You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

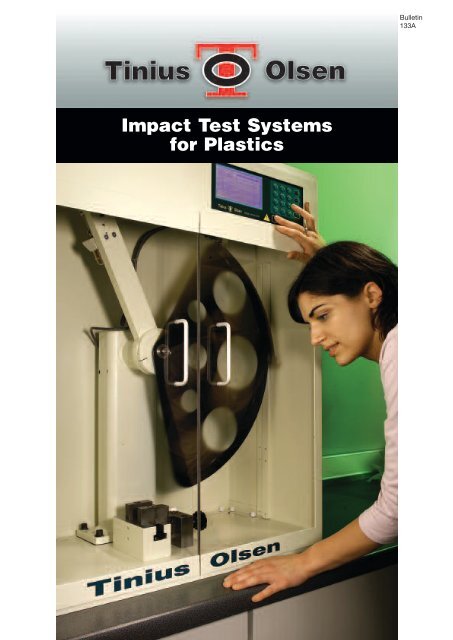

<strong>Impact</strong> <strong>Test</strong> <strong>Systems</strong><strong>for</strong> <strong>Plastics</strong>Bulletin133A

Model IT 503The new model IT 503 plasticsimpact tester, together with the modelIT 504, continues to set the industrystandard <strong>for</strong> versatility, ease ofoperation, and display of in<strong>for</strong>mationwith high resolution.These machines are capable ofdetermining the impact strength usingeither a Charpy or Izod configuration,without changing the pendulum.The user attaches the appropriatestriking tup on the pendulum and thespecimen clamp or anvils in the baseof the unit, to test plastics in accordancewith ASTM D256 (Izod impact),ISO 179 (Charpy impact), ISO 180(Izod impact), ASTM D6110 (Charpy<strong>Impact</strong>), ASTM D4812 (UnnotchedCantilever Beam <strong>Impact</strong>), ASTMD4508 (Chip <strong>Impact</strong>), ASTM D950(Adhesive Bond <strong>Impact</strong>), and othersimilar standards.The aerodynamically designedcompound pendulum provides maximumrigidity in the direction of theimpact and virtually eliminates anywindage losses. Pendulum capacityis easily changed by adding on anyone of seven optional weight sets.The energy absorbed in breakingthe specimen can be configured inSI, metric, or English units and isdetermined by an optical encodermounted on the shaft of the machineand is based on the latched height ofthe hammer (relative to the zeropotential energy point), the maximumpost-impact height of the hammer,and the frictional losses of themachine. Energies of less than 0.03%of the pendulum capacity can beresolved and this resolution is vastlysuperior to dial type displays andother currently available displays.Both the IT 503 and IT 504 comewith a standard “low blow” feature.This provides a convenient andreliable means <strong>for</strong> releasing thependulum from a lower than usualheight, allowing testing at lowerimpact velocities and energy levels.Additionally, the model IT 503 issupplied with all necessary safetyshielding to protect the operator andbystanders from the broken samples.To make impact testing on plasticseasier and more flexible, the machinescan be connected to a pc runningTinius Olsen’s impact software.Model IT 503<strong>Plastics</strong><strong>Impact</strong> <strong>Test</strong>er.Key Features ofModel IT 503• Aerodynamic compound pendulumthat can accommodate weights toincrease test capacity• Interlocked safety doors to ensurependulum cannot be released withthese doors open• Simple and rapid change betweenIzod and Charpy test setup• Con<strong>for</strong>ms to all applicableEuropean CE DirectivesOptional Featuresof Model IT 503• Automatic braking system <strong>for</strong>increased safety and higherthroughput• Motorized pendulum return <strong>for</strong>added safety• Pneumatic Izod clamping system<strong>for</strong> higher test repeatability• Pneumatic specimen rack and feedsystem <strong>for</strong> more automated testing• Hot and cold chambers <strong>for</strong> testingat different temperaturesClose-up of Izod test setup.

