ecophon focus - Rigips

ecophon focus - Rigips

ecophon focus - Rigips

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HANDBOOK- ceiling systems

CONTENTAPPLICATION GUIDERecommendations for the planning of an acoustic ceiling in aspecific type of area. A quick point of entry to a closer study ofEcophon system families.4ECOPHON - OUR MISSIONWe strongly believe in good acoustics as an essential part of a goodworking environment - for the eye, the ear and the mind.6FUNCTIONAL DEMANDSAcoustics | Accessibility | Cleanability | Light efficiency | Influenceof climate | Indoor climate | Environmental influence | Fire safety |Mechanical properties | Installation10SYSTEM DESCRIPTIONSSystems with unique performances and a variety of edge designs,sizes and surfaces - each one developed for specific needs and areas.44CEILING INTEGRATIONAdvice, ideas and detailed solutions for the integration of serviceinstallations and building components into the ceiling - from atechnical as well as a room design point of view.204ECOPHON CONNECT SUSPENSION SYSTEMSThe full range of grids, accessories and installation tools for theceiling.234ECOPHON - THE COMPANYMore than 40 years of global experience of the acoustic ceilingsbusiness has given us a genuine knowledge of the importance of agood sound environment as well as of developing, manufacturingand marketing acoustic ceilings.266E-TOOLS AND SPECIFICATIONSEcophon offers several digital tools that will help to speed up andsecure the planning, design and specification of suspended ceilings.You can find these tools at www.<strong>ecophon</strong>.com268OVERVIEWSEdge Design | Colours | Technical data | Acoustics glossary270

ECOPHON FOCUS The most comprehensive system family. It offers flat and curved panels,level changes, unique perimeter details and integrated lighting.46ECOPHON MASTER Provides excellent sound absorption, especially in open-plan offices andlecture rooms, conference halls, etc where easy communication is mostimportant.ECOPHON COMBISON Combines sound insulation and sound absorption in the very samesystems, e.g. for buildings where room divisions have to be flexible.106124ECOPHON GEDINA A dependable standard solution in cases when functional requirements arestrict and design possibilities are limited.136ECOPHON ACCESS Hinged panels with no obstructing cross tees give quick and full accessto services in the void that need frequent inspection, alteration ormaintenance.ECOPHON ADVANTAGE Our budget alternative which still meets the most essential requirements.142152ECOPHON SOMBRA Systems for premises where a really dark ceiling is desired. Offerspossibilities for sound control, e.g. in cinemas.158ECOPHON HYGIENE Combines excellent acoustics and washability properties. Well suitedfor premises in the food industry, the pharmaceutical industry andprofessional kitchens.ECOPHON SUPER G Ceiling systems with high mechanical resistance for areas such as sportshalls and gymnasiums.166188ECOPHON WALL PANEL To be used as an alternative in cases where an acoustic ceiling does not fit,or as a complement in certain rooms or areas.198| 3

APPLICATION GUIDEThis guide is intended to help you find a suitable ceiling solution fora specific type of area. The recommendations are based on our longexperience of meeting the demands and requirements of acoustic ceilingsunder general conditions in selected areas. However, specific conditionscould mean that a system range shown in the chart for a particular areamight not be as suitable as another, which is not shown. It all depends onthe situation. We have decided to present the two best alternatives for eacharea, also indicating that there could be other, lower ranked alternativesamong our systems.In the section for Functional demands you will find detailed descriptionsof the demands and standards for ceilings. For information on theperformance of each system, please refer to the system description. Shouldyou have any special requirements or require further information you arewelcome to contact us.Offi ce building Kv. Farao Solna, Sweden,Architect: Kristian Lindgren Arkitektkontor AB,Photo: Lars Hallén4 |

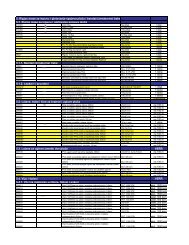

FOCUS MASTER COMBISON GEDINA ACCESS ADVAN-TAGESOMBRA HYGIENE SUPER G WALLPANEL46 106 124 136 142 152 158 166 188 198OfficesReception/Entrance ••• •• •• •••Corridor •• •••Open plan solution •• ••• ••• •• •••Quiet zone ••• •••Quiet room •• ••• •• •••Rest area ••• ••Cellular offi ce ••• ••Room with movable partitions•••Meeting room •• ••• •••Conference andlecture room ••• •••Copying and printing room •• ••• •• •••Kitchen•••Canteen ••• •• ••Educational premisesEntrance/Communalarea/Cloak room ••• ••Corridor/Stairs •• •• •••Classroom ••• •• •••Open-plan teachingenvironment •• ••• •••Conference room/Groupstudy room •• ••• ••Lecture theatre/Assemblyhall/Auditorium •• ••• •••Workshop •• •••Music room/Drama room/Dancing room ••• •••Library/Multimedia resourcecentre/Study room/Staffroom •• •••Cellular offi ce/Reception ••• ••Canteen/Cafeteria/Restaurant •• •••Kitchen•••Changing room •• •••Gymnasium/sports hall* ••• •••Swimming pool* ••• ••• ••Play and activity room •• ••• ••Health care premisesWard room/Patient Room •• •••Entrance hall ••• ••Circulation area/Corridor •• •• •••Consultation Room/Treatment Room•••Operating theatre•••Laboratory•••Hygiene room•••Waiting room/Library ••• ••Restaurant/Café ••• •• ••Intensive care/Recoveryroom•••Kitchen•••Cellular offi ce ••• ••Offi ce room with movablepartitions•••CinemaEntrance hall ••• ••Movie theatre ••• •••Projector room •• •••Corridor ••• ••Rest room ••• ••Sports and leisureTennis hall ••• ••Sports hall* ••• •••Swimming pool* ••• ••• ••RestaurantsDining room ••• •• ••Kitchen•••CommercialShop ••• ••• ••Shopping mall ••• ••IndustryPharmaceutical•••Food preparation•••Electronic•••••• = recommendation •• = good alternative * = investigation required| 5

6 |

OUR MISSION IS TO CONTRIBUTE TO AGOOD WORKING ENVIRONMENT FORTHE EYE, THE EAR AND THE MIND.It is a well-known fact that our environment in general has an impacton our well-being. But how are we affected by sound? What soundsdo we want to hear? What sounds disturb us? Our business concept isrooted in these simple yet crucial questions.OUR MISSION IS TO CONTRIBUTE TO A GOOD WORKINGENVIRONMENT...Noise and a poor acoustic environment are obviously not the only thingsthat affect our behaviour, our reactions and other events around us.However, there is no doubt that we are affected by these two factors, bothphysically and psychologically. Numerous studies have confirmed this.The idea behind our acoustic ceilings is that they should be an elementof the whole - an interior system, a building system, an experience- where each element influences how we feel. Therefore our aim - ourmission - extends beyond manufacturing and selling suspended ceilingtiles. We want to contribute to interiors that appeal to the eyes, the earsand the entire minds of the people who occupy and work in these varioussurroundings.We are therefore constantly developing solutions that are tailored to suitdifferent purposes and end-users. For example, a school should be plannedfrom the point of view of the pupils and teachers, and a hospital with theobjective of promoting healing and recovery.LEFT:ABOVE:Photo: Elisabeth ZeilonMälardalenshögskola, Sweden,Architect: White Arkitekter,Photo: Åke E:son Lindman| 7

RIGHT:Brabant Mobiel Oosterhout, The Netherlands,Architect: Van Tienen Ontwerpburerau, Terheijden,Photo: Ron Huizer Reclamefotografi e, OosterhoutABOVE:Klinteskolan Gotland, Sweden,Architect: Gunnar Gustafsson, BJ Konsult AB,Photo: Thore Nilsson, Bildvision AB,Visby...FOR THE EYE...In most cases, the suspended ceiling is the largest continuous surface ina room, which means it affects the entire feel of the interior. It is one ofthe surfaces that encloses the room, as well as being an important area inwhich the various service installations are integrated.Sometimes the ceiling contributes as a visual design element,sometimes as a neutral, timeless background. Whatever its role, itsinteraction with the room in general is fundamental. For the ceiling tocontribute to an attractive unified appearance, it must be possible to deviseelegant junctions with walls and services in the ceiling and to make infillseasily.The suspended ceiling also plays an important role in using anddistributing light - incident daylight as well as artificial light....THE EAR...A beautiful interior setting, but with all due respect, what auditoryimpression does it give? Hearing is a sense that never rests. If we shut outdisturbing sounds, we also risk missing what we really want to hear. Notonly loud sounds but also undesirable sounds are major problems today,both for the body and for the mind. A space where we need to concentratefor some tasks and in which we can communicate with other people onother occasions, requires a good, well-designed acoustic environment.Our workplaces have numerous sound sources competing for ourattention. At the same time, we are expected to be efficient and to performwell. However, if we are forced to expend energy on shutting out noiseand other sounds we do not want to hear, there is little left for performingour tasks. And when we are not at work, and wish to relax with familyand friends, our energy may be exhausted. This can result in unnecessarystress and poor health.8 |

