Packed Bed flooding.pdf - Youngstown State University's Personal ...

Packed Bed flooding.pdf - Youngstown State University's Personal ... Packed Bed flooding.pdf - Youngstown State University's Personal ...

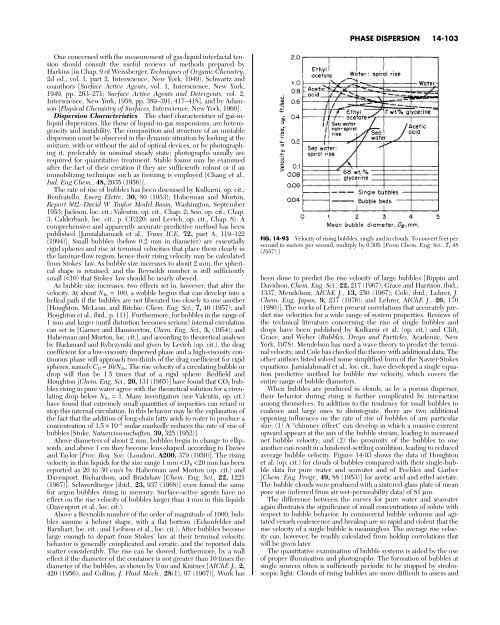

One concerned with the measurement of gas-liquid interfacial tension should consult the useful reviews of methods prepared by Harkins [in Chap. 9 of Weissberger, Techniques of Organic Chemstry, 2d ed., vol. 1, part 2, Interscience, New York, 1949), Schwartz and coauthors [Surface Acttve Agents, vol. 1, Interscience, New York, 1949, pp. 263–271; Surface Active Agents and Detergents, vol. 2, Interscience, New York, 1958, pp. 389–391, 417–418], and by Adamson [Physical Chemistry of Surfaces, Interscience, New York, 1960]. Dispersion Characteristics The chief characteristics of gas-inliquid dispersions, like those of liquid-in-gas suspensions, are heterogeneity and instability. The composition and structure of an unstable dispersion must be observed in the dynamic situation by looking at the mixture, with or without the aid of optical devices, or by photographing it, preferably in nominal steady state; photographs usually are required for quantitative treatment. Stable foams may be examined after the fact of their creation if they are sufficiently robust or if an immobilizing technique such as freezing is employed [Chang et al., Ind. Eng Chem., 48, 2035 (1956)]. The rate of rise of bubbles has been discussed by Kulkarni, op. cit.; Benfratello, Energ Elettr., 30, 80 (1953); Haberman and Morton, Report 802: David W. Taylor Model Basin, Washington, September 1953; Jackson, loc. cit.; Valentin, op. cit., Chap. 2; Soo, op. cit., Chap. 3; Calderbank, loc. cit., p. CE220; and Levich, op. cit., Chap. 8). A comprehensive and apparently accurate predictive method has been published [Jamialahamadi et al., Trans ICE, 72, part A, 119–122 (1994)]. Small bubbles (below 0.2 mm in diameter) are essentially rigid spheres and rise at terminal velocities that place them clearly in the laminar-flow region; hence their rising velocity may be calculated from Stokes’ law. As bubble size increases to about 2 mm, the spherical shape is retained, and the Reynolds number is still sufficiently small (

14-104 EQUIPMENT FOR DISTILLATION, GAS ABSORPTION, PHASE DISPERSION, AND PHASE SEPARATION require careful technique. Satisfactory photographic methods have been developed by Vermenlen, Williams, and Langlois [Chem. Eng. Progr., 51, 85 (1955)] and by Calderbank [Trans. Instn. Chem. Engrs., 36, 443 (1958)] and are described by these authors. Calderbank’s technique resulted in particularly precise measurements that permitted a good estimation of the surface area of the dispersed bubbles. Methods of Gas Dispersion The problem of dispersing a gas in a liquid may be attacked in several ways: (1) The gas bubbles of the desired size or which grow to the desired size may be introduced directly into the liquid; (2) a volatile liquid may be vaporized by either decreasing the system pressure or increasing its temperature; (3) a chemical reaction may produce a gas; or (4) a massive bubble or stream of gas is disintegrated by fluid shear and/or turbulence in the liquid. Spargers: Simple Bubblers The simplest method of dispersing gas in a liquid contained in a tank is to introduce the gas through an open-end standpipe, a horizontal perforated pipe, or a perforated plate at the bottom of the tank. At ordinary gassing rates (corresponding to the jet regime), relatively large bubbles will be produced regardless of the size of the orifices. Perforated-pipe or -plate spargers usually have orifices 3 to 12 mm in diameter. Effective design methods to minimize maldistribution are presented in the fifth edition of this handbook, p. 5–47, 1973, and by Knaebel [Chem. Eng., 116 (Mar. 9, 1981)]. For turbulent flow conditions into the sparger, the following relationship will allow design of a perforated-pipe sparger for a given degree of maldistribution provided N h > 5 and length/diameter

