Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

®<br />

ARCTICCAT Effective Date: May, 2004<br />

Special<br />

Tools<br />

Catalog<br />

Snowmobile

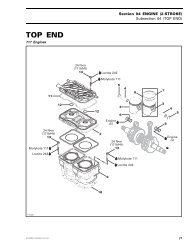

FOREWORD<br />

This publication is designed to help authorized Arctic Cat Snowmobile dealers in identifying the special tools available<br />

from Arctic Cat Inc. Each of these special tools is identified by part number and by name. A brief function<br />

description is also included for each special tool.<br />

In several cases, two or more tools of those listed will serve the same purpose. Determine which of the tools will<br />

best suit your needs and order accordingly. If additional information is required about any of the special tools, call<br />

the Service Parts Department at Arctic Cat Inc.<br />

Order all special tools using any of the following methods:<br />

� NOTE: Alaskan dealers should order the special tools from their distributor at 907-272-5351.<br />

A. For Phone Orders, call our WATS line (7 a.m. to 6 p.m. Central Time) - U.S.<br />

1-800-279-2281<br />

B. For Telefax Orders, call (24 hours a day, 7 days a week - after hours voice mail) 218-681-2822<br />

C. For Mail Orders, address to ARCTIC CAT INC.<br />

P.O. Box 810<br />

Thief River Falls, MN 56701<br />

ATTN: Service Parts Department<br />

Pickup Orders require 24-hour notice. Pickup Orders will automatically be shipped 3 days after processing unless<br />

a special pickup date is requested.<br />

Remember to include Dealer Name<br />

Dealer Number<br />

Purchase Order Number<br />

Method of Shipment (1 day or 2 day service is available)<br />

Specify if Emergency Service Processing (ESP) is desired<br />

1

2<br />

TABLE OF<br />

CONTENTS<br />

Accessory Adapter . . . . . . . . . . . . . . . . . . . . . . . . .11<br />

Alcohol Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

Angle Finder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6<br />

Ball Hone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6<br />

Ball Joint Fork . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19<br />

Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . .12<br />

Bearing Cap Seal Protector. . . . . . . . . . . . . . . . . . .19<br />

Bearing Removal Tool . . . . . . . . . . . . . . . . . . . . . . .24<br />

Bearing Removal and Installation Tool . . . . . . . . . .23<br />

Blind-Hole Bearing <strong>Puller</strong> . . . . . . . . . . . . . . . . . . . . .5<br />

Brake Disc Socket Wrench (ACT Drive) . . . . . . . . .25<br />

Bushing Tool Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . .23<br />

Carbide & Stud Specifications Gauge . . . . . . . . . . .20<br />

Carburetor Adjustment Screwdriver (90°) . . . . . . . . .9<br />

Carburetor Synchronizer . . . . . . . . . . . . . . . . . . . . . .8<br />

Carburetor Synchronizing Tool Adapter. . . . . . . . . . .8<br />

Carburetor Tool Set (Mikuni) . . . . . . . . . . . . . . . . . . .8<br />

Chip <strong>Puller</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10<br />

<strong>Clutch</strong> Alignment Bar. . . . . . . . . . . . . . . . . . . . . . . .23<br />

<strong>Clutch</strong> Bushing Installation Tool (Arctic) . . . . . . . . .21<br />

<strong>Clutch</strong> Compressor . . . . . . . . . . . . . . . . . . . . . . . . .22<br />

<strong>Clutch</strong> Compressor (Arctic Round-Shaft) . . . . . . . .22<br />

<strong>Clutch</strong> Compressor (Comet) . . . . . . . . . . . . . . . . . .22<br />

<strong>Clutch</strong> <strong>Puller</strong> (Arctic) . . . . . . . . . . . . . . . . . . . . . . . .21<br />

<strong>Clutch</strong> <strong>Puller</strong> (Comet) . . . . . . . . . . . . . . . . . . . . . . .22<br />

Compression/Pressure Tester Kit . . . . . . . . . . . . . . .7<br />

Coolant Cap (Non-Pressurized) . . . . . . . . . . . . . . . .7<br />

Crankshaft Bearing Remover . . . . . . . . . . . . . . . . . .4<br />

Crankshaft Protector Cap . . . . . . . . . . . . . . . . . . . . .4<br />

Drive Belt Deflection Tool. . . . . . . . . . . . . . . . . . . . .24<br />

Drive Belt Deflection Tool. . . . . . . . . . . . . . . . . . . . .25<br />

Drive Belt Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . .24<br />

Drive Belt Replacement Tool . . . . . . . . . . . . . . . . . .25<br />

Drive <strong>Clutch</strong> Spanner Wrench . . . . . . . . . . . . . . . . .22<br />

Driven Pulley <strong>Puller</strong> . . . . . . . . . . . . . . . . . . . . . . . . .24<br />

Driven Pulley Compressor Tool . . . . . . . . . . . . . . . .25<br />

Driven Pulley Spring Adjustment Tool . . . . . . . . . . .25<br />

Duck-Foot T-Handle Wrench (8 mm) . . . . . . . . . . .10<br />

EFI Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11<br />

EFI Analyzer Test Harness . . . . . . . . . . . . . . . . . . .11<br />

EFI Throttle Cable Jam Nut/<br />

Oil-Injection Pump Jam Nut Wrench. . . . . . . . . .10<br />

Engine Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5<br />

Engine Timing Gauge . . . . . . . . . . . . . . . . . . . . . . . .6<br />

Exhaust Spring Pliers . . . . . . . . . . . . . . . . . . . . . . . .9<br />

Fan Spanner Wrench (Suzuki) . . . . . . . . . . . . . . . . .5<br />

Floating Piston Location Gauge . . . . . . . . . . . . . . .18<br />

Floating Piston Removal Tool . . . . . . . . . . . . . . . . .18<br />

Floating Piston Removal Tool Kit . . . . . . . . . . . . . . .19<br />

Flywheel <strong>Puller</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3<br />

