SAFETY PRECAUTIONS

SAFETY PRECAUTIONS SAFETY PRECAUTIONS

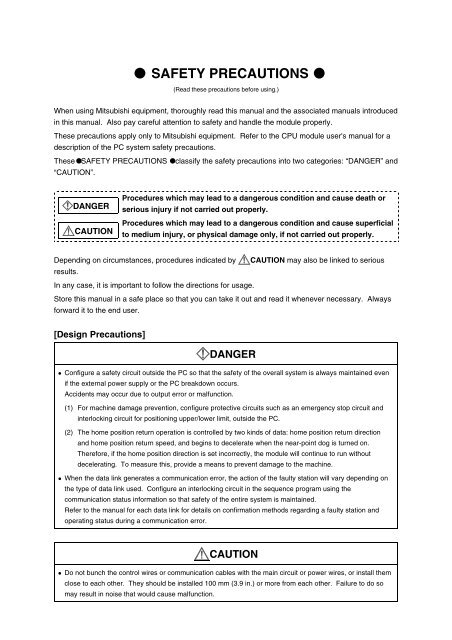

SAFETY PRECAUTIONS(Read these precautions before using.)When using Mitsubishi equipment, thoroughly read this manual and the associated manuals introducedin this manual. Also pay careful attention to safety and handle the module properly.These precautions apply only to Mitsubishi equipment. Refer to the CPU module user's manual for adescription of the PC system safety precautions.These SAFETY PRECAUTIONS classify the safety precautions into two categories: “DANGER” and“CAUTION”.DANGERCAUTIONProcedures which may lead to a dangerous condition and cause death orserious injury if not carried out properly.Procedures which may lead to a dangerous condition and cause superficialto medium injury, or physical damage only, if not carried out properly.Depending on circumstances, procedures indicated by CAUTION may also be linked to seriousresults.In any case, it is important to follow the directions for usage.Store this manual in a safe place so that you can take it out and read it whenever necessary. Alwaysforward it to the end user.[Design Precautions]DANGER! Configure a safety circuit outside the PC so that the safety of the overall system is always maintained evenif the external power supply or the PC breakdown occurs.Accidents may occur due to output error or malfunction.(1) For machine damage prevention, configure protective circuits such as an emergency stop circuit andinterlocking circuit for positioning upper/lower limit, outside the PC.(2) The home position return operation is controlled by two kinds of data: home position return directionand home position return speed, and begins to decelerate when the near-point dog is turned on.Therefore, if the home position direction is set incorrectly, the module will continue to run withoutdecelerating. To measure this, provide a means to prevent damage to the machine.! When the data link generates a communication error, the action of the faulty station will vary depending onthe type of data link used. Configure an interlocking circuit in the sequence program using thecommunication status information so that safety of the entire system is maintained.Refer to the manual for each data link for details on confirmation methods regarding a faulty station andoperating status during a communication error.CAUTION! Do not bunch the control wires or communication cables with the main circuit or power wires, or install themclose to each other. They should be installed 100 mm (3.9 in.) or more from each other. Failure to do somay result in noise that would cause malfunction.

- Page 2 and 3: [Installation Precautions]CAUTION!

- Page 5 and 6: About This ManualsThe following man

- Page 7 and 8: 3.4.6 JOG speed ...................

- Page 9 and 10: 7.16 Present Feed Value Clear Funct

- Page 11 and 12: 10.4.8 Dwell time at home position

- Page 13 and 14: Part 1Function Explanation VolumePa

- Page 15 and 16: 1. Overview MELSEC-A1.1 FeaturesThe

- Page 17 and 18: 1. Overview MELSEC-A1.2 Purpose of

- Page 19 and 20: 1. Overview MELSEC-A(4) Circular in

- Page 21 and 22: 1. Overview MELSEC-A1.4.2 Positioni

- Page 23 and 24: 1. Overview MELSEC-A1.4.4 Operation

- Page 25 and 26: 1. Overview MELSEC-A1.4.6 Overview

- Page 27 and 28: 1. Overview MELSEC-A1.4.8 Overview

- Page 29 and 30: 1. Overview MELSEC-A(4) Data-set ty

- Page 31 and 32: 1. Overview MELSEC-A1.5.1 Cyclic tr

- Page 33 and 34: 1. Overview MELSEC-A1.6 General Pro

- Page 35 and 36: 1. Overview MELSEC-A1.8 Parts Suppl

- Page 37 and 38: 2. System Configuration MELSEC-A2.2

- Page 39 and 40: 2. System Configuration MELSEC-A2.4

- Page 41 and 42: 3. Specification MELSEC-A3.2 Perfor

- Page 43 and 44: 3. Specification MELSEC-A3.2.2 Spec

- Page 45 and 46: 3. Specification MELSEC-A(2) Specif

- Page 47 and 48: 3. Specification MELSEC-A10) Speed/

- Page 49 and 50: 3. Specification MELSEC-A(c)Interna

- Page 51 and 52: 3. Specification MELSEC-A3.3 I/O Si

<strong>SAFETY</strong> <strong>PRECAUTIONS</strong>(Read these precautions before using.)When using Mitsubishi equipment, thoroughly read this manual and the associated manuals introducedin this manual. Also pay careful attention to safety and handle the module properly.These precautions apply only to Mitsubishi equipment. Refer to the CPU module user's manual for adescription of the PC system safety precautions.These <strong>SAFETY</strong> <strong>PRECAUTIONS</strong> classify the safety precautions into two categories: “DANGER” and“CAUTION”.DANGERCAUTIONProcedures which may lead to a dangerous condition and cause death orserious injury if not carried out properly.Procedures which may lead to a dangerous condition and cause superficialto medium injury, or physical damage only, if not carried out properly.Depending on circumstances, procedures indicated by CAUTION may also be linked to seriousresults.In any case, it is important to follow the directions for usage.Store this manual in a safe place so that you can take it out and read it whenever necessary. Alwaysforward it to the end user.[Design Precautions]DANGER! Configure a safety circuit outside the PC so that the safety of the overall system is always maintained evenif the external power supply or the PC breakdown occurs.Accidents may occur due to output error or malfunction.(1) For machine damage prevention, configure protective circuits such as an emergency stop circuit andinterlocking circuit for positioning upper/lower limit, outside the PC.(2) The home position return operation is controlled by two kinds of data: home position return directionand home position return speed, and begins to decelerate when the near-point dog is turned on.Therefore, if the home position direction is set incorrectly, the module will continue to run withoutdecelerating. To measure this, provide a means to prevent damage to the machine.! When the data link generates a communication error, the action of the faulty station will vary depending onthe type of data link used. Configure an interlocking circuit in the sequence program using thecommunication status information so that safety of the entire system is maintained.Refer to the manual for each data link for details on confirmation methods regarding a faulty station andoperating status during a communication error.CAUTION! Do not bunch the control wires or communication cables with the main circuit or power wires, or install themclose to each other. They should be installed 100 mm (3.9 in.) or more from each other. Failure to do somay result in noise that would cause malfunction.

