Controlled Atmosphere Storage of Fruits and Vegetables, Second ...

Controlled Atmosphere Storage of Fruits and Vegetables, Second ...

Controlled Atmosphere Storage of Fruits and Vegetables, Second ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

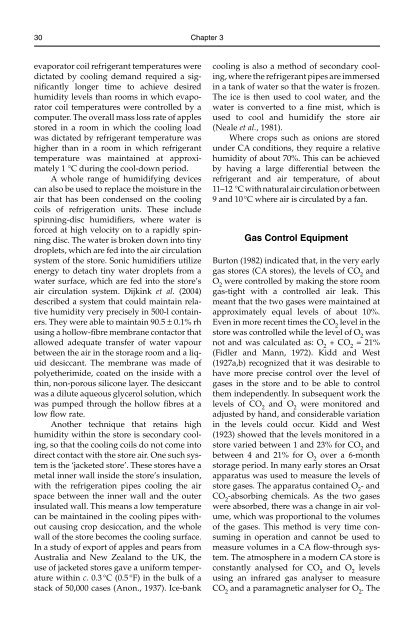

30 Chapter 3evaporator coil refrigerant temperatures weredictated by cooling dem<strong>and</strong> required a significantlylonger time to achieve desiredhumidity levels than rooms in which evaporatorcoil temperatures were controlled by acomputer. The overall mass loss rate <strong>of</strong> applesstored in a room in which the cooling loadwas dictated by refrigerant temperature washigher than in a room in which refrigeranttemperature was maintained at approximately1 °C during the cool-down period.A whole range <strong>of</strong> humidifying devicescan also be used to replace the moisture in theair that has been condensed on the coolingcoils <strong>of</strong> refrigeration units. These includespinning-disc humidifiers, where water isforced at high velocity on to a rapidly spinningdisc. The water is broken down into tinydroplets, which are fed into the air circulationsystem <strong>of</strong> the store. Sonic humidifiers utilizeenergy to detach tiny water droplets from awater surface, which are fed into the store’sair circulation system. Dijkink et al. (2004)described a system that could maintain relativehumidity very precisely in 500-l containers.They were able to maintain 90.5 ± 0.1% rhusing a hollow-fibre membrane contactor thatallowed adequate transfer <strong>of</strong> water vapourbetween the air in the storage room <strong>and</strong> a liquiddesiccant. The membrane was made <strong>of</strong>polyetherimide, coated on the inside with athin, non-porous silicone layer. The desiccantwas a dilute aqueous glycerol solution, whichwas pumped through the hollow fibres at alow flow rate.Another technique that retains highhumidity within the store is secondary cooling,so that the cooling coils do not come intodirect contact with the store air. One such systemis the ‘jacketed store’. These stores have ametal inner wall inside the store’s insulation,with the refrigeration pipes cooling the airspace between the inner wall <strong>and</strong> the outerinsulated wall. This means a low temperaturecan be maintained in the cooling pipes withoutcausing crop desiccation, <strong>and</strong> the wholewall <strong>of</strong> the store becomes the cooling surface.In a study <strong>of</strong> export <strong>of</strong> apples <strong>and</strong> pears fromAustralia <strong>and</strong> New Zeal<strong>and</strong> to the UK, theuse <strong>of</strong> jacketed stores gave a uniform temperaturewithin c. 0.3 °C (0.5 °F) in the bulk <strong>of</strong> astack <strong>of</strong> 50,000 cases (Anon., 1937). Ice-bankcooling is also a method <strong>of</strong> secondary cooling,where the refrigerant pipes are immersedin a tank <strong>of</strong> water so that the water is frozen.The ice is then used to cool water, <strong>and</strong> thewater is converted to a fine mist, which isused to cool <strong>and</strong> humidify the store air(Neale et al., 1981).Where crops such as onions are storedunder CA conditions, they require a relativehumidity <strong>of</strong> about 70%. This can be achievedby having a large differential between therefrigerant <strong>and</strong> air temperature, <strong>of</strong> about11–12 °C with natural air circulation or between9 <strong>and</strong> 10 °C where air is circulated by a fan.Gas Control EquipmentBurton (1982) indicated that, in the very earlygas stores (CA stores), the levels <strong>of</strong> CO 2<strong>and</strong>O 2were controlled by making the store roomgas-tight with a controlled air leak. Thismeant that the two gases were maintained atapproximately equal levels <strong>of</strong> about 10%.Even in more recent times the CO 2level in thestore was controlled while the level <strong>of</strong> O 2wasnot <strong>and</strong> was calculated as: O 2+ CO 2= 21%(Fidler <strong>and</strong> Mann, 1972). Kidd <strong>and</strong> West(1927a,b) recognized that it was desirable tohave more precise control over the level <strong>of</strong>gases in the store <strong>and</strong> to be able to controlthem independently. In subsequent work thelevels <strong>of</strong> CO 2<strong>and</strong> O 2were monitored <strong>and</strong>adjusted by h<strong>and</strong>, <strong>and</strong> considerable variationin the levels could occur. Kidd <strong>and</strong> West(1923) showed that the levels monitored in astore varied between 1 <strong>and</strong> 23% for CO 2<strong>and</strong>between 4 <strong>and</strong> 21% for O 2over a 6-monthstorage period. In many early stores an Orsatapparatus was used to measure the levels <strong>of</strong>store gases. The apparatus contained O 2- <strong>and</strong>CO 2-absorbing chemicals. As the two gaseswere absorbed, there was a change in air volume,which was proportional to the volumes<strong>of</strong> the gases. This method is very time consumingin operation <strong>and</strong> cannot be used tomeasure volumes in a CA flow-through system.The atmosphere in a modern CA store isconstantly analysed for CO 2 <strong>and</strong> O 2 levelsusing an infrared gas analyser to measureCO 2<strong>and</strong> a paramagnetic analyser for O 2. The

![()] 1](https://img.yumpu.com/45117883/1/190x143/-1.jpg?quality=85)