WinMOD Configurations (WinMOD 7.0) WinMOD Configurations

WinMOD Configurations (WinMOD 7.0) WinMOD Configurations

WinMOD Configurations (WinMOD 7.0) WinMOD Configurations

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

eal plant<br />

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

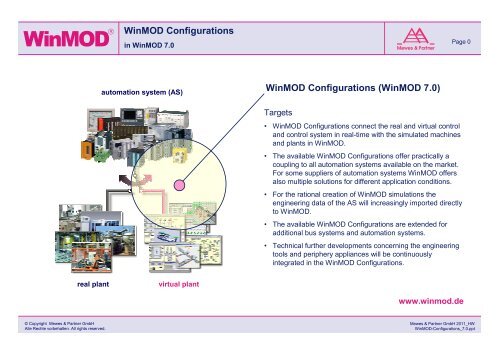

<strong>WinMOD</strong> <strong>Configurations</strong><br />

in <strong>WinMOD</strong> <strong>7.0</strong><br />

automation system (AS)<br />

virtual plant<br />

Mewes & Partner<br />

<strong>WinMOD</strong> <strong>Configurations</strong> (<strong>WinMOD</strong> <strong>7.0</strong>)<br />

Targets<br />

Page 0<br />

<strong>WinMOD</strong> <strong>Configurations</strong> connect the real and virtual control<br />

and control system in real-time with the simulated machines<br />

and plants in <strong>WinMOD</strong>.<br />

The available <strong>WinMOD</strong> <strong>Configurations</strong> offer practically a<br />

coupling to all automation systems available on the market.<br />

For some suppliers of automation systems <strong>WinMOD</strong> offers<br />

also multiple solutions for different application conditions.<br />

For the rational creation of <strong>WinMOD</strong> simulations the<br />

engineering data of the AS will increasingly imported directly<br />

to <strong>WinMOD</strong>.<br />

The available <strong>WinMOD</strong> <strong>Configurations</strong> are extended for<br />

additional bus systems and automation systems.<br />

Technical further developments concerning the engineering<br />

tools and periphery appliances will be continuously<br />

integrated in the <strong>WinMOD</strong> <strong>Configurations</strong>.<br />

www.winmod.de<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

Automation System:<br />

S7-PLCSIM<br />

S7-PCS7<br />

S7-PCS7<br />

Rockwell<br />

B&R-PLC/ APROL<br />

AS neutral: OPC<br />

PHOENIX CONTACT<br />

PHOENIX CONTACT<br />

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

<strong>WinMOD</strong> <strong>Configurations</strong><br />

<strong>WinMOD</strong> <strong>7.0</strong><br />

New – and further development in the overview<br />

<strong>WinMOD</strong> Configuration:<br />

A750 coupling, virtual PLC<br />

A770 memory access area; I/O,M,DB<br />

A780 PROFIBUS DP & PROFINET-Emulation<br />

B110 specific coupling over EtherNet/IP<br />

I300 I/O-simulation driver<br />

Y500 coupling; AS-neutral<br />

X520 INTERBUS emulation for PLCs and AS-neutral<br />

X700 PROFINET I/O emulation for PLCs<br />

Access:<br />

Mewes & Partner<br />

new license necessary<br />

scope of software maintenance<br />

scope of software maintenance<br />

scope of software maintenance<br />

new license necessary<br />

scope of software maintenance<br />

scope of software maintenance<br />

new license necessary<br />

Page 1<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

AS neutral field bus emulation<br />

real PROFIBUS network<br />

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

<strong>WinMOD</strong> <strong>Configurations</strong> with <strong>WinMOD</strong> <strong>7.0</strong><br />

Configuration A740 (AS neutral PROFIBUS DP emulation)<br />

(e.g. for PLC/ PLS from: ABB, B&R, Beckhoff, Emerson, Mitsubishi, Siemens, … )<br />

PROFIBUSemulatorPCIcard<br />

PCI<br />

emulated PROFIBUS network<br />

Mewes & Partner<br />

Page 2<br />

For all Automation Systems (AS) with PROFIBUS<br />

Master<br />

With the AS neutral PROFIBUS DP emulation<br />

<strong>WinMOD</strong> is connected to all AS, where the I/O<br />

periphery is connected over one/several PROFIBUS<br />

networks in the real project or for the simulation to the<br />

entire periphery simulation as PROFIBUS periphery<br />

replaceable, as basis for virtual commissioning.<br />

The generation of the emulated PROFIBUS networks<br />

occurs very rational with the integrated PROFIBUS<br />

editor and/or for selected automation systems via<br />

structure import.<br />

The library of the simulated PROFIBUS appliances<br />

will be generated in the PROFIBUS editor through<br />

import of the corresponding GSD file.<br />

Utilizable PROFIBUS Simulation Components:<br />

PROFIBUS simulation card (PC PCI card) with one<br />

simulation channel (max. 125 PROFIBUS DP-Slave)<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