[Installation Precautions]CAUTION! Use the PC in the environment given in the general specifications of this manual. Using the PC outside therange of the general specifications may result in electric shock, fire or malfunction, or may damage ordegrade the module.! Tighten the module installation screws with the specified torque. If the screws are loose, it may result inshort circuits, malfunction or cause the module to fall out.If the screws are tightened too much, it may damage the screws and the module may result in short circuits,malfunction or cause the module to fall out.! Do not directly touch the conducted part of the module or electric parts. This may cause malfunction orbreakdowns.! Make sure connectors for the drive module and peripheral devices are installed securely in the connectorsof the module. Make sure the connectors make a clicking sound when attached. Defective contact maycause malfunction or false input/output.! When the drive module or peripheral devices are not connected to the module, be sure to attach the coverto the connector area. Failure to attach the cover may result in malfunction.[Wiring Precautions]CAUTION! The FG terminal should always be grounded using the class-3 or higher grounding designed specially forPC. Failure to ground the terminal may cause malfunction.! When wiring the PC, check the rated voltage and terminal layout of the wiring, and make sure the wiring isdone correctly. Connecting a power supply that differs from the rated voltage or wiring it incorrectly maycause fire or breakdown.! Correctly perform wiring to the module after confirming the terminal layout.! Be careful not to let foreign matter such as filings or wire chips get inside the module. These can cause fire,breakdowns and malfunction.! Tighten the terminal screws with the specified torque. If the terminal screws are loose, it may result in shortcircuits, fire or malfunction.If the terminal screws are tightened too much, it may damage the screws and the module may result in shortcircuits, malfunction or cause the module to fall out.! Before beginning any installation or wiring work, make sure all phases of the power supply have beenobstructed from the outside. Failure to completely shut off the power-supply phases may cause electricshock and/or damage to the module.

[Wiring Precautions]CAUTION! When turning on the power or operating the module after installation or wiring work, be sure the module'sterminal covers are correctly attached. Failure to attach the terminal covers may result in electric shock.! Correctly perform soldering for connectors for the outside. Incorrect connection may cause short circuits ormalfunction.[Setup and Maintenance Precautions]CAUTION! Do not touch the terminals while the power is on. Doing so may cause electric shock or malfunction.! Never disassemble or modify the module. This may cause breakdowns, malfunction, injury and fire.! Before cleaning the module or retightening the screws, make sure all phases of the power supply have beenobstructed from the outside. Failure to completely shut off the power-supply phases may causebreakdowns and malfunction.! Before attaching or detaching the module, make sure all phases of the power supply have been obstructedfrom the outside. Failure to completely shut off the power-supply phases may cause module breakdownsand malfunction.! When conducting a test operation, set the speed limit parameter at low speed and prepare to stopimmediately if any dangerous situation should occur.[Disposal Precautions]DANGER! When disposing of this product, treat it as industrial waste.

About This ManualsThe following manuals are available regarding this product.Please order desired manuals using this chart.Related ManualsManual nameControl & Communication-Link System Master-Local module type AJ61BT11/A1SJ61BT11User’s ManualThis manual describes the system configuration, performance specifications, functions,handling, wiring and troubleshooting of the AJ61BT11 and A1SJ61BT11 (sold separately).AJ61QBT11/A1SJ61QBT11 Control & Communication Link System Master/Local ModuleUSER’S MANUALThis manual describes the system configuration, performance specifications, functions,handling, wiring and troubleshooting of the AJ61QBT11 and A1SJ61QBT11 (sold separately).Positioning module software package type SW1IVD-AD75P Operating ManualThis manual describes how to create data (such as parameters and positioning data) and theoperations to transfer data to the module, monitor positioning and conduct tests using theabove software package (supplied with each software package product).Manual No.(Type code)IB (NA) 66721(13J872)IB (NA) 66722(13J873)IB (NA) 66714(13J915)

IntroductionThank you for purchasing the Mitsubishi MELSEC-A-series.Before using the equipment, please read this manual carefully to develop full familiarity with the functions andperformance of MELSEC-A-series you have purchased, so as to ensure correct use.Please forward a copy of this manual to the end user.Table of ContentsPart 1Function Explanation Volume1. Overview 1-1 to 1-221.1 Features............................................................................................................................................................ 1- 21.2 Purpose of Positioning ...................................................................................................................................... 1- 41.3 Types of Positioning.......................................................................................................................................... 1- 51.4 Overview of Positioning Control........................................................................................................................ 1- 71.4.1 Data setting required for positioning control........................................................................................ 1- 71.4.2 Positioning control methods ................................................................................................................ 1- 81.4.3 Specification of positioning address .................................................................................................... 1- 91.4.4 Operation pattern................................................................................................................................. 1-101.4.5 Block positioning control...................................................................................................................... 1-111.4.6 Overview of acceleration/deceleration processing .............................................................................. 1-121.4.7 Overview of start.................................................................................................................................. 1-131.4.8 Overview of restart .............................................................................................................................. 1-141.4.9 Overview of home position return........................................................................................................ 1-151.5 Overview of Communication ............................................................................................................................. 1-171.5.1 Cyclic transmission.............................................................................................................................. 1-181.5.2 Transient transmission ........................................................................................................................ 1-191.6 General Procedure before Operation................................................................................................................ 1-201.7 Abbreviations, General Names and Terms Used in this Manual ...................................................................... 1-211.8 Parts Supplied with the Module ........................................................................................................................ 1-222. System Configuration 2-1 to 2-52.1 System Configuration when Using the D75P2.................................................................................................. 2- 12.2 Applicable System ............................................................................................................................................ 2- 22.3 List of Equipment .............................................................................................................................................. 2- 32.4 Precautions when Using a Stepping Motor....................................................................................................... 2- 43. Specification 3-1 to 3-283.1 General Specifications ...................................................................................................................................... 3- 13.2 Performance Specifications .............................................................................................................................. 3- 23.2.1 Performance specifications ................................................................................................................. 3- 23.2.2 Specifications for I/O interface with external devices .......................................................................... 3- 43.3 I/O Signals for the Master Module..................................................................................................................... 3-123.3.1 List of I/O signals................................................................................................................................. 3-123.3.2 Functions of I/O signals....................................................................................................................... 3-163.4 Remote Register ............................................................................................................................................... 3-233.4.1 Remote register assignment................................................................................................................ 3-233.4.2 Positioning start number...................................................................................................................... 3-243.4.3 Override............................................................................................................................................... 3-243.4.4 New present value............................................................................................................................... 3-243.4.5 New speed value................................................................................................................................. 3-25

