Download PDF... (1.1 mb) - Eastech Flow Controls

Download PDF... (1.1 mb) - Eastech Flow Controls

Download PDF... (1.1 mb) - Eastech Flow Controls

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

®WASTEWATERCOSTMANAGEMENTPROGRAMA Billing and <strong>Flow</strong> AnalysisSystem for ControllingMunicipal Sewage Treatment CostsCONSULTING ENGINEERLOCAL MUNICIPALITYWASTEWATER DISTRICT

®The requirement for Interagency wastewater billing is alwayscarried out under harsh sewer conditions. Sewers are continuallypolluted with sludge, solids, fibers, grease and oil. Structuralconditions often mean difficult hydraulic conditions. <strong>Flow</strong>measurement ranges will vary from extremely low levels atnight, to high levels during the day, to surcharge levels duringextreme periods of rain.What does this all mean for municipalities and industries thathave their wastewater treated by independent facilities thatcharge for these services? It means that anyone involved withthe process of either paying for sewage treatment or chargingfor that treatment should be totally familiar with the myriad ofconditions that can quickly add up to thousands of dollars.UNLESS A BILLING COST MANAGEMENT SYSTEM IS PUT INTOPLACE THAT CAN RECOGNIZE FLOW UNDER ALL CONDITIONS,THOUSANDS OF DOLLARS IN QUESTIONABLE BILLINGS ORLOST INCOME WILL QUICKLY ACCUMULATE FOR RAIN EVENTS,REVERSE FLOWS, STAGNATION, BLOCKAGES, SURCHARGESAND NON-UNIFORM HYDRAULIC CONDITIONS.2

THE COSTVIEW PROGRAMTHE SOLUTIONFOR CONTROLLINGMUNICIPAL SEWAGETREATMENT COSTSEvery Municipality and large industry in the country is underintense pressure to cut costs from their yearly operating budgets.Cost-allocation billings to communities that contribute flowageinto municipal systems are now changing over from proratedpopulation-based cost assessments to billings that are calculatedfrom actual volumetric data. A recent survey by the NUS ConsultingGroup determined that during the past five years the averagenational wastewater treatment rate rose 28.6%. The AverageNational Billing Rate in 2007 was calculated to be $3.88/1000 Gal.In addition, the U.S. Department of Justice has penalized morethan 50 city and county wastewater systems for violations of theU.S. EPA’s 1994 co<strong>mb</strong>ined sewer overflow rules and now, Congresshas proposed a bill that would toughen enforcement withrequirements for monitoring and community notification of bothCo<strong>mb</strong>ined and Sanitary Sewer Overflows.CostView addresses each of these issues by providing both thehardware and diagnostic tools for ultimately reducing potentiallyescalating treatment costs and eliminating governmental agencyfines through a system of constant monitoring and analysis ofconditions within the wastewater collection system.High Performance Billing MeterThe Municipality responsible for satisfying wastewatertreatment charges can either purchase or lease aCostView Billing and <strong>Flow</strong> Analysis Meter from <strong>Eastech</strong> Corporation.A Hybrid Technology <strong>Flow</strong> Meter (see page 8), capable of monitoringand measuring volumetric wastewater flow under all openchannel conditions, is installed within the collection system at anagreed upon point of measurement. Proprietary algorithmscompile and convert the collected data into cost form, which inturn, is presented to the Municipality in a simple and easy to readpie chart format (see Page 4).Billing Cost AnalysisGraphically displayed Cost Analysis Reports (see Page 4)are generated on a monthly basis that describe in detailbilling costs for distinct categories of flow conditions. Municipalmanagers may now access a highly accurate window depictingthe exact conditions under which wastewater charges are beinggenerated. Billing cost treatment charges are categorized into sixmajor areas that include normal diurnal flows, inflow and infiltration,reverse flows, stagnation, surcharges and non-uniform flowconditions. Upon review of the categorized data, areas for potentialcost savings can be highlighted for immediate or future action.Collection System <strong>Flow</strong> AnalysisOnce cost-intensive collection system conditions arepinpointed, municipal administrators may begindeveloping plans for a reduction in capital outlays. Whether inpartnership with a professional consulting firm or through theutilization of in-house personnel, CostView’s <strong>Flow</strong> Analysis Program(see Page 5) will assist in determining the problematic areas onwhich to focus. Through the continual capture of historical flowdata, diagnostic algorithms are presented in a simple graphicalformat for review by those familiar with the intricacies of thewastewater collection system.CostView’s High Performance Billing Meter, in conjunction with it’sCost and <strong>Flow</strong> Analysis reporting capability, provides the insightrequired to make intelligent decisions concerning the physicalstate of a municipalities collection system network while providingthe necessary data for deciding whether a capital improvementproject is economically justifiable.3