Complete virtual test- and training simulators for SIMATIC S7 Systems.<br />

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

<strong>WinMOD</strong> <strong>Configurations</strong> with <strong>WinMOD</strong> <strong>7.0</strong><br />

Configuration A750 (SIMATIC S7 PLCSIM 120 interconnection, virt. PLC)<br />

Mewes & Partner<br />

For SIMATIC S7/ PCS7 Simulation PLCSIM<br />

Page 3<br />

For SIMATIC PLCSIM version V5.4-SP3, PLCSIM has<br />

multi-instance ability. The <strong>WinMOD</strong> Configuration<br />

A750 supports now an additional direct access to the<br />

periphery address areas, flags, data blocks and the<br />

multi-instance ability from PLCSIM.<br />

<strong>WinMOD</strong> Configuration A750 ST (standard)<br />

<strong>WinMOD</strong> coupling to a PLCSIM-instance with:<br />

read/write modus of the with PLCSIM simulated<br />

-S7-I/O-memory areas<br />

-S7-I/O-periphery areas<br />

-S7-flags<br />

-S7-data blocks<br />

-<strong>WinMOD</strong> Configuration A750 XT (extended)<br />

<strong>WinMOD</strong> coupling to PLCSIM-multi-instances<br />

(currently up to 8) with:<br />

read/write modus of the with PLCSIM simulated<br />

- S7-I/O-memory areas<br />

- S7-I/O-periphery areas<br />

- S7-flags<br />

- S7-data blocks<br />

Advantages:<br />

With the system coupling between <strong>WinMOD</strong> and<br />

SIMATIC S7 Simulation PLCSIM it is possible to<br />

realize cost-efficient test- and training simulations.<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

MPI<br />

S7-CPU Memory Area<br />

DBx.<br />

DB10. DBX0.0-0.7<br />

DB2. DBX0.0-0.7 …<br />

DBX0.0-0.7 …DBB10<br />

…<br />

…DBB10<br />

DBW16 … …<br />

DBB10 DBW16 DBD254 … … …<br />

DBW16 DBD254 A0.0-0.7 … …<br />

DBD254 A1.0 … -1.7<br />

E0.0-0.7 …<br />

E1.0 -1.7 AB10 …<br />

… AW16 …<br />

EB10 … AD254 …<br />

EW16 …<br />

ED254 …<br />

<strong>WinMOD</strong> <strong>Configurations</strong> with <strong>WinMOD</strong> <strong>7.0</strong><br />

Configuration A770 (S7-memory area access; I/O,M,DB)<br />

Netlink<br />

MPI RS232/MPI-converter<br />

M0.0-0.7<br />

M1.0 -1.7<br />

…<br />

MB10 …<br />

MW16 …<br />

MD254 …<br />

Ethernet<br />

memory access to<br />

SIMATIC S7/PCS7 System<br />

RS232<br />

Mewes & Partner<br />

For SIMATIC S7/ PCS7 Automation Systems<br />

Direct access of <strong>WinMOD</strong> to SIMATIC S7-CPUmemory<br />

areas.<br />

S7-CPU Memory Area:<br />

read/write in and of:<br />

- S7-I/O-memory areas<br />

- S7-flags<br />

- S7-data blocks<br />

System Coupling Over<br />

- direct Ethernet connection via TCP/ IP<br />

- MPI with Netlink (TCP/ IP to MPI-converter)<br />

- MPI with RS232 to MPI-converter<br />

Advantages:<br />

Page 4<br />

Simulation of additional communication lines, for<br />

example couplings of other controllers or devices that<br />

are not included in the test.<br />

Recording of S7-internal data with the <strong>WinMOD</strong>-<br />

Recorder.<br />

Simple coupling of S7-Systems by copying I/Omemory<br />

mappings (please regards restrictions !).<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

PROFINET<br />

Slave-network<br />

PROFIBUS DP Slavenetwork<br />

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

<strong>WinMOD</strong> <strong>Configurations</strong> with <strong>WinMOD</strong> <strong>7.0</strong><br />