3.4.6 JOG speed .......................................................................................................................................... 3-253.4.7 Present feed value .............................................................................................................................. 3-253.4.8 Feed speed ......................................................................................................................................... 3-263.4.9 Valid M code........................................................................................................................................ 3-263.4.10 Axis error number................................................................................................................................ 3-263.4.11 Axis warning number........................................................................................................................... 3-263.4.12 Axis operation status ........................................................................................................................... 3-263.5 Transmission Delay Time ................................................................................................................................. 3-274. Function List 4-1 to 4-24.1 Function List...................................................................................................................................................... 4- 15. Home Position Return Function 5-1 to 5-315.1 What is the Home Position Return Function? ................................................................................................... 5- 15.2 Types of Home Position Return ........................................................................................................................ 5- 15.3 Precautions when Performing Home Position Return....................................................................................... 5- 25.4 Home Position Return Start Method ................................................................................................................. 5- 35.4.1 Start flow.............................................................................................................................................. 5- 35.4.2 Mechanical home position return start................................................................................................. 5- 45.4.3 High-speed home position return start ................................................................................................ 5- 45.4.4 High-speed mechanical home position return ..................................................................................... 5- 65.4.5 Data-set type home position return ..................................................................................................... 5- 75.5 Home Position Return Method.......................................................................................................................... 5- 85.5.1 Near-point dog type home position return ........................................................................................... 5- 85.5.2 Count-type 1) home position return (using the zero signal)................................................................. 5-105.5.3 Count-type 2) home position return (not using the zero signal)........................................................... 5-125.5.4 Stopper stop-type 1) home position return (using time out of dwell time) ........................................... 5-145.5.5 Stopper stop-type 2) home position return (using the zero signal upon hitting the stopper) ............... 5-185.5.6 Stopper stop-type 3) home position return (no near-point dog method).............................................. 5-215.5.7 Data-set type home position return ..................................................................................................... 5-235.6 Home Position Return Retry Function............................................................................................................... 5-245.6.1 What is the home position return retry function?................................................................................. 5-245.6.2 Actions of the home position return retry function ............................................................................... 5-245.6.3 Home position return methods and execution of the home position return retry function ................... 5-265.6.4 Conditions when executing the home position return retry function.................................................... 5-265.6.5 Dwell time setting at home position return retry .................................................................................. 5-275.7 Home Position Shift Function............................................................................................................................ 5-285.7.1 What is the home position shift function?............................................................................................ 5-285.7.2 Specifying speed during home position shift ....................................................................................... 5-305.8 Home Position Return Request Flag OFF Request .......................................................................................... 5-315.9 Combining Home Position Return with Other Functions................................................................................... 5-315.9.1 Home position return start after home position return operation stops................................................ 5-315.9.2 Changing the speed during home position return................................................................................ 5-316. Positioning Function 6-1 to 6-646.1 Positioning Control Methods ............................................................................................................................. 6- 16.1.1 Control method.................................................................................................................................... 6- 26.1.2 Interpolation control............................................................................................................................. 6- 36.1.3 Single-axis linear control ..................................................................................................................... 6- 56.1.4 Dual-axis linear interpolation control ................................................................................................... 6- 76.1.5 Fixed-dimension feed control .............................................................................................................. 6-116.1.6 Circular interpolation control with a specified auxiliary point ............................................................... 6-156.1.7 Circular interpolation control with the specified center point ............................................................... 6-206.1.8 Speed control (forward rotation/reverse rotation)................................................................................ 6-25