®BILLING ANALYSISREPORTSCostView Billing Analysis Reports not only bring documented proofto all parties concerned that the charges levied for wastewatertreatment are both fair and correct, but when utilized to their fullestextent, create the potential for either lowering existing costs ormaintaining them under tight fiscal control.Monthly Treatment Volume: 31 million GallonsWastewater Billing Cost: $3.88/1000 Gal. 1MONTHLY BILLING COST REPORT (Typical Example, May, 2008)WASTEWATER VOLUME (Mil.Gal.) AT-A- GLANCEWASTEWATER COST ($) AT-A-GLANCENormal <strong>Flow</strong> Conditions (77%)Inflow & Infiltration 2 (18%)23.87 Mil. Gal.($92,615)Reverse <strong>Flow</strong> Conditions (3%)Non-Uniform <strong>Flow</strong> Conditions (2%)1A survey by the NUS Consulting Group determined that theaverage national wastewater rate rose 28.6% during the pastfive years. Average National Rate (2007): $3.88/1000 Gal.2According to a recent AMSA survey (Association ofMetropolitan Sewage Agencies), inflow and infiltration (alongwith storm water that goes to a treatment plant) comprisesalmost 25% of total flows. The Massachusetts Water ResourcesAuthority (MWRA), in 1998, calculated inflow and infiltration asaccounting for 60% of total flows.2008 Monthly Volume History (Mil. Gal.)5.58 Mil. Gal.($21,650).93 Mil. Gal.($3,608).62 Mil. Gal.($2,405)Surcharge Events . . . . . . . . . . 2Stagnation . . . . . . . 14.88 hoursTREATMENT COST: YEAR TO DATE (5/31/08)28.429.2 31.7 33.2 31.0Jan. Feb. March April MayNormal <strong>Flow</strong>Probable I & IMiscellaneousTOTAL ANNUAL COST$476,464$89,337$29,779$595,580EXAMPLEIn the above example, Cost Savings of over $250,000 per year can be achieved by reducing I&I from15% to 5%, detecting Reverse and Stagnant <strong>Flow</strong>s, eliminating EPA fines for Sewer Overflows andavoiding Potential Lawsuits for sewage backing up into residential developments.4

®FLOW ANALYSIS REPORTSCostView <strong>Flow</strong> Analysis Reports provide operating personnelwith a clear picture of exactly what is transpiring within thecollection system environment. This detailed information maybe employed as a proactive tool to identify areas of potentialsurcharges, inflow and infiltration, maintenance issues andprevention of illegal discharges. If utilized in conjunction witha local consulting engineering firm, CostView Analysis Reportsbecome an important first step towards the implementation ofdiscovering weaknesses within the system. Once rectified, theelimination of these weaknesses can lead to substantialreductions in wastewater treatment charges.G1Inflow & FiltrationUpon establishment of a Normal Dry Day <strong>Flow</strong> baseline, abnormallyhigh flows, plotted against both the Dry Day baseline and thetemperature data acquired from the thermocouple e<strong>mb</strong>edded withinthe Sensor Cartridge, will alert to the possibility of inflow from local rainevents or infiltration due to groundwater or parking lot runoff.G1FLOWPROBABLE I & IG2Surcharge EventsAn integrated ultrasonic level sensor with cellular transmissioncapability will proactively alert local operating personnel of thepossibility of a sewer overflow event. The capability for early warning ofa potential surcharge will lead the way to reductions in governmentalagency fines. In the event that the Surcharge incident cannot beavoided, Costview will graphically record the time and duration of theoverflow for adherence to current EPA reporting requirements.G2LEVELDIURNAL FLOWTEMPERATURETIMESURCHARGE EVENTG3StagnationThe monitoring of Normal Dry Day <strong>Flow</strong>s and Levels against periodsof Stagnation may be utilized to alert maintenance crews to possibleconditions of upstream or downstream blockages.G3PROBABLE BLOCKAGETIMEG4Illegal DischargesIllegal discharges have always been an issue for every community.Whether it is from a large industrial facility or from the connecting ofrain gutters to the nearest sewer line, these discharges translate intoadditional treatment fees for each taxpayer in the community.By detecting abnormal spikes graphically captured within Normal DryDay <strong>Flow</strong> sequences, a plan of action may be put into place in orderto discover the source of illegal discharge, eventually leading to arecovery of costs through court mandated monetary restitution.FLOWG4FLOWDIURNAL FLOWTIMESURCHARGE LEVEL MONITORPROBABLE ILLEGAL DISCHARGEDIURNAL FLOW TIME5

