WORKING AT HEIGHTS - Wind Energy Network

WORKING AT HEIGHTS - Wind Energy Network

WORKING AT HEIGHTS - Wind Energy Network

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INTRODUCTION‘Spotlight’on the Tyne& the TeesContinuing our successful‘Spotlight On’ features weagain visit the Tyne & Teesas ‘an area of excellencein the wind energy industrythroughout Europe andbeyond’The area is becoming more and moreimportant to the wind energy industry.As you will see the depth and breadthof the companies and organisationswho have contributed to this feature donot disappoint.The feature boasts the largest pagecount so far which stretches over 40pages!Collaboration and the VesselCo-OperativeOur industry lead article in this editionfeatures the conference held inGreat Yarmouth recently organisedby Offshore Marine Support. As youwill find within the article the aim ofthe conference was to get as manyinterested parties involved in movingforward, with the objective of servingthe industry’s needs.We will continue to follow the cooperative’sprogress in future editions.Regular featuresWe can boast no fewer than 9 separatefeatures within this edition. Someare planned and can be found in our‘Forthcoming Features’ tab on ourwebsite – we do however react to editorialreceived, which we believe is importantto the industry and create new features tosuit.Therefore please do not hesitate to let usknow about any subject area which youfeel is important to the continued progressof the industry and we will endeavour tobring it to the fore.<strong>Wind</strong> energy industry skills gap– initiative updateI year ago we reported that there were 4main areas to focus on if we are to satisfythat need and would include a focusedapproach in the following areas.We have over that period covered...• Schools – from primary throughsecondaries to 6th form• Schools’ 6th Form /further education –schools/colleges• Engineering and science graduateattraction – universities• Mature experienced individuals fromother relevant energy industries/sources e.g. oil & gas industry/forcesThe time has now come to reviewthe situation having gathered all theinformation and response from theindustry and you will find this within thefeature.Magazine and websiteinteraction – QR codesYou will have noticed that we changed ourpink and green flashes indicating moreinformation online in the last edition. QRcodes have been substituted which meansthat you can scan the code with your smartphone and it will direct you to the featuredcompany/organisation micropage heldwithin our website, so that you can learnmuch more in all sorts of formats.These have already become very popularas it links the printed magazine in a veryinteractive way – a great marketing toolfor our decision making readership tofind out about products and servicesimmediately following the reading of aninteresting article. Contact the commercialdepartment to find out how to get one foryour company.Click to view more info= Click to view videoDuncan McGilvrayEditor | <strong>Wind</strong> <strong>Energy</strong> <strong>Network</strong>www.windenergynetwork.co.ukwww.windenergynetwork.co.uk01

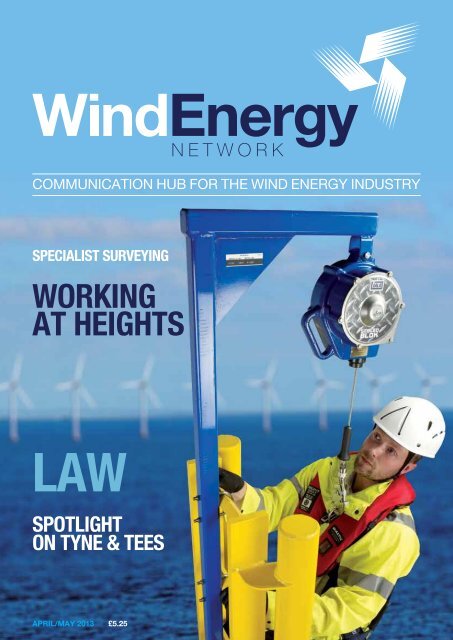

WIND ENERGY NETWORKCHALLENGINGENVIRONMENTSThe cover image was supplied byCapital Safety just to remind usthat working environments can bechallenging!Our feature on ‘Working at Heights andwithin Confined Spaces’ contains anumber of very helpful editorials fromsome of the best experienced in theindustry.Regular featuresAmongst some 9 features within thisedition we focus on Specialist Surveying,Law and Lubrication & Filtration to namebut 3.Spotlight on the Tyne & TeesThe largest regional feature so far atmore than 40 pages, with a wide rangeof articles from small companies tomulti-nationals as well as organisations,educational established and membershipgroups featured.Skills GapAn update on this initiative which startedjust over 1 year ago and has featuredprimary and secondary schools, 6thforms, colleges, universities, companies,both large and small, and the Forces.Duncan McGilvrayEditor | <strong>Wind</strong> <strong>Energy</strong> <strong>Network</strong>Front cover image: courtesy of Capital Safety02www.windenergynetwork.co.uk

CONTENTSCONTENTSPage 4Industry lead article – the UK & Ireland vesselco-operative conference 2013 held recently inGreat YarmouthPage 78Offshore <strong>Wind</strong>: A Guide For Business conference– held at the Advanced Manufacturing ResearchCentre (AMRC), RotherhamPage 8Page 14Page 16Page 20Page 24Page 26Page 70Your Industry News section starts hereYour regular events calendar and what’s newSkills Gap – our <strong>Wind</strong> Industry Careers initiativeupdate now 1 year on, including more contributionsacross the 4 target areasBusiness Development section – regular advice fromour team of expertsAll in a day’s work – Jeff Main, Managing Director ofTyne & Wear MarineSpotlight on the Tyne & Tees– we return to theregion to highlight progressRisk management – Risktec, our regularcontributors, on Quantitative Risk Assessments, part 2Page 80Page 86Page 88Page 94Page 96Page 100Page 102Andrew Jackson Solicitors heads up ourLaw featureEvent feature – EEEGR’s SNS 2013 conference heldat the Norfolk Showground, NorwichWorking at heights and within confined spacesfeature – we hear from the expertsEvent feature – Humber Renewables Awardsceremony held in Hull‘Distributed wind’ feature – ICE Renewables start byexplaining the conceptEvent feature – RenewableUK event ‘Future ofoffshore wind’ held in OrbisCentre, LowestoftMetmasts featurePage 72Feature on Lubrication & Filtration - expert advicePage 108Substantial feature on Specialist Surveyingp27p40p98Green <strong>Energy</strong> Publishing Ltd (Northern) The Oaks, Oakwood ParkBusiness Centre, Bishop Thornton, Harrogate, North Yorkshire HG3 3JNGreen <strong>Energy</strong> Publishing Ltd (SOUTHERN)Orbis<strong>Energy</strong>, Wilde Street, Lowestoft, Suffolk NR32 1XHTELEPHONE 01765 644224WEB SITE www.windenergynetwork.co.ukEditorial duncan@greenenergypublishing.co.ukSales sales@greenenergypublishing.co.uk<strong>Wind</strong> <strong>Energy</strong> <strong>Network</strong> magazine is happy to accept unsolicited contributions for consideration. Editorial opinions expressedin this magazine are not necessarily those of Green <strong>Energy</strong> Publishing Ltd and the company does not accept responsibilityfor advertising content. The publishers cannot accept any responsibility for omissions or errors. The contents of thismagazine are fully protected by copyright and may not be reproduced without written permission.www.windenergynetwork.co.uk03

INDUSTRY ARTICLEIndustry Vessel Co-operativeWithin the lastedition the leadarticle highlightedthe importance ofcollaboration in theindustry.With this in mind we featured thework of Offshore Marine Support ingetting together many companiesand organisations to service the windenergy industry by setting up a vesselco-operative.The first event was held in Gt Yarmouthrecently and we now report on theconference – it is also well worth featuringthe progress of the co-operative in futureeditions because of its significance in thewind energy industry.Limited riskThe co-operative market the vessel andsubmit tenders for appropriate jobs, takinga small percentage of the charter rateshould the vessel be successful, thus riskto the owner is minimal. The range ofvessels, and related equipment, availablewithin the co-operative is vast – fromsurvey vessels to jack-up barges.Cost efficientFor the end user, the daily charter ratesare kept to a reasonable level as OMSdo not have the overheads of a largerorganisation.DiversificationThe co-operative has enabled owner/operators of vessels to diversify theirown businesses and work in an industrysector that still displays growth – i.e. manyfishing companies have joined the cooperativeto offer their vessels for guardduties. We have a number of fishermenwho completely endorse the concept ofOffshore <strong>Wind</strong> which has gone a long wayto change the mind-set of those who maypreviously have been against it.Currently, there are offices in Gloucester,Preston and the Isle of Wight andvessels available are at various locationsthroughout the UK and Southern Ireland.About the co-operativeThis co-operative has brought togetherseveral small owner/operators with one ortwo vessels with the aim of presenting amore forceful presence in the RenewablesSector. The co-operative has built upmany senior contacts within the industrywhich enables the smaller operator to gainaccess to people that they may not havebeen able to before by joining the cooperative.There is no charge to join.04www.windenergynetwork.co.uk

