Carbopol Ultrez 21 Polymer Technical Data Sheet

Carbopol Ultrez 21 Polymer Technical Data Sheet

Carbopol Ultrez 21 Polymer Technical Data Sheet

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

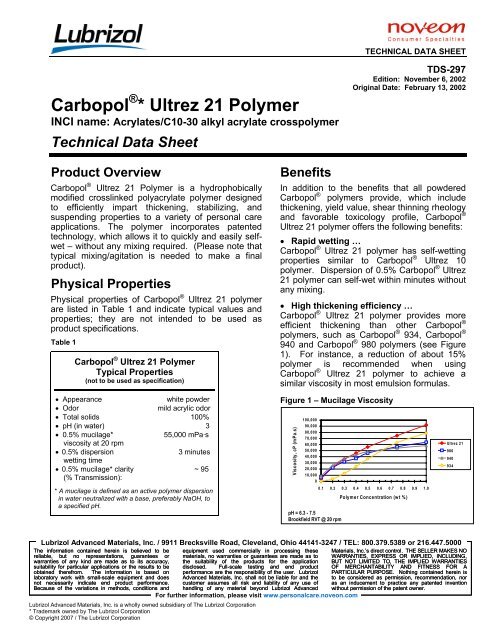

TECHNICAL DATA SHEET<strong>Carbopol</strong> ® * <strong>Ultrez</strong> <strong>21</strong> <strong>Polymer</strong>INCI name: Acrylates/C10-30 alkyl acrylate crosspolymer<strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>TDS-297Edition: November 6, 2002Original Date: February 13, 2002Product Overview<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> <strong>Polymer</strong> is a hydrophobicallymodified crosslinked polyacrylate polymer designedto efficiently impart thickening, stabilizing, andsuspending properties to a variety of personal careapplications. The polymer incorporates patentedtechnology, which allows it to quickly and easily selfwet– without any mixing required. (Please note thattypical mixing/agitation is needed to make a finalproduct).Physical PropertiesPhysical properties of <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymerare listed in Table 1 and indicate typical values andproperties; they are not intended to be used asproduct specifications.Table 1<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> <strong>Polymer</strong>Typical Properties(not to be used as specification)BenefitsIn addition to the benefits that all powdered<strong>Carbopol</strong> ® polymers provide, which includethickening, yield value, shear thinning rheologyand favorable toxicology profile, <strong>Carbopol</strong> ®<strong>Ultrez</strong> <strong>21</strong> polymer offers the following benefits:• Rapid wetting …<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer has self-wettingproperties similar to <strong>Carbopol</strong> ® <strong>Ultrez</strong> 10polymer. Dispersion of 0.5% <strong>Carbopol</strong> ® <strong>Ultrez</strong><strong>21</strong> polymer can self-wet within minutes withoutany mixing.• High thickening efficiency …<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer provides moreefficient thickening than other <strong>Carbopol</strong> ®polymers, such as <strong>Carbopol</strong> ® 934, <strong>Carbopol</strong> ®940 and <strong>Carbopol</strong> ® 980 polymers (see Figure1). For instance, a reduction of about 15%polymer is recommended when using<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer to achieve asimilar viscosity in most emulsion formulas.• Appearancewhite powder• Odormild acrylic odor• Total solids 100%• pH (in water) 3• 0.5% mucilage*55,000 mPa·sviscosity at 20 rpm• 0.5% dispersion3 minuteswetting time• 0.5% mucilage* clarity ~ 95(% Transmission):* A mucilage is defined as an active polymer dispersionin water neutralized with a base, preferably NaOH, toa specified pH.Figure 1 – Mucilage ViscosityViscosity, cP (mPa.s)100,00090,00080,00070,00060,00050,00040,00030,00020,00010,0000pH = 6.3 - 7.5Brookfield RVT @ 20 rpm0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0<strong>Polymer</strong> Concentration (wt %)<strong>Ultrez</strong> <strong>21</strong>980940934Lubrizol Advanced Materials, Inc. / 9911 Brecksville Road, Cleveland, Ohio 44141-3247 / TEL: 800.379.5389 or <strong>21</strong>6.447.5000The information contained herein is believed to beequipment used commercially in processing theseMaterials, Inc.’s direct control. THE SELLER MAKES NOreliable, but no representations, guarantees ormaterials, no warranties or guarantees are made as toWARRANTIES, EXPRESS OR IMPLIED, INCLUDING,warranties of any kind are made as to its accuracy,the suitability of the products for the applicationBUT NOT LIMITED TO, THE IMPLIED WARRANTIESsuitability for particular applications or the results to bedisclosed. Full-scale testing and end productOF MERCHANTABILITY AND FITNESS FOR Aobtained therefrom.The information is based onperformance are the responsibility of the user. LubrizolPARTICULAR PURPOSE. Nothing contained herein islaboratory work with small-scale equipment and doesnot necessarily indicate end product performance.Because of the variations in methods, conditions andAdvanced Materials, Inc. shall not be liable for and thecustomer assumes all risk and liability of any use ofhandling of any material beyond Lubrizol Advancedto be considered as permission, recommendation, noras an inducement to practice any patented inventionwithout permission of the patent owner.For further information, please visit www.personalcare.noveon.comLubrizol Advanced Materials, Inc. is a wholly owned subsidiary of The Lubrizol Corporation* Trademark owned by The Lubrizol Corporation© Copyright 2007 / The Lubrizol Corporation

