdown unit or allstainless steel construction.(Reasonably priced).N-SeriesR-SeriesDouble Helical Parallel ShaftThe <strong>Sharpe</strong> Mixers N-Series is an in-linehelical drive with a wide range <strong>of</strong>options. The units are available inhollow or solid output shafts, up to 50different ratios per case size andtypically used in 1-to-150 hp range.Built with heavy duty tapered rollerbearings and Quadrilip Seals on theoutput shaft. Designed for use in topentry, side entry open and closed tanks.Available with optional leak safe“Effective Drywell” (shown right)designed to prevent the gearboxlubricant from contaminating the <strong>mixing</strong>medium. Vertical motor assembly. Highquality for reasonable prices.Heavy Duty RAM drives<strong>Sharpe</strong> Mixers R-Series is a right anglehelical-Spiral-bevel drive designed tohandle the most demandingrequirements <strong>of</strong> <strong>mixing</strong> applications. 5-300 Horse Power. Typically used in hightorque, large tank applications. Unitincludes drywell and oversized drivecomponents. Heavy Duty-ExpensiveOil Safe Design

Mounting Options Primary purpose: Mount mixer to tankRing Base Plate Mount Flange Mount Ferrule MountRing base mountingis standard on E-Series unit. Mountson beams or supportsPlate mount on tankbeams is standard for opentanks. (N and R Series)10° riser also shown.Flange mounting is typicalfor closed tanks with ashaft seal. Meets standardANSI Flange Dimensions.Ferrule clampmounting is <strong>of</strong>tenused in sanitaryapplications.Gearbox Shaft Mounting Options Primary purpose: Mount Shaft to gearboxFlanged Gearbox Coupling Split Coupling Hollow Bore drive stubFlanged couplings are used onsolid output shaft gearboxes.Couplings are registered forexact alignment with matingshaft coupling.Split Couplings are used on gearboxeswith solid output shafts and mixerswith a mechanical seals.Coupling allows for seal removal without removing gearbox.Upper shaft <strong>of</strong> mixer shaftmachined to fit into hollowbore gearbox. Held in placeby a keeper plate and bolt.Typical for most mixers.In-Tank Shaft and Options Primary purpose: connect lower and upper shaftsIn-Tank Couplings Threaded Coupling ShaftsShaft In-Tank couplings areused to separate the shaft intomore manageable lengths.Common for long shafts orwhen space is limited.Sanitary Threaded couplings aretypically used in Pharmaceuticalor Food applications. Used onlonger shafts when all weldedimpellers are required.Pipe shafts. Lightweight &strong. Available in 20’ sections.Used with Split impellers.Solid shafts Small shafts(

Seal Options Primary purpose: hold pressure and liquid in the tankExcluder Seal Dust Cup Vapor Seal Low Pressure High PressureSimple costeffectivedesign. Keepdebris out <strong>of</strong>flat top tanks.Made <strong>of</strong> Bunaor VitonRubber.Dust cups aremade <strong>of</strong>UHMW Plasticand an O-ring.Basic splashguarddesignto fit on top <strong>of</strong>tank nozzle.Flange mountVapor Seal.Designedwith twoBuna or VitonRubber lipseals. 1-2psiratedLow Pressure 2-Ringpacked glands(stuffing boxes) aredesigned for 15psi.Flangedmountunits.High Pressure 7-ringpacked glands are designfor up to 150psi. Usuallynon-Sanitary applications.Flange mounted units.Single Seal Dry Running Split Seal Double Seal LubricatorSingle seals arefor closed tankswith moderatepressures andtemperature.Many optionsavailable, forwet and dryoperation.Dry running sealsrequire no externallubrication. Availablewith Sanitary debriswell and C.I.P. flushport design.Common for foodand Pharmaceuticalapplications.Split Mechanicalseals are a twopieceseals thatare easy toinstall andservice.Compact designdoes not requirecoupling.Double “UniMech” Sealsfor high temp & press.applications. Adjacentbearing minimizes shaftrun out. Designed to beserviced withoutdisturbing drive/shaftassembly. Also availablein cartridge design.LubricationReservoirsare used tolubricateand coolmechanicalseals. Pipedto seal.Impeller Mounting Options Primary purpose: Install impeller onto mixer shaft1-Piece Hub Split clamp-on Hub Split Sanitary All Welded Bolted Blade1-piece impellerattaches to solidshaft withsetscrews.Optional keyway.Clamps onto the shaft.Easy to adjust & remove.Fits thru manway.Optional Keyway orlocking torque pin.Includes O-Ringsand Gaskets atsplit. May bepolished forsanitary use.Used forpolishedsanitary use orcoatings.(Rubber /Halar)Bolt-on bladesare used forexotic alloys,titanium,hastelloy etc.