INDUSTRY ARTICLEThe UK &Irelandvessel cooperativeconference2013Image courtesy of Fendercare MarineWelcomeThe Mayor of Gt Yarmouth, Her WorshipCouncillor Colleen Walker, welcomed allpresent to Gt Yarmouth and describedhow important the wind industry has, andwill continue to be a very important sectorto the success of the area.IntroductionAndy Iannetta, MD of Offshore MarineSupport and Chairman for the day, gavea very enthusiastic introduction of what toexpect during the conference and invitedall to voice any opinions and/or concerns.He emphasised that it was very early daysin the life of the co-operative and everyoneinvolved felt it essential that every basewas covered regarding any concernsexpressed.Andy further explained, assisted by video,the reasoning behind the set up andexpressed his eagerness to involve allinterested parties, including educationalestablishments, colleges and fishermen/fishermen’s organisations.Speakers included...• Sean Matthews (Navitus Bay) – theNavitus Bay project• Jules Morgan (KPM-Marine) – safety atsea and crew habitation• Tim Smith (Fendercare) – support basefacilities and vessel innovations• Mark Hart & Alistair Hackett (OceanSafety) – man overboard & life safetyequipment• Ian Pease (Lowestoft College) – skills &training for wind farm support vessels• John Hawthorn (Red7Marine) – thevessel fund• Chris Holden – what do RES Offshoreneed from vessel suppliers to providea ‘one-stop-shop’• Paul Lines – the importance of safetymanagement systems within theco-operative• Jimmy Buchan – diversification andthe views of fishermenConclusionAll in all a very worthwhile day and we lookforward to following the progress of theco-operative through its formative yearsand beyond.There were a number of subject areaswithin the speakers’ presentations whichwe will be elaborating on in future editionsOffshore Marine Support ltdwww.offshoremarinesupport.comwww.windenergynetwork.co.uk05

INDUSTRY NEWSAlnmaritecmakesDiscoveryin 2000 - at the time, the first offshoreinstallation anywhere in the world - andduring this time we’ve built a lasting andtrusting relationship with Alnmaritec.”Specifically in regard to ‘NSL Discovery’Mr Armstrong said “I am delightedwith the performance of the new boat.She has proved herself on trials tobe extremely capable in some verydemanding conditions and she will be areal asset to our North Sea operations.She is a credit to theworkforce at Alnmaritec andI am confident that she willprove to be one of the bestvessels in the industry”.Wave Captain class specificationThe 19m Wave Captain class boat ispowered by 2 x 880bhp Doosan enginesand reaches over 25 knots. She hasdemonsatrated exceptional sea-keepingcharacteristics and superb handling whenapproaching and pushing up on the windturbines.Finished with the innovative ‘Intersleek’paint system designed to provide fuel andenvironmental benefits, this state of the artwind farm support vessel (WFSV) designhas full suspension seating for 12 andincludes a large galley and mess area aswell as four day berths on the lower deck.Alnmaritec Company progressThe 11th boat built by Alnmaritec forNorth Sea Logistics, Discovery is alsohull number 150 for the Blyth basedcompany. Managing Director ChrisMillman commented “We’re delighted tohand over ‘NSL Discovery’ which is thelatest of our builds intended to work inthe growing offshore wind industry.”North Sea Logistics progressNorth Sea Logistics Managing DirectorDavid Armstrong commented “We havebeen involved in the offshore windindustry for 13 years, starting with theconstruction of the Blyth <strong>Wind</strong> FarmChris Millman said “I amextremely happy with theway the boat has turned out.The wind farm market is animportant one for us and weare determined to stay in thevanguard of the developmentof these boats.”Relevant pastexperienceBut it’s not just the offshorewind sector Alnmaritec supplyto as Mr Millman explains, ”Wehave been building boats forover 20 years and have supplied vesselsto operate in some of the harshestconditions on every continent in theworld, for clients operating in a range ofsectors. For example currently in buildwe have a pilot boat for a project in WestAfrica, a passenger vessel for a Scottishconstruction project and workboats forclients in Korea and Singapore which willbe used in the Oil & Gas industry.”Alnmaritec Ltdwww.alnmaritec.co.uk08www.windenergynetwork.co.uk

SKILLS GAP<strong>Wind</strong> energyindustry skills gapinitiative updateHistoryIn the April/May 2012 edition we featuredthe ‘Kent Schools <strong>Wind</strong> <strong>Energy</strong> EnterpriseChallenge’ which started our initiative onaddressing the wind energy industry skillsgap as a matter of urgency.I year ago we reported that we see thereare 4 main areas to focus on if we areto satisfy that need and would include afocused approach in the following areas...• Schools – student engagement andawareness at the early stages ofcareer development (ages 14 onwards)• Schools’ 6th Form /further education –schools/colleges• Engineering and science graduateattraction – universities• Mature experienced individuals fromother relevant energy industries/sourcese.g. oil & gas industry/forces etcA major feature in the June/July 2013highlighted each of these areas as aprelude to a series focusing more in detailin each of the following editions.Editorial evolved over those editions andfeatured all sorts of contributions frommany areas of the UK and also drew lotsof interest from Europe and beyond.The time has now come to reviewthe situation having gathered all theinformation and response from theindustry.<strong>Wind</strong> Industry Careers websitePreparations are in hand to launch thenew <strong>Wind</strong> Industry Careers website. Wedelayed this launch until the industryunderstood what we are trying to achievein the best interests of the industry as awhole.This interactive and informative websitebe used to attract people of all ages andabilities into the wind energy industry.There are a number of initiatives to helpthe industry progress in the skills areaand it is our policy to compliment theseinitiatives and not to be in competition withanyone.<strong>Wind</strong> Industry Careers steeringgroupWith this in mind we created the <strong>Wind</strong>Industry Careers steering group to guideus through the set up and monitor theprogress of the initiative.The group met in late 2012 to set policyand procedures – the first meeting wasextremely successful and the secondmeeting is scheduled in 2013 followed bythe launch of the new website.<strong>Wind</strong> Industry Careers ‘roadshows’It remains our intention to tour the UKand organise road-shows at appropriatevenues suited to the 4 target areas i.e.selected schools, colleges, universitiesand company sites/forces bases – alldecision makers from the relevant areas ofthe industry, some of which have alreadybeen approached for their comments,were enthusiastic about getting involvedwith this initiative. Following furtherconsultation with interested partiestimescales and road-show formats can bediscussed and decided.We will keep you informed ofdevelopments.Regular skills gap featureThe Skills Gap initiative has attracted manyeditorial contributions from educationalestablishments who are carrying outsterling work in their own areas ofexpertise.We will therefore continue to host a regularskills gap feature within each edition of themagazine – please feel free to contributeregular editorial for inclusion.Duncan McGilvrayEditor14www.windenergynetwork.co.uk

SKILLS GAPLowestoftCollegefacilitiesunderspotlightLowestoft College’s engineering andmaritime facilities were under thespotlight recently when Skills MinisterMatthew Hancock had a tour of thespecialist facilities.Matthew Hancock, Skills Minister, with Waveney MP PeterAldous in the Lowestoft College training tankMatthew Hancock, Skills Minister, atLowestoft College’s Ship’s Bridge SimulatorMatthew Hancock with apprentices/studentsWhistle-stop tourMr Hancock had a whistle-stop tour ofsome of the College’s facilities includingthe 18 metre wind turbine tower whichwas installed just over a year ago to trainworkers in the wind farm industry. He alsowatched Uniformed Services studentsbeing put through their paces with anemergency evacuation drill in the TrainingTank before being wowed by just howrealistic the Ships’ Bridge Simulator was.ApprenticesMr Hancock also spoke with EngineeringApprentices and watched them at work inthe recently upgraded workshop which nowboasts state-of-the-art training facilities.There was also time to meet travel andtourism students and answer their questions.Gaining an insightSimon Summers, Principal at LowestoftCollege, said: “We were very pleased thatSkills Minister Matthew Hancock spenttime with us and was able to see whatLowestoft College offers. By talking toapprentices and students he was ableto gain a good insight in to the issuesfacing them and see just how committedthey are to their studies. The visit wasalso an excellent opportunity for us toshowcase the range of courses we offerincluding those which support the keylocal industries of Maritime, Offshore and<strong>Energy</strong>.”The Minister was joined by Waveney MPPeter Aldous and Leader of Suffolk CountyCouncil, Cllr Mark Bee.Lowestoft Collegewww.lowestoft.ac.ukwww.windenergynetwork.co.uk15