- Page 1 and 2: Previous Page 14-58 EQUIPMENT FOR D

- Page 3 and 4: 14-60 TABLE 14-13 Characteristics o

- Page 5 and 6: 14-62 EQUIPMENT FOR DISTILLATION, G

- Page 7 and 8: 14-64 EQUIPMENT FOR DISTILLATION, G

- Page 9 and 10: 14-66 EQUIPMENT FOR DISTILLATION, G

- Page 11 and 12: 14-68 EQUIPMENT FOR DISTILLATION, G

- Page 13 and 14: 14-70 EQUIPMENT FOR DISTILLATION, G

- Page 15 and 16: 14-72 EQUIPMENT FOR DISTILLATION, G

- Page 17 and 18: 14-74 EQUIPMENT FOR DISTILLATION, G

- Page 19 and 20: 14-76 EQUIPMENT FOR DISTILLATION, G

- Page 21 and 22: 14-78 (a) (b) (c) FIG. 14-71 High-v

- Page 23 and 24: 14-80 EQUIPMENT FOR DISTILLATION, G

- Page 25 and 26: 14-82 EQUIPMENT FOR DISTILLATION, G

- Page 27 and 28: 14-84 EQUIPMENT FOR DISTILLATION, G

- Page 29 and 30: 14-86 EQUIPMENT FOR DISTILLATION, G

- Page 31 and 32: 14-88 EQUIPMENT FOR DISTILLATION, G

- Page 33 and 34: 14-90 EQUIPMENT FOR DISTILLATION, G

- Page 35 and 36: 14-92 EQUIPMENT FOR DISTILLATION, G

- Page 37 and 38: 14-94 EQUIPMENT FOR DISTILLATION, G

- Page 39 and 40: 14-96 EQUIPMENT FOR DISTILLATION, G

- Page 41 and 42: 14-98 EQUIPMENT FOR DISTILLATION, G

- Page 43 and 44: 14-100 EQUIPMENT FOR DISTILLATION,

- Page 45: 14-102 EQUIPMENT FOR DISTILLATION,

- Page 49 and 50: 14-106 EQUIPMENT FOR DISTILLATION,

- Page 51 and 52: 14-108 EQUIPMENT FOR DISTILLATION,

- Page 53 and 54: 14-110 EQUIPMENT FOR DISTILLATION,

- Page 55 and 56: 14-112 EQUIPMENT FOR DISTILLATION,

- Page 57 and 58: 14-114 EQUIPMENT FOR DISTILLATION,

- Page 59 and 60: 14-116 EQUIPMENT FOR DISTILLATION,

- Page 61 and 62: 14-118 EQUIPMENT FOR DISTILLATION,

- Page 63 and 64: 14-120 EQUIPMENT FOR DISTILLATION,

- Page 65 and 66: 14-122 EQUIPMENT FOR DISTILLATION,

- Page 67 and 68: 14-124 EQUIPMENT FOR DISTILLATION,

- Page 69 and 70: 14-126 EQUIPMENT FOR DISTILLATION,

- Page 71 and 72: 14-128 EQUIPMENT FOR DISTILLATION,

One concerned with the measurement of gas-liquid interfacial tension<br />

should consult the useful reviews of methods prepared by<br />

Harkins [in Chap. 9 of Weissberger, Techniques of Organic Chemstry,<br />

2d ed., vol. 1, part 2, Interscience, New York, 1949), Schwartz and<br />

coauthors [Surface Acttve Agents, vol. 1, Interscience, New York,<br />

1949, pp. 263–271; Surface Active Agents and Detergents, vol. 2,<br />

Interscience, New York, 1958, pp. 389–391, 417–418], and by Adamson<br />

[Physical Chemistry of Surfaces, Interscience, New York, 1960].<br />

Dispersion Characteristics The chief characteristics of gas-inliquid<br />

dispersions, like those of liquid-in-gas suspensions, are heterogeneity<br />

and instability. The composition and structure of an unstable<br />

dispersion must be observed in the dynamic situation by looking at the<br />

mixture, with or without the aid of optical devices, or by photographing<br />

it, preferably in nominal steady state; photographs usually are<br />

required for quantitative treatment. Stable foams may be examined<br />

after the fact of their creation if they are sufficiently robust or if an<br />

immobilizing technique such as freezing is employed [Chang et al.,<br />

Ind. Eng Chem., 48, 2035 (1956)].<br />

The rate of rise of bubbles has been discussed by Kulkarni, op. cit.;<br />

Benfratello, Energ Elettr., 30, 80 (1953); Haberman and Morton,<br />

Report 802: David W. Taylor Model Basin, Washington, September<br />

1953; Jackson, loc. cit.; Valentin, op. cit., Chap. 2; Soo, op. cit., Chap.<br />

3; Calderbank, loc. cit., p. CE220; and Levich, op. cit., Chap. 8). A<br />

comprehensive and apparently accurate predictive method has been<br />

published [Jamialahamadi et al., Trans ICE, 72, part A, 119–122<br />

(1994)]. Small bubbles (below 0.2 mm in diameter) are essentially<br />

rigid spheres and rise at terminal velocities that place them clearly in<br />

the laminar-flow region; hence their rising velocity may be calculated<br />

from Stokes’ law. As bubble size increases to about 2 mm, the spherical<br />

shape is retained, and the Reynolds number is still sufficiently<br />

small (