Impeller Options Primary purpose: Pump liquidProp 1.0 HYF-218 HYF-518 AFT-455 FBT-700Standard 3-BladePropellers aredesigned forsmalldiameterhigh-speedapplications.<strong>Sharpe</strong> Mixers most popularHydr<strong>of</strong>oil style impeller.Generates the most flow forthe least amount <strong>of</strong> power.Reduces operating costs.Improves performance.Max viscosity <strong>of</strong> 5000 cps.Hydr<strong>of</strong>oil-bladeimpellerdesigned forhigher viscosityapplications.More flow, lesspower.Flat Blade AxialFlow Turbinesare typically 45°pitched blade.Used in Higher5,000 – 50,000cps viscosity<strong>mixing</strong>.Four 90° blades.Radial flowimpellers aretypically used as“ticklers” toagitate the bottom<strong>of</strong> a tank.RDT-710 CBT- 730 SBT-100 Folding FBT-455 Stabilizer Ring“Rushton” diskradials areused for highshear & gasdispersion.“Cup” BladeDisk Radialused for gasdispersion.High-speed impellerdesigned for veryhigh shear, at highspeeds.Folding impellers areused on smallimpellers whenimpeller must fit thrusmall mixer nozzle.Stabilizer rings orfins are used to helpstabilize longershafts.Anchor Anchor/Scraper Double Helix Coatings PolishingAnchor styleimpellers areused for highviscosityapplications.Slow speeds.Sweeper style anchorimpellers are used for“sweeping” walls <strong>of</strong>heated tanks withhigh viscosityproducts.Helix styleimpellers usedfor blending &heat transfer <strong>of</strong>high viscosityproductCoatings are usedfor chemical orabrasion resistance.Rubber, Halar, FRP,etc. All weldedassembly.Mechanicalpolishing andelectropolishing.Usedfor sanitaryapplications.Other OptionsLab Testing PB Mixer Portables Technical/Field Service

Side Entry Belt Drive Mixers Primary purpose: MixingV-SeriesSide-Entering<strong>Sharpe</strong> Mixers V-SERIESagitators have proven to be thebest choice for hundreds <strong>of</strong>applications, from large pulp andpaper jobs to asphalt andpetroleum processes. Thesimplicity <strong>of</strong> SHARPE’S V-Beltmixers provides distinctadvantages over other mixerdesigns in installation, operationand maintenance. Wheredowntime is a problem, no othermixer is as dependable, or aseasily serviced. Most all <strong>of</strong> thewearing parts are available fromyour preferred bearing supplyhouse, within 24 hours. Nospecial proprietary gearing,shims, bearings or adapters arerequired.Optional Guards/drain ass’yMechanical Seal w/ LubePortable Mixers Primary purpose: Clamp mount or Fix mounted MixersClamp Mount Cup Plate Plate/Angle Riser Flanged Mounted Ferrule MountedClamps to side<strong>of</strong> tank, beamor stand.Cup platemounts totank beams ortank support.Plate mounts foropen tank tops withsupport beams.Flange mounted unitsfor closed tanks.Vapor seal shown.Sanitary Ferrulesfor use on closedtop tanks.Mixer Stands Primary purpose: Support mixers above tanksMixer Stand(Standard)Stainless standAir lift/SanitaryCustomStandsCaster Wheels(Locking)VFD Mounted