SKILLS GAPHonorary degrees forindustry leadersIndustry leaders in the power andenergy sector have been madehonorary graduates of the Universityof Strathclyde – recognising theiroutstanding contribution to one of themost important fields in the Scottisheconomy.International technologicaluniversityAs a leading international technologicaluniversity, Strathclyde plays a pivotal rolein research, teaching and knowledgeexchange in power and energy, and iscurrently the Times Higher Education UKUniversity of the Year.The Power <strong>Network</strong>sDemonstration CentreThe University of Strathclyde is home tothe largest electrical power engineeringand energy research group in Europe.Later this year it will officially open– a worldclass research centre which is the first ofits kind in Europe.PresentationThe honorary degrees were presented ata specially-arranged Power and <strong>Energy</strong>event held in the Glasgow Science Centre,with First Minister Alex Salmond deliveringthe keynote address.Receiving the awards were KeithCochrane, Group Chief Executive of theWeir Group; Ignacio Galán, Chairmanand Chief Executive Officer of Iberdrola;Steve Holliday, Chief Executive of theNational Grid; Professor David MacKay,Chief Scientific Advisor at the Departmentof <strong>Energy</strong> and Climate Change; IanMarchant, Chief Executive Officer of SSEand Sir Ian Wood.Academic seminarThe ceremony was preceded by anacademic seminar involving the sixgraduates, where each spoke on themajor themes and challenges facing theindustry. It was attended by researchers,students and figures from across thesector.Professor Sir Jim McDonald, Principalof the University of Strathclyde, said:“Strathclyde plays a key part in theglobal power and energy sector and thisevent provides us with the opportunityto recognise the significant contributionmade by key individuals.“As a major contributor to economicdevelopment in Scotland, it is vitallyimportant that academia and industrycollaborate to develop world-classresearch and ensure that Scotlandcontinues to flourish as a leader in powerand energy.“In being named UK University of theYear, Strathclyde was described asa ‘bold, imaginative and innovativeinstitution’ – an approach we share withthe individuals we have honoured today.”First Minister’s commendationFirst Minister Alex Salmond said: “The sixprominent energy figures honoured byStrathclyde University today have beencentral to the development of the energyindustry in Scotland in recent yearsthrough their business leadership andacademic expertise.“These deserving graduates have made,and are making, a major difference to oneof Scotland’s most important sectors andby doing so are also making a differenceto the prosperity and wellbeing ofcommunities across the country.“Today’s event also recognises the extentto which universities such as Strathclydebenefit from close links to industry, andhow much each of the industry figuresreceiving these awards gain from theirinteraction with the education sector.“Only by forging partnerships andcollaborations such as the ones highlightedtoday will Scotland’s energy sector be ableto harness the talent of our young peopleand continue to drive the renewablesrevolution in the coming decades.”Technology and InnovationCentre (TIC)In addition, 2014 will see the opening ofthe TIC. The centre will forge new levels ofcollaboration with business and industry,creating jobs and attracting inwardinvestment.Major partnersDeveloped with industry, for industry, the£89 million centre has already attractedmajor partners including SSE, the WeirGroup and ScottishPower and it willbecome the cornerstone of Scotland’sInternational Technology and Renewable<strong>Energy</strong> Zone (ITREZ), a global research anddevelopment hub in the heart of Glasgow.University of Strathclydewww.strath.ac.uk16www.windenergynetwork.co.uk

SKILLS GAPCompany re-launchesto tackle skills challenge“There is not a significant skills shortageyet, but with the continuing gas fieldwork, new nuclear and the developingwindpower sector, if we do not get ouract together now the gap could becomehuge. We want to ensure clients areprepared.“What we are looking to achieve as abusiness is to provide a seamless supportservice to our clients.”The company can also offer recruitmentprocess outsourcing to clients withouttheir own specialist or HR teams.John Balch (left), NWES Strategic Director, welcomes PWE ManagingDirector Stuart Smith to Orbis<strong>Energy</strong>.The search for enough skilled workersto meet the future demands of theEast of England energy industry hasprompted one recruitment business tore-name and re-launch itself ready forthe challenges ahead.People with <strong>Energy</strong> (PWERecruitment Group Ltd)Inspired by its own slogan, Beccles-basedPDS will from this week be known as thePWE Recruitment Group focusing totallyon recruitment and saying farewell to a25-plus year heritage since it started life asProject Design Services.“Over the last few years, we have gonefrom strength to strength and expect lastyear’s £2.4m turnover to leap to £3m thisyear,” he said. “We’re not only steppingup the recruitment business but intendtaking on six new staff ourselves over thecoming three years.”Sister companiesThe group comprises sister companiesForces4<strong>Energy</strong>, which recruits ex-militarypersonnel for the energy industry, andLondon-based Forces4City, which hasa wider industry brief and specialises infinance and information technology.ClientsRecruiting everyone from directors andsenior managers through to techniciansand labourers, PWE has companies likeMott McDonald, Proserv Controls, TycoFire & Integrated Solutions and 3sunamong its clients.EEEGRMr Smith said they were indebted toEEEGR (the East of England <strong>Energy</strong>Group) and consultant John Balch forsupport and funding arrangements duringthe redevelopment plans.PWE Recruitment Groupwww.peoplewithenergy.co.uk2013 – a year of changeStuart Smith, who took control of thebusiness four years ago after workingthere for nearly two decades, said 2013would be a year of change, evolutionand expansion with more than £65,000invested in the company’s re-branding.And as well as its Beccles headquarters,PWE has offices at Orbis<strong>Energy</strong>,Lowestoft, and Sunningdale and isopening shortly in Aberdeen.Keeping the lights on“Keeping the lights on is paramount sothe energy industry is always buoyant.”said Mr Smith.www.windenergynetwork.co.uk17

BUSINESS DEVELOPMENTCoachingLet’s start with coaching. This is awork activity that rates highly amongstprogressive people at all levels. It seemsthat many of us really enjoy developing theskills of new and improving staff. In factmany regard passing on skills and adviceto ‘learners’ as one of the most fulfillingparts of their job whether they are in asupervisory role or in an expert role.No problem anticipated here then. Maybeyou just need to let the boss know thatyou want to start coaching or spend moretime doing it. The more you do the morewidespread will be your legacy of goodpractice in your profession.On the days when you take someoneto a higher level or stop someone doingsomething wrong you are ‘changing’ thefuture for that person. Indeed it might besaid that you are changing the future - oneperson at a time.MentoringLet’s move on now to mentoring.Speaking personally I can only coachpeople in my areas of experience andexpertise e.g. management, teambuilding, negotiating, presentation skillsetc. However over the years I seem tohave acquired more and more ‘mentoring’clients i.e. people who want the magic ofone-to-one learning sessions as well as, orinstead of, the classroom experience.I am usually a mentor to professional,technical and scientific people becauseI cannot really coach them to performtheir individual calling. I am not on thepremises, like you might be, to coachthem, to run behind them or sit alongsidethe individual who wants to do his/her jobbetter, or inspire a group of disgruntledpeople at a meeting.What you and I can do in the mentoringrole is listen carefully to the individual’sconcerns and then bring a lot of goodexperience into play in a discussion abouta problem that is really vexing an individualor his/her employer.Again I can only speak for myself - butthe type of problems and work situationsI have helped people tackle successfullythrough mentoring include career issuesat junior and senior levels; dealing withdemanding people, performance issues atjunior and senior levels and a wide rangeof other thorny management questions.How is this done? Typically the mentoring Ido is face-to-face at a convenient location,or on the telephone (in an emergency).I increasingly mentor on-line with e-mailmessages going back and forth.ResultsResults as far as I can tell seem to have allbeen positive to date. This is in no smallpart down to the honesty and realismthat comes from a one-to-one session.For example a middle manager in a highlysuccessful company, seeking a £25k perannum pay rise immediately, becamemore realistic following our telephonementoring session he was able to quicklysecure an extra £20k per year – with theincrease spread over three years.In recent times I spent a day mentoringa young and untrained supervisor whohad reading and writing difficulties of hisown. He confided that he would neverattend conventional management trainingcourses because of the (continuing) painand embarrassment he had suffered sincehis school days. However, one to onementoring sessions, that involved a lot ofwalking around his premises and talkingabout his job, helped him to transformhis performance and his employer nowrecommends mentoring wholeheartedly.Again in recent times an outgoingmanager sent his replacement (his deputy)for a series of half day mentoring sessions.After each session workplace goalswere set for the coming week and theindividual would then report on his resultsat our next half day session. The outgoingfellow was able to monitor results, whichexceeded everyone’s expectations, andby using the quieter half days disruption tonormal working was minimised.So if you are looking to add even moresatisfaction to your role then thinkabout mentoring as a way to boost theperformance and confidence of yourpeople. It is cost-effective use of your timeand you can customise it to the needs ofthe individual and the requirements of youremployer.Good luck with changing the future – oneperson at a time. In the second part of thisarticle I will look at how you can changethe future by making presentations topeople – standing up and speaking up!Frank Newberrywww.franknewberry.comwww.windenergynetwork.co.uk19