Flywheel <strong>Puller</strong> Insert . . . . . . . . . . . . . . . . . . . . . . . .4<br />

Flywheel <strong>Puller</strong>/Spanner Wrench . . . . . . . . . . . . . . .3<br />

Flywheel Spanner Wrench . . . . . . . . . . . . . . . . . . . .4<br />

Fuel Pressure Tester . . . . . . . . . . . . . . . . . . . . . . . . .7<br />

Fuel Pump Socket Wrench . . . . . . . . . . . . . . . . . . .10<br />

Gas Gauge Removal Tool . . . . . . . . . . . . . . . . . . . . .9<br />

Gas Shock Retaining Blocks . . . . . . . . . . . . . . . . . .17<br />

Gas Shock Rod/Body Clamping Tool. . . . . . . . . . . .17<br />

Hex Bits (1/4 in. Hex Drive) . . . . . . . . . . . . . . . . . . .14<br />

Hex <strong>Clutch</strong> <strong>Puller</strong> (Arctic). . . . . . . . . . . . . . . . . . . . .21<br />

Idle Speed Screw Jam Nut Wrench . . . . . . . . . . . . . 10<br />

Idler Wheel Alignment Tool . . . . . . . . . . . . . . . . . . . 20<br />

Idler Wheel <strong>Puller</strong> Kit . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Ignition Test Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Inflation Needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

Inflation Needle Replacement . . . . . . . . . . . . . . . . . 18<br />

Insert Holder (5/16 in.) . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Jack Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Linkage Wrench (8 mm). . . . . . . . . . . . . . . . . . . . . . 10<br />

Multimeter (Fluke Model 73 w/Case) . . . . . . . . . . . . 12<br />

Nitrogen Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . 17<br />

Oil Filter Wrench (Adjustable) . . . . . . . . . . . . . . . . . . 9<br />

Oil Injection Usage Tool . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Oil Seal Installation Tool. . . . . . . . . . . . . . . . . . . . . . . 5<br />

Peak Voltage Reading Adapter . . . . . . . . . . . . . . . . 12<br />

Phillips-Head Bits (1/4 in. Hex Drive) . . . . . . . . . . . . 14<br />

Pinion Shimming Tool<br />

(650 and 700 cc Engines) . . . . . . . . . . . . . . . . . . . . 5<br />

Piston Location Tool . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

Piston Pin <strong>Puller</strong>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Quick-Disconnect Coupler . . . . . . . . . . . . . . . . . . . . 15<br />

Rear Axle Nut Socket. . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Rear Shock Adjuster . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Rear Suspension Spring Tool. . . . . . . . . . . . . . . . . . 15<br />

Replacement Bolt (Center). . . . . . . . . . . . . . . . . . . . 17<br />

Replacement Bolt (Side) . . . . . . . . . . . . . . . . . . . . . 17<br />

Replacement Rivnuts . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Reverse Gear Adjustment Gauge . . . . . . . . . . . . . . 24<br />

Rigid Hone Stone Set (2.7-4.1 in.) . . . . . . . . . . . . . . . 6<br />

Ring Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Rivnut Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Rivnut Tool Insert Bit . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Roller Pin Removal Tool. . . . . . . . . . . . . . . . . . . . . . 24<br />

Shock Absorber Air Pump . . . . . . . . . . . . . . . . . . . . 16<br />

Shock Rod Clamping Tool . . . . . . . . . . . . . . . . . . . . 17<br />

Shock Spanner Wrench . . . . . . . . . . . . . . . . . . . . . . 16<br />

Shock Spring Removal Tool . . . . . . . . . . . . . . . . . . . 15<br />

Side Guard Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Spider Removal Kit . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

Spring Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Starter Assembly Tool . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Stud Runner (6, 8, & 10 mm) . . . . . . . . . . . . . . . . . . 13<br />

Surface Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Synchronizer Repair Kit . . . . . . . . . . . . . . . . . . . . . . . 8<br />

T-Handle Wrench . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

T Wrench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Tachometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Throttle Position Sensor (TPS)<br />

Adjustment Tool Kit . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Timing Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Torx Bit Insert (5/16 in. Hex Drive) . . . . . . . . . . . . . . 14<br />

Torx Bits (1/4 in. Hex Drive) . . . . . . . . . . . . . . . . . . . 14<br />

Track Clip Installation Tool . . . . . . . . . . . . . . . . . . . . 19<br />

Track Stud Hole Drill (7 mm) . . . . . . . . . . . . . . . . . . 20<br />

Track Stud Hole Drill (1/4 in.) . . . . . . . . . . . . . . . . . . 20<br />

V Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Vacuum Test Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Water Pump Bearing & Seal Kit . . . . . . . . . . . . . . . . . 5<br />