Page 2 of 4• Improved electrolyte tolerance …<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer provides superiorelectrolyte tolerance compared to most <strong>Carbopol</strong> ®polymers, resulting in improved clarity and higherviscosity in electrolyte containing systems.Figure 2 – Salt ToleranceViscosity, cP (mPa·s)100,00090,00080,00070,00060,00050,00040,00030,00020,00010,00000.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0Brookfield RVT @ 20 rpmNaCl Concentration (wt %)• Excellent clarity …<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer provides excellentclarity to applications such as hair gels and handsanitizers.• Smooth aesthetic appearance …<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer provides a non-grainyglossy appearance to gels and emulsions similar togels and emulsions made with <strong>Carbopol</strong> ® 940 and934 polymers.• Superior skin feel …<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer is less tacky than other<strong>Carbopol</strong> ® polymers.• Broad application use …<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer has the best overallperformance in a wide variety of applications whencompared with other <strong>Carbopol</strong> ® polymers.Suggested Applications<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer can be used in a widevariety of applications, such as:• Hair Styling Gels• Hand and Body Lotions• Baby Lotions• Hand Sanitizers• Moisturizing Gels• Sunscreen Lotions• Bath Gels• Shampoos<strong>Ultrez</strong> <strong>21</strong><strong>Ultrez</strong> 10Processing GuidelinesThe development of the self-wetting technology hasgreatly improved the dispersability of <strong>Carbopol</strong> ®polymers - especially in water. These polymersbehave differently in their dispersion as well ashydration rates and need to be processed andhandled in a slightly different manner.980Using No Agitation (Self-Wetting) -PreferredThis is the preferred method of dispersion andwill result in less entrapped air.In most situations, <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong>polymer can simply be “sprinkled” onto thesurface of the water without any specialequipment or handling.The powder will wet and drop below thesurface in minutes. When there is no visiblewhite powder on the water surface, mixing canbegin.Using Moderate to High AgitationDispersions can also be prepared by slowlysifting the polymer into the vortex of a rapidlystirred solution, although this technique mayentrap more air.Techniques or devices which sprinkle thepowder as discrete particles are the mosteffective. The ideal method should efficientlysprinkle the polymer at a controlled rate as wellas break-up the soft agglomerates of drypowder formed by static electricity or humidconditions. This allows each particle tocompletely wet out in the water vortex.In general, high shear rates disperse thepolymer very rapidly; however, extremely highshear mixers or homogenizers should becarefully employed because they can breakdown the polymer molecule - resulting inpermanent viscosity loss. Moderate agitationequipment is the preferred choice.Conventional impellers such as propellers orturbines are recommended.Wetting Time, Dispersion Viscosity, andOthersThe total wetting time is dependent upon theamount of <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer added,vessel geometry, and most importantly, watertemperature. When the <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong>polymer dispersion is first neutralized, thesurface texture may have a grainy“applesauce” appearance. Over the next 30-60 minutes, the neutralized gel clusterscontinue to relax and expand. Light mixing willyield a smooth gel.Some users choose to predisperse <strong>Carbopol</strong> ®<strong>Ultrez</strong> <strong>21</strong> polymer in water and then add thisdispersion to their formulation mix tank. Unlikethe traditional <strong>Carbopol</strong> ® polymers, <strong>Carbopol</strong> ®<strong>Ultrez</strong> <strong>21</strong> polymer can be dispersed atconcentrations up to 6% and still remainpumpable. See Figure 3.