...AND THE MINDBeing in a comfortable and safe environment promotes the inner balancewe all strive for. Just imagine the feeling of harmony you experience ona beautiful day in a natural setting or in an environment which has beenperfectly planned, built and equipped to meet your needs.This is the feeling that guides us in our developing work. Ceilingsystems should form part of a good working environment that satisfiespeople’ s minds from a visual, acoustic and physical point of view. Thisshould contribute to people feeling good in spite of the high demands thatare placed on their level of efficiency, productivity and concentration.In addition to the challenges regarding design and acoustics, ourceilings must also meet stringent demands with regard to function invarious technical and practical areas. Their potential for integration andtheir non-visible properties, e.g. influence on the environment and indoorclimate, are factors that also bring peace of mind to the users.EHPT Stockholm, Sweden,Architect: Sheiwiller Svensson Arkitektkontor AB,Photo: Åke E:son LindmanKonkurrensverket (The Swedish Competition Authority)Stockholm, Sweden,Architect: Scheiwiller Svensson Arkitektkontor, Stockholm,Photo: Åke E:son LindmanHöjgaard & Schultz Copenhagen, Denmark,Architect: Dissing+Weitling,Photo: Ole Jais| 9

kgFUNCTIONALDEMANDSThe physical requirements of buildingsand the demands put on them spanmany technical areas and can differconsiderably from one environment toanother as well as between variousapplications. To make buildingsfunction as intended, with user-friendlyenvironments, high demands are placedon the building materials and technicalsolutions used. The functional demandsplaced on ceilings are often considerable.Properties and performance must conformto building standards, regulations andindividual specifications, which take intoconsideration both present and futureactivities in the premises.AcousticsAccessibilityCleanabilityLight effi ciencyInfl uence of climateIndoor climateEnvironmental infl uenceFire safetyMechanical propertiesInstallation12222426283132333841

MUSIC ROOMSLARGE ROOMS FOR COMMUNICATION• Wall-to-wall ceiling• Limited sound absorption inhigher frequencies• Short reverberationtime for good speechintelligibility• Some sound refl ectionmight be needed• Sound absorbers on therear wallIf a classroom is solely used for music, werecommend that the whole ceiling area iscovered with a sound absorbing ceiling systemthat has limited absorption in the higherfrequencies. This will provide greater tonerichness.OPEN PLAN OFFICES• Good sound absorption inall frequencies for limitingthe refl ection of the sound• Effi cient space dividersneeded• Meeting rooms and roomsfor concentration work mustbe availableWhen it comes to minimising sounddisturbance between people in an open planoffice, the layout is very important. Speech isthe most disturbing factor because it is verydifficult to 'tune out'. However, in open planoffices individuals must be given as muchprivacy as possible, for example in caseswhere they are speaking on the phone or witha visitor.In order to prevent sound from beingreflected and propagated via the ceiling, it iscrucial that the acoustic ceiling has excellentsound absorption properties across the wholefrequency range.Good speech intelligibility is highly importantin auditoriums, large teaching rooms,conference rooms etc. This means that a shortreverberation time is required, especially ifa loudspeaker system is used. Useful soundreflections offer a way to improve the clarityof speech far away from the speaker. Oneway of achieving this is to combine absorberswith high sound absorption with more soundreflective ones, ideally those with some lowfrequency absorption.In these larger rooms it is alwaysrecommended to install a wall absorber withhigh sound absorption on the rear wall.SOUND ABSORPTIONA material's sound absorbing properties areexpressed by the sound absorption coefficient,α , (alpha), as a function of the frequency.α ranges from 0 (total reflection) to 1.00 (totalabsorption).ConvertedenergyIncidentenergyTransmitted energyRefl ectedenergyConverted energy+Transmitted energy=Incident energy* absorption coeffi cientWhen a sound wave strikes one of the surfaces of a room,some of the sound energy is refl ected back into the room andsome penetrates the surface. Parts of the sound wave energy areabsorbed by conversion to heat energy in the material, while therest is transmitted through. The level of energy converted to heatenergy depends on the sound absorbing properties of the material.14 |

STI and RASTISTI stands for Speech Transmission Index andRASTI for RApid Speech Transmission Index.They are both measured in similar ways, butSTI covers more frequencies. Consequentlythe figures will be about the same, even if bigdifferences in frequency response can givedeviations. Different figures will howeverbe obtained depending on the volume of theroom.STI and RASTI values vary between 0 and1.00 - where 0 stands for no intelligibilityat all and 1.00 gives total intelligibility. Forexample, in a normal sized classroom, figuresabove 0.75-0.80 would be regarded as good.%-Alcons%-Alcons stands for the percentageArticulation Loss of CONSonants. In otherwords, it takes into account the parts in aspoken word that are most important forunderstanding speech.It is believed that a loss of more than15 % consonants (15 %-Alcons) would bedeemed to be unacceptable for any type ofcommunication. Below 10-5 %-Alcons meansthat the listening conditions are good toexcellent.Signal to noise ratio (S/N)Another important parameter influencingspeech intelligibility is the background noiselevel or, more specifically, the signal to noiseratio (S/N). This is the ratio between signal(e.g. speech) and background noise (e.g.ventilation noise). To achieve good speechintelligibility a signal is considered to be atleast 15 dB above noise level. For hearingimpairedpeople the need is even greater; aratio of at least 20 dB is often referred to.On the other hand, if the signal to noise ratiois much less, or if the signal is lower than thenoise, the signal will be partly masked. Thussome privacy can be achieved.SPEECH PRIVACY BETWEEN WORKING PLACESAccording to the American standard ASTM E1130, speech privacy between working placescan be measured objectively in open planoffices and other environments arranged withan open layout. Such measurements are onlyvalid for their specific configurations and aredependent on certain parameters:• sound absorption effi ciency of the acoustic ceiling and othersurfaces• sound insulation effi ciency of space dividers• layout of working places• background noise level• speech spectrum and levelAccording to ASTM E 1111, acousticsuspended ceilings can be measuredobjectively for their properties in suchapplications. This standard provides themeans to measure the Interzone Attenuationof Ceiling Systems, and the linked standardASTM E 1110 gives the tools to calculate theArticulation Class for classification of ceilingsystems.• STI, RASTI and %-Alcons- methods for measuring andevaluating speech intelligibility.| 17

• A high Articulation Classgives some privacy, a lowerArticulation Class meanslower privacy. Confi dentialconversation and work tasksdemanding concentration needgood privacy.Interzone Attenuation of Ceiling SystemsThe measurement of interzone attenuationdemonstrates the sound reflectivecharacteristics of ceiling systems when used inconjunction with partial-height space dividers.This arrangement is commonly used in officesin order to achieve speech privacy betweenworking places.PlenumLoudspeakerReferencelocation (source)Ceiling test specimenScreenThe measurement set up for interzone attenuation is fi xed with adefi ned layout, a given 1.5 meter high space divider and defi nedpositions for source and receiver. The interzone attenuation iscalculated as the difference in sound pressure level between sourceand receiver for each one-third octave band in the frequency range200-5000 Hz and at each distance.Articulation ClassThe Articulation Class (AC) can be calculatedfrom the interzone attenuation. This can thenbe used as a tool to classify and compareacoustic ceiling systems.The higher the AC the better the speechprivacy in an open plan situation. Werecommend that you use a suspended ceilingwith minimum Articulation class 180 in orderto achieve acceptable speech privacy.SPEECH PRIVACY VALUESArticulation Class200 Master A/alpha, Super G Plus190 Master C, D, E/alpha, Combison Duo A, E,Focus A, Gedina A.180 Focus C, D, DG, E, Gedina EIncreased background noise - not recommendedIncreased background noise can havelong-term negative effects, such as illness,fatigue, decreased productivity and efficiency.Therefore it is not recommended to attemptto obtain better daily speech privacy byincreasing the ventilation noise, or use othersound masking systems.Another thing to bear in mind is that peopleare differently sensitive to sound and noisein general. Privacy and seclusion in openplan spaces can only be solved satisfactoryby creating separate rooms for confidentialdiscussions and work tasks needing higherconcentration.SOUND INSULATIONSound insulation is the ability of a buildingstructure to prevent sound from passingbetween two premises. Two types of soundinsulation will be discussed:• airborne sound insulation• impact (footstep) sound insulationAIRBORNE SOUND INSULATIONWhen airborne sound energy strikes apartitioning structure, some of the soundenergy is reflected by the structure and somepasses through. The structure thus reducesthe sound energy that would otherwise betransmitted to adjacent spaces. The structureis said to have a sound reduction index R (dB),which indicates a particular air-borne soundinsulation.170 Master A/beta160 Combison Solo A, D, E130 Master A/gamma18 |