Zipper Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Piston Pin <strong>Puller</strong><br />

p/n: 0644-328 (Complete Set)<br />

p/n: 0643-073 (Extractor Nut Only-Small)<br />

p/n: 0643-074 (Extractor Nut Only-Medium)<br />

p/n: 0643-075 (Extractor Nut Only-Large)<br />

p/n: 0643-072 (Threaded T-Handle)<br />

Usage: Remove piston pins.<br />

Fig. 1<br />

0644-328<br />

Ring Compressor<br />

p/n: 0644-378<br />

Usage: Compress piston rings for cylinder installation.<br />

Features a quick-release function for removing tool from<br />

underside of piston.<br />

Fig. 2<br />

0644-378<br />

Flywheel <strong>Puller</strong><br />

p/n: 0644-423 (Complete Set)<br />

p/n: 0643-086 (Body)<br />

p/n: 0643-087 (Bolt)<br />

p/n: 0423-482 (6 mm Cap Screw)<br />

p/n: 0423-483 (8 mm Cap Screw)<br />

Usage: Pull flywheel off crankshaft on all Arctic Cat 2stroke<br />

models.<br />

Fig. 3<br />

0644-423<br />

Flywheel <strong>Puller</strong>/Spanner Wrench<br />

p/n: 0144-310<br />

Usage: Pull flywheel off crankshaft and hold Arctic-style<br />

clutches.<br />

Fig. 4<br />

AE047<br />

3

Flywheel Spanner Wrench<br />

p/n: 0144-007<br />

Usage: Hold starter cup while removing/installing flywheel<br />

nut.<br />

Fig. 5<br />

4<br />

AE030<br />

Flywheel <strong>Puller</strong> Insert<br />

p/n: 0644-179<br />

Usage: Protect the crankshaft end on the 900 cc engine<br />

during flywheel removal.<br />

Fig. 6<br />

Crankshaft Protector Cap<br />

p/n: 0644-234<br />

Usage: Protect the crankshaft end during flywheel<br />

removal.<br />

Fig. 7<br />

AE109<br />

0644-234<br />

Crankshaft Bearing Remover<br />

p/n: 0144-302<br />

Usage: Remove crankshaft bearings.<br />

Fig. 8<br />

Surface Plate<br />

p/n: 0644-016<br />

Usage: True sealing surfaces.<br />

Fig. 9<br />

V Blocks<br />

p/n: 0644-022<br />

Usage: Check crankshaft runout.<br />

Fig. 10<br />

AE043<br />

AE058<br />

0644-022

Fan Spanner Wrench (Suzuki)<br />

p/n: 0644-340<br />

Usage: Hold fan in place during disassembly and<br />

assembly.<br />

Fig. 11<br />

AE104<br />

Engine Stand<br />

p/n: 0644-079<br />

Usage: Hold engine during assembling/disassembling.<br />

Fig. 12<br />

Pinion Shimming Tool (650 and<br />

700 cc Engines)<br />

p/n: 0644-055<br />

Usage: Determine size and number of pinion gear<br />

shims.<br />

Fig. 13<br />

AE079<br />

AE073<br />

Water Pump Bearing & Seal Kit<br />

p/n: 0644-084<br />

Usage: Remove/install crankcase water pump bearings<br />

and seals.<br />

Fig. 14<br />

AE080<br />

Oil Seal Installation Tool<br />

p/n: 0644-219<br />

Usage: Install the oil seal on the water pump driveshaft<br />

on the 440, 550, 580, 650, 700, 800, and 900 cc Arctic<br />

Cat engines.<br />

Fig. 15<br />

Blind-Hole Bearing <strong>Puller</strong><br />

p/n: 0644-381<br />

Usage: Remove small and large blind bearings on all<br />

models.<br />

Fig. 16<br />

AE130<br />

0644-381<br />

5

Rigid Hone Stone Set (2.7-4.1 in.)<br />

p/n: 0644-043<br />

Usage: Replacement stones for Cylinder Hone Set (p/n<br />

0644-041).<br />

Fig. 17<br />

6<br />

AE068<br />

Ball Hone<br />

p/n: 0644-290 (60-64 mm)<br />

p/n: 0644-291 (65-70 mm)<br />

p/n: 0644-292 (72-74 mm)<br />

p/n: 0644-293 (76-83 mm)<br />

p/n: 0644-294 (83-88 mm)<br />

Usage: Deglaze Nicosil plated cylinders. All are 320 grit<br />

and are recommended for reconditioning all Arctic Cat<br />

snowmobile engine cylinders (1976-2000).<br />

Fig. 18<br />

Ignition Test Plug<br />

p/n: 0144-306<br />

Usage: Test engine ignition.<br />

Fig. 19<br />

AE065<br />

AE045<br />

Angle Finder<br />

p/n: 0644-097<br />

Usage: Identify levelness and pitch.<br />

Fig. 20<br />

Engine Timing Gauge<br />

p/n: 0144-009<br />

Usage: Static time engines without CDI ignition.<br />

Fig. 21<br />

Timing Light<br />

p/n: 0644-296<br />

Usage: Check ignition timing.<br />

Fig. 22<br />

AE090<br />

AE031<br />

AE054

Starter Assembly Tool<br />

p/n: 0644-052<br />

Usage: Hold brushes for assembling UTC brand starter<br />

motor.<br />

Fig. 23<br />

AE072<br />

Compression/Pressure Tester Kit<br />