BUSINESS DEVELOPMENTManagement MattersIn the last of the workshop series,created by of Renewables <strong>Network</strong>to help businesses prepare forthe demands of the offshore windenergy supply chain, the subject ismanagement. Here John Britton,Director of Renewables <strong>Network</strong>Ltd, discusses the critical, but oftenmisrepresented role of management.Many things have been published overthe years that have simply served toconfuse managers by mixing styleand function as if they are the samething. In this workshop the focus is onfunction, leaving the question of styleto the individual. The only style thatwill work is the one that is natural toyou.LEAD OR MANAGE?This is the first question that needs to beresolved. One hears a number of onelinersthat are designed to capture theessence of each.“Leading is transformational, managing istransactional”“Leaders are inspirational, managers aretechnical”These statements sound catchy, butthey confuse function and style. Oneof my favourite books on the subject is“Burn! 7 Leadership Myths in Ashes”by Mitch McCrimmon. In it he clarifiesvery effectively that leadership andmanagement are distinct roles, both ofwhich can be accomplished in a rangeof styles. For him the role of leadership isto set a new agenda for the team. Thismakes the role more than innovation,there are plenty of innovators who don’tmanage to sell the change of agenda towhich their innovation opens the door.A leader has to sell the change to the‘agenda setters’. As such a leader canexist anywhere in an organisation, not justat the top.The role of management is to executethe agenda. The agenda can be one ofincremental improvement of performanceto maintain a ‘no change’ strategy, or itcan be to execute exciting and significanttransformation triggered by a newstrategic vision. The specific challengesmay be different, but the role is the same –to execute the agenda.• Are these roles mutually exclusive?No, a manager can also be a leader.• Are these roles mutually dependent?No, a leader can emerge from thelaboratory or from the sales force tosell a new concept, never having hadany management experience at all.Also a manager can be a superbmanager without ever being a leader.CHANGE MANAGEMENTThere you have it. The function thatis the subject of countless seminarsand hundreds of books is changeMANAGEMENT, not ‘change leadership’.This whole topic embraces the two roles,but the far more significant functionin the achievement of change is themanagement role of executing the changeagenda. John Kotter is, perhaps, a betterknown author than Mitch McCrimmonand his book ‘Our Iceberg is Melting’co-authored with Holger Rathgeber hascertainly achieved book of the monthstatus in management circles. The clarityKOTTER1 Create a sense of urgency – help others to see the need forchange and the importance of acting immediately2 Pull together the guiding team – make sure there is a powerfulgroup guiding the changewith which Kotter describes the essentialsteps required to secure organisationalchange is very helpful for every manager.3 Develop the change vision and strategy – clarify how the futurewill be different from the past4 Communicate for understanding and buy-in – make sure asmany others as possible understand and take ownership of thestrategyThese steps are:Step 1 is exclusively the role of leadership;this is where the change concept is soldto the agenda-setters. Steps 2 and 3 willcertainly involve the leader to ensure theconcept is not diluted or hi-jacked byanother influence, but it is in these stepsthat the management of change beginsto be organised. From there on in the roleis exclusively management. WheneverI check my own conviction by readingthrough this list I get questioning thoughtssuch as “Step 5: Empowering others –that sounds like leadership”. But I soonrealise that I am thinking about style ratherthan function, I am thinking about inspiringand then charismatic communication.Empowerment of others (or delegation)is a management function and can be asuccess in a number of styles, just thesame as it can be a miserable failure in anumber of styles, but more of that later.5 Empower others to act – remove all the barriers so that those whoare committed to the change can succeedMcCRIMMONLEADMANAGE/LEADMANAGE/LEADMANAGEMANAGE6 Produce short term wins - create some visible, unambiguoussuccesses as soon as possible.7 Don’t let up – be relentless in achieving change after change untilthe vision is a reality8 Create a new culture – hold on to the new ways of behaving untilthey become strong enough to replace the old traditionsMANAGEMANAGEMANAGE20www.windenergynetwork.co.uk

BUSINESS DEVELOPMENTQUALITY MANAGEMENTWhether the subject is the management ofquality or the quality of management themessage is the same.The principles of ISO9001 are almostuniversally valuable, but the value ofISO9001 implementation is almostuniversally ridiculed.The subject of implementation, and theoutrage of consultants selling overlybureaucratic compliance systemswithout a single care for the achievementof ownership throughout the team,is discussed at greater length in theworkshop.Let us concentrate on the positive firsthalf of the statement in this short text.We are talking about Kotter’s steps4 and 5. The delivery of a consistentquality performance depends upon thedecisions that every individual takeswhen confronted with the variables ofhis/her operation. Any other concept ofteam performance is significantly lessproductive.When every individual can take ownershipof, and personally commit to the principlesof quality management he or she is thenable to implement them consistently in allthe varying situations with which he/she isconfronted. We call this initiative.So what are the principles of ISO9001?1 Understand our customers’requirements2 Create the environment to succeed3 Involve the team fully to achieveobjectives4 Identify the activities & resource thatmake a process5 Manage the processes that make abusiness system6 Turn experience into learning &improvement7 Manage information to improvedecisions8 Create value together with ourcustomersIt sounds good stuff doesn’t it? And so itis. However, I would guess that 95% ofthe individuals who work for businessesthat have been sold ISO9001 have nofamiliarity with this set of principles.The ONLY chance of successfullyimplementing ISO9001 is if 100% ofthe individuals understand how theseprinciples relate to their work experience,and are committed to applying them.ENVIRONMENTIn our workshop on competence youwill recall that the three constituents oforganisational competence are Expertise,Equipment and Environment. One cansee just how important it is for managersto create, maintain and develop theright work environment. Without theunderstanding of objectives and principlesindividuals in the team cannot volunteertheir commitment, andwithout each individual’scommitment to performa manager is consignedto the close supervisionof everyone’s actions.These managers feelthe need to monopolisethe authority to makedecisions because, intheir view, no-one hasearned the trust to be‘let loose’.The litmus test fora successful workenvironment isdelegation.DELEG<strong>AT</strong>IONWhen I think aboutthe good managers I have worked for(there have been some) and the badmanagers (there have been more) thereis one common factor… delegation.All of the good ones were successfuldelegators, and all the bad ones wereawful delegators. Indeed there are veryfew shades between good and baddelegation.What is the difference between a gooddelegator and a bad delegator?For me the answer is authority. Thinkabout it as it affects you. In order tosucceed in achieving an objective youneed to know that the responsibility isyours, and that you have the authority totake the necessary action. And there youhave it, good ones delegate responsibilityand authority, and bad ones delegateresponsibility, but not authority.FINAL THOUGHTSMcCrimmon and Kotter have clarified thesubject of management for me. I urgeyou to read the books I have detailed. Forthose avid readers amongst you there isone other book in my list of ‘must reads’.Marcus Buckingham’s ‘First Break All theRules’ sounds like a call to rebellion, butit really isn’t. It is challenging and thoughtprovoking, anything less would be a wasteof time.Management is a function, a responsibilityto execute the agenda.Resist the temptation to mimic someoneelse’s style. Even if they have beenhugely successful, they have got thereby doing it THEIR WAY. They may sellbooks by promoting style, but they won’timprove your chances of being a bettermanager by persuading you to adopttheir style. There is only one successfulstyle…YOURS, but the functions of goodmanagement are universal.John Brittonjohn@renewablesnetwork.co.ukwww.windenergynetwork.co.uk21