Good sound absorption in a room also reducesthe sound transmission to the adjacent spaces,as well as the sound level generated in thereceiving room.The sound reduction of a structure dependson the frequency of the sound, the compositionof the structure and how it is connected tosurrounding structures.TEST METHOD AND RESULTSNormally the sound reduction index ismeasured in one-third octave bands accordingto EN ISO 140 or ASTM E 90 and E 1414.For building acoustic applications, the soundreduction index is examined over the 100-3150Hz frequency range in ISO and 125-4000 Hzin ASTM.A weighted sound reduction single valuecan be obtained by weighting the 16 onethirdoctave band values (included in abovefrequency ranges). According to EN ISO 717-1the airborne sound insulation in laboratoryis expressed as R wdB for a wall or floorconstruction and as D n,c,w(dB) for a suspendedceiling system. On site the airborne soundinsulation between two premises is expressedas R' w(dB).For a sub-structure like a suspended ceilingthe improvement is expressed as ∆ R wdB and∆ R' w(dB) respektively.According to ASTM E 413, thecorresponding expressions for wall or floorconstructions are STC dB and CAC dB forsuspended ceiling systems in laboratory. Onsite the airborne sound insulation is expressedas FSTC or NNIC dB.IMPACT SOUND INSULATIONThe impact sound insulation is the reduction ofdefined footstep sound by a floor construction,expressed as the impact sound level L n(dB)in the room below the floor. It is measuredaccording to EN ISO 140 in the same frequencyrange as the air-borne sound insulation andweighted into a single value impact sound levelaccording to EN ISO 717-2. In laboratory theweighted impact sound level is expressed asL n,w(dB) and on site as L' n,w(dB).For a sub-structure like a suspended ceilingthe improvement is expressed as ∆ L n,w(dB)and ∆ L' n,w(dB) respectively.SUSPENDED CEILINGS AND SOUNDINSULATIONA suspended ceiling system can improvesound insulation in several different ways, bothhorizontally and vertically.• Room-to-room sound insulation• One-way sound insulation• Air-borne sound insulation• Impact sound insulationROOM-TO-ROOM INSULATIONIn many cases a continuous suspended ceilingis chosen in order to achieve maximumflexibility. However these constructions willgive lower sound insulation compared toconstructions where the partitions are allowedto penetrate the suspended ceiling or reach allthe way up to the soffit.| 19

If partitions do not reach the structural soffita horizontal transmission path for the soundvia the void over the suspended ceiling iscreated. Therefore, traditional acoustic ceilingsoften provide insufficient sound insulation. Inthese cases special acoustic ceiling systemsare required which offer additional soundinsulating properties.When estimating the airborne sound insulation• consider the whole structure• note that on site values are lower than laboratory valuesLaboratory value/site valueIn practice on site, the room-to-room soundinsulation ( R' w) can be estimated to be 5-8dB lower than the lowest value in laboratoryfor the suspended ceiling and partitionrespectively. This is due to the fact thatinteraction between the suspended ceilingand the partition considerably reduces soundinsulation. Also flanking transmission mightoccur and some installation details might notbe perfect.RecommendationsDifferent transmission paths between rooms.In order to provide reasonable privacy werecommend that normal offices have soundinsulation between adjacent rooms of R' w= 35dB. This requires a suspended ceiling with alaboratory value D n,c,w= 40 dB.The general approach is to combine a soundinsulating suspended ceiling with partitionsthat offer at least the same sound insulationvalue in a laboratory. Other transmission paths,i.e. ventilation systems, should have an evenbetter sound insulation value. The values usedfor the suspended ceiling and the partitionshould also include possible installations intothem, such as lighting and ventilation units ordoors and windows.ROOM-TO-ROOM SOUND INSULATION VALUESLaboratory value D n,c,w40-42 dB Combison Solo/Combison Duo43-45 dB Combison Solo/Combison Duo + Combison XR600 mm on each side of the partitionONE-WAY SOUND INSULATION46-48 dB Combison Solo/Combison Duo + Combison XRall over the suspended ceiling46-54 dB Combison Solo/Combison Duo + CombisonBarrier over the partitionSite result will be 5-8 dB lower than laboratory value.Installations in the void between the structural soffi t and thesuspended ceiling, such as piping and ductwork systems, can giverise to noise. In such cases, a sound insulating suspended ceilingsystem can be used to reduce the noise to acceptable levels in theroom below.20 |

ONE-WAY SOUND INSULATION VALUESIMPACT SOUND INSULATIONLaboratory value R w12-15 dB Master20-25 dB Combison Solo/Combison Duo23-30 dB Combison Solo/Combison Duo+ Combison XRIn order to determine the noise level generated by a source in thevoid, you should ascertain the frequency spectra of the suspendedceiling's sound insulation and the noise source.AIRBORNE SOUND INSULATIONThe airborne sound insulation of a floorstructure can be improved by means of asuspended ceiling system. Airborne soundinsulation may relate to sounds generated inboth the room below and the room above.Improvements are always linked to a specifictype of floor structure.Impact sound insulation relates to thereduction of footstep sound from peoplewalking on a floor structure. It is determinedby the impact sound level in the room below.A suspended ceiling system can be used toimprove the impact sound insulation andtherefore reduce the impact sound level.Improvements are always linked to a specifictype of floor structure.IMPACT SOUND LEVEL VALUESImprovement of laboratory value ∆ L n,w4-7 dB Master7-10 dB Combison Solo/Combison Duo11-14 dB Combison Solo/Combison Duo+ Combison XRThe improvements are linked to a homogenous concrete fl oor of normalthickness (160-200 mm) and with a plastic carpet.AIRBORNE SOUND INSULATION VALUESImprovement of laboratory value ∆ R w5-8 dB Master6-10 dB Combison Solo/Combison Duo10-14 dB Combison Solo/Combison Duo+ Combison XRThe improvements are linked to a homogenous concrete fl oor ofnormal thickness (160-200 mm) and with a plastic carpet.| 21

ACCESSIBILITYAn important function of a suspended ceiling is to conceal plumbing and heating systems,as well as the electrical, telephone and data communications services that are installed inthe ceiling void. Many suspended ceilings will need to be demounted totally or partiallyduring their service life when such services are augmented, maintained or repaired. Also,damaged panels must sometimes be replaced.PLAN FOR MAXIMUM DEMOUNTABILITYThe design of the ceiling tile edges togetherwith the suspension system provides differentdegrees of demountability. The Ecophon rangeoffers ceiling systems with full demountability,even with concealed suspension systems.However, cable management, ventilationequipment, lighting installations and otherfeatures can limit the demountability ofindividual ceiling panels. These problems canbe reduced by carefully planning the ceilinglayout and by following the plans throughoutthe installation. Examples of this can be foundin section ”Integration”.The Connect T15/T24 Cross tees can bedemounted even in the middle of a ceilingarea. This is a great advantage when aninstallation passage is required.ACCESSIBLE SPACE FOR SERVICEFor every system featured in this cataloguethe minimum overall depth of system (o.d.s.)and the minimum depth for demountability(m.d.d.) are given. These measurements arealso denoted ∆ (o.d.s.) and δ (m.d.d.).The o.d.s. is measured, while the figuresfor the required m.d.d. are empiricallyassessed. In practical terms, this means that themeasurements might vary slightly dependingon the skill and experience of the installer.VERTICAL DIMENSIONS∆ = Minimum overall depth of systemδ = Minimum depth for demountabilityThe overall depth of the system (o.d.s.) is the dimension from theunderside of the structural soffi t to the underside of the suspendedceiling.The minimum depth for demountability (m.d.d.) is the dimensionrequired, to fi t and demount individual ceiling panels. It is measuredfrom the underside of the suspended ceiling.FOR FREQUENT ACCESSHinged ceiling panels (Ecophon Access) arerecommended in areas where the servicesabove the ceiling are frequently accessed.These systems provide complete accessibilitywith no obstructing profiles.Inspection panels (Connect Inspectionpanel) are recommended, even in ademountable ceiling, where access to the voidis frequently needed, e.g. under stop valves.NOTE• Clean cotton gloves should always be worn to avoid soiling theceiling during demounting or maintenance work.• Avoid placing panels in the void, since they might be damagedby sharp profi le edges, etc.• Consider how accessible thevoid needs to be.• Concealed grid anddemountability is possible.• A special system is availablewhen frequent access to the voidis needed.22 |

SURVEY OF SYSTEMS ACCESSIBILITY ACCESSIBILITY GUIDEAccessibility Ceiling system Minimum Minimum All available accessibility guides canoverall depth depth forof system, demountability,be downloaded from the homepage ofmmmmour web-site atwww.<strong>ecophon</strong>.com/Easily demountable,completeaccessibilityAccess AAccess CAccess EFrom 120From 130From 130809090EasilydemountableFocus AFocus DFocus DGFocus EFocus EbxMaster AMaster ECombison Solo ACombison Solo DCombison Solo EGedina AGedina EAdvantage AAdvantage ESombra ASombra DSombra E50 -10060-13065-11560-11011050-10070-12050-10013060-11050-10060-11050-10060-11050-15060-13060-110120-13030-5030-55120-160150170-20017012030120100-12090-16010090-11012030110DemountableFocus A XLFocus D XLFocus DG XLFocus E XLFocus S-LineFocus L-LineFocus QuadroMaster DCombison Duo ACombison Duo EHygiene Meditec AHygiene Meditec EHygiene Performance AHygiene Protec AHygiene Advance ASuper G40-10050 -13011550-110---105-14580-10090-1105060150-170150150-170200-25065-10030-753075-110---80220230100110150150150200-250NondemountableFocus BFocus CFocus FFlexiformMaster BMaster CMaster FHygiene Protec CSuper G Plus2323-13520-4343-1554013542-300---------| 23