6.1.9 Speed/position switch control (forward rotation/reverse rotation)........................................................ 6-276.1.10 JUMP instruction ................................................................................................................................. 6-316.2 Operation Pattern of Positioning Control .......................................................................................................... 6-336.2.1 Individual positioning control (operation pattern: 00)........................................................................... 6-336.2.2 Continuous positioning control (operation pattern: 01)........................................................................ 6-346.2.3 Continuous locus control (operation pattern: 11) ................................................................................ 6-356.3 Starting Positioning Control .............................................................................................................................. 6-436.3.1 Overview of start.................................................................................................................................. 6-436.3.2 Start method........................................................................................................................................ 6-496.3.3 Special start......................................................................................................................................... 6-516.3.4 Setting the bias speed at start............................................................................................................. 6-546.4 Stop of Positioning Control ............................................................................................................................... 6-556.4.1 Stop command and stop factors.......................................................................................................... 6-556.4.2 Stop processing and priority................................................................................................................ 6-586.4.3 Stop processing during deceleration ................................................................................................... 6-606.4.4 Stop processing during interpolation operation ................................................................................... 6-606.4.5 Continuous-operation interrupt function .............................................................................................. 6-616.5 Restarting Positioning Control .......................................................................................................................... 6-636.5.1 What is restart after a stop? ................................................................................................................ 6-636.5.2 Specifying the restart after a stop........................................................................................................ 6-636.5.3 Precautions ......................................................................................................................................... 6-647. Other Functions 7-1 to 7-687.1 Manual Operation ............................................................................................................................................. 7- 17.1.1 JOG operation ..................................................................................................................................... 7- 17.1.2 Manual pulse generator operation....................................................................................................... 7- 77.2 Speed Change Function during the Positioning Operation............................................................................... 7- 97.2.1 Speed change via the remote register for speed change.................................................................... 7- 97.2.2 Speed change by the override function............................................................................................... 7-137.2.3 Acceleration/deceleration-time setting for speed change.................................................................... 7-157.3 Torque Limit Function ....................................................................................................................................... 7-177.3.1 Torque limit function ............................................................................................................................ 7-177.3.2 Torque change function....................................................................................................................... 7-197.4 Stroke Limit Function ........................................................................................................................................ 7-207.4.1 Stroke limit function via external input................................................................................................. 7-207.4.2 Software stroke limit function............................................................................................................... 7-227.5 Confirmation and Change of Present Value...................................................................................................... 7-277.5.1 Confirmation of present value.............................................................................................................. 7-277.5.2 Present value change.......................................................................................................................... 7-297.6 Electronic Gear ................................................................................................................................................. 7-327.7 Backlash Compensation Function .................................................................................................................... 7-347.8 M-code Function ............................................................................................................................................... 7-357.9 Acceleration/Deceleration Processing .............................................................................................................. 7-387.9.1 Relationship among speed limit value, JOG speed limit value, acceleration time,deceleration time and rapid stop deceleration time............................................................................. 7-397.9.2 Acceleration/deceleration processing.................................................................................................. 7-407.10 Skip Function .................................................................................................................................................... 7-417.11 Step Function.................................................................................................................................................... 7-437.12 Command In-position Function ......................................................................................................................... 7-477.13 Teaching Function ............................................................................................................................................ 7-497.14 Handling when the Control Unit is in “Degree” ................................................................................................. 7-537.14.1 Address of present feed value and machine feed value ..................................................................... 7-537.14.2 Setting valid/invalid of software stroke limit......................................................................................... 7-537.14.3 Positioning control ............................................................................................................................... 7-557.15 Setting the Stepping Motor Mode...................................................................................................................... 7-57

7.16 Present Feed Value Clear Function at the Start of Speed Control and Speed/Position Switch Control ........... 7-617.17 Write to the Flash Memory................................................................................................................................ 7-627.18 Pulse Output Logic Switch ................................................................................................................................ 7-637.19 Parameter Initialization Function....................................................................................................................... 7-647.20 When Constructing the Absolute Position Detection System Using the D75P2 ............................................... 7-657.21 Servo ON/OFF .................................................................................................................................................. 7-678. Buffer Memory 8-1 to 8-378.1 Outline of Buffer Memory .................................................................................................................................. 8- 18.2 Classification of Buffer Memory Areas.............................................................................................................. 8- 18.3 Reading and Writing Data in the Buffer Memory............................................................................................... 8- 38.4 Configuration of Buffer Memory ........................................................................................................................ 8- 48.5 Parameter Area................................................................................................................................................. 8- 58.5.1 Basic parameter 1 ............................................................................................................................... 8- 58.5.2 Basic parameter 2 ............................................................................................................................... 8- 58.5.3 Extended parameter 1......................................................................................................................... 8- 78.5.4 Extended parameter 2......................................................................................................................... 8- 98.5.5 Home position return basic parameters............................................................................................... 8-108.5.6 Home position return extended parameters ........................................................................................ 8-118.6 Monitor Area ..................................................................................................................................................... 8-128.6.1 System monitor area ........................................................................................................................... 8-128.6.2 Axis monitor area................................................................................................................................. 8-198.7 Control Data Area ............................................................................................................................................. 8-238.7.1 System-control data area .................................................................................................................... 8-238.7.2 Axis-control data area ......................................................................................................................... 8-268.8 Positioning Data Area ....................................................................................................................................... 8-288.9 Positioning Start Information Area .................................................................................................................... 8-308.9.1 Positioning start data area................................................................................................................... 8-318.9.2 Special start data area ........................................................................................................................ 8-328.9.3 Condition data area ............................................................................................................................. 8-338.10 Indirect Specification Area ................................................................................................................................ 8-358.11 PC CPU Memory Area ...................................................................................................................................... 8-368.12 Area for Block Transfer ..................................................................................................................................... 8-37Part 2Setup Volume9. Setup 9-1 to 9-259.1 Name of Each Part............................................................................................................................................ 9- 19.2 Handling Precautions........................................................................................................................................ 9- 39.3 Module Installation ............................................................................................................................................ 9- 59.3.1 DIN rail installation (removal) .............................................................................................................. 9- 69.3.2 Installation to (removal from) the panel ............................................................................................... 9- 89.4 Wiring/Connections........................................................................................................................................... 9- 99.4.1 Pin connection to the drive module connector .................................................................................... 9-119.4.2 Connector connection (removal) ......................................................................................................... 9-149.4.3 Twisted cable connection .................................................................................................................... 9-159.5 Setting the Main Module ................................................................................................................................... 9-179.5.1 Setting the station number of the main module ................................................................................... 9-189.5.2 Setting the transmission speed of the main module............................................................................ 9-199.6 Display Viewpoint.............................................................................................................................................. 9-209.6.1 17-segment/corresponding-axis display LEDs .................................................................................... 9-209.6.2 Message descriptions for operation monitor 2..................................................................................... 9-219.6.3 Signal names of I/O information “n”..................................................................................................... 9-219.6.4 Descriptions of other messages .......................................................................................................... 9-219.7 System Test ...................................................................................................................................................... 9-22