Configuration A780<br />

(S7-specific PROFIBUS DP & PROFINET- simulation)<br />

PROFINET-Emulator Box<br />

PROFIBUS-Emulator Box<br />

real PROFIBUS- /PROFINET network<br />

PCI<br />

Ethernet<br />

emulated PROFIBUS- / PROFINET network<br />

Mewes & Partner<br />

For SIMATIC S7/ PCS7 Automation System<br />

(SIMATIC S7-3xx / 4-xx / C7 / WinAC, … ) with<br />

PROFINET<br />

Page 5<br />

The <strong>WinMOD</strong> Configuration A 780 was specially<br />

developed for SIEMENS AS with PROFIBUS-DP and<br />

PROFINET Master. The <strong>WinMOD</strong> Configuration<br />

includes SIEMENS specific emulation functions and<br />

allows also the coupling of H-Systems and Fail-Safe<br />

Systems.<br />

The real I/O-periphery can be simulated completely or<br />

partially. It is possible to connect one or several AS<br />

with one or several networks.<br />

The generation of the emulated PROFIBUS-<br />

/PROFINET networks is carried out utmost rational by<br />

structure import of data from the STEP7-hardware<br />

configuration.<br />

Suitable PROFIBUS Simulation Components:<br />

PROFIBUS simulation cards (PC PCI-cards) with one<br />

simulation channel (max. 125 PROFIBUS DP-Slave)<br />

PROFIBUS emulator box<br />

available variants:<br />

2 / 4 / - channel (125 PROFIBUS DP-Slave)<br />

Suitable PROFINET Simulation Components:<br />

PROFINET emulator box<br />

available variants:<br />

1 - channel (128 PROFINET-Slave)<br />

Advantage:<br />

Connection to the simulation-PC over Ethernet.<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

<strong>WinMOD</strong> Configuration with <strong>WinMOD</strong> <strong>7.0</strong><br />

B110 (Rockwell specific-interconnection over EtherNet/IP)<br />

Replacement of the real I/O periphery areas (Local-I/O, DeviceNet, ControlNet, EtherNet/IP with „direct tag access“ via EtherNet/IP)<br />

Local I/O; DeviceNet; ControlNet; EtherNet/IP<br />

RS Logix5000<br />

EtherNet/IP<br />

direct IO simulation<br />

(direct tag access)<br />

Mewes & Partner<br />

For Rockwell PLC (Allen-Bradley)<br />

Logix Family (ControLogix)<br />

Page 6<br />

<strong>WinMOD</strong> Configuration B110 was specifically<br />

developed for the simulation of all I/O-tags for<br />

Rockwell-Controllers. It is a rational and cost-efficient<br />

solution, since it requires no specific hardware, for the<br />

simulation of all I/O-tags, as basis for the realization of<br />

the virtual commissioning.<br />

An optimal workflow consists of:<br />

1.Export of the I/O-tag structure from the AS<br />

development environment (RS Logix 5000).<br />

2.Direct import to <strong>WinMOD</strong> with automatic<br />

generation of the simulated I/O-tag structure and<br />

linked alias correlations of the PLC program variables.<br />

This allows a rational and automatic generation of the<br />

I/O- simulation.<br />

In the PLC-program, the real I/O-driver has only to be<br />

deactivated („inhibit“ in RS Logix 5000-dialog).<br />

Advantages:<br />

The solution for the I/O-simulation is independent from<br />

the real planned I/O-periphery (local I/Os, DeviceNet,<br />

ControlNet, EtherNet/IP).<br />

Technical requirement is only an EtherNet/IPscanner<br />

component in all control systems.<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

B&R I/O systems: OnBoard, X200, Powerlink<br />

B&R Automation Studio TM<br />

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

<strong>WinMOD</strong> Configuration with <strong>WinMOD</strong> <strong>7.0</strong><br />

I300 (B&R-I/O simulation driver for PLC and APROL)<br />

EtherNet/IP<br />

direct I/O simulation<br />

For Automation Systems of B&R<br />

(Bernecker + Rainer):<br />

- X200 control system<br />

- APROL process control system<br />

Mewes & Partner<br />

<strong>WinMOD</strong> Configuration I300 was specifically<br />

developed for B&R. It offers a cost-efficient and<br />

rational solution for the simulation of all B&R-specific<br />

I/O-systems and requires no specific hardware.<br />

Page 7<br />

The system coupling is suitable for all real B&R<br />

controllers with available B&R-driver „WinIO“, as well<br />

as for the virtual controller AR000 Automation<br />

Runtime TM AR000 that is integrated into the B&R<br />

Automation Studio TM .<br />

The workflow is highly optimized:<br />

1.Online import of the I/O-tag structure which is<br />

obtained directly from the connected B&R-controller.<br />

2.Direct tag import from the Automation StudioTM (e.g. via clipboard from the IO-mapping table).<br />