p/n: 0644-366 (Complete Kit w/Case)<br />

p/n: 0644-388 (T-Fitting - Fuel Pressure Gauge)<br />

p/n: 0644-133 (Three Carburetor Plugs)*<br />

p/n: 0644-176 (Three Rubber Gaskets)*<br />

p/n: 0644-177 (Three Exhaust Plates)*<br />

p/n: 0644-367 (Twelve 8 mm Nuts and Bolts)<br />

p/n: 0644-368 (Vacuum Plugs)<br />

p/n: 0644-369 (Two Exhaust Plates)*<br />

p/n: 0644-370 (Three Exhaust Valve Cover<br />

Plates - Standard APV Engine)*<br />

p/n: 0644-406 (Exhaust Valve Cover<br />

Plates - Laydown APV Engine)*<br />

p/n: 0644-371 (8 mm Oil Pressure Adapter)<br />

p/n: 0644-372 (10 mm Compression Tester<br />

Adapter)<br />

p/n: 0644-373 (12 mm Compression Tester<br />

Adapter)<br />

p/n: 0644-374 (Hose Assembly)<br />

p/n: 0644-375 (Oil/Fuel Pressure Gauge)<br />

p/n: 0644-376 (Compression Gauge)<br />

p/n: 0644-377 (Leak-Down Tester Gauge)<br />

Usage: Test all compression/pressure-related assemblies<br />

on all Arctic Cat products. Contains all necessarycomponents<br />

to test oil/fuel pressure, compression, and<br />

leak-down. *Can be ordered individually.<br />

Fig. 24<br />

644-366A<br />

Fuel Pressure Tester<br />

p/n: 0644-203<br />

Usage: Test fuel pressure on both EFI and carbureted<br />

models. A valuable tool for troubleshooting EFI fuel systems.<br />

Fig. 25<br />

AE124<br />

Coolant Cap (Non-Pressurized)<br />

p/n: 0644-156<br />

Usage: Fill cooling system on the 1992, 1995, and 1996<br />

models equipped with bleed system.<br />

Fig. 26<br />

Vacuum Test Pump<br />

p/n: 0644-131<br />

Usage: Check components for air leaks.<br />

Fig. 27<br />

AE129<br />

AE099<br />

7

Oil Injection Usage Tool<br />

p/n: 0644-007<br />

Usage: Measure exact amount of oil used by the oil<br />

injection pump during a given time period.<br />

Fig. 28<br />

Alcohol Test Kit<br />

p/n: 0644-044<br />

Usage: Test gasoline for alcohol.<br />

Fig. 29<br />

Carburetor Synchronizer<br />

p/n: 0644-069<br />

Usage: Synchronize Mikuni carburetors.<br />

Fig. 30<br />

8<br />

AE108<br />

AE069<br />

AE076<br />

Carburetor Synchronizing Tool<br />

Adapter<br />

p/n: 0644-023<br />

Usage: Threads into carburetor fitting and slides into<br />

synchronizer hose.<br />

Fig. 31<br />

Carburetor Tool Set (Mikuni)<br />

p/n: 0636-072<br />

Usage: Disassemble/assemble Mikuni carburetors.<br />

Fig. 32<br />

CE029<br />

AE049<br />

Synchronizer Repair Kit<br />

p/n: 0644-062<br />

Usage: Replacement components for Carburetor Synchronizer<br />

(p/n 0644-069).<br />

Fig. 33<br />

AE138

Carburetor Adjustment<br />

Screwdriver (90°)<br />

p/n: 0644-289<br />

Usage: Make carburetor adjustments on all twin and triple<br />

cylinder engines. Will be especially useful for adjusting<br />

the pilot circuit screw on all TM-style carburetors.<br />

Fig. 34<br />

Gas Gauge Removal Tool<br />

p/n: 0644-357<br />

Usage: Remove gauge from the gas tank.<br />

Fig. 35<br />

Exhaust Spring Pliers (0°)<br />

p/n: 0644-391<br />

Usage: Remove/install exhaust springs.<br />

Fig. 36<br />

0644-289<br />

0644-357<br />

644-391A<br />

Exhaust Spring Pliers (90°)<br />

p/n: 0644-397<br />

Usage: Remove/install exhaust springs.<br />

Fig. 37<br />

Spring Tool<br />

p/n: 0644-072<br />

Usage: Remove/install exhaust springs.<br />

Fig. 38<br />

0644-397<br />

Oil Filter Wrench (Adjustable)<br />

p/n: 0644-389<br />

Usage: Remove oil filters from 4-stroke engines. Features<br />

adjustments between 62-96 mm.<br />

Fig. 39<br />

AE077<br />

0644-389<br />

9

EFI Throttle Cable Jam Nut/Oil-<br />

Injection Pump Jam Nut Wrench<br />

(10 mm)<br />

p/n: 0644-242<br />

Usage: Loosen and tighten jam nuts on both the oilinjection<br />

pump and EFI throttle cable.<br />

Fig. 40<br />

Duck-Foot T-Handle Wrench<br />

(8 mm)<br />

p/n: 0644-332<br />

Usage: Adjust oil-injection pump mechanical linkage.<br />

Fig. 41<br />

Linkage Wrench (8 mm)<br />

p/n: 0644-333<br />

Usage: Adjust oil-injection pump mechanical linkage.<br />

Fig. 42<br />

10<br />

BE024<br />

BE024<br />

0644-333<br />

Idle Speed Screw Jam Nut<br />

Wrench<br />

p/n: 0644-311<br />