Part 3Setting Volume10. Setting Positioning Parameters 10-1 to 10-2810.1 Basic Parameters.............................................................................................................................................. 10- 110.1.1 Unit setting .......................................................................................................................................... 10- 410.1.2 Travel increment per pulse.................................................................................................................. 10- 410.1.3 Pulse output mode............................................................................................................................... 10- 610.1.4 Rotation direction setting..................................................................................................................... 10- 810.1.5 Speed limit value ................................................................................................................................. 10- 810.1.6 Acceleration time 0.............................................................................................................................. 10- 910.1.7 Deceleration time 0.............................................................................................................................. 10- 910.1.8 Bias speed at start............................................................................................................................... 10- 910.1.9 Stepping motor mode selection........................................................................................................... 10- 910.2 Extended Parameters ....................................................................................................................................... 10-1110.2.1 Backlash compensation ...................................................................................................................... 10-1410.2.2 Software stroke limit ............................................................................................................................ 10-1410.2.3 Software stroke limit selection............................................................................................................. 10-1410.2.4 Software stroke limit valid/invalid setting............................................................................................. 10-1410.2.5 Command in-position range ................................................................................................................ 10-1510.2.6 Torque limit.......................................................................................................................................... 10-1510.2.7 M-code ON signal output timing .......................................................................................................... 10-1510.2.8 Speed switch type ............................................................................................................................... 10-1510.2.9 Interpolation speed specification ......................................................................................................... 10-1610.2.10 Present feed value during speed control............................................................................................. 10-1710.2.11 Manual pulse-generator selection ....................................................................................................... 10-1710.2.12 Selection for pulse output logic to drive module.................................................................................. 10-1710.2.13 Acceleration/deceleration time setting size selection .......................................................................... 10-1810.2.14 Acceleration time 1 to 3....................................................................................................................... 10-1810.2.15 Deceleration time 1 to 3....................................................................................................................... 10-1810.2.16 JOG speed limit value ......................................................................................................................... 10-1810.2.17 JOG operation acceleration/deceleration time selection ..................................................................... 10-1810.2.18 JOG operation deceleration time selection.......................................................................................... 10-1910.2.19 Acceleration/deceleration processing selection .................................................................................. 10-1910.2.20 S-curve ratio ........................................................................................................................................ 10-1910.2.21 Rapid-stop deceleration time............................................................................................................... 10-2010.2.22 Rapid-stop selection (Stop groups 1 to 3) ........................................................................................... 10-2010.2.23 Positioning-complete signal output time.............................................................................................. 10-2010.2.24 Allowable circular-interpolation error range......................................................................................... 10-2110.2.25 External start function selection .......................................................................................................... 10-2110.3 Home Position Return Basic Parameters.......................................................................................................... 10-2210.3.1 Home position return method .............................................................................................................. 10-2210.3.2 Home position return direction............................................................................................................. 10-2210.3.3 Home position address........................................................................................................................ 10-2310.3.4 Home position return speed ................................................................................................................ 10-2310.3.5 Creep speed........................................................................................................................................ 10-2410.3.6 Home position return retry................................................................................................................... 10-2510.4 Home Position Return Extended Parameters ................................................................................................... 10-2610.4.1 Home position return dwell time .......................................................................................................... 10-2610.4.2 Travel increment setting after near-point dog ON ............................................................................... 10-2610.4.3 Home position return acceleration time selection................................................................................ 10-2610.4.4 Home position return deceleration time selection................................................................................ 10-2610.4.5 Home position shift amount................................................................................................................. 10-2610.4.6 Home position return torque limit value............................................................................................... 10-2810.4.7 Home position shift speed specification .............................................................................................. 10-28

10.4.8 Dwell time at home position return retry .............................................................................................. 10-2811. Setting Positioning Data 11-1 to 11-1311.1 What is Positioning Data?................................................................................................................................. 11- 111.2 Positioning Data................................................................................................................................................ 11- 111.2.1 Operation pattern................................................................................................................................. 11- 411.2.2 Control method.................................................................................................................................... 11- 411.2.3 Acceleration time number.................................................................................................................... 11- 411.2.4 Deceleration time number ................................................................................................................... 11- 411.2.5 Positioning address/travel increment .................................................................................................. 11- 511.2.6 Circular address .................................................................................................................................. 11- 611.2.7 Command speed ................................................................................................................................. 11- 611.2.8 Dwell time............................................................................................................................................ 11- 711.2.9 Jump destination data number ............................................................................................................ 11- 711.2.10 M code................................................................................................................................................. 11- 711.2.11 Condition data number ........................................................................................................................ 11- 711.3 Positioning Start Information............................................................................................................................. 11- 811.3.1 Positioning start data........................................................................................................................... 11- 811.3.2 Special start data................................................................................................................................. 11- 911.4 Condition Data .................................................................................................................................................. 11-1111.4.1 Condition identifier............................................................................................................................... 11-1111.4.2 Address ............................................................................................................................................... 11-1311.4.3 Parameter 1......................................................................................................................................... 11-1311.4.4 Parameter 2......................................................................................................................................... 11-1311.4.5 Parameter 1 and parameter 2 settings for simultaneous start............................................................. 11-1312. Building a System 12-1 to 12-3812.1 Overview ........................................................................................................................................................... 12- 112.2 Master Station Settings..................................................................................................................................... 12- 212.3 D75P2 Settings ................................................................................................................................................. 12- 312.4 Concept of Transient Transmission .................................................................................................................. 12- 412.4.1 Read/write of the buffer memory ......................................................................................................... 12- 412.4.2 Transient transmission ........................................................................................................................ 12- 612.4.3 Control data/send data setting procedures ......................................................................................... 12- 712.5 Programming..................................................................................................................................................... 12-1612.5.1 Programming procedure...................................................................................................................... 12-1612.5.2 Notes on creating programs ................................................................................................................ 12-1712.5.3 Creating programs............................................................................................................................... 12-1812.5.4 Parameter setting/data link start program ........................................................................................... 12-2212.5.5 Communication/positioning programs ................................................................................................. 12-2513. Troubleshooting 13-1 to 13-1213.1 Troubleshooting Flow when “ERR” LED of Master Station is Flickering ........................................................... 13- 113.2 Errors/Warnings of D75P2 ................................................................................................................................ 13- 313.2.1 Errors................................................................................................................................................... 13- 313.2.2 Warnings ............................................................................................................................................. 13- 413.2.3 Resetting the error............................................................................................................................... 13- 513.2.4 Invalid operations ................................................................................................................................ 13- 513.3 Corrective Actions for Errors............................................................................................................................. 13- 613.4 Corrective Actions for Warnings ....................................................................................................................... 13-1013.5 Error Start History ............................................................................................................................................. 13-12Appendix A-1 to A-42Appendix 1 External Dimensions Diagram .............................................................................................................. A- 1