Advantages:<br />

Only the ,,WinIO“-driver has to be inserted into the ASproject<br />

in the Automation StudioTM . Afterwards each<br />

I/O-channel can be locked or unlocked for simulation<br />

access.<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

OPC server n<br />

OPC (AS-spezifisch)<br />

server 2<br />

OPC (ASserver specific) 1<br />

(AS specific)<br />

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

<strong>WinMOD</strong> <strong>Configurations</strong> with <strong>WinMOD</strong> <strong>7.0</strong><br />

Y500 (OPC interconnection; AS neutral)<br />

Ethernet<br />

indirect I/O simulation<br />

over OPC<br />

OPC-Client n<br />

OPC-Client 2<br />

OPC client 1<br />

Texte.<br />

Mewes & Partner<br />

Open coupling with OPC to different control- and<br />

process control systems, other simulation<br />

systems, external database, etc.<br />

Page 8<br />

The <strong>WinMOD</strong> Configuration Y500 provides OPCclients<br />

as <strong>WinMOD</strong> periphery drivers (OPC-DA, Data<br />

Access). Every configured OPC-client Y500 driver is<br />

able to communicate with exactly one OPC-server.<br />

For the communication with several OPC-servers it is<br />

possible to configure several OPC-client Y500 drivers<br />

(requires <strong>WinMOD</strong> System Software XT).<br />

The suitability of OPC for coupling automation systems<br />

for I/O-simulation has to be verified on a case to case<br />

basis.<br />

Advantages<br />

Cost-efficient I/O simulation (via OPC-variables).<br />

Replacement of real communication connections (for<br />

example coupling to other control systems or<br />

components which are not available during testing<br />

phase).<br />

Data recording from OPC-variables and open coupling<br />

to all systems. That means to any kind of external<br />

application with OPC-server.<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

INTERBUS G4<br />

PC WORX<br />

<strong>WinMOD</strong> <strong>Configurations</strong> with <strong>WinMOD</strong> <strong>7.0</strong><br />

<strong>WinMOD</strong> Configuration X520<br />

(INTERBUS simulation; for PHOENIX CONTACT PLC and AS-neutral)<br />

Ethernet<br />

TCP/ IP<br />

INTERBUS G4<br />

Emulator<br />

direct I/O simulation<br />

INTERBUS G4 emulation<br />

Mewes & Partner<br />

Page 9<br />

For all Automation Systems (AS) with INTERBUS-<br />

Master (INTERBUS G4-standard).<br />

With the AS neutral INTERBUS emulation <strong>WinMOD</strong> is<br />

connected to all AS, where the I/O-periphery in the real<br />

project is connected with one or several INTERBUS<br />

networks.<br />

An optimal workflow for the generation of the<br />

emulated INTERBUS network is specifically<br />

developed to the automation system of PHOENIX<br />

CONTACT.<br />

The AS program software PC WORX exports special<br />

XML-data which are used for <strong>WinMOD</strong>. These XMLdata<br />

are needed in order to generate automatically<br />

the simulated INTERBUS structure during the import<br />

process in <strong>WinMOD</strong>. Moreover these data are also<br />

transferred into the connected INTERBUS emulator.<br />

At the same time all I/O operands which are connected<br />

with the bus-structure are transferred into the <strong>WinMOD</strong><br />

project.<br />

For the INTERBUS simulation to several other kinds of<br />

automation systems with INTERBUS master it is<br />

possible to develop adapted workflows.<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

PC WORX<br />

<strong>WinMOD</strong> <strong>Configurations</strong> with <strong>WinMOD</strong> <strong>7.0</strong><br />