CLEANABILITYEcophon ceilings can be dusted, vacuum cleaned, wet cleaned or foam cleaned withhigh pressure hosing, depending on actual sound absorber and construction of the ceilingsystem.In order to obtain a long-lasting ceiling with a long service life and economicalmaintenance, the visible surface should be dirt and dust repellent and easy to keep clean.Ecophon panels with Akutex T are a good choice, as they have a coating that preventsdust from adhering. Therefore, they have a high resistance to soiling.• Cleaning properties affectlife-span and economy• Plan for minimum soiling andregular cleaning• Different ceiling systemswithstand different cleaningmethodsHOW TO PREVENT SOILINGVentilation is often responsible for soilingceilings. Regular maintenance of theventilation system is one way of minimisingthis. Generally, a displacement ventilationsystem (a ventilation system with low velocityair supply located at low level) gives lesssoiling than a mixing ventilation system (withthe air supply in the ceiling).Another way to keep the ceiling clean is toavoid pressure differences between the roomand void. Open grilles, perforated shadowlinetrims, open light fittings or similar caneliminate such pressure differences. If there isa pressure difference, the ceiling will act like afilter and might become dirty.It is important that the ceiling can becleaned throughout its service life. Thisapplies particularly to ceiling tiles thatbecome soiled around ventilation components,or when installations in the ceiling void areserviced.To avoid unnecessary soiling it is advisableto always wear clean cotton gloves whenhandling the panels.For the same reason the ceiling should beinstalled as late as possible in the buildingprocess.CLEANING METHODSIf the entire ceiling or parts of it areparticularly subjected to soiling, it is importantto get it regularly cleaned. In this way thecleaning work will be straight forward, ratherthan allowing dirt to build up over long periodsof time. Using clips on the back of the ceilingtiles facilitates cleaning.For more detailed information seeMaintenance instructions at www.<strong>ecophon</strong>.com.DRY CLEANINGDusting should be carried out with a dry, softcloth, a soft brush or similar.Vacuum cleaning must be conducted withreduced suction asfor textiles, curtainsetc.MANUAL WET CLEANINGWet cleaning should be carried out with a softsponge or cloth saturated with a detergentsolution of the same type and concentration asis recommended for use on painted surfaces.After washing, rinseimmediately withclean water. Usecircular movementswith moderatepressure during boththe washing andrinsing of the ceiling surface. Wipe dry with aclean, well wrung-out cloth or sponge so thatthe dirt released into the rinsing water does notdry and leave marks.24 |

HIGH PRESSURE WASHINGIn rooms with a requirement for regularwashing or washing methods such as foamcleaning with high pressure hosing, werecommend EcophonHygiene panelswith Connect C3grid system. TheHygiene systemscan withstandmore frequentand/or extensive cleaning and the ConnectC3 grid system fulfils corrosivity category C3according to ISO 12944-2.The recommended working pressure is 2-4MPa (20-40 bar). Working pressures up to 8MPa can be used, provided that the scatteringangle is at least 30° and the distance betweenthe nozzle and the surface of the ceiling isat least 300 mm. Most effective rinsing isachieved by holding the nozzle at an angle ofabout 45° to the ceiling.RESISTANCE TO WET ABRASIONThere are several methods for testing theresistance of painted surfaces to wet abrasion.Ecophon has used the Gardner machine (asdescribed in ASTM D 2486 and SS 184164)to determine the wet abrasion resistance of thepanel’s surface. The Gardner machine featuresa standardised abrasive brush that is passedover the panel’s surface. The number of cyclesneeded to penetrate the surface is counted andcan be used as way of judging the relativestrength of various painted surfaces.Ecophon Hygiene Meditec, Performance andProtec can withstand more than 400 cycleswithout any damage to the surface by theabrasive brush. Hygiene Advance is unaffectedby the brush.CLEANABILITY OF ECOPHON PRODUCTSDrycleaningManual wetcleaningHigh pressurewashingHygiene Advance Daily Daily 1) , 2) Daily 1) , 2)Hygiene Protec Daily Weekly 1) , 2) Twice a year 1) , 2)Hygiene Performance Daily Weekly 1) Twice a year 1)Hygiene Meditec Daily Weekly 1) NoFocus Daily Weekly NoMaster Daily Weekly NoCombison Daily Weekly NoGedina Daily Weekly NoAccess Daily Weekly NoSuper G Daily Weekly NoWall Panel/Akutex T Daily Weekly NoWall Panel/Super G Daily Weekly NoWall Panel/Colorado Weekly No NoAdvantage Weekly No NoSombra Weekly No No1)Appropriate detergents and disinfectants should be used for thispurpose.2)Hygiene Advance, Protec A and Protec Baffl es are demountable,can be cleaned on all surfaces and can withstand frequenthandling. Hygiene Advance and Protec Baffl es can also withstandhigh pressure hosing on all surfaces.| 25

LIGHT EFFICIENCYLighting can make a huge contribution to the overall look and feel of a room. A key factoris how the ceiling refl ects and diffuses the light. To create a pleasant interior the ceilingshould be the lightest surface in the room - a white ceiling will refl ect more light than adarker one. The lighting itself should not cause glare or surface refl ection. This can beavoided by the installation of indirect lighting.When a ceiling gives good light refl ectance and light diffusion, the need for installedlighting is reduced. This results in improved energy efficiency and a better workingenvironment.• Light coloured ceilings makepleasant interiors• Ceilings with high light refl ectancegive cost-effective lighting• Avoid glare and irritatingrefl ections by using indirectlightingLIGHT REFLECTANCELight reflectance is expressed as a percentageand states how much of the light falling on asurface is reflected back.In order to get the best efficiency, both forincident daylight and lighting, the ceiling’slight reflectance should be high. High lightreflectance also reduces the risk of glare fromlight fittings, because this in turn reducesthe luminance ratio (i.e. the difference inbrightness between the light fittings’ luminoussurfaces and the ceiling). In the case ofdirect lighting the suspended ceiling’s lightreflectance should be at least 70%.With indirect lighting, light reflectanceneeds to be higher, because the level ofillumination in the room then depends largelyon how much light the ceiling surface reflects.For satisfactory indirect lighting, the ceilingsurface requires a light reflectance of at least80%.Ceilings with high light reflectance also leadto cost-effective lighting, particularly whencombined with indirect lighting. The diagramshows, in a situation with 100% uplight, howthe illuminance from a certain luminaire in aroom varies depending on the light reflectanceof the ceiling.ILLUMINANCE FROM A CERTAIN LUMINAIRE IN AROOM WITH 100% UPLIGHTIlluminance (lux)Akutex Twhite 010(84%)Akutex T Akutex Tyellow 364 light grey(81%) 965 (65%)Akutex Tmediumgrey 966(49%)Ceilingsurface (lightrefl ectance)Light reflectance is measured in accordancewith the CIE Publication No. 15.2 (1986).Measurement values are evaluated with CIE10 degree Standard Observer (1964) and CIEStandard Illuminant D65.LIGHT REFLECTANCE OF ECOPHON TILESHigh light refl ectance. (Relates toproducts with white surface fi nish.)Medium light refl ectance. Can beused for indirect lighting to someextent.Limited light effi ciency. Not suitablefor indirect lighting.FocusMasterCombisonGedinaAccessHygiene PerformanceHygiene ProtecHygiene MeditecWall Panel/Akutex TAdvantage/whiteColoured productsSombraHygiene AdvanceSuper GSuper G PlusWall Panel/Super GWall Panel/Colorado26 |

LIGHT DIFFUSIONLight diffusion (how light is spread) cansignificantly decrease dazzle and glarefrom the different surfaces and objects ina room. The more diffusely and evenly thelight is spread the better dazzle and glare areprevented. Light diffusion can be defined asthe ratio of the diffused reflected light to thetotally reflected light. According to DIN 5036measurements, Ecophon´s ceiling tiles in lightcolours provide over 99% light diffusion,which means that practically all reflected lightcan be regarded as diffuse.GLOSSAnother way to describe a surface is tomeasure ”gloss”. This value is always relatedto a certain angle (e.g. 20°, 60° or 85°) anddoes not describe how evenly the reflectedlight is distributed in space. The gloss valueis between 0 and 100, where 70 is high gloss,according to most of the relevant standards,i.e. ISO 2813, ASTM D 523 and DIN 67530.The gloss of the Ecophon tiles is low,