Appendix 2 Format Sheet........................................................................................................................................ A- 2Appendix 2.1 Positioning module operation diagram......................................................................... A- 2Appendix 2.2 Parameters, home position return data........................................................................ A- 3Appendix 2.3 Positioning data (data number to )........................................................................... A- 7Appendix 3 Positioning Data Number and Buffer Memory Address Conversion Table.......................................... A- 8Appendix 4 Connection Examples of D75P2 and Servo Amplifier .......................................................................... A-10Appendix 4.1 Connection example of D75P2 and MR-H # A(differential driver (open collector), negative logic) ...................................................... A-10Appendix 4.2 Connection example of D75P2 and MR-J # A(differential driver (open collector), negative logic) ...................................................... A-11Appendix 4.3 Connection example of D75P2 and MR-J2- # A(differential driver (open collector), negative logic) ...................................................... A-12Appendix 4.4 Connection example of D75P2 and MR-C # A(differential driver (open collector), negative logic) ...................................................... A-13Appendix 5 Connection Example with Servo Amplifier by Yasukawa ..................................................................... A-14Appendix 5.1 Connection example of D75P2 and CACR (R series)(differential driver, negative logic)................................................................................ A-14Appendix 6 Connection Examples with Stepping Motors by Oriental ..................................................................... A-15Appendix 6.1 Connection example of D75P2 and VEXTA UDX2107(differential driver, positive logic) ................................................................................. A-15Appendix 6.2 Connection example of D75P2 and VEXTA UPD(differential driver, positive logic) ................................................................................. A-16Appendix 6.3 Connection example of D75P2 and VEXTA-FX(differential driver, positive logic) ................................................................................. A-17Appendix 6.4 Connection example of D75P2 and VEXTA UDX2107(open collector method, negative logic) ....................................................................... A-18Appendix 6.5 Connection example of D75P2 and VEXTA UPD(open collector method, negative logic) ....................................................................... A-19Appendix 6.6 Connection example of D75P2 and VEXTA-FX(open collector method, negative logic) ....................................................................... A-20Appendix 7 Connection Example with Servo Amplifier by Toei Electric .................................................................. A-21Appendix 7.1 Connection example of D75P2 and VLASE 010P(differential driver, positive logic) ................................................................................. A-21Appendix 8 Connection Example with Servo Amplifier by Matsushita Electric Industries ...................................... A-22Appendix 8.1 Connection example of D75P2 and MSD5A3A1X(differential driver, positive logic) ................................................................................. A-22Appendix 9 Station Numbers - Remote I/O and Remote Register Conversion Table ............................................ A-23Appendix 10 MELSEC Glossary of Positioning Terms .............................................................................................. A-24

Part 1Function Explanation VolumePart 1 describes the basic topics relating to the AJ65BT-D75P-S3 positioningmodule product, as well as the information the user should know when operating theproduct.Chapter 1 OverviewChapter 2 System ConfigurationChapter 3 SpecificationChapter 4 Function ListChapter 5 Home Position Return FunctionChapter 6 Positioning FunctionChapter 7 Other FunctionsChapter 8 Buffer Memory

1. Overview MELSEC-A1. OverviewThis users manual describes the specifications, handling and programming method for the AJ65BT-D75P2-S3 positioning module (hereinafter referred to as the D75P2), which can be used as anintelligent device station for the CC-Link system.An overview of the D75P2’s positioning control is shown in Figure 1.1.Master moduleCommunicationD75P2Set dataForwardpulseError valueDrive moduleD/ASpeedcommandServoServo motorMReversepulseCounterConverterAmplifierInterfacePGFeedback pulse· A7PHP· A7HGP· PC9800series· DOS/Vpersonalcomputer· AD75TUSpeed (V)Pulse standing amountPulse distributionServo motor speedTime (t)Fig. 1.1 Overview of positioning control1-1

1. Overview MELSEC-A1.1 FeaturesThe features of the D75P2 are listed below.(1) Compatible with distributed systemsThe D75P2 can be placed near a distributedly allocated servo amplifier or stepping motor.(2) Easily adaptable to an absolute-position detection system(a) By connecting a servo system that supports absolute positions, the D75P2 can be used withan absolute-position detection system.(b) Once the location of the home position has been determined, the D75P2 can return to theaddress prior to power-up using the absolute-position restoration function.(c) With the absolute-position detection system, the location of the home position can bedetermined by means of the data-set-type home position return.Therefore, wiring to items such as a near-point dog is required.(3) Control via mechanical system input is possibleWith external inputs such as external start, stop and speed/position switch, the positioning controlcan be performed without using a sequence program.(4) Various positioning control functions are available(a) Various functions required of a positioning system are included, such as positioning controlto any position, fixed-dimension feed control and uniform speed control.An overview of positioning control functions is provided in Section 1.4.• A maximum of 600 data items per axis can be set for positioning data, including thepositioning address, control method, operation pattern, etc..• Linear control (two-axis simultaneous execution is allowed) can be performed for thepositioning of each axis: independent positioning using one positioning data item, orcontinuous positioning via the continuous execution of multiple data items.• Linear interpolation control with two axes, as well as circular interpolation control, can bedone for the positioning of multiple axes: independent positioning using one positioningdata item, or continuous positioning via the continuous execution of multiple data items.(b) The control methods specified by positioning data include the position control, speed controland speed/position switch control.(c) Depending upon the operation pattern set by the user using positioning data, continuouspositioning can be performed for multiple axes or each axis using multiple positioning dataitems.Continuous positioning can also be performed for multiple blocks, each of which consistingof multiple positioning data items.(d) The home position return control has been extended.• Seven types of home position return methods are available: the near-point dog method(one type), stopper stop method (three types), count method (two types) and data-setmethod (one type).(However, the data-set method is available only when using an absolute-positionsystem.)• The home position return retry function is now available in order to realize positioningcontrol from any position relative to the home position of a machine.(e) Two acceleration/deceleration methods are available: the automatic trapezoidacceleration/deceleration and S-curve acceleration/deceleration. The user can select fromthe automatic trapezoid acceleration/deceleration or S-curve acceleration/deceleration.1-2