COMPARATIVE COST ANALYSISFlume / Level Sensor Co<strong>mb</strong>inationFlumes, besides being time consuming and expensive to install,lose their ability to measure flow in the event of debris or blockages,require non-turbulent flow conditions, are incapable of detecting reverseflows, cease to function during periods of extreme wet weather andrecognize stagnation and zero flow as normal flow.COST ANALYSISWastewater Billing Cost: $3.88/1000 Gal. 1Daily Treatment Volume: 2 MGDYearly Treatment Volume: 730 Million GallonsNormal <strong>Flow</strong> Conditions (70%)Inflow & Infiltration (15%) 2A Flume is incapable of identifying I&IReverse <strong>Flow</strong> Conditions (3%)Flumes recognize reverse flows as normal forward flowStagnant <strong>Flow</strong> Conditions (2%)Flumes recognize zero flow as normal forward flowSurcharge/Submergence Conditions (8%)Flumes cease to function under conditions of submergence$424,860$84,972$56,648$226,592$56,648$1,982,680Non-Uniform <strong>Flow</strong> Conditions (2%)Flumes lose their accuracy doing turbulent flow conditions1A survey by the NUS Consulting Group determined that theaverage national wastewater rate rose 28.6% during the pastfive years. Average National Rate (2007): $3.88/1000 Gal.2According to a recent AMSA survey (Association ofMetropolitan Sewage Agencies), inflow and infiltration (alongwith storm water that goes to a treatment plant) comprisesalmost 25% of total flows. The Massachusetts Water ResourcesAuthority (MWRA), in 1998, calculated inflow and infiltration asaccounting for 60% of total flows.Normal <strong>Flow</strong>Inflow & InfiltrationReverse <strong>Flow</strong>StagnationSurcharge/SubmergenceNon-Uniform <strong>Flow</strong>TOTAL ANNUAL COSTANNUAL COST$1,982,680$424,860$84,972$56,648$226,592$56,648$2,832,4006

Hybrid Cartridge MeterHybrid Cartridge Meters co<strong>mb</strong>ine U.S. Bureau of Reclamation computer aidedHydraulic Structure design with high accuracy Custody Transfer multipathtechnology and NIST Traceable <strong>Flow</strong> Lab Calibration to create the first HighPerformance Wastewater Billing Meter. The Cartridge Meter’s technologyallows for precise and highly accurate wastewater measurement that includeperiods of reverse, surcharge, stagnant and non-uniform flow conditions.COST ANALYSISWastewater Billing Cost: $3.88/1000 Gal. 1Daily Treatment Volume: 2 MGDYearly Treatment Volume: 730 Million GallonsNormal <strong>Flow</strong> Conditions$1,982,680$141,620$33,989$0.0$0.0$0.0Inflow & Infiltration 2I&I identified through temperature gradient analysisReverse <strong>Flow</strong> ConditionsVelocity sensors recognize and identify reverse flowsStagnant <strong>Flow</strong> ConditionsVelocity sensors recognize and identify zero flowSurcharge/Submergence ConditionsIntegral Level Monitor alerts to impending surcharge conditionsNon-Uniform <strong>Flow</strong> ConditionsMultipath technology accurately measures non-uniformflow conditionsANNUAL COSTNormal <strong>Flow</strong>Inflow & InfiltrationReverse <strong>Flow</strong>StagnationSurcharge/SubmergenceNon-Uniform <strong>Flow</strong>TOTAL ANNUAL COSTIdentified & ReducedIdentified & DeductedIdentified & DisregardedIdentified & EliminatedAccurately Measured$1,982,680$141,620$0$0$0$33,989$2,158,289ANNUAL COST SAVINGS$674,1117