INFLUENCE OF CLIMATEAll kinds of material are affected by the surrounding climate. Ecophon products aredesigned for indoor use. Hence, the key climatic factors for consideration are moisture,heat and microbiological activity.The core material in all Ecophon tiles isglass wool that has been treated to be waterrepellent.Therefore, the material does not takeup water by capillary action and the absorptionof moisture from the air is relatively low.Water that occasionally may penetrate thetiles (e.g. in conjunction with cleaning) driesout quickly thanks to the open structure of theglass wool material.Defl ection of ceiling tiles that are deformed after absorbing moisture.Glass wool is one of the materials most resistant to moisture.Thus, glass wool ceiling tiles are dimensionally stable and stayfl at even in environments with high or varying air humidity.At high relative humidity, there is a seriousrisk of condensation, because of thetemperature difference over the ceiling. At95% RH and 30°C, a temperature drop of only1°C will cause condensation. The presenceof liquid water might have many undesiredeffects, such as stains from water-solublesubstances on the visible surface of the ceiling.There is a physical relationship betweenabsolute humidity, temperature and relativehumidity. The warmer the air, the more watervapour it can hold. In other words - a certainabsolute humidity means a lower relativehumidity at a high temperature than at a low.(See graph).Absolute humidity (g/m 3 )RHAlso Ecophon Connect grids and accessoriesare developed to withstand high humidity.NOTE• Ecophon products should be stored indoors. If, temporarily, theyhave to be stored outdoors, they need to be protected againstmoisture.• If the tiles are to be glued, the temperature must be 15-25°Cduring installation.• The panels do have a thermal resistance. This may infl uencethe temperature and the relative humidity in the room and inthe plenum, and should therefore be considered in the moistureand thermo-technical design. Ventilating the plenum will preventcondensation.Temperature (°C)Relationship between temperature, absolute humidity and relativehumidity.• Moisture, heat andmicrobiological activity affectthe ceiling• Too high relative humidity is notcomfortable for people• Special panels and accessoriesshould be used in aggressiveenvironmentsTEMPERATURE, ABSOLUTE HUMIDITYAND RELATIVE HUMIDITY (RH)The relative air humidity varies depending onthe time of year, temperature and climatic zone.Relative humidity RH, expressed in %, isthe ratio of the actual amount of moisture inthe air to the maximum amount of moisture theair can hold at a given temperature. A relativehumidity of 100% means the air can hold nomore water, i.e. condensation forms, and arelative humidity of 0% indicates there is nomoisture in the air.CEILING DESIGN FOR HUMID AREASIn order to minimise the risk of problems withcorrosion, mould and aesthetic performancein a building, the relative humidity shouldnot exceed 70-80% more than temporarily. Inany case, it is not comfortable for people tobe in environments with any higher relativehumidity than this. In comparison, the averagerelative humidity in a rain forest is 75-90%.28 |

When moisture is increased, as in professionalkitchens, swimming pool facilities, showerareas or food preparation industries, theair humidity can rise substantially andoccasionally reach saturation which meanscondensation forms. The indoor climate insuch rooms should therefore be carefullysurveyed before the ceiling systems areinstalled.Moisturecontentand hence give results that are not reliable.Leading testing institutes, such as SP (SwedishNational Testing and Research Institute) andTNO (Netherlands Organisation for AppliedScientific Research) cannot perform tests withsufficient accuracy at RH>95%.Sorption isothermMOISTURE TESTSMost Ecophon ceiling tiles are tested inaccordance with the methods and instructionsstated in ISO 4611. The majority of thetiles can withstand a permanent relativeair humidity of up to 95% at 30°C withoutwarping, deflecting, sagging or delaminating(see Moisture resistance table for details).Occasionally, for example during temporarydamage to air-conditioning plant, etc., theabove limits for air humidity/temperaturecan be exceeded without deterioration of theproducts or their performance. However, this isonly possible provided the tiles are allowed todry out in between.Ecophon does not present higher valuesthan 95% RH at 30°C due to technical andphysical limitations in the testing methods.The fact is, that if the RH exceeds 95%, themoisture equilibrium is extremely sensitivealso to very small climate variations in thetesting chamber. For each specific material, themoisture content can be shown in a sorptioncurve. The sorption curve is very steep athigh RH, and a hysteresis effect exists. Themoisture content in the material is thereforeunpredictable. Thus, attempts to carry outtests at a relative humidity >95% will fail,as the relative humidity will be unstableHysteresis effectRelative humidity (%)ISO 12944-2 deals with the classificationof the principal environments to which steelstructures are exposed. All Ecophon Connectgrids and accessories can withstand a C2environment according to this standard.The Connect C3 grid system has an extraanti-corrosion protection, which makes theproducts withstand a C3 environment.EXTREME ENVIRONMENTS ANDMICRO-ORGANISMSSustained high temperatures and/or airhumidity or environments with aggressivegases or other substances may affect theceiling systems´ appearance and properties.In cases where regular washing or hosingof the ceiling is necessary specially designedsystems, Ecophon Hygiene, should be used. Inthese environments, and in environments withhigh air humidity grid systems with additionalcorrosion protection, Ecophon Connect C3,should also be installed.| 29

The risk of mould and bacteria is animportant consideration in environments withhigh relative humidity. Ecophon productsthemselves do not serve as a natural breedingmedia for mould and bacteria. By keeping theenvironment of the ceiling clean, and having acontrolled climate below the critical humidityand temperature level, the risk for these microorganismsis reduced considerably.Mould and bacteria need specialgrowing conditionsMOISTURE RESISTANCEMax. permanent* relative air humidity95% at 30°C. Higher air humidity/temperature in conjunction with Hygienecleaning.95% at 30°C* FocusMasterCombison SoloGedinaAdvantageAccessSombraSuper GWall Panel/Akutex T andSuper G75% at 30°C* Combison DuoWall Panel Colorado*The air humidity/temperature can be exceeded temporarily– see under Moisture Tests in this chapter.Moisture Right temperature Growth media= Risk for mould and bacteriaEcophon tiles have been tested formicrobiological growth according to theASTM-standard G 21-96 at SLU (the SwedishUniversity of Agricultural Sciences). Thestandard rates the products in 6 classes 0-5.All tested Ecophon tiles were in class 0, whichmeans that they were unaffected.The Moisture Resistance table shows whichclimate the different products can withstandwithout warping, deflecting or delaminating.Note, however, that micro-organisms can alsobe active in less humid climates.Please note that the Hygiene products havethe same climate limitations as for examplethe Focus and Master products, but theHygiene products can withstand more frequentand extensive cleaning. Also see chapterCleanability.30 |

INDOOR CLIMATEDust and various types of emissions make a huge contribution to the increased incidenceof allergies. This is why there often is a <strong>focus</strong> on good indoor climate in new ormodernised buildings.GOOD INDOOR CLIMATEThe indoor climate has a significant impacton people’s health. A poor climate can oftentrigger allergies and stress related illness. Toachieve a good indoor climate:• avoid the formation of dust and dust-gathering surfaces andmaterials• avoid materials that have undesirable emissions• choose material that can easily be cleaned• choose material providing a good acoustic environment• choose material and lighting that provides a good lightenvironment• air frequently and/or have adapted ventilationTHE INDOOR CLIMATE LABELLINGThe Indoor Climate Labelling (DIM) includestesting for emissions and their decay periods.Measurements are carried out to establishhow long it takes for emissions of ammonia,formaldehyde, VOC (Volatile OrganicCompounds) and particles to decay belowspecified levels. The classes are related todecay within 10, 20 and 30 days. Ecophonproducts that are certified by DIM pass thehighest requirement i.e. they are within the 10days decay level. Included are also odour tests.In Finland, the ”Emission classificationof building material”, run by the BuildingInformation Foundation RTS, places mostEcophon products in the highest class (M1).RECOMMENDATION BY THE SWEDISHASTHMA AND ALLERGY ASSOCIATIONProducts recommended by the Associationhave been assessed to be free from allergens,perfume and irritating substances to a degreethat no known, medically reported cases exist.The assessments are made by the ProductCouncil of the Association (specialists inmedicine, chemistry and technology) and arebased on research results, analyses and theformula for the actual product.CLEAN ROOM CLASSIFICATIONIn some environments, it is necessary tolimit the number of airborn particles. Thiscan be a requirement in the pharmaceutical,electronic and food industries, as in somehospital environments. Two standards forclassifying air cleanliness are US FederalStandard 209E and EN ISO 14644-1. Theclassification systems are exclusively basedon the concentration of airborne particles andthere sizes. The table shows the classes definedand how they approximately corresponde.g. ISO class 4 lies between M2 and M 2.5.Included also are the zone classes defined inthe guide ”Good manufacturing practice formedicinal products” issued by the EuropeanCommission.ISO14644-1ISO Class 1ISO Class 2ISO Class 3ISO Class 4ISO Class 5ISO Class 6ISO Class 7ISO Class 8ISO Class 9US FS209 EM 1M 1.5 (1)M 2M 2.5 (10)M 3M 3.5(100)M 4M 4.5(1 000)M 5M 5.5(10 000)M 6M 6.5(100 000)M 7EU/GMPA and BExamples of activities/environmentsZones unoccupiedby personnelTransplantation surgeryManufacturing of highperformance opticalinstrumentsVarious tests and practical experience showthat the Ecophon Hygiene systems can be usedin room classified as M 2.5. For informationregarding other Ecophon systems - seerelevant system description.CDFood and drink industry• Indoor Climate Label• Finnish emission classifi cation• Swedish Asthma & AllergyAssociation• Clean Room Classifi cations| 31