X700 (PROFINET IO Device-Emulator; for PHOENIX CONTACT PLC)<br />

PROFINET I/O<br />

Ethernet standard interface<br />

direct I/O simulation<br />

PROFINET emulation<br />

Mewes & Partner<br />

Page 10<br />

For all Automation System (AS) of PHOENIX<br />

CONTACT with PROFINET-Master.<br />

Using the specifically developed PROFINET emulation<br />

<strong>WinMOD</strong> is connected to automation systems, where<br />

the periphery of the AS is connected to one or multiple<br />

PROFINET networks in the real project or for the<br />

simulation of complete periphery simulation as<br />

PROFIRNET periphery.<br />

An optimal workflow for the generation of the<br />

emulated PROFINET networks is especially<br />

developed for the automation systems of PHOENIX<br />

CONTACT.<br />

The AS-program software PC WORX exports special<br />

XML-data which are used for <strong>WinMOD</strong>. These XMLdata<br />

are used to generate automatically the<br />

simulated PROFINET structure during the import<br />

process in <strong>WinMOD</strong>.<br />

At the same time all I/O-operands which are connected<br />

with the bus-structure are transferred into the <strong>WinMOD</strong><br />

project (export-/import process currently under<br />

development).<br />

3 variants (licensable):<br />

- cyclic IO device emulation (max. 254)<br />

- additonal safty layer emulation (saftey devices)<br />

-addinitional acyclic data transfer<br />

The PROFINET emulation is carried out with a special<br />

developed Windows kernel-application. Suitable<br />

Ethernet-network hardware (mostly standard-Ethernetnetwork<br />

cards) need the approval by Mewes &<br />

Partner.<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

For any AS-Controller mit PROFINET IO<br />

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

<strong>WinMOD</strong>-Konfigurationen <strong>WinMOD</strong> <strong>7.0</strong><br />

X700 (PROFINET IO Device-Emulator; for any PROFINET-Controller)<br />

PROFINET IO<br />

PLC – hardware configuration<br />

with different Profinet IO-Device<br />

Ethernet standard interface<br />

PCI<br />

simulated PROFINET IO devices<br />

For all Automation Systems (AS)<br />

with PROFINET IO-Master<br />

Mewes & Partner<br />

Page 11<br />

With <strong>WinMOD</strong> Configuration X700 any PROFINET IOparticipant<br />

can be simulated (emulated) and can be<br />

connected to any automation system (AS) with<br />

PROFINET IO-controller.<br />

The PROFINET devices that are to be simulated are<br />

configured in the <strong>WinMOD</strong> PROFINET Configurator<br />

manually or automatically online.<br />

For selected automation systems, additional functions<br />

for workflow optimisation of signal list import and<br />

export can be developed and provided.<br />

one Variant (AS-neutral, licensable):<br />

- cyclic IO device emulation (up to 254)<br />

Usage:<br />

Support for development and test of single AS<br />

program functions and complete AS programs,<br />

independent from a correctly planned IO-periphery.<br />

No special is hardware required.<br />

The PROFINET-Emulation is executed by an<br />

especially developed Windows kernel application. The<br />

Ethernet network hardware has to be approved by<br />

Mewes & Partner. Typically a standard Ethernet<br />

network card can be used.<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt

for any AS-Controller with PROFINET IO<br />

© Copyright Mewes & Partner GmbH<br />

Alle Rechte vorbehalten. All rights reserved.<br />

<strong>WinMOD</strong>-Konfigurationen <strong>WinMOD</strong> <strong>7.0</strong><br />

Configuration X700-ND<br />

(PROFINET IO Normdevice for uUniversal IO-Simulation)<br />

PROFINET IO<br />

PLC – hardware configuration<br />

with PROFINET IO-Normdevice<br />

Slots for in-/output moduls<br />

per slot max. 128 Byte IO-adress space<br />

Ethernet standard interface<br />

PCI<br />

simulated PROFINET IO-Normdevice<br />

For all Automation Systems (AS)<br />

with PROFINET IO-Master<br />

Mewes & Partner<br />

Page 12<br />

The PROFINET Normdevice is imported by its<br />

GSDML-file in the PROFINET configurator of the AS<br />

and is parameterized with the required IO-modules.<br />

In the <strong>WinMOD</strong> PROFINET Configurator the<br />

Normdevice that is to be simulated is configured<br />

manually or automatically online.<br />

This enables a general simulation of IO-ranges for any<br />

type of AS.<br />

two Variants (licensable) :<br />

<strong>WinMOD</strong>-PROFINET-Normdevice ST<br />

-24 slots, up to 256/256 cyclic I/O-Byte<br />

<strong>WinMOD</strong>-PROFINET-Normdevice XT<br />

-128 slots, up to 1024/1024 cyclic I/O-Byte<br />

Usage:<br />

Support for development and test of single AS<br />

program functions and complete AS programs,<br />

independent from a correctly planned IO-periphery.<br />

No special is hardware required.<br />

The PROFINET-Emulation is executed by an<br />

especially developed Windows kernel application. The<br />

Ethernet network hardware has to be approved by<br />

Mewes & Partner. Typically a standard Ethernet<br />

network card can be used.<br />

Mewes & Partner GmbH 2011_HW<br />

<strong>WinMOD</strong>-<strong>Configurations</strong>_<strong>7.0</strong>.ppt