1. Overview MELSEC-A(5) Faster pulse output and longer distance to the drive module(a) The D75P2 is equipped with pulse-output interfaces for a differential driver and an opencollector.(b) By connecting to the differential driver, higher speed and longer distance can be achieved.• When connecting to a differential driver• When connecting to an open collector: 400 kpps, 10 m (32.8 ft.) maximum.: 200 kpps, 2 m (6.6 ft.) maximum.(6) Easy maintenanceThe D75P2 has achieved improved maintainability, as in the following:(a) Various data such as positioning data and parameters are stored internally in the flashmemory of the D75P2.Therefore, data can be retained without a battery.(b) Error display and the status of mechanical system input and zero input can be checked onthe 17-segment monitor.(c)Errors are subdivided in order to improve first-time diagnostics.(d) Confirmation of the contents of errors and warnings is done easier than the way it has beenconventionally done, since 16 items each of history data, such as errors and warnings, canbe retained.1-3

1. Overview MELSEC-A1.2 Purpose of PositioningThe positioning refers to moving a movable object (processed materials, tools, etc.) at a fixed speedand stopping it accurately at the intended position.Typical usage examples are shown below.(1) Fixed-dimension feedFeed a sheet for a fixed dimensionand cut it.CutMFeed motorFig. 1.2 Fixed-dimension feed(2) TappingTo perform thread chasing to afixed depth for processed material,repeat the following steps:1) Fast forward2) Process feed (thread chasing)3) Fast rewindThread chasing motorMFast forwardWorkProcess feedFast rewindFig. 1.3 Tapping(3) Steel-plate drilling (X-Y table movement)Drill a hole at the fixed positionusing two motors (one motor eachfor vertical and horizontal).Y2Y3Y4No.1No.2No.3No.4Vertical feed motorY1X1 X2 X3 X4ZeroHorizontal feed motorFig. 1.4 Steel plate drilling1-4

1. Overview MELSEC-A1.3 Types of PositioningEach of the two axes can be used independently for positioning, or the two axes can be used for thepositioning of orthogonal axes.The following methods as shown in the figures are available when positioning from address number 1to number 2.(1) Individual operationThis is a method by which each of the vertical and horizontal directions is positioned individually.First, positioning is performed in the horizontal direction X, then in the vertical direction Y.No.2YNo.1X(2) Simultaneous operationThis is a method that designates one of the two motors to perform positioning in the X directionand the other in the Y direction, driving them simultaneously to reach the intended position.Since each of the acceleration/deceleration time, speed and travel distances for the two motors isindependent, this operation moves along a curve.No.2YNo.1X(3) Linear interpolation operationThis is a method that operates two motors simultaneously to move along a straight diagonal line.To move along a straight line, calculation is performed via the positioning module equipped withan interpolation function, and the resultant pulse is distributed to the two motors for control,because the acceleration/deceleration times and speeds of the two motors generally vary.No.2YNo.1X1-5

1. Overview MELSEC-A(4) Circular interpolation operationThis is a method that operates two motors simultaneously to execute the interpolation operationfor the circular locus.To move along a circular line, calculation is performed for the positioning module equipped with acircular interpolation function that controls the acceleration/deceleration times and speeds of thetwo motors, and the resultant pulse is distributed to the two motors for control.AuxiliarypointNo.2YNo.1YNo.1Center pointNo.2Circular interpolation by specifyingan auxiliary pointXXCircular interpolation by specifyingthe center point1-6

1. Overview MELSEC-A1.4 Overview of Positioning ControlThis section describes the data that needs to be set for positioning, along with the types of positioningcontrols and operation patterns available.1.4.1 Data setting required for positioning controlIn order to perform positioning using the D75P2, several data items listed below must be set.Data for which setting is requiredParameters for positioning Basic parameter 1Basic parameter 2Extended parameter 1Extended parameter 2These are set according to the system configuration andmechanical equipment.Parameters forhome position returnBasic parameterExtended parameterData for positioningPositioning dataThis sets how to control and operate a machine.Positioning startinformationThis is set when a special start such as block start,simultaneous start, repeated start or start by conditiontesting is performed.Positioning start dataThis sets which positioning data to start with,and whether to end or continue positioningfor the next block.Special start dataThis sets the start type.Condition dataThis sets the conditions for special positioning.1-7

1. Overview MELSEC-A1.4.2 Positioning control methodsThe following positioning functions are available for the D75P2, and they are controlled by controlmethods *1 of 1) through 8). Use positioning data to set the control method.* 1) to 6): Control of “positioning” locus and operation7) to 8): Control of “positioning” dataLinear positioning function1) Linear control of single-axisThis performs positioning along a straight locus from2) Linear interpolation control .................. the current stop position toward the specified position.of dual-axesFixed-dimension feed-positioning function3) Fixed-dimension feed control .................. This performs positioning for the specified travel alonga straight locus from the current stop position.Circular positioning function4) Circular interpolation control .................... This performs positioning along a circular locus fromthe current stop position towards the specified position.Speed-control positioning function5) Speed control .......................................... This moves at the specified speed from the current stopposition toward the specified position.(The operation continues until a stop command isinput.)Speed/position switch positioning function6) Speed/position switch control .................. This moves at the specified speed from the current stopposition toward the specified position, and performspositioning for the specified travel from the moment aspeed/position switch signal is input.Present-value change function7) Present value change .............................. This changes the present feed value to the specifiedvalue.JUMP function8) JUMP instruction ...................................... This jumps the control point to the specified positioningdata number while in the continuous locus control(operation pattern: 02). (Specification of unconditionalor execution condition is made.)*1: See Section 6.1 for details on control methods.1-8

1. Overview MELSEC-A1.4.3 Specification of positioning addressFor positioning control, there are two methods used to designate a position.(1) Absolute methodThis method performs positioning by specifying the position relative to home position (absoluteaddress). This address is used as the positioning address (the starting point can be positioned atany location).AddressAddress100100 Address150 Address300Address 150Address 100Address 150• Starting pointEndpointHome position(reference point)100Point A150Point B300Point CWithin the stroke limit rangeFig. 1.5 Positioning by absolute method(2) Increment methodThis method performs positioning by specifying the direction and increment of travel using thecurrently stopped position as the starting point.Travel increment+100Travel increment +100Travel increment+100Travel increment-100Travel increment -150Travel increment -100 Travel increment +50• Starting pointEndpointHome position(reference point)100Point A150Point B300Point CWithin the stroke limit rangeFig. 1.6 Positioning by increment method1-9