ENVIRONMENTAL INFLUENCEAdministration of the earth’s resources is one of the most important environmental issuesfor the future. This calls for environmental consciousness, knowledge and a desire to worktowards improvement. Therefore, environmental concern should be at the forefront of alldecision-making.310007GLASS AND GLASSWOOL IN THEECOLOGICAL CYCLEGlasswool consists almost entirely of glass.Over 70% of the basic material in Ecophonsound absorbers consist of recoveredhousehold glass and recycled glasswool. Theremaining parts are normally produced fromglass that is made from raw materials such assand and sodium. Glasswool production wastecan be recycled by two unique methods: theOxymelt and the Contiroll processes.CONNECT GRID AND ACCESSORIESIN THE ECOLOGICAL CYCLEConnect grids are manufactured fromgalvanised steel that consists of approximately50% recycled steel. This means that the gridscan be recycled all over again.In the production all steel waste is takencare of local contractors for recyclingTRANSPORT AND INSTALLATIONDue to consistent development work, Ecophonhas been able to decrease the average thicknessof its acoustic tiles, while maintaining theirexcellent properties. This has lead to areduction in volumes, resulting in less energyconsumption during transportation.Another advantage of this decreased volumeis that the tiles are easier to handle, and withtheir low weight, easier for ceiling installersto use.LIFE-SPANThe technical life span for Ecophonceiling systems is the same as that of thebuilding. The practical life span, however,is usually about 20 years, due to changesin fashion, abnormal soiling and/or poormaintenance.THE NORDIC “SWAN” ECO-LABELThe Nordic ”Swan” Eco-label, signifies thatthe product satisfies the Nordic EnvironmentalLabelling Board criteria and requirements overthe whole life cycle. This standard covers boththe external and internal environment and theproduct’s manufacture all the way from theraw materials to recycling. Listed below aresome examples from the criteria document:• have none or in some cases minimum content of substancesharmful to the environment or health• have a high recyclable content• require low energy consumption during manufacture• meet general requirements for low environmental impact onwater, soil and airECOLOGICAL LABELLINGThe Nordic Swan (Licence no 310 007)FocusMasterCombisonGedinaAccessAdvantageSombraHygieneSuper GWall Panel••••••••For detailed information see section System Description• Recycling• Transportation• Ergonomics• Life-span32 |

FIRE SAFETYA fire in a building can develop very quickly and lead to devastating consequences. Inthe design process of a building and when selecting building materials it is therefore ofgreatest importance that the fire safety aspects are treated carefully and with knowledge.REQUIREMENTS ON SUSPENDEDCEILINGSThe fire safety demands on suspended ceilingscan vary depending on both the type of roomand building where they are to be installed.Detailed requirements can be found in thenational building regulations. Three generalrequirements can, however, be identified ascrucial for suspended ceilings in the earlystages of fire. The first two should be regardedas ”compulsory” in all premises, while thethird is normally only required when theceiling void contains relatively large amountsof combustible materials, e.g. cables.FIRE SAFETY IN BUILDINGSThe main purpose of the fire safety design of abuilding is to minimise the consequences of afire. Principally, it concerns the prevention ofinjury to people but it also entails limiting thematerial and economic damage which is likelyto ensue.80°C• They must only make a negligible contributionto the fire development and to the productionof smoke. This is fulfilled by using a ceilingconsisting of materials and surface liningscomplying with at least Euroclass B-s1, d0.• They must not break and collapse during theearly stages of the fire when evacuation andrescue operations can still be carried out.To pass this requirement a ceiling systemshould be able to withstand a heat exposureof approx. 300°C. (The heat radiation from asmoke gas layer with a temperature of 300°Ccorresponds approximately to what a fullyequipped fire fighter can withstand.)• They should prevent ignition of combustiblematerial in the ceiling void in order to delayor prevent the occurrence of flash over. Thisrequirement, as well as the second, is met withceiling systems classified as class K 110/K 210or as ”Fire protection covering” according toNT Fire 003.In a burning building the circumstances can quickly become suchthat there is imminent risk of personal injury. Within the parametersof safe evacuation, consideration must be given to fi re gases,visibility, heat radiation and temperature. E.g. in order to evacuatesafely, the air temperature in rooms through which people areescaping should not exceed approx. 80°C.The total fire protection of a building andits specific function is a complex issue,comprising several areas and how they interactwith one another:• The building itself including its design, building elements,materials, interior fi ttings and furnishing• The fi re detection systems and alarms• The organisation and practice of conducting evacuation, e.g. inschools and nursing homes• The rescue efforts of fi re brigades• The extinguishing and control of the fi re. Partly through automaticfi re extinguishing systems and/or partly through active actions,e.g. of the fi re brigadeBuilding regulations and various types ofstandards normally cover these aspects.The building regulations are formulated ona national basis and vary between differentcountries. Standards can be on either anational base (e.g. DIN, BS and ASTM) orinternational (EN- and ISO-standards).• The surface linings of walls andceiling are crucial for the earlydeveloment of a room fi re• Flash over occurs at atemperature of about 600°C• The maximum air temperature forsafe evacuation is appr. 80°C| 33

At the point of fl ashover the entireroom is engulfed by the fi re andlarge fl ames burst out from door andwindow openings. The fi re can nowspread to other parts of the building.DESCRIPTION OF A FIREWITHIN A ROOMA room fire can be divided into various phases.The incipient phase or beginning of a fire isdependent on the size of the ignition sourceand the properties of the materials and objectsthat are directly affected.During the growth phase the fire increasesin size and other objects around the fire originwill begin to burn. Even the surface linings ofthe walls, floor and ceiling close to the fire canignite. Increasing amounts of smoke and heatbegin to develop and a layer of hot fire gasesforms beneath the ceiling.In the growth phase the fi re is local. The fi re characteristics of thesurface linings play an important part in the fi re development.During the growth phase flashover can occur.This is when the intensity of the fire is so greatthat it ceases to remain local but involves allcombustible material in the room. A largeamount of heat is released and flames burst outthrough windows and door openings.Generally, flashover occurs once the firegases in the room reach 500-600°C. The heatradiation from the layer of fire gases is sogreat at this stage that it causes all combustiblematerials to ignite.Flashover can occur just a few minutes afterignition. However, it can also be delayed oravoided altogether. This could be the casein a room which has just a small amount ofcombustible furnishings and is equipped withsurface linings that make just a negligiblecontribution to the fire development.After flashover the fire reaches its maximumlevel and is fully developed. The length andintensity of the fire is now mainly determinedby the supply of air and the fire load, i.e. theamount of combustible materials present.The decay phase is when the fire fades out.TESTING AND CLASSIFICATION OFPRODUCTSFire testing methods are generally designedto simulate the different phases of the fireprocess. Consequently, tests on surface liningsare conducted using fire sources representativeof the incipient and growth phases of a fire.These test methods are referred to as ”reactionto fire” tests and the purpose is to evalutate thecontribution of products and materials to theearly stages of a fire in terms of:• Ignitability• Flame spread• Heat release• Smoke production• Occurrence of fl aming droplets/particlesNormally reaction to fire tests are carried outin small or intermediate scale.Complete building elements (doors, floorstructures, partitions etc.) which are used forseparating fire compartments are tested forthe case of a fully developed fire. These testmethods are called ”fire resistance” and arecarried out in full scale. The temperature in34 |

the test furnace follows the so-called ”standardfire curve” which is designed to represent afully developed fire. The properties that areevaluated are:• Insulation (ability to reduce the heat transfer)• Integrity (ability to prevent leakage of fl ames and hot gases)• Load bearing capacityBuilding elements classified as ”fire resistant”with respect to integrity and insulation areused as a means to prevent fire being spreadbetween fire compartments.THE EUROPEAN SYSTEMREACTION TO FIRE - EUROCLASSThe new reaction to fire testing andclassification system for linings and materialsin Europe is called Euroclass.Altogether there are 39 classes divided into7 main levels; A1, A2, B, C, D, E and F whereA1 is the best and F are for products andmaterials not classified.Most of the main classes also include anadditional classification regarding smokeproduction and the occurrence of flamingdroplets/particles.The classes for smoke are s1, s2 and s3,where s1 is the best.The classes for flaming droplets andparticles are d0, d1 and d2, where d0 is thebest.A2- s1,Main classSmokeproduktiond0Occurence offl aming droplets/particlesEUROCLASSESTemperatureA1A2-s1,d0 A2-s1,d1 A2-s1,d2A2-s2,d0 A2-s2,d1 A2-s2,d2A2-s3,d0 A2-s3,d1 A2-s3,d2B-s1,d0 B-s1,d1 B-s1,d2B-s2,d0 B-s2,d1 B-s2,d2B-s3,d0 B-s3,d1 B-s3,d2C-s1,d0 C-s1,d1 C-s1,d2C-s2,d0 C-s2,d1 C-s2,d2C-s3,d0 C-s3,d1 C-s3,d2D-s1,d0 D-s1,d1 D-s1,d2D-s2,d0 D-s2,d1 D-s2,d2D-s3,d0 D-s3,d1 D-s3,d2EE-d2FEuroclasses according to classifi cation standard EN 13501-1 Fireclassifi cation of construction products and building elements - Part 1Classifi cation using test data from reaction to fi re tests.Flash overIncipient Growth Fully developed DecayEuroclasses andclass K 210Fire resistance classesTimeThe graph shows the relationship between fi re process and thefi re classesFIRE PROTECTION ABILITY - CLASS KThe information regarding class K reflectsthe situation of March 2003 when theworking process with the European test andclassification standard still was under progress.Changes may therefore have occurred.Class K comprises four classes: K 110, K 210,K 230 and K 260.Class K 110/K 210 derives from andcorresponds mainly to the Nordic testing andclassification standard NT Fire 003 ”Fireprotection ability - Coverings”. This class wasdeveloped and designed for evaluating thefire protection ability of coverings, such assuspended ceilings, in the growth phase of afire.| 35