Usage: Loosen/tighten idle speed screw jam nut on batteryless<br />

EFI system.<br />

Fig. 43<br />

0644-311<br />

Fuel Pump Socket Wrench<br />

p/n: 0644-364<br />

Usage: Remove plastic nut securing the fuel pump to<br />

the gas tank.<br />

Fig. 44<br />

0644-364<br />

Chip <strong>Puller</strong><br />

p/n: 0644-188<br />

Usage: Safely remove EPROM chip from the ECU on all<br />

EFI models.<br />

Fig. 45<br />

AE117

EFI Analyzer<br />

p/n: 0644-342<br />

p/n: 0644-422 (Harness)<br />

p/n: 0644-341 (Complete Kit)<br />

p/n: 0643-081 (EPROM)<br />

p/n: 0686-716 (Harness)<br />

Usage: Troubleshoot all Arctic Cat EFI systems. A valuable<br />

tool to assist the technician in locating EFI problems<br />

quickly.<br />

Fig. 46<br />

0644-342<br />

EFI Analyzer Test Harness<br />

p/n: 0644-181<br />

Usage: Troubleshoot EFI system (1993-1996 models).<br />

Fig. 47<br />

AE113<br />

EFI Analyzer Test Harness<br />

p/n: 0644-624<br />

Usage: Troubleshoot EFI battery system (1997-1998<br />

models).<br />

Fig. 48<br />

AE143<br />

Tachometer<br />

p/n: 0644-386<br />

Usage: Measure engine RPM for 2-stroke and 4-stroke<br />

engines.<br />

Fig. 49<br />

0644-386<br />

Accessory Adapter<br />

p/n: 0644-387<br />

Usage: With Tachometer (p/n 0644-386), measure RPM<br />

for diesel engines.<br />

Fig. 50<br />

0644-387<br />

11

Throttle Position Sensor (TPS)<br />

Adjustment Tool Kit<br />

p/n: 3639-891 (Complete Set)<br />

p/n: 0686-999 (Harness Only)<br />

p/n: 0644-359 (Torx-Head Screwdriver - #25<br />

Only)<br />

p/n: 0644-344 (Torx-Head Screwdriver - #30<br />

Only)<br />

p/n: 0644-345 (Pin Gauge Only)<br />

Usage: Precisely adjust the throttle position sensor on<br />

carbureted and EFI models.<br />

Fig. 51<br />

Battery Charger<br />

p/n: 0436-634<br />

Usage: Charge sealed, maintenance-free batteries.<br />

Fig. 52<br />

12<br />

3639-891<br />

0436-634<br />

Zipper Case<br />

p/n: 0644-190<br />

Usage: Protect the Fluke Multimeter.<br />

Fig. 53<br />

0644-190<br />

Peak Voltage Reading Adapter<br />

p/n: 0644-307<br />

Usage: With Fluke Model 73 Multimeter (p/n 0644-191),<br />

read peak voltage.<br />

Fig. 54<br />

Multimeter (Fluke Model 73 w/<br />

Case)<br />

p/n: 0644-191<br />

Usage: Ditgital multimeter accurate to within ± 0.5%.<br />

Fig. 55<br />

0644-307<br />

AE114

Stud Runner<br />

p/n: 0644-018 (6 mm)<br />

p/n: 0644-019 (8 mm)<br />

p/n: 0644-020 (10 mm)<br />

Usage: Install studs on cylinders and crankcase.<br />

Fig. 56<br />

T Wrench<br />

p/n: 0644-021<br />

Usage: Drive 3/8 in. square-drive sockets.<br />

Fig. 57<br />

T-Handle Wrench<br />

p/n: 0644-257 (8 mm)<br />

p/n: 0644-024 (10 mm)<br />

p/n: 0644-025 (12 mm)<br />

p/n: 0644-026 (14 mm)<br />

Usage: Remove and install nuts and bolts.<br />

Fig. 58<br />

AE059<br />

AE060<br />

AE115<br />

Rivnut Tool<br />

p/n: 0644-232<br />

Usage: Collapse and install rivnuts.<br />

Fig. 59<br />

0644-232<br />

Rivnut Tool Insert Bit<br />

p/n: 0644-233 (1/4 x 20)<br />

p/n: 0644-405 (10-32)<br />

p/n: 0644-430 (5/16 x 18)<br />

p/n: 0644-431 (3/8 x 16)<br />

Usage: With Rivnut Tool (p/n 0644-232) and Replacement<br />

Rivnuts, replace rivnuts.<br />

Fig. 60<br />

0644-233<br />

13

Replacement Rivnuts<br />

p/n: 0623-557 (1/4 x 20)<br />

p/n: 0623-582/627 (1/4 x 20)<br />

p/n: 0623-581 (5/16 x 18)<br />

p/n: 0623-699 (3/8 x 16)<br />

p/n: 0623-874 (8-32)<br />

p/n: 0623-529/779 (10-32)<br />

Usage: With Rivnut Tool (p/n 0644-232), replace rivnuts.<br />

Fig. 61<br />

14<br />

0623-557<br />

Hex Bits (1/4 in. Hex Drive)<br />

p/n: 0644-317 (5 mm)<br />

p/n: 0644-316 (6 mm)<br />

Usage: With Quick-Disconnect Coupler (p/n 0644-308),<br />

remove and install bolts and screws.<br />

Fig. 62<br />

0644-316<br />

Phillips-Head Bits (1/4 in. Hex<br />

Drive)<br />

p/n: 0644-319 (#2)<br />

p/n: 0644-318 (#3)<br />

Usage: With Quick-Disconnect Coupler (p/n 0644-308),<br />

remove and install Phillips-head screws.<br />

Fig. 63<br />

0644-318<br />

Torx Bits (1/4 in. Hex Drive)<br />

p/n: 0644-312 (#25)<br />

p/n: 0644-393 (#27)<br />