Page 3 of 4Figure 3 – Dispersion ViscosityFigure 5 – Effect of pH on ViscosityViscosity, cP (mPa·s)90,00080,00070,00060,00050,00040,00030,00020,00010,00000.0 1.0 2.0 3.0 4.0 5.0<strong>Polymer</strong> Concentration (wt %)Viscosity, cP (mPa·s)70,00060,00050,00040,00030,00020,00010,000NaOH - 18 (wt %)Brookfield RVT @ 20 rpm03 4 5 6 7 8 9 10 11 12pH<strong>Ultrez</strong> <strong>21</strong><strong>Ultrez</strong> 10ETD 2020ETD 2050<strong>Ultrez</strong> <strong>21</strong> <strong>Ultrez</strong> 10 ETD 2001 980 940Under high shear agitation, dispersions of <strong>Carbopol</strong> ®<strong>Ultrez</strong> <strong>21</strong> polymer can stabilize entrapped air.Antifoam, at use levels of 0.02 - 0.05%, can beadded to the water prior to the <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong>polymer in order to minimize or eliminate foaming.Figure 4 – Effect of Water Temperature on Wetting TimeWetting Time (minutes)6543<strong>21</strong>00 10 20 30 40 50 60 70 80Water Temperature (°C)*Note: Some large undispersed particles were observed at 60°CRecommended Dispersion Temperature: 25 - 55°CWater temperature can help speed the dispersionand swelling process. With traditional carbomers,warm water is avoided because of lumping problemsit incurs. With <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer,however, any heating needed for formulation canbegin before or during the dispersion process. Asfigure 4 shows, the wetting time of the polymerdecreases with warmer temperatures to about 55°C.Once above this temperature, the effect is reversedand lumping may result.Formulating GuidelinesIn most situations, <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymershould be added to the water at the start of the batchcycle. This will allow it time to thoroughly wet out anddisperse. At this point, the pH will be about 3 with avery low viscosity.NeutralizationUpon neutralization, the <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymerinstantly thickens as shown in Figure 5.Because of the high viscosity, the addition ofthe neutralizing agent is often best addedtowards the end of the batch cycle. Forformulations with high levels of electrolytes orsurfactants, the addition of a small amount ofthe neutralizer to the <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong>polymer dispersion is beneficial (partialneutralization).Different neutralizers can be used, and differentamounts are needed for the dispersion to reacha pH value of 7.0. Table 2 provides the weightratios of commonly used neutralizers vs.<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer to achieve pH 7.For a complete list of neutralizers that can beused with <strong>Carbopol</strong> ® polymers, see TDS-237 -Neutralizing <strong>Carbopol</strong> ® and Pemulen ®<strong>Polymer</strong>s in Aqueous and HydroalcoholicSystems.Table 2Weight ratios of commonly used neutralizers vs.<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer to achieve pH 7Neutralizer TradeName/SupplierNeutralizer INCINameWeight Ratio –Neutralizer /<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong>TEA (99%) Triethanolamine 1.5 / 1.0AMP-95 ® / AngusAminomethyl0.9 / 1.0PropanolNeutrol ® TE / BASF Tetrahydroxypropyl2.3 / 1.0EthylenediamineNaOH (18%) Sodium Hydroxide 2.3 / 1.0Diisopropanolamine /DowDiisopropanolamine 1.2 / 1.0Preservation<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer does not supportbacteria or fungal growth, but neither does itprevent such growth on nutrients found innormal water systems. The addition of apreservative is recommended for applicationsinclined to these issues.

Page 4 of 4<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer is compatible with mostpreservatives, such as Germaben ® II, DMDMHydantoin, Dowici ® l 200, Parabens and Phenonip ® .Phenonip ® has limited solubility in clear gelformulations, which may result in reduced clarity.CompatibilityThe viscosity of products with <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong>polymer is moderately sensitive to ions. Increasedlevels of monovalent ions (like sodium) will result in adecrease in application viscosity. The effect can beminimized by the use of potassium salts or amineneutralizing agents. Di-and multi-valent ions (likecalcium and magnesium) will precipitate <strong>Carbopol</strong> ®polymers. Therefore, formulating with deionized (orat least soft) water is highly recommended.Due to its anionic nature, <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong>polymer has limited compatibility with cationicformulating materials.Handling and Storage<strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer is supplied in 20-kilogram cardboard boxes.In the dry form, <strong>Carbopol</strong> ® <strong>Ultrez</strong> <strong>21</strong> polymer is stablefor a long period of time. It is important, however, tokeep the containers tightly closed to prevent moisturepick-up.See the Material Safety <strong>Data</strong> <strong>Sheet</strong> for <strong>Carbopol</strong> ®<strong>Ultrez</strong> <strong>21</strong> polymer for further information on theproper handling and safety aspects of this product.