The main reason for using a ceiling classifiedas K 110/K 210 is that it should prolong thetime to flash over or even prevent it. This isachieved by not allowing any combustiblematerial behind the covering, e.g. cablesand timber members in a ceiling void, tocome into contact with the fire and thereforecontribute to its growth. This means that thefire development will only be governed by theconditions of the room itself.The class also means that the ceiling, orparts of it, does not break and collapse duringthe time evacuation and rescue operations canbe carried out.If there is a need of extending the protectionfunction over the flash over point into thephase of a fully developed fire class K 230 andK 260 could be used.Contrary to the Euroclasses, class Kincludes the complete ceiling system i.e.panels, suspension hangers, fixings, perimetertrims etc. The Euroclass system is onlyconcerned with the panels of a ceiling system,provided that the grid and other componentsdo not contribute to the fire development, e.g.if they are made of metal.Class K 2Load Integrity Insulation Time class10The main classes used for the fire resistanceclassification of building elements are:R = Load bearing capacityE = Integrity (ability to prevent leakage of fl ames and hot gases)I = Insulation (ability to reduce the heat transfer)The classes are always combined with a timecould be from 15 up to 360 minutes in stepsdefined in the classification standard EN13501-2. A separating and load bearing wallcould for example be classified as REI 60,capacity as well as its fire separating functionduring 60 minutes of a fully developed fire.A non-load bearing element will only bea time class. The latter case is for examplewill prevent the penetration of flames and hotgases but not provide insulation against heat.a separating element, can, accordingly, onlya time class.R E I 60From Norwegian/Danish ”Kledning/beklaedning”(covering)Number ofminutes of fi retest.FIRE RESISTANCEclass expressed in minutes. These time classeswhich means that it will retain its load bearinggiven the classification EI or E combined withrelevant for special fire glazed partitions whichA load bearing column, which is obviously nothave the fire resistance class R combined withbearingcapacity(ability topreventleakage offl ames andhot gases)(ability toreducethe heattransfer)10 minutes represents the early stage of fi re. The fi re gastemperature in the test furnace reaches appr. 680°C which is overthe critical temperature for fl ash over.THE ASTM SYSTEMREACTION TO FIREIn the US market products are tested andclassified according to ASTM standards(American Society for Testing and Materials).Flame spread and smoke production ofsurface linings, for example on ceilings, are36 |

tested and evaluated according to ASTM E 84”Surface Burning Characteristics of BuildingMaterials”. A smoke production index andflame spread index is then derived from themeasurements that are taken.Acoustic ceiling products are classifiedaccording to ASTM E 1264. Three fire classesare defined; A, B and C. The classes areequivalent to classes I, II and III, respectively,of various building code authorities. Class A(I) is the best.ASTM fi re classes. In addition, for class A ceiling products thematerial should not show evidence of continuos progressivecombustion after the test fl ame has been extinguished.FIRE RESISTANCEMax allowed indexclass Flame spread Smoke developmentA 25 50B 75 -C 200 -Fire separating elements, such as fire wallsand floor structures, are tested and evaluatedin accordance with ASTM E 119 ”Fire Testsof Building Construction and Materials”.The tests are carried out in full scale. The testspecimens are subjected to a heat exposure thatcorresponds to a fully developed fire.THE SUSPENDED CEILING AS FIREPROTECTION IN PRACTICEClass K 110/K 210 (Fire protection covering)and Euroclass classifications play a crucialrole in the early development of fire andconsequently for the fire safety of a buildingas a whole. In order to obtain the requiredfunctions the assembly instructions and otherconditions included in the classification mustbe followed at the building site.Class K 110/K 210 is a classification, which,unlike the surface lining classifications,encompasses the complete structure, i.e.panels, grid, suspension hangers, fixingsand other included components. None of thecomponents incorporated in the ceiling systemmay be changed in any way without riskingthe validation of the classification.Even if the surface lining classifications arenot as tightly bound as class K 110/K 210 tothe constructional design of the ceiling, thereare still limitations. For example, any kindof repainting or alteration of the surface willmake the classification of the surface lininginvalid. Furthermore, repainting will also havean effect on other properties, such as soundabsorption.REACTION TO FIRE CLASSIFICATIONSUK BS 476 part 6 & 7EUROPE EN 13501-1FR NFP 92-501/510FDP 92-507DE DIN 4102 part 2US ASTM E 1264NL NEN 6065/6066ClassProductsClassProductsClassProductsClassProductsClassProductsClassProductsClass 0FocusGedinaAdvantageSombraMasterCombisonAccessSuper GHygieneWall PanelA2-s1, d0FocusGedinaAdvantageSombraMasterCombison DuoAccessSuper GHygieneWall PanelClassementM0ClassementFocusGedinaAdvantageSombraMasterAccessSuper GHygieneWall PanelFocus S-lineNichtbrennbarA2Schwerentflammbar B1FocusGedinaSombraMasterCombison DuoSuper GWall PanelFocus S-lineFocus QuadroFocus FlexiformClass AFocusGedinaAdvantageSombraMasterCombison SoloAccessSuper GHygieneWall PanelKlasse 1FocusGedinaAdvantageSombraMasterCombison SoloAccessSuper GHygieneWall PanelB-s1, d0Focus S-lineM1Focus QuadroAdvantageFocus QuadroFocus L-lineHygieneFocus L-lineCombisonFocus FlexiformHygiene AdvanceCombison Solo| 37

kgMECHANICAL PROPERTIESMechanical properties embrace load bearing capacity and impact resistance.The tilesand grid of a ceiling system are subjected to different loads. All of these possible loadsmust be considered during the process of planning and designing a ceiling.LOAD BEARING CAPACITY -GRID SYSTEMThe live load - both static and dynamic - towhich the suspension system can be subjected,depends on the demands made on breakageand deformation. In such cases deformationcan be a form of deflection or twisting.DEFLECTION OF GRIDWhen the maximum allowable load ofEcophon ceiling systems is establishedand determined, it is always deflection, notbreakage, that is the decisive factor.A suspended T-profi le exposed with load (F) giving a defl ection (f).VOCABULARY - LOADSStatic loadThe weight of the ceiling itselfand the weights of items attachedto the ceiling e.g. light fi ttings,loudspeakers, ventilation grills, signsand so on.Dynamic loadMechanical impacts, for examplecontact from balls in gymnasiums orwater pressure when the ceiling isbeing cleaned with high pressurehoses.Own weight (g)The weight of the ceiling systemitself (including the tiles, the totalsuspension system and all mountingdetails). This is always a static load.A form of deformation: Twisted profi leBREAKAGEIt is imperative to prevent a ceiling frombreakage or collapsing because it has beenoverloaded. Therefore the recommendedmaximum allowable load for each ceilingsystem (see the installation diagrams) iscalculated and determined with a multiplesafety margin against any kind of failure.Maximum allowable load can only beapplied if the ceiling is complete and has beeninstalled in accordance with the installationdiagram. In other words, the prescribedproducts must be used and all the ceiling tilesmust be in place in the grid.While the grid profiles and hangersconstitute the load bearing capacity andstrength of the ceiling, the ceiling tiles playan important role in stabilising the profilessideways. This is especially important whena profile is loaded eccentrically, which oftenforces it to twist. In light of this, centricloading is always preferable. For example,it is important to install light fittings andother additional components so that the liveload will be transferred centrically into theT-profiles.A load on a profile will always causedeflection (f). The deflection is proportional tothe load and strongly depends of the span (L)between the supports. If the load (F) doubles,the deflection will double. The deflectionbecomes, however, even bigger if the distancebetween two supports doubles. The deflectionfrom a point load will, for example, becomeeight times bigger.In the table below, with recommendationsfor Connect suspension systems and maximumpermitted loading of live load, we have takeninto account the most important standards:ASTM C635, BS 8290 part 2, DIN 18 168and SS 81 51 13. The decisive factor has beenthat deformation should be limited to L/500.When the deflection reaches around L/400it is possible for the human eye to notice thedeformation. The limit L/500 gives, withsafety, a ceiling with a smooth appearance.E x a m p l e : For the span L=1200 mm theallowed deflection is 2,4 mm.38 |