p/n: 0644-215 (#30)<br />

p/n: 0644-313 (#40)<br />

Usage: With Quick-Disconnect Coupler (p/n 0644-308),<br />

remove and install torx-head screws.<br />

Fig. 64<br />

BE012<br />

Torx Bit Insert (5/16 in. Hex Drive)<br />

p/n: 0644-314<br />

Usage: With Insert Holder (p/n 0644-315), remove and<br />

install torx-head screws.<br />

Fig. 65<br />

BE012

Insert Holder (5/16 in.)<br />

p/n: 0644-315<br />

Usage: With Torx Bit Insert (p/n 0644-314), remove and<br />

install torx-head screws.<br />

Fig. 66<br />

0644-315<br />

Quick-Disconnect Coupler<br />

p/n: 0644-308<br />

Usage: Hold 1/4 in. hex drive Torx Bits (Fig. 64), Hex<br />

Bits (Fig. 62), and Phillips-Head Bits (Fig. 63).<br />

Fig. 67<br />

Rear Suspension Spring Tool<br />

p/n: 0144-311<br />

Usage: Install/remove rear suspension springs.<br />

Fig. 68<br />

0644-308<br />

AE048<br />

Rear Axle Nut Socket<br />

p/n: 0644-399<br />

Usage: Loosen/tighten rear axle nut on 2004 and earlier<br />

AWS VI models.<br />

Fig. 69<br />

Rear Shock Adjuster<br />

p/n: 0644-015<br />

Usage: Rotate rear shock adjusting cam on external<br />

AFS models.<br />

Fig. 70<br />

Shock Spring Removal Tool<br />

p/n: 0644-057<br />

Usage: Remove/install shock absorber spring.<br />

Fig. 71<br />

0644-399<br />

AE057<br />

AE074<br />

15

Shock Spanner Wrench<br />

p/n: 2604-878<br />

Usage: Adjust pre-load on Fox Zero Pro shock absorber.<br />

Fig. 72<br />

16<br />

2604-878<br />

Shock Spanner Wrench<br />

p/n: 0644-398<br />

Usage: Adjust pre-load on front arm rebuildable shock<br />

absorber.<br />

Fig. 73<br />

Shock Spanner Wrench<br />

p/n: 0644-305<br />

Usage: Adjust pre-load on front arm standard shock<br />

absorber.<br />

Fig. 74<br />

0644-398<br />

0644-305<br />

Shock Absorber Air Pump<br />

p/n: 2603-324<br />

Usage: Adjust air pressure on Fox Air Shocks.<br />

Fig. 75<br />

Jack Stand<br />

p/n: 0644-076 (Standard Models - Low)<br />

p/n: 0639-462 (ETT Models - High)<br />

Usage: Support rear of snowmobile off the ground.<br />

Fig. 76<br />

Side Guard Kit<br />

p/n: 0639-611<br />

Usage: With Jack Stand (p/n 0644-076/0639-462).<br />

Fig. 77<br />

2603-324<br />

AE133<br />

0639-611

Replacement Bolt (Side)<br />

p/n: 0644-101<br />

Usage: Replaces side bolt in Track Clip Tool (p/n 0144-<br />

301).<br />

Fig. 78<br />

Replacement Bolt (Center)<br />

p/n: 0644-103<br />

Usage: Replaces center bolt in Track Clip Tool (p/n<br />

0144-301).<br />

Fig. 79<br />

Shock Rod Clamping Tool<br />

p/n: 0744-021<br />

Usage: Hold shock absorber rod for servicing.<br />

Fig. 80<br />

AE093<br />

AE094<br />

AE145D<br />

Gas Shock Rod/Body Clamping<br />

Tool<br />

p/n: 0644-425<br />

Usage: Hold gas shock absorber for servicing.<br />

Fig. 81<br />

0644-425<br />

Gas Shock Retaining Blocks<br />

p/n: 0644-334<br />

Usage: Hold gas shock secure during disassembly and<br />

assembly.<br />

Fig. 82<br />

Nitrogen Regulator<br />

p/n: 0644-151<br />

Usage: Recharge rebuildable gas shock absorbers.<br />

Fig. 83<br />

AP042<br />

AE095<br />

17

Inflation Needle<br />

p/n: 0744-020<br />

Usage: Pressurize rebuildable gas shock absorbers with<br />

nitrogen.<br />

Fig. 84<br />

18<br />

AE110<br />

Inflation Needle Replacement<br />

p/n: 0644-162<br />

Usage: Replacement needle assembly for Inflation Needle<br />

(p/n 0744-020).<br />

Fig. 85<br />

0644-162<br />

Piston Location Tool<br />

p/n: 0644-169<br />

Usage: Precisely locate the floating piston in the rebuildable<br />

gas shock absorber.<br />

Fig. 86<br />

AE135<br />

Floating Piston Location Gauge<br />

p/n: 0644-350<br />

Usage: Precisely locate and measure floating piston<br />

depth without use of a calipers.<br />

Fig. 87<br />

0644-350<br />

Floating Piston Removal Tool<br />

p/n: 0644-348<br />

Usage: Remove floating piston from cross-link suspension<br />

shocks on 2002 models.<br />

Fig. 88<br />

0644-348

Floating Piston Removal Tool Kit<br />

p/n: 0644-402 (Complete Kit)<br />

p/n: 0644-416 (Removal Tool)<br />

p/n: 0644-417 (Location Gauge)<br />

p/n: 0644-418 (Gauge Set Screw)<br />