ALL IN A DAYS WORKALL IN ADAY’S WORK...Name: Jeff MainCompany: Tyne & Wear MarineOccupation: Managing DirectorHabitat: TyneAccoladeNot many people can boast the accoladeof 500 years experience in a specialistenvironment, collectively in the company!well Tyne & Wear Marine certainly can.Leading the way is Jeff Main, all told aneclectic and charismatic person who’s storyis a most unusual and enlightening one.In the beginning...A background as a fabricator and welderfor many years, Jeff utilised his experienceand became a welding inspector forsome 10 years. However the oil industrybeckoned, where he enjoyed many yearsemployment.Alas, with the slump in the 80’s he wasone of the casualties and was maderedundant.Not one to rest on his laurels, havinggained a wealth of experience and a ‘cando attitude’ he set about designing andbuilding his own salvage vessel. No meanfeat!Jeff, his colleagues in the businessand also his marine engineering friendscreated a 20 m 140 tonne steel workboatcomplete with a 15 tonne hydraulic crane– The TWM Reclaim. Almost 1 year to theday of sitting down to design his salvagevessel the company of Tyne and WearMarine Ltd was born in 1987.This quickly became a successfulbusiness, where there was muchdemand for his expertise, not only withinthe salvage business, but also withinengineering. With his diverse experience,he grew the company employing over 20personnel and over the years owning andmanufacturing some 20 vessels, 14 inplace currently.Challenges into solutionsJeff’s passion derives from the ability toturn challenges into solutions and has theinnate ability to be innovative – thinking‘out-side of the box’ as the saying goes.When he was building the TWM Reclaimhe was met with many build issues, oftennot having the correct tool or equipmentwith which to work – there was nothingsuitable available on the market - so hedesigned and built one which did!Jeff is very quick to point out that hissuccess is due to the support and loyaltyof his team, with particular mention tohis Business Manager and PA MargaretCarrigan and in recent years his ProjectsManager John Crammon who, he believesis very much on the same wavelength.Often coming up with the same solutionsto problems without conversing. Theybounce ideas off one another whendesigning and forward planning andtherefore make a formidable team.DiversificationThe success of his business is the abilityto diversify and offer a variety of serviceswithin the marine environment – with thisin mind Jeff and his team are constantlyflexing to the demands required within theindustry.New premisesSo much so, that they are currentlyplanning on new premises on thewaterfront, seeking an ideal location with adeep water berth, as they are increasinglydealing with the wind industry and wish toconcentrate on wind farm mobilisation.<strong>Wind</strong> energyAs the wind sector expands Jeff is findingthat the company is undertaking more andmore windfarm related projects.While chatting, Jeff just happened tomention matter of factly that he was one ofthe pioneers for deep wreck diving usingrebreathers and blending mixed gases in theNorth Sea. Diving - a passion he still enjoysto this day and has been involved for over30 years for both sport and work.Micro-ROVsTo add to his list of talents, he pilotsmicro-ROVs, and undertakes numerousdemonstrations and seminars on aregular basis. These micro-ROVs area scaled down version of their largerrelative, however just as adept andskilled in undertaking inspections suchas foundations, ships, j tubes, quaysides,walls and pipelines.Jeff has forged such a good rapportwith the company called Video Ray, whodesigned the micro-ROVs, in the USA thathe has undertaken seminars and talksover there as well as with Atlantas Marinein the UK; TWM has even designed toolsfor them!Jeff and John have also developed sidescanningfor quay walls and jetties whereimages can be processed immediatelyand work can be physically underwaywithin hours; where previously it wouldtake a dive team weeks to come up withthe same information. This developmenthas created a great deal of interestthroughout the world.Real life scenarioTyne & Wear Marine were called upon toassist with a wind farm vessel which hadbeen holed in the river, on an exposed oldpile, which ripped through the bottom ofthe ship. Thankfully, it did not sink and thewater was contained. Jeff’s team went inwith a micro-ROV, surveyed the damageand an underwater team sealed the holeon the outside of vessel - crisis averted!HobbiesDesigning and inventing (not surprisingly)and also skiing. Jeff also has a passionfor Salsa dancing, as he and his wife areregular travellers to Cuba, and no doubtend up dancing in the streets! Not sure ifthis is the case in Tyneside, but if anyoneheralds the way it will be Jeff and Gill!Unusual circumstances?One particular challenge that was broughtto his table was one that encapsulatesJeff in a nutshell – this was one whichdemanded tenacity, strategic thinking andabove all ingenuity! – all three things hehas in abundance!A client had some damaged dock gatesin a marina which were constantly leaking.They had to be sealed before work couldcommence and repairs carried out. Anumber of contractors had tried and failedpreviously to do this, however the gatescontinued to leak.22www.windenergynetwork.co.uk

ALL IN A DAYS WORKInnovative SOLUTIONAt home, asleep and in the middle of thenight, Jeff sat up bolt upright and askedhis wife “how much is butter?” His wife,somewhat bemused from her slumberresponded.Jeff had had an epiphany moment. Thiswas his solution to the leaking dock gateswhich had been giving him a problem!Boxes and boxes of Lurpak butter (salted)were bought and used to seal the gates.Eureka! It worked allowing the repair totake place in the dry. A week later, ondive inspection there was found to bea natural marvel – thousands of crabshad congregated to the gates and werefeasting on the gastronomy – just goes toshow what a superior butter it was!In the past when operating his salvagebusiness he was called upon to salvageshipwrecks, whereupon insurancecompanies would contact him. Alas nogold bullion was recovered!Variety is the spice of life– no two days are the sameVariety certainly keeps the momentumgoing and there is no such thing asa typical day. Jeff is called upon toundertake inspections on a regular basisand he is a regular at the Port of Tyneadvising on fabrication projects – he canbe fitting fenders on the dock sides or benegotiating with clients.Ingenious by design and yet so simple, itconsists of standard 10m x 4m pontoons,interconnected, and when assembled cancarry loads of up to 100 tonnes over waterutilising an interlocking pushing tug also10 x 4; it is extremely manoeuvrable andvery versatile.The FutureJeff’s ambition is to grow the business –he is not yet ready to retire, to build a newdeep water berth and to establish newpremises and continue...Describe yourself in 3 wordsModestly, he declined to remark,whereupon his wife came to his rescueand stated; kindness; integrity and a ‘cando’ attitudeIn short Jeff’s ingenuity and enthusiasm isinfectious, his attitude is inspiring and hisambition is boundless. It was a joy to havejust had a snippet of this enthusiasm inour brief interview.Fliss Chaffer<strong>Wind</strong> <strong>Energy</strong> <strong>Network</strong>Click to view more infoInnovative prowessAnother example of his innovative prowessis the design of a modular pontoon whichhe uses within the wind industry. Thisallows the huge turbines to be transportedvia water and not road, which has beenused for transporting massive structures– Technip have recently utilised this totransport one of their new SMD Trenchers.www.windenergynetwork.co.uk23

SPONSORS OF TYNE & TEES FE<strong>AT</strong>URESpotlight focuson the Tyne& the TeesWelcome again to an area of the UK describedas ‘an area of excellence in the wind energyindustry throughout Europe and beyond’On this occasion we visit the North East, which our readersmay remember from some time ago, when we featuredthe entire area in a fairly general way. We now focus in onthe specific area of the Tyne and the Tees where particularadvances have been made.Existing projects and Round 3 preparationsThe area not only prepares itself in readiness for the Round 3Offshore <strong>Wind</strong> developments but also continues the work alreadyundertaken within existing offshore wind projects includingconstruction, service and maintenance.Our sponsors for the feature, PD Ports, pick up the story withcomments for moving things forward more quickly...24www.windenergynetwork.co.uk

SPONSORS OF TYNE & TEES FE<strong>AT</strong>UREwww.windenergynetwork.co.uk25

SPONSORS OF TYNE & TEES FE<strong>AT</strong>UREThinking bigthe challenge for logisticsThe logistical challenges oftransporting or installing outsize andheavy components such as turbinesand blades are considerable, andwith larger units on the horizon thoseinvolved in the renewable energysector require planning and foresight,alongside more Government clarity.UncertaintyThere is great uncertainty in the wind farmsector which many believe is based onlack of demand and no clear directionfrom the UK Government.The uncertainty of manufacturers in therenewable energy market is reflected bycompanies, including those involved inproviding transport and logistics servicesto those manufacturers. The problemis particularly acute because much ofthe equipment and facilities required tohandle, for instance, wind turbines, willneed to be purpose-built.TransportationAbout 90% of the world’s non-bulkcargo is transported in containers, butsubstructures, turbines and blades fallinto the 10% of cargo that is too large orheavy to be shipped in a sea container.And while some transport companies andports are used to handling a wide varietyof ‘heavy and ugly’ freight, it makes nosense for them to invest in facilities forhandling wind farm equipment until theyknow exactly what will be manufactured.Going in blindJerry Hopkinson, Managing Director –bulks, ports and logistics at PD Ports,explains: “We have the ability to developour port assets to cater for a rangeof different scenarios, but, given thediffering requirements of the variousmanufacturers and fabricators, untilwe know exactly the nature and scopeof what will be fabricated and shippedthrough the port, it is difficult to developthe port infrastructure.”Mr Hopkinson further explains, “We needthe developers and the manufacturersto make the decisions, but they are notmaking the orders because they arewaiting on Government commitments onlong-term policies and subsidies.”Time, the greatest hurdleThe problem is made worse by the factthat building vessels and upgrading portand other transport facilities takes time.But time is something the UK Governmentdoes not have. It has signed up to the EURenewable <strong>Energy</strong> Directive, committingit to producing 15% of UK energy fromrenewable resources by 2020. Andfor electricity specifically, the target is30%, with more than two-thirds of thatpredicted to come from onshore andoffshore wind.Round 3 developmentsIn 2010, the Crown Estate announced thesuccessful bidders for Round 3 of the UK’soffshore wind development, in nine furtherzones. These Round 3 developments areenvisaged on a much bigger scale thanRounds 1 and 2 combined.At the moment, there are just 16 offshorewind farms, generating 1,858.20 MWe(compared with 324 onshore wind farms)according to RenewableUK. “Unless theGovernment makes some decisions verysoon, or manufacturers make the bolddecision to build wind turbines withoutany firm orders, our ability to build thefacilities to assist in meeting these targetsis hindered.” says Mr Hopkinson.Hampering potentialPD Ports owns the ports of Teesport andHartlepool and has already designatedHartlepool as the focus for its renewableenergy facilities. The port has deep water,plenty of land available for companies tobuild manufacturing facilities and is alreadyhome to JDR Cable Systems, a leadingcable manufacturer for renewable energyprojects, and HeeremaFabrication Group,which specialises in theengineering and fabricationof large and complexstructures, mainly for theoffshore oil and gas andenergy industry.“We are talking to theindustry all the time butthere are still so manyvariables. We couldconfigure Hartlepool ina particular way to suit aturbine manufacturer, butit would need to be different if it was asub-structure manufacturer – so we can’tprepare in advance.”While some vessels are being built witha view to the Round 3 market, there willpotentially not be enough to meet needsif a sudden upsurge in demand follows aGovernment policy announcement.Unlike electronics, where products getsmaller as technology advances, there isno reason to believe the same is true aswind power technology advances. In fact,the European <strong>Wind</strong> <strong>Energy</strong> Association(EWEA) predicts that as the number ofwind farms grows, the more they will haveto be located in deeper water where thewind speeds are higher – and the larger theturbines will have to be.Huge potentialMr Hopkinson concludes: “Like someother ports, we already have stronglinks with manufacturers in the sectorand have handled a range of productsfor renewable energy customers. Thereis huge potential for ports and othertransport companies to develop at leastpart of their businesses around therenewable energy sector, but we areall hampered by the lack of informationabout what is needed.”PD Portswww.pdports.co.uk26www.windenergynetwork.co.uk