kgRECOMMENDED LIVE LOADThe recommendations apply to live loadin addition to the suspended ceiling’s ownweight. The live load can be point loads (lightfittings, signs etc) located arbitrarily on thesuspension system, but separated by at least 1m. With hangers located more closely together,higher permissible live load than stated in thetable can be achieved. Heavier loads must,however, be hung directly from the soffit.If an actual live load is distributed overan area of 0.36 m² (600x600, 1200x300)or more, the grid is able to take a load 65%bigger than the recommended maximum liveload regarding deformation in the table. Thisis provided the live load is fixed to the gridsystem. The actual live load must, of course,be considered for hangers and fixings.E x a m p l e : A recessed light fitting,600x600 mm, with a weight of 7 kg isacceptable in a Focus ceiling which, accordingto the table, are able to carry a maximum liveload of 83 N (8,3 kg) if the distributed area is0,36 m² or more.Recommended loadEcophon ceiling systemaccording to relevantinstallation diagramFocus, Gedina,Advantage, Sombra,Hygiene 20mm,Meditec, Super G PlusFocus XL1600 incorridors, Master, SuperG, Hygiene 40 mmFocus XL 1800 incorridors, CombisonSoloFocus XL 2000 incorridorsRecommendedmaximum liveload regardingdeformation(point load(F) with 1 mseparation)50 N(5 kg)40 N(4 kg)20 N(2 kg)10 N(1 kg)Recommendedmaximum live loaddistributed on a biggerarea than 0.36 m 2 ,regarding deformation(uniformly distributedloads (q) with 1 mseparation)83 N(8,3 kg)66 N(6,6 kg)33 N(3,3 kg)16 N(1,6 kg)The above applies provided that the distancefrom the joint between two main runners to thenearest support point does not exceed ¼ of theallowable distance between suspensions.The joint to nearest support point should not exceed ¼ of thedistance between two suspensions.This means that, when the distance betweenthe suspensions are 1200 mm, the couplingpoint between two main runners has to beless than 300 mm from the support point. Theabove applies provided that the load will betransferred centric to the T-profile.LOAD BEARING CAPACITY– SUSPENSIONS AND FIXINGSThe chosen suspensions and fixings, such ashangers, direct fixing brackets, screws etc.must be able to carry the design load (theown weight of the suspended ceiling andactual live load) with at least factor three ofthe safety limit set against breaking. Thismeans that suspensions and fixings used tosupport a ceiling must be able to carry, withoutcollapsing, a load at least three times the loadthat they will be imposed to. All Connectadjustable hangers and direct fixing bracketsmeet these demands, providing the installationis carried out according to Ecophon installationdiagrams and the maximum live load for theceiling system has been respected.Suspended T-profi le with differentloads.VOCABULARY - LOADSLive loadAll loads added to the ”naked”ceiling system. Live loads can bestatic or dynamic and embrace:• Uniformly distributedload (q) from light fi ttings,signs, pressure differences,cleaning, etc.• Point load (F) from lightfi ttings, signs, impact, cleaning,etc.• Normal force (N) Forcecaused by impact, abrasion,cleaning and/or installationwork. A dynamic load.Design loadThe own weight of the suspendedceiling and the actual live loads theceiling is designed for.| 39

kgThe load bearing capacity (maximumallowable load) for Connect suspensionand fixing products can be found in sectionConnect grid and accessories. The maximumallowable live load and the required minimumload bearing capacity of the fixings and thehangers for each individual ceiling system canbe found in the installation diagrams.E x a m p l e : For Ecophon Master A themaximum allowable live load is 40 N (4 kg).The minimum load bearing capacity for thehangers and fixings must not be less than 160N (16 kg), included a safety margin of at leastthree against breaking.LOAD BEARING CAPACITY – ABSORBERSThe basic rule is that loads must not beimposed on the absorbers. Light fittings,ventilation components etc. located in thesuspended ceiling should be supported by thesuspension system or be hung directly fromthe soffit.The loading on the tile must bedistributed evenly around the rimof the aperture.However, Ecophon absorbers in 600x600 mmand 1200x600 mm sizes can take small loads,such as halogen spotlights. For absorbers thatare 20 mm or thicker, e.g. Focus or Master,a maximum of 500 g applies, with a largestaperture diameter of 100 mm. The equivalentfor 15 mm absorbers, e.g. Gedina, is 300 g.Tiles wider than 600 mm and longer than1200 mm must not be subjected to loads.DYNAMIC LOAD BEARINGCAPACITY - IMPACT RESISTANCEDynamic load bearing capacity is ameasurement of how well a product or asystem handles dynamic live load, e.g.abrasion or impact. The need for suchresistance to mechanical action differs indifferent environments. The dynamic live loadcan be a separate blow from a ball or a stick.It can also be recurrent, for example an objectthat is being pushed forwards and backwardsalong a surface for a long time. Anotherdynamic live load is the pressure differencethat may occur in a room because of opendoors or the ventilation system.There are different, generally accepted,methods for testing and evaluating the impactresistance of ceiling systems. Ecophon usesthe Ballwurfsicherheit-method according toDIN 18 032, part 3 and an internal test method.Both test methods are based on allowing ahandball to hit the system, after which itsimpact resistance is judged visually.In rooms where the ceiling might besubjected to impact, we recommend EcophonSuper G systems. If no extra protection againsthard or sharp objects has been installed, theacoustic system should be placed away fromthe occupied zone and well out of normalreach. For further advice regarding this, pleasecontact Ecophon.40 |

INSTALLATIONA well-installed ceiling system can really contribute to the overall look and feel of a room.This can be attained by combining Ecophon absorbers with the Connect grid system.Both are simple to handle and install, and together will create a well-fitted ceiling system.HANDLINGThe Ecophon ceiling system is lightweightand therefore extremely undemandingin terms of transportation, handling andinstallation. The structure of glass wool issuch that the tiles have excellent mechanicalproperties relative to their weight. This meansthat Ecophon sound absorbers are stable andcan withstand handling, but are nonethelesspliable and very easy to work with.Of course,the panels canwithstand normalhandling duringinstallation,but due careshould be takento avoid breakingor damaging the edges and surface.It is worth bearing in mind that ceilingproducts are visible parts of the interior andshould be regarded as part of the furniture.Cartons containing panels and grids must behandled according to the instructions on thelabels, such as ’Handle with Care’, ’This SideUp’, and so on. The cartons must be protectedagainst rain and moisture and therefore shouldnot be stored outside.All available installationguides can be downloadedfrom www.<strong>ecophon</strong>.com.Glass wool is very easy to work with in that itis flexible and does not crumble. This meansthat you can easily cut perimeter tiles orholes for pipe-work and cables using just anordinary craftknife. If edgescut on site needpainting, a specialedge sealant isavailable.For aesthetic reasons perimeter tiles should be at least 300 mmwide and lengthening pieces of profi les and angle trims etc. at least400 mm long.CEILING ASSEMBLYSuspended ceilings should always be installedas late as possible in the building processin order to avoid soiling the panels. MostEcophon ceiling panels will come with aninstallation guide for the system you havechosen. The system pages in this catalogueinclude a single installation drawing whichprovides an overview of each system.The Connect grid system, made fromgalvanised steel, is also easy to work with. Apair of metal scissors is all you need to cut theprofiles.In small rooms, such as toilets, pressureshocks can occur when opening and closingthe door, making the tiles lift from theirposition in the grid. This can be avoided byusing open grilles and hold down clips or otherarrangements.• Install the ceiling late in thebuilding process to avoidsoiling it• Always use clean cotton gloveswhen handling ceiling panels| 41

MAINTENANCEClean cotton gloves should be worn at alltimes, both during ceiling assembly andthroughout all work in the suspended ceiling,e.g. installation of light fittings and servicingof ventilation systems. When the panels aredemounted they must be taken completely outof the grid and stored on a flat surface. Thepanels should be laid face to face to preventsoiling and damage during the work.For more information, see thedetailed Maintenance instructions onwww.<strong>ecophon</strong>.com/Inspection panels for ceilings with non-demountable tiles or whenfrequent access is neededLight fi tting clips for installation of uplights, signs, etc.For more information regarding installationtools and accessories see section Connect.TOOLS AND ACCESSORIESIn order to secure a good ceiling system itis imperative that you use well designedinstallation tools and accessories. TheConnect product range offers a vast numberof accessories for a variety of different needs.Below are some examples of the installationtools and accessories offered by Ecophon:A uniquely designed laser tool for securing a perpendicular gridsystemEdge tools for creating edges on perimeter tiles42 |

| 43

AKUTEX T – A UNIQUESURFACE COATINGMost Ecophon sound absorbershave the unique Akutex T surfacecoating.The microporous Akutex Tsurface allows almost 100 percentof the sound waves to penetrateinto the glass wool core and beabsorbed by it. The microscopicpores, however, are much too smallto admit dust and dirt, so from acleaning point of view the surface istight and smooth, dirt-repellant andeasy to clean.Akutex T produces a surfacestructure with very high lightrefl ectance for both incident daylightand that from lighting systems.Moreover, the light is refl ectedvery diffusely and evenly, so itcauses no dazzle or glare. Thisis very important in ensuring lighteffi ciency where indirect lighting isconcerned.