p/n: 0644-419 (Gauge Stop Collar)<br />

Usage: Remove floating piston from rebuildable gas<br />

shock absorbers.<br />

Fig. 89<br />

0644-402<br />

Bearing Cap Seal Protector<br />

p/n: 0644-268<br />

Usage: Protect cap seal on rebuildable shock absorbers<br />

through 2002 models.<br />

Fig. 90<br />

AE142<br />

Bearing Cap Seal Protector<br />

p/n: 0644-403 (1/2 in.)<br />

p/n: 0644-404 (5/8 in.)<br />

Usage: Protect cap seal on rebuildable shock absorbers<br />

on 2003 and newer models.<br />

Fig. 91<br />

Ball Joint Fork<br />

p/n: 0644-098<br />

Usage: Separate ball joint from spindle or drag link.<br />

Fig. 92<br />

AE142<br />

AE091<br />

Track Clip Installation Tool<br />

p/n: 0644-194<br />

Usage: Install track clips on Camoplast and Yokohama<br />

rubber tracks.<br />

Fig. 93<br />

0644-194<br />

19

Track Stud Hole Drill (7 mm)<br />

p/n: 1639-629<br />

Usage: Drill 7 mm hole through rubber tracks for installing<br />

studs.<br />

Fig. 94<br />

20<br />

AE137<br />

Track Stud Hole Drill (1/4 in.)<br />

p/n: 1639-628<br />

Usage: Drill 1/4 in. hole through rubber track for installing<br />

studs.<br />

Fig. 95<br />

Carbide & Stud Specifications<br />

Gauge<br />

p/n: 1639-632<br />

Usage: Check stud length and carbide angle.<br />

Fig. 96<br />

AE137<br />

AE088<br />

Idler Wheel <strong>Puller</strong> Kit<br />

p/n: 0644-122 (Complete Kit - 6 in.)<br />

p/n: 0644-400 (Complete Kit - 8 in.)<br />

p/n: 0644-114 (A. Handle - 6 in.)<br />

p/n: 0644-401 (A. Handle - 8 in.)<br />

p/n: 0644-111 (B. Insertion Tool)<br />

p/n: 0644-120 (C. Pivot Plate)<br />

p/n: 0644-118 (D. Adapter Plate)<br />

p/n: 0623-310 (E. Cap Screw)<br />

p/n: 0644-119 (F. <strong>Puller</strong> Bolt) - 6 in. Kit<br />

p/n: 0644-432 (F. <strong>Puller</strong> Bolt) - 8 in. Kit<br />

Usage: Remove/install skid frame idler wheels.<br />

Fig. 97<br />

Idler Wheel Alignment Tool<br />

p/n: 0644-228<br />

Usage: Align center idler wheels during replacement<br />

without removing the suspension.<br />

Fig. 98<br />

AE097B<br />

BE025

Spider Removal Kit<br />

p/n: 0644-449 (Complete Kit)<br />

p/n: 0744-037 (Handle)<br />

p/n: 0744-036 (Removal Tool)<br />

p/n: 0644-380 (<strong>Clutch</strong> Holder - 33 mm)<br />

p/n: 0744-035 (<strong>Clutch</strong> Holder - 30 mm)<br />

p/n: 0644-138 (Thin Wall Deep Socket - 1 7/16 in.)<br />

Usage: Disassemble/assemble/remove spider on Comet<br />

and Arctic drive clutches.<br />

p/n: 0644-380 (33 mm)<br />

Usage: Hold clutch stationary sheave for 33 mm crankshaft<br />

on 2001 and later 800/900 cc and 2003 and later<br />

700 cc “Laydown” engines.<br />

p/n: 0744-035 (30 mm)<br />

Usage: Aid in assembling/disassembling of 108 & 102C<br />

Comet and Arctic drive clutches.<br />

p/n: 0644-138 (1 7/16 in.)<br />

Usage: Remove and install spider nut on Arctic roundshaft<br />

drive clutch.<br />

Fig. 99<br />

0644-449<br />

<strong>Clutch</strong> Bushing Installation Tool<br />

(Arctic)<br />

p/n: 0644-006<br />

Usage: Replace sheave/cover bushings on Arctic hexdrive<br />

clutches.<br />

Fig. 100<br />

AE053<br />

Hex <strong>Clutch</strong> <strong>Puller</strong> (Arctic)<br />

p/n: 0644-010<br />

Usage: Remove Arctic hex-drive clutch from crankshaft.<br />

Fig. 101<br />

AE056<br />

<strong>Clutch</strong> <strong>Puller</strong> (Arctic)<br />

p/n: 0644-207<br />

Usage: Remove Arctic round-shaft drive clutch from the<br />

crankshaft.<br />

Fig. 102<br />

AE125<br />

21

<strong>Clutch</strong> <strong>Puller</strong> (Comet)<br />

p/n: 0644-096<br />

Usage: Remove Comet drive clutch (short bolt w/<br />

retainer plug style).<br />

Fig. 103<br />

<strong>Clutch</strong> <strong>Puller</strong> (Comet)<br />

p/n: 0644-100<br />

Usage: Remove Comet drive clutch (long bolt style).<br />

Fig. 104<br />

<strong>Clutch</strong> Compressor (Arctic<br />

Round-Shaft)<br />

p/n: 0644-245<br />

Usage: Compress and hold Arctic round-shaft drive<br />

clutch in the compressed position for changing cam<br />

arms.<br />

Fig. 105<br />

22<br />

AE089<br />

AE055<br />

AE132<br />