SPONSORS OF TYNE & TEES FE<strong>AT</strong>URENewcastle GatesheadPowering the future of wind energyRenewable energy is a key growthsector for Newcastle/Gateshead.The area has been chosen by the UKgovernment as the national centre forresearch into renewable energy andis the location of some of the world’slargest testing facilities for offshorewind and marine renewables. We’realso one of six designated Centre’sfor Offshore Renewable Engineering(CORE) in England.LocationTheir location on the north east coast ofEngland means Newcastle/Gatesheadis situated perfectly as a gateway to thevast amount of opportunities created asthe sector grows. They’re the closestport (96 nautical miles) to the world’slargest proposed wind farm zone, DoggerBank, making Newcastle/Gateshead anideal place for businesses involved in theresearch & development, manufacturing,specialist logistics and operations &maintenance of wind turbines.Company clusterNewcastle/Gateshead has a strongcluster of companies with the key skillsrequired for the development of offshorewind farms such as: Cable and umbilicalmanufacture and expertise; ploughing,laying and subsea cables; sea bedoperations and undersea connectiontechniques; project management anddesign engineering; specialist logistics andprofessional services.Innovative riverside facilitiesand local supply chainThe innovative riverside facilities,development sites and local supply chainof supporting technologies add to thealready compelling offer tothe industry’s businesses,and provide an ideal settingfor them to offer directsupply lines to UK offshorewind farms.Working togetherA key element of the area’sproposition to offshore windsupply-chain is the extentto which local schools,colleges and trainingproviders are workingwith major companieslike Maersk, Siemens andNewcastle InternationalPositioned for successPipeshield has been operating fromtheir Teesside supply base at AVDawson’s for over 10 years. Theysupply subsea protection andstabilisation products and services toclients and projects far and wide.Their products are designed andengineered to withstand the toughestand most challenging environmental andsubsea conditions in the North Sea andare used for submarine pipeline and cableprotection, scour prevention, crossingsand much more.ConvenienceHaving access to well-maintainedquayside facilities affords their clients theconvenience and benefit of collectingproducts alongside their manufacturingsite, saving on handling and delivery costs,as well as time and transportrestrictions.Port facilityPositioned on the east coastof the country, Dawson’sQuay facility near Teessideprovides an uncongestedand efficient port facilityto serve the immediaterespective offshore windfarmdevelopments, includingthose operational and futureplanned projects.Airport to develop new skills and trainingprogrammes specifically for the industry.Every day they deliver innovative offshorewind solutions globally, helping to shapethe industry’s exciting future.Whether you’re looking for office space,need the inside track on what’s happeningin the region, or want to know how totap into the best talent, their InwardInvestment team is here to help.NewcastleGateshead Initiativewww.investnewcastlegateshead.com<strong>Wind</strong> energy industryFrom their Teesside supply base, theyhave recently supplied products andservices for the Lincs, Lynn and InnerDowsing wind farms within the North Sea,as well as wind-farms in the German andDutch sectors.They continue to promote Dawson’s Quayas a well-positioned, efficient and effectivequayside facility to support the needs ofthe renewable sector.Pipeshieldwww.pipeshield.comClick to view more infoAV Dawsonwww.av-dawson.comClick to view more infowww.windenergynetwork.co.uk27

SPONSORS OF TYNE & TEES FE<strong>AT</strong>UREDe-risking energytechnologies before goingoffshore28www.windenergynetwork.co.uk

SPONSORS OF TYNE & TEES FE<strong>AT</strong>UREModus:TWO SIGNIFICANT PROJECTSSpecialist subsea contractor, ModusSeabed Intervention has delivered twosignificant projects for Van Oord on thehigh profile EDF <strong>Energy</strong> RenewablesTeesside Offshore <strong>Wind</strong> Farm.In addition to providing inter-array cabletrenching and survey services, Modusdelivered new equipment to bury theexport cables that will carry the powergenerated by the array to the shore.Specialist modificationTo facilitate the burial of the two 1.2kmexport power cables, the Darlington-basedcompany invested in a shore approachand shallow water towed jetting spread,which was specially-modified by Modus’engineers to meet the requirements ofoffshore wind farm construction.The trencher, designated JS1, wasoriginally designed to bury fibre opticcables up to 3m below seabed level inwater depths of up to 18 metres. Modus’engineers modified the unit to enable it tobury heavier and more rigid power cableswith a diameter of around 200mm.Local supply chain supportWith the support of its North EastEngland-based supply chain, Modus alsoincreased the instrumentation of JS1 anddesigned a new control system, to ensurethe operation was less labour intensive,and added a number of features to furtherenable it to meet the requirements ofrenewables projects such as sonar andunderwater cameras.Delivering important projectsJake Tompkins, Managing Director ofModus Seabed Intervention, said: “Wewere very proud to deliver these twoimportant projects for Van Oord and EDF.“As well as being a strong endorsementof our position in the offshore wind supplychain, delivering these contracts continuesto demonstrate our ability to innovate anddevelop technology-led solutions, whichsupport the cost-effective construction ofoffshore wind farms.”experience and expertiseJake added: “By applying our technologydevelopment experience and expertise,we have expanded our trenchingservices through the introduction of theJS1 trenching spread.“Modus is now able to deliver shallowwater cable trenching from offshorewind farms to the beach to complementthe capability of our existing fleet oftrenching systems.”Moduswww.modus-ltd.comInnovative engineering solutionsACEDA, a leading provider ofintegrated engineering solutions,based in Stokesley, Teesside,are working closely with keyorganisations within the offshore windsector to design and deliver turnkeyIP integrated services using leadingedge fibre optic technologies.Core infrastructureFibre optic cables form part of the exportand array cables between substationsand offshore wind turbines. This core fibreoptic backbone provides a platform for IPconnectivity for SCADA communicationswhilst providing future scalability foradditional IP edge device utilisation.ACEDA provide connectivity for a numberof edge devices that are controlled,monitored and maintained through asingle IP management platform.Nick Harker, GroupManaging Director30www.windenergynetwork.co.uk