Model IT 504The model IT 504 continues to setthe industry standard <strong>for</strong> accuracy,versatility, ease of operation, anddisplay of in<strong>for</strong>mation with highresolution.As with the model IT 503, Izodand Charpy impact fixtures can beeasily added and removed via theT-slotted block, making the IT 504one of the most versatile machinesavailable.Key Features• Aerodynamic compound pendulum• Selectable energy units of J, in.lbf,ft.lbf, kgf.m and kgf.cm• Selectable strength calculations inft.lbf/in, J/m, in.lbf/in, kgf.m/m,ft.lbf/in 2 , kJ/m 2 , in.lbf/in 2 , orkgf.m/m 2• Break type input options ofComplete, Hinge, Partial,Non-break, and Necking• Automatic or manual Tosscorrection• Auto calibration <strong>for</strong> bearing windageand friction• Automatic or manual update ofspecimen number• Real time display of energy isavailable <strong>for</strong> verifying the displayaccuracy against traceablemeasurements of pendulum heightand weightBASIC PENDULUMCAPACITY— WITH LOW BLOWINCREASEDPENDULUMCAPACITYDROP HEIGHTIMPACT VELOCITYPOWERDIMENSIONSW x D x HWEIGHTTECHNICAL SPECIFICATIONSJ 2.82ft.lb 2.08ft.lb 25J 2.75 to 2ft.lb 2.03 to 1.475ft.lb 24.38 to 17.73Jft.lbin.lbadd-on weights available <strong>for</strong> up to 25 Jadd-on weights available <strong>for</strong> up to 18.44 ft.lbadd-on weights available <strong>for</strong> up to 221.63 in.lbm 0.61ft 2m/s 3.46ft/s 11.35110/220 VAC, 50/60 Hz, 1phmm 660 x 380 x 840in 26 x 15 x 33Model IT 504shown with hot andcold chamber.kg 110 (90)lb 240 (200)Close-up ofCharpy test setup. Model IT 504<strong>Plastics</strong> <strong>Impact</strong><strong>Test</strong>er.Optional Features• Hot and cold chambers• Instrumentation package <strong>for</strong>impact testing• Separate 1Jand 0.5JhammersOptional weight sets, clamps,anvils, and striking tups.

<strong>Impact</strong> Specimen NotcherThe Tinius Olsen Model 899 <strong>Impact</strong>Specimen Notcher <strong>for</strong> <strong>Plastics</strong> isdesigned to machine a notch in aplastic specimen in accordance withISO 179, ISO 180, ASTM D256 andASTM 6110.Prior to per<strong>for</strong>ming tests, thespecimens must be notched in orderto create a stress riser and to predictthe point of fracture. The Tinius OlsenModel 899 <strong>Impact</strong> Specimen Notcher<strong>for</strong> plastics can accurately machineup to 28 3.2 mm (1/8”) thickspecimens at one time.The Model 899 Specimen notcherfeatures an air cooling system thatdirects air flow at the cutting area toreduce the risk of thermal degradationof the specimens. A clear safetycover over the cutting area protectsthe operator, while doubling as anattachment <strong>for</strong> a vacuum system(not supplied) to remove chips fromthe cutting area.Routine operation of the Model899 <strong>Impact</strong> Specimen Notcher isautomated and requires minimaloperator supervision. After samplesare loaded, the operator initiates theautomatic notching cycle by simplypressing a button.After the notching process iscompleted, the notch depth can beverified by using the Model 799Notch Depth Verification Device.Model 899 <strong>Impact</strong>Specimen Notcher.Model 799 Notch DepthVerification Device.<strong>Impact</strong> Software• User-selected reporting and exporting<strong>for</strong>mats• Built-in SPC programs <strong>for</strong> X-bar, R,and frequency distribution chart/histograms• <strong>Test</strong> mode allows configuring,running, and saving of tests andresults• Recall mode permits viewing ofpreviously saved results andper<strong>for</strong>ms database maintenance1065 Easton RoadHorsham, PA 19044 USA(215) 675-7100Fax (215) 441-0899www.TiniusOlsen.cominfo@TiniusOlsen.comContact Your Local Representative:6 Perrywood Business ParkHoneycrock Lane, Sal<strong>for</strong>dsRedhill, Surrey RH1 5DZ England+44 (0) 1737 765001Fax +44 (0) 1737 764768© 2004, Tinius Olsen 11/04 Printed in UK