<strong>Clutch</strong> Compressor (Comet)<br />

p/n: 0644-123<br />

Usage: Compress and hold drive clutch in the compressed<br />

position for changing cam arms.<br />

Fig. 106<br />

AE098<br />

<strong>Clutch</strong> Compressor<br />

p/n: 0644-420<br />

Usage: Compress and hold drive clutch in the compressed<br />

position for changing cam arms and removing/<br />

installing six-post drive clutch on AWS VI models.<br />

Fig. 107<br />

0644-420<br />

Drive <strong>Clutch</strong> Spanner Wrench<br />

p/n: 0644-136<br />

Usage: Hold Comet and Arctic round-shaft drive clutch<br />

in place during removal and installation.<br />

Fig. 108<br />

AE101

Bushing Tool Kit<br />

p/n: 0644-137<br />

Usage: Remove and install cover plate and movable<br />

sheave bushings in Arctic round-shaft drive clutch<br />

through 1998.<br />

Fig. 109<br />

AE127A<br />

Bearing Removal and Installation<br />

Tool<br />

p/n: 0644-167<br />

Usage: Remove and install bearings in the driven clutch<br />

movable sheave and button plate.<br />

Fig. 110<br />

AE112<br />

<strong>Clutch</strong> Alignment Bar (1.365 in.<br />

Offset)<br />

p/n: 0644-320<br />

Usage: Align the drive clutch and driven pulley on models<br />

using the reverse cam driven pulley.<br />

Fig. 111<br />

AE052A<br />

<strong>Clutch</strong> Alignment Bar (1.562 in.<br />

Offset)<br />

p/n: 0644-246<br />

Usage: Align drive clutch and driven pulley on 1997<br />

models using the Arctic internal-helix driven pulley.<br />

Fig. 112<br />

AE140<br />

<strong>Clutch</strong> Alignment Bar (1.485 in.<br />

Offset)<br />

p/n: 0644-428<br />

Usage: Align drive clutch and driven pulley on Bearcat<br />

Wide Track models.<br />

Fig. 113<br />

0644-428<br />

<strong>Clutch</strong> Alignment Bar (1.620 in.<br />

Offset)<br />

p/n: 0644-427<br />

Usage: Align drive clutch and driven pulley on ACT Drive<br />

models.<br />

Fig. 114<br />

AE052A<br />

23

Reverse Gear Adjustment Gauge<br />

p/n: 0644-244<br />

Usage: Adjust reverse gear linkage on all 1996-2002<br />

reverse gear transmissions.<br />

Fig. 115<br />

Driven Pulley <strong>Puller</strong><br />

p/n: 0744-023<br />

Usage: Remove driven pulley from driven shaft. It can<br />

be used on both the roller and button style.<br />

Fig. 116<br />

24<br />

BE027<br />

0744-023<br />

Roller Pin Removal Tool<br />

p/n: 0644-276<br />

Usage: Remove roller pins from retainer plate on driven<br />

pulley.<br />

Fig. 117<br />

AE146D<br />

Bearing Removal Tool<br />

p/n: 0644-421<br />

Usage: Remove chain case bearings on 2003 and<br />

newer models.<br />

Fig. 118<br />

Drive Belt Gauge<br />

p/n: 0644-443<br />

Usage: Measure drive belt width.<br />

Fig. 119<br />

0644-421<br />

0644-443<br />

Drive Belt Deflection Tool<br />

p/n: 0644-412<br />

Usage: Adjust driven pulley for proper drive belt deflection<br />

and aid in drive belt removal on models using the<br />

ACT Roller Driven Pulley.<br />

Fig. 120<br />

0644-412

Drive Belt Replacement Tool<br />

p/n: 0644-435<br />

Usage: Replace drive belt and adjust belt deflection on<br />

models using the ACT Roller Driven Pulley.<br />

Fig. 121<br />

0644-435<br />

Driven Pulley Spring Adjustment<br />

Tool<br />

p/n: 0644-413<br />

Usage: Adjust driven pulley spring pre-load on models<br />

using the ACT Driven Pulley.<br />

Fig. 122<br />

0644-413<br />

Drive Belt Deflection Tool<br />

p/n: 0644-424<br />

Usage: Adjust driven pulley for proper drive belt deflection<br />

and aid in drive belt removal on 2004 440 Sno Pro<br />

model.<br />

Fig. 123<br />

0644-424<br />

Driven Pulley Compressor Tool<br />

p/n: 0644-444<br />

p/n: 0644-439 (A. Compressor Assembly Only)<br />

p/n: 0643-095 (B. Disc Only)<br />

Usage: Disassemble/assemble Arctic ACT and Team<br />

Industries roller driven pulleys.<br />

Fig. 124<br />

644-444A<br />

Brake Disc Socket Wrench<br />

(ACT Drive)<br />

p/n: 0644-415<br />

Usage: Remove/install brake disc on ACT Drive models.<br />

Fig.125<br />

0644-415<br />

25

Printed in U.S.A. ®Trademarks of Arctic Cat Inc., Thief River Falls, MN 56701 p/n 2257-251