SPONSORS OF TYNE & TEES FE<strong>AT</strong>URETyne & WearMarinea case studyTransporting a 55 tonneTrencher with TWM’s ModularPowered Pontoon System (MPPTS)The powered pontoon system is the latestmulti-functional bespoke TWM designedand built equipment added to the growingrange of resources that is available for hirethrough the company. Tyne and WearMarine Ltd has specifically invested inbuilding these resources to meet the evergrowing needs of their oil, gas and windenergy business sector clients.Project (March 2013)Operation carried out: Thetransportation of a SMD 55 tonneTrencher valued at £4.3 million.After many hours of planning, 10 minuteswas all it took to carry out the operation oftransporting the Trencher from the Northside to the South side of the River Tyne.Using the MPPTS proved to be a costeffective way by avoiding the logistics oftrying to move the 55 tonne trencher bydismantling it, and transporting by roadthrough the City of Newcastle.After the launch of this multi-role system in2012, it has been so successful it has nowhandled a range of diverse contracts. Therecent enhancement of building anothertwo units now taking the equipment towell over a 100 tonne payload.Unique interlocking systemThrough a unique interlocking systemcreated and manufactured by TWM, thiseight piece Modular Pontoon Systemwhich can be powered by a 10 x 4interlocking Pushing Tug and becoming a9 piece Modular System, so flexible that ithas for example been used as follows...• A crane barge• Dredging• Transporting equipment up to 100 tonne• Stand-off pontoons• A quick and easy to install ferry landingwith a 25m linkspan• Dive support platformThe system benefits are...• Multiple uses in many configurations• Easily mobilised and de-mobilised• Totally road transportable• Can be fitted with spud legs• An 8 tonne knuckle crane (removable)is fitted to one of the pontoons• Can be fitted with a 4 point mooringsystemTyne & Wear Marinewww.tyneandwearmarine.comClick to view more infoLeading technologyPossibilities for IP edge device integrationare infinite. The company is currentlyconducting research and developmenton a number of IP solutions for the windturbine industry, including monitoringsolutions using fibre optic technologiesto detect strain, movement and thermalchanges on subsea cables and turbinestructures. Other technologies includeIP CCTV to monitor health & safety andenvironmental conditions during theinstallation, operation and maintenancephases of an asset lifecycle. Integrated IPAccess Control allows key stakeholders torestrict and monitor access within certainareas of a wind turbine to authorisedpersonnel.Flagship project – The LincsACEDA are currently involved in The Lincsoffshore wind farm project providing aturnkey engineering solution, includingthe fibre optic network. Paul Warnes,<strong>Energy</strong> & Process Divisional Director,said, “The Lincs is a flagship projectfor the company, being involved fromevolution to execution has allowed usto design and deliver an IP networkengineering solution, which provides theclient with the SCADA communicationscapability and the facility for further IPedge device integration. We believethat the potential to develop the coreinfrastructure on offshore wind farms isinvaluable. Working with clients duringthe design stage is essential to ensurefull operational capability is achieved forthe lifecycle of the asset.”Skills capabilityAs a turnkey solutions provider, they havea strong in-house engineering team todesign and deliver each project. Eachsolution is often complex and requires ahigh level of engineering experience andexpertise. The company has overcomethis by recruiting and training a numberof specialist engineers who have thecapability to provide a multi-skilled servicefrom subsea HV and fibre terminating andcommissioning to integrating an IP CCTVand IP access control system if required.North East drivenACEDA was founded by Group ManagingDirector, Nick Harker, and has recentlycelebrated 20 years of trading. Majorprojects are managed from the head officein Stokesley, and have regional officesin Aberdeen, London and Manchester.Nick Harker commented, “ACEDA hasbenefited from being based in the NorthEast of England, over the years wehave excelled by sourcing local skilledengineering resource and buildingrelationships with key clients andsuppliers who are often located nearby.A number of key players in the windindustry are based in the region and haveaccess to excellent transport links and anumber of large industrial ports. We arein an excellent position and will continueto support the region through recruitmentand building local supply chains.”ACEDAwww.energy-process.aceda.co.ukwww.windenergynetwork.co.uk31

SPONSORS OF TYNE & TEES FE<strong>AT</strong>URESMD deliver an HD3 Plough ahead ofschedule to Reef SubseaSoil Machine Dynamics Ltd (SMD),subsea equipment designer andmanufacturer, succeeded in the earlydelivery of an HD3 inter array cableplough to Reef Subsea’s subsidiarycompany, Reef Subsea Power &Umbilical Ltd (RSPU).The vehicle which RSPU have named theirHDIA (Heavy Duty Inter Array) Plough willsoon be mobilised onto the Polar Princesubsea construction vessel.Gwynt y Môr Offshore <strong>Wind</strong> FarmThe HD3 cable plough, which is scheduledto go straight onto the Gwynt y Môr offshorewind farm, is well suited to the simultaneousor post-lay burial of large bend radiusproducts up to 200mm diameter.SpecificationsIt can be towed with up to 150 tonnesin consolidated soils, has on-boardjetting to boost performance in sands,and is equipped with subsea loadingand unloading capabilities. It has anunique feature allowing it to cut a trenchat shallow trench depths (1 to 1.5m)or at deep trench depths (2.4m) withminimal risk to the product compared to aconventional plough.Q1000 jet trencherThe HD3 plough follows the delivery of theQ1000 jet trencher in October 2012. TheQ1000 has now successfully completedsea trials and her maiden scope of work inthe North Sea.HD3 cable ploughPaul Davison, SMD Trenching Manager,said: “We are particularly pleased withthe successful build and delivery ofthis plough. To meet and exceed achallenging schedule is a testament tothe SMD and Reef Subsea project teams.We look forward to supporting the ploughtrials and subsequent operations. Interarray cable burial with the HD plough isan enhancement to previous operationson the Polar Prince with the SMD MD3Plough. Ploughing inter array cables isa step change in process and we lookforward to supporting such innovation tohelp our clients improve assurance andreduce installation time.”Reef Subsea Power & UmbilicalTim Sheehan, Reef Subsea ChiefOperating Officer, said: “These latestacquisitions to Reef Subsea Power &Umbilical positions the Group at thetop of its sector. The new HDIA cableplough, added to the Q1000 TrenchingROV delivered last year, allows us toanswer the needs of our clients in a largerange of soil conditions. Both tools canbe easily mobilised onto any of ReefSubsea’s subsea construction vessels aspart of our integrated subsea services.”Daryl Lynch, Managing Director of ReefSubsea Power & Umbilical, said: “Thelaunch of the new Heavy Duty Inter-Arraycable plough is sure to place Reef SubseaPower & Umbilical as a leader in subseainstallation and trenching sectors. Weare extremely pleased to have securedthe plough work for the next year as itwill play a fundamental role in the Gwynty Môr offshore wind farm, and will thencomplete a workscope in 2014 on theGrane Life of Field project in Norway.With the introduction of the new ploughand the jet trencher, we are well preparedto handle forthcoming wind farm and oil &gas developments in the UK, as well as inEuropean and Nordic waters.”Soil Machine Dynamics Ltdwww.smd.co.ukClick to view more info= Click to view videoReef Subsea Power & Umbilicalwww.reefsubsea.comClick to view more info32www.windenergynetwork.co.uk

SPONSORS OF TYNE & TEES FE<strong>AT</strong>URE6 figure investmentfor BarrierBarrier Ltd, which is part of the BarrierGroup, has completed a significantnew investment to support thetransference of skills and technologyinto the offshore wind sector.steam that spreads and bonds therubberto Risers and J-Tubes. The vulcanisedrubber protects the componentsfrom corrosion and provides abrasionprotection.Barrier Group was formed in 1975 to carryout painting of structures to be installed aspart of the growing North Sea oil industry.The company has gone on to completemore than 200 major contracts, totallingmillions of square metres of surfaceprotection and has worked for most of theworld’s major oil companies.Further expansionMore recently the company has expandedits operations beyond the oilsector and the group now carriesout passive fire protection, metalspraying, powder coating andsub-sea insulation across theaerospace, marine and offshorerenewable energy sectors.The Wallsend-based company hasexpanded its Coatings Division to be ableto deliver neoprene coatings and rubberclamps for offshore wind towers.InvestmentAs part of a six-figure investment, Barrierhas introduced a 14 metre x 3 metrevulcanising vessel, which enables theprocess of applying rubber to externalRisers and J-Tubes, which are fitted tocollector platform jackets and larger deepwater wind turbines.The steam-driven vessel generatesconsiderable amounts of high-pressureIn addition, Barrier also has the capabilityto apply ribbed rubber to the internal partsof clamps, which are welded onto jacketsor wind turbines to hold the J-Tubes andRisers in place.Proven corrosion protectionprocessThe corrosion protection process usingvulcanised rubber is already used inthe oil & gas market, particularly in theNorwegian market. However, Barrierhas diversified the process to meet therequirements of the offshore wind sector,which has included up-skilling a team offifteen of its engineers.Paul Harriman, Managing Directorof Barrier Ltd, said: “While thisis a relatively new market for us,the principles of delivering highquality engineering solutionsare the same as we have beenapplying for nearly 40 years. Theability to diversify our productsand services is essential asenergy generation opportunitiesemerge and grow.“The offshore wind sector hasseen a lot of transference in its supplychain from the oil & gas sector. This hasbeen due to the technical expertise andextensive experience of companies likeBarrier, which have a proven track recordof successfully meeting the requirementsof contractors and operators.”He added: “We are very pleased with theinvestment we have made as it will openup new opportunities for the business andhelp establish a position in the offshorerenewables supply chain.”Barrier Groupwww.barriergroup.comwww.windenergynetwork.co.uk33