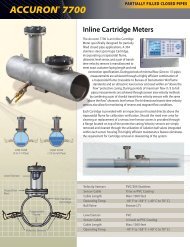

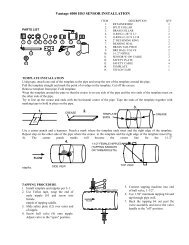

CUSTODY TRANSFER BILLING METERSMeasurement of minimalflows is accomplishedthrough WinFlume*Hydraulic Structuretechnology supported byNIST traceable <strong>Flow</strong> Labdesign confirmation.*Bureau of ReclamationMeasurement of averageto maximum flows isaccomplished throughdual path transit- timetechnology specificallydeveloped for thecustody transfer ofhydrocarbons.Measurement ofnon-uniform flows isaccomplished throughcrossed path transit-timetechnology specificallydeveloped for thecustody transfer ofnatural gas.HIGH PERFORMANCEHYBRID TECHNOLOGYThe engineers at <strong>Eastech</strong> concluded that in order to provide a solutionthat was capable of achieving any degree of reasonable accuracy duringthe majority of the billing period, a new “application specific” flowmetertechnology would have to be developed. CostView® Billing Meterscouple WinFlume computer aided Hydraulic Structure design with highaccuracy Custody Transfer technology. Today, multipath transit-timeflow meters are the first choice for custody transfer applications in the oiland natural gas industry. This is why <strong>Eastech</strong> has chosen to provide thisidentical technology for custody transfer measurement of wastewater.CostView co<strong>mb</strong>ines two proven flow measurement technologies,Hydraulic Structures and Multiple Transit-TimeSensors, with NIST Traceable <strong>Flow</strong> Lab Calibration to createthe first High Performance Sewer Billing Meter.CARTRIDGE: 304 Stainless Steel.TRAPEZOIDAL FLUME: Bureau of ReclamationWinFlume software is utilized for the design ofevery trapezoidal flume. Winflume software wasdeveloped to meet unique operational requirementswhile eliminating the need for laboratorycalibrations.ULTRASONIC LEVEL SENSOR: In a 5 year levelsensor study by the Bureau of Reclamation,<strong>Eastech</strong> was the only sensor to successfullypenetrate through dish soap foam while displayingalmost perfect linearity, hysteresis close tozero, and excellent long-term reliability.BILLING METERULTRASONIC LEVEL SENSORCARTRIDGETRANSIT-TIME VELOCITY SENSORS:In 1998, the American Gas Association approvedAGA Report #9. AGA-9 sets the standard formultiple path transit-time flow meters in naturalgas custody transfer applications. <strong>Eastech</strong> hasfollowed the lead of the AGA by utilizing theidentical technology in order to provide themunicipal market with a Custody TransferWastewater Billing Meter.TRANSIT-TIME VELOCITY SENSORSTEMPERATURE SENSORTRAPEZOIDAL FLUME8

®OPEN CHANNEL FLOW TECHNOLOGYFOR THE 21ST CENTURYLaboratory TraceabilityPrior to shipment, every High PerformanceBilling Meter is individuallytested, calibrated and certified at<strong>Eastech</strong>'s in-house <strong>Flow</strong> MetrologyLab. All flow meter calibrations aredirectly traceable to Standardsestablished by the NIST and areavailable for real time viewingthrough scheduled Internet access.Guaranteed Installed Accuracy& 30 minute InstallationA stainless Cartridge, pre-sized for itsspecific application, arrives at the jobsite as a fully integrated unit. Everycomponent is factory precisionaligned, calibrated and programmed instrict accordance to customer suppliedoperating specifications.SENSOR SELF-VALIDATIONMaintenance-Free OperationBy utilizing “above the flow” ultrasoniclevel sensors and non-fouling velocitysensors, the Cartridge Meter remains freefrom the ongoing problems of sedimentbuild-up, fouled sensors and accumulateddebris. The flat straight throughbottom of the trapezoidal flume permitsdebris to pass quite easily and reducesthe problem of sediment build-upupstream of the flume.Self-ValidationCostView provides state-of-the-arttechnology for self-validation of sensorcalibration stability without the needfor confined space entry. STATUS IQeliminates manhole entry safetyconcerns through remote verificationof flow meter sensor accuracy.Level Sensor ValidationDuring normal operation, ultrasoniclevel sensor readings are self-validatedby continuously recording andcomparing the ultrasonic signal to aknown reference distance securelyfixed within the stainless frame of theCartridge. This method also allows forself-recalibration of the level sensorduring daily temperature variations.Velocity Sensor ValidationAlso during normal operation,velocity sensor readings are selfvalidatedby repeatedlycomparingvolume at a certain height calculatedby the area-velocity transit-timemethod to the known volume at thisidentical height previously calculatedby the flume/level sensorco<strong>mb</strong>ination.9