1. Overview MELSEC-A1.4.4 Operation patternThe following types of operation patterns are available.• Individual positioning Individual positioning control (operation pattern: 00)(ends positioning)• Continuous positioning Continuous positioning control (operation pattern: 01)(continues positioning)Continuous locus control (operation pattern: 11)(1) Individual positioning control (operation pattern = 00: ends positioning)The operation is completed with positioning for the specified positioning data alone. Thepositioning completion of this operation pattern is also used as the operation pattern for the lastpositioning data of continuous positioning and continuous-locus positioning.(2) Continuous positioning control (operation pattern = 01: continues positioning)The operation stops temporarily upon the completion of positioning for the specified positioningdata, then continues with the next positioning data number.This is specified when performing positioning in which the direction changes because of multiplepositioning data items having consecutive positioning data numbers.(3) Continuous locus control (operation pattern = 11: continues positioning)After executing positioning using the specified positioning data, the operation changes its speedto that of the next positioning data number and continues positioning.This is specified when continuously executing multiple positioning data items having consecutivepositioning data numbers at a specified speed.1-10

1. Overview MELSEC-A1.4.5 Block positioning controlBlock positioning is a control that continuously executes the positioning of specified blocks. One blockis equivalent to a series of positioning data up to the completion of positioning (operation pattern = 00)by individual or continuous positioning control.A maximum of 50 blocks per axis can be specified.Using a one-time start command from the PC CPU or external, complex positioning control can beperformed.The block positioning control can be performed by specifying the positioning start number andpositioning start information in the buffer memory.SpeedPositioning continued (01)Dwell timePositioning completed (00)PositioningAddress (+) directioncompleted (00)Positioning completed (00)TimePositioning continued (11)Address (-) directionPositioning continued (11)SpeedOne blockOne blockOne blockONOFFPositioning startONOFFStart completedONOFFBUSYPositioning completed OFF ON1-11

1. Overview MELSEC-A1.4.6 Overview of acceleration/deceleration processingAcceleration/deceleration processing for the positioning operation, manual pulse-generator operation,home position return operation and JOG operation is performed using the user-specified method,acceleration time and deceleration time.(1) Acceleration/deceleration methodThere are two types of acceleration and deceleration processing: the automatic trapezoidacceleration/deceleration method and the S-curve acceleration/deceleration method. Anextended parameter is used to set which method is used.The specified acceleration/deceleration method is applied to all accelerations and decelerationswhen starting and completing the positioning operation, home position return operation and JOGoperation, as well as when changing the speed.1) Automatic trapezoid acceleration/deceleration methodThis method accelerates and decelerates in a linear fashion based on the speed limit valueand user-specified acceleration time/deceleration time.SpeedDistance2) S-curve acceleration/deceleration methodThis method reduces the load on the motor when starting and stopping.This method gradually accelerates or decelerates based on the user-specified accelerationtime and deceleration time, S-curve ratio (1 % to 100 %) and speed limit value.SpeedDistance(2) Acceleration time, deceleration time, rapid-stop deceleration time(a) Four types each of the acceleration time and deceleration time for positioning control can beset using basic parameter 2 and extended parameter 2.Also, the acceleration time and deceleration time can be selected from 1 to 65535 ms or 1 to8388608 ms using the acceleration/deceleration time setting size selection in extendedparameter 1.• Acceleration time ..... The time elapses before the speed of 0 reaches the limit value.• Deceleration time ..... The time elapses before the speed at the limit value reaches 0.(b) The rapid-stop deceleration time (1 to 65535 ms or 1 to 8388608 ms) is set using theacceleration/deceleration time setting size selection of extended parameter 1.RemarkThe selection of 1 to 65535 ms or 1 to 8388608 ms for the acceleration time, deceleration time andrapid-stop deceleration time is set for each axis.1-12

1. Overview MELSEC-A1.4.7 Overview of startWith the positioning control, operation is started in the following flow after the necessary parametersand data have been set.Setting the start number• Set a start number.A start number can be set within the range of 1 to 600, 7000 to 7010, 9001 to 9003, 9900 and 9901.The start contents at the time the start signal is turned on are determined by the set number.StartFor single-axis: RY(n+1)0 is turned on.For dual-axis: RY(n+1)1 is turned on.Start number: 9900Absolute position restorationStart number: 9901Present value changeStart number: 9901Mechanical home position return startStart number: 9902High-speed home position return startStart number: 9903High-speed mechanical home position returnStart number: 7000 to 7010Block positioningStart number: 1 to 600Positioning numbers 1 to 6001-13

1. Overview MELSEC-A1.4.8 Overview of restartIf the operation stops due to the generation of a stop factor during the positioning operation, thepositioning of stopped positioning data can be performed to the endpoint using the restart command.(1) When the remote I/O generates a restart command1) If the axis operation is in the stop state, positioning from the stopped position to the end ofthe stopped positioning data is performed regardless of the absolute method or incrementmethod used.2) If the axis operation is in other than the stop state, a restart disabled warning (warning code104) occurs and the restart command is ignored.[For the increment method]When the travel increment along axis 1 is 600 and that along axis 2 is 300Axis 2Axis 2400200100Stop position by a stop factorStartingpoint address100 300 700Specified positionRestartAxis 1400200Stop position by a stop factor300 700Stop positionafter restartOperation uponrestartAxis 1(2) When the positioning start signal or external start signal is turned onIf the axis operation is in standby or the stop state, positioning is performed from the head of thepositioning start data regardless of the absolute method or increment method used (as withnormal positioning).[For the increment method]When the travel increment along axis 1 is 600 and that along axis 2 is 300400200100Axis 2Stop position by a stop factor 500Startingpoint address100 300 700Specified positionPositioning startAxis 1200Axis 2Stop position by a stop factorStarting point address300 900Stop positionafter startOperationwhen startingpositioningAxis 11-14