SPONSORS OF TYNE & TEES FE<strong>AT</strong>UREDemolitionmaking waves atNorth East portA fresh wave of demolition projectstaking place at a burgeoningNorth East port are freeing upmuch needed space for strategicexpansionPort of Sunderland bosses have given thegreen light to a number of new demolitionprojects, as it clears space that will allowit to unlock opportunities for expansion.Clearance of the Cemex UK site atJunction Wharf (formerly No 31 Berth)between Hendon and Hudson Docks inthe Port of Sunderland was completedby the Washington-based Hellens Groupas part of a scheme to flatten derelictbuildings and create new investmentopportunities.Increased potential storage anddevelopment areasDemolition of the dilapidated metal-cladshed, once used by a concrete producer,has increased potential storage anddevelopment areas, contributing to plansto bring more trade and offshore vesselsto the Wear. It is the second phase ofdemolition projects undertaken at the portover the past few months, all designedto make it a more attractive prospect forinvestors.34www.windenergynetwork.co.uk

SPONSORS OF TYNE & TEES FE<strong>AT</strong>URETyne Gangwaya world leader in the design andmanufacture of lightweight marineaccess systemsThe company is experienced in supplying equipmentworldwide using a network of skilled agents, which allowsthem to fulfill overseas requirement quickly and efficiently.ServicesGangways, accommodation ladders, bridges, lightweightstructures and stowing gear are designed and manufacturedin the company’s modern production facility using a skilled andflexible workforce.They offer a standard range of ship and offshore accessequipment which are approved by all of the major classificationsocieties and regulatory bodies.HistoryThe company was established in 1934 when most of the worldsmarine access equipment was manufactured from selectedhardwood and built by skilled carpenters.In the 1960’s Tyne Gangway were pioneers in the introductionof lightweight aluminum alloys for manufacturing this equipment.Assembled using cold riveting techniques until the introduction ofwelding in the early 1980’s.Leading the way insupporting renewablesTAG <strong>Energy</strong> Solutions has created theUK’s fi rst offshore wind turbine tubularfoundation production plant.With extensive experience in oil & gas,TAG combines this expertise with state-ofthe-artfacilities to design, project manageand construct monopile foundations, jackets,sub-station jackets and topside fabrication & fi tout for the offshore energy sector.Located in North East England, TAG unites this new £20 millionproduction facility and new modern blast and paint facility with itsexisting large construction hall, extensive wet dock and 6,000te loadout quay.Today welding is carried out using the latest synergic pulsemachines which offer superior quality and a high performance.Available items• Accommodation ladders – a comprehensive range ofaccommodation ladders ranging from 3.5 metresto 30 metres in length with step spacing and designcriteria in accordance with the British Standard BSMA89 orthe International Standard ISO5488.• Gangways – a range of Lightweight Gangways from 1.5metres to 48 metres in length, the longer units being jointedfor ease of transportation. The Gangways are provided withself-locking socket type stanchions to keep stowage spaceto a minimum, or permanent rigid handrails, making up astrong girder configuration, used where a gangway is subjectto an extreme high design load.• Design and Manufacture – using the very latest Design &Drawing software (Staad Pro & Autocad) the in-house designdepartment within the company is able to work closely withall their clients.The company offers a fast and efficient service, ensuring thattheir customers’ expectations are met and exceeded from theinitial design concept, manufacture, delivery, installation andthrough life service.Repairs – statutory examination andthrough life servicingTyne Gangways’ service department have fully trained in-housetechnical engineers that offer a comprehensive on-site and or inhouserepair service. Their engineer’s flexibility ensures that theycan travel globally to carry out statutory testing and examinationof their clients’ access equipment.Tyne Gangwaywww.tynegangway.comClick to view more infoT +44 (0)1642 565500 | E enquiries@tagenergysolutions.comwww.tagenergysolutions.com36www.windenergynetwork.co.uk

SPONSORS OF TYNE & TEES FE<strong>AT</strong>UREMoving picturesAlmond Productions are a North-East based videoproduction company specialising in working withengineering and offshore related organisations. They area team who are passionate about making video that is notonly good quality, but can convey the right message for theirclients.History and leading clientsAlmond Productions was set up justover 10 years ago by Almond Kellacherwho was initially trained in the broadcastindustry. The team has now grown andeach team member has a professionalqualification in their specialist area.Previous clients include Amec, BP,Mammoet and Tyne Tunnel 2 amongstothers. Having produced video for the oil, gas and constructionindustries they are keen to offer their bespoke services to the windenergy and renewables sector.Why Video?Video has become the most powerful and effective communicationstool of the last 100 years. Video on the Internet is growing quickly,and viewing content online has actually surpassed traditionaltelevision viewing. Video included on a website not only portrays avisual message but also aids Google searches and can become apart of search engine optimisation.There may be many reasons that a company might choose toengage with video. Video can show a product or service in action,and for large engineering projects this means that their large scaleprojects can be showcased not only to investors, but to otherinterested parties quickly and easily.Video can also help you reach markets, or locations that could bedifficult or costly for live training or speakers to reach, with the addedbonus of a consistent message to all who view it.Further advantagesApart from ‘showing’ an aspect of a project or a completedconstruction in full working order, video also has the advantage ofbeing able to tell a story and engage with audiences on a deeperlevel. Because of this, the company likes to work closely with theirclients to make sure that the finished video meets all of its objectives,especially in terms of getting the right message across. This mayinclude design and construction of a wind farm, and add value toin-house training.Service and Quality is Never an AccidentIt is Always the Result of Intelligent EffortSUBFLEX Cable Protection SystemsSUBSEA ENERGY SOLUTIONS HAS BEEN FOUNDED ASA DIRECT REQUEST FROM THE RENEWABLE ENERGYINDUSTRY FOR THE NECESSITY FOR INCREASEDCOMPETITION, REDUCED SYSTEM COSTS ANDENHANCED SOLUTIONS, WITHIN A LIMITED CABLEPROTECTION SYSTEM MARKET PLACE.DEMAND FOR COST REDUCTIONSubsea <strong>Energy</strong> Solutions, an ISOQAR 9001 : 2008registered company, has risen to the urgent industrychallenge for the demand for offshore wind farm longterm sustainability, through means of cost reduction.With industry assistance, Subsea <strong>Energy</strong> Solutionscan signifi cantly contribute towards the reduction ofoffshore wind farm design, construction, operational,maintenance and de-commissioning costs.EXPERIENCE & INDUSTRY ADVICEWith our industry and project wide experience, theunique patent pending SUBFLEX TM Cable ProtectionSystem offers many unrivalled and unparalleledtechnical and commercial features.Subsea <strong>Energy</strong> Solutions have sought industryadvice during the development of the SUBFLEXTMCable Protection System and taken intoconsideration many requirements such as purchasecost, rapid offshore assembly, rapid installation,rapid burial, enhanced cable protection, eliminationof maintenance requirements, standardisation ofcomponents to name just a small selection of features.CABLE INSTALL<strong>AT</strong>ION IMPORTANCEOffshore windfarm cable installation is a highcost / high insurance claims theatre and it is welldocumented that 70% of insurance claims fromwindfarm operators relate to cable damage, so therehas never been a greater, more important time,for the renewable industry to come together andsupport a rapidly emerging company in developing afully coordinated and fully standardised approach tomonopile J-tube & J-tube-less installations.Return on investmentAll of these aspects benefit from having a well thought out plan forthe video which they can help to develop. Like many engineeringprojects video production can work in a similar way, the morefront end research and development the stronger and better theoutcome. All of which makes for a good return on investment.Computer Generated Imagery (CGI)Almond Productions recognises that sometimes it is difficult to filmoperations such as the inner workings of a piece of machinery orunderwater drilling. To overcome this they can now incorporate CGIinto video to create a realistic view of what the operation actuallylooks like.Almond Productionswww.almondproductions.co.ukFOR MORE INFORM<strong>AT</strong>ION PLEASE CALL:+44 (0) 1748 828580E sales@subenesol.co.ukW www.subenesol.co.ukwww.windenergynetwork.co.uk37

SPONSORS OF TYNE & TEES FE<strong>AT</strong>URENewcastleChambers ofEngineeringHistoryNewcastle has a long history ofengineering from the Victorian era rightthrough to the Second World War.Newcastle was a hub of engineeringproviding the world with armaments,railways, shipbuilding and miningequipment. The companies providing thiswere engineering giants of their time suchas Vickers, Armstrongs, CA Parsons,Clarke Chapman, Hugh Woods andalso The Swan Electric Light Companyamongst others. Design and developmentof power distribution systems such aselectrification of Newcastle commercialand transport system was developed byMertz & McLellan who were fundamentalin designing the national grid system.More than a hundred years later Newcastleis still a hub of engineering because of itshistoric roots and prime location.38www.windenergynetwork.co.uk