HIGH PERFORMANCE UNDER ALL FLOW CONDITIONSMinimal <strong>Flow</strong>s(Accuracy: ±1–2%)In 95% of sanitary sewers, average flow isonly 30% - 40% of the pipe diameter withnighttime flows hovering around 5% - 10%.The trapezoidal flume permits for a widermeasurement range than other flumes whileefficiently passing sediment and debris.<strong>Eastech</strong>'s <strong>Flow</strong> Laboratory has confirmedaccurate measurements down to 15 GPM ina 12” I.D. pipe.During periods of minimal flow (0- 30% Pipe I.D.), trapezoidal flumetechnology in co<strong>mb</strong>ination withan “above the flow” precisionaccuracy (+/-.02”) ultrasonic levelsensor is utilized to ascertain thecorrect volume of wastewater.Average to Maximum <strong>Flow</strong>s(Uniform & Non-uniform)(Accuracy: ±1–2%)The recently published EPA Report 600/R-06-120-2006 states that “Accuracy of flowmeasurements vary greatly depending onflow conditions. Depending upon theassumed flow profile, errors can exceed 25%of the true flow rate under poor conditions.MULTIPATH INSTRUMENTS MAY HAVEERRORS AS LOW AS 1% TO 3% OF THE TRUEFLOW RATE.”1000During periods of average tomaximum flows (30 –100% PipeI.D.), wastewater volume ismeasured by a dual pair of highlyaccurate transit-time velocitysensors in conjunction with aprecision (±.02”) ultrasonic levelsensor.Borrowing from the multipath technologyutilized for custody transfer of oil and naturalgas, a dual pair of transit-time velocity sensorsare strategically positioned within theCartridge at 30% of the sewer I.D. Dependingupon severity and type of non-uniformity, thecrossed pattern sensors will provide highaccuracy measurement during turbulent,disturbed and asymmetrical flow conditions.GALLONS PER MINUTE800600400010 20 30 40 50 60 70 80MINUTESAs can be seen from the following graph generated during months of testingat our <strong>Flow</strong> Metrology Lab, a non-uniform flow disturbance is negated byaveraging the volumetric totals of each separate Path. Path 1 andPath 2 added together and then averaged creates the volumetricaverage shown as Dataline A. When compared to the actual volume,Dataline B, calculated simultaneously from volumetrically determinedreference measurements recorded at the <strong>Flow</strong> Lab, we see that the averageof both paths, Dataline A, and the actual volume, Dataline B recorded by the<strong>Flow</strong> Lab, are practically identical.10

®Inflow & Infiltration(Accuracy: ±1–2%)A standard thermocouple is incorporatedwithin the housing of each Sensor Cartridgein order to monitor the temperature of thewastewater. Wastewater temperature,emanating from homes and businesses,hardly varies during the year as compared toexternal watershed temperatureSince there exists a definite temperaturegradient between the morevariable outside water sources andthe source of the wastewater, thismethod can serve as an inexpensivegauge for determining the existenceof inflow and infiltration.Reverse <strong>Flow</strong>(Accuracy: ±1–2%)Reverse flows, caused by instances of backwateringor surcharges, may cause errors in thebilling process. Hydraulic structures, inco<strong>mb</strong>ination with a level sensor, recognize allmanner of flow as traveling in a forwarddirection. The CrossFire provides redundantmonitoring of flow under both forward andreverse conditions.Once the level of sewage rises abovethe capacity of the flume, which isnormally the condition duringback-watering caused by downstrea<strong>mb</strong>lockages or surchargeevents, reverse flows are redundantlyconfirmed by each individual pair oftransit-time sensors.Stagnant Conditions(Accuracy: ±1–2%)Stagnation is primarily caused by a downstrea<strong>mb</strong>lockage requiring maintenance for reinstatementof normal flow conditions. Since this typeof blockage will usually cause a rise in level, ahydraulic structure only Billing System willconsider these high levels of sewage asmaximum periods of flow, thereby elevatingtreatment charges.The possibility of paying fortreatment of sewage that has neverarrived at the processing facility isnow eliminated through redundantvelocity sensor monitoring of “zeroflow” conditions. In addition, alarmsmay be initiated to alert maintenancepersonnel of the situation.Surcharge Conditions(Accuracy: ±1–2%)To allow for the monitoring of conditions thatchange from normal open channel flow tosubmerged flow, as experienced during astorm event or downstream blockage, anindependent, maintenance-free level sensor islocated at the highest point of the manholecapable of immediately detecting surchargingconditions..The optional Surcharge Monitor, inconjunction with each pair ofvelocity sensors, maintains uninterruptedmonitoring of forward andreverse flows. Field personnel maynow oversee both dry and wetweather flow conditions withoutencountering the need for repetitivemanhole entry.11

4250 S. 76th E. Ave.Tulsa, OK 74145email: info@eastechflow.com918-664-1212800-226-3569Fax: 918-664-8494www.eastechflow.com