Chilled Water and Process Cooling Systems for Industrial Applications

Chilled Water and Process Cooling Systems for Industrial Applications Chilled Water and Process Cooling Systems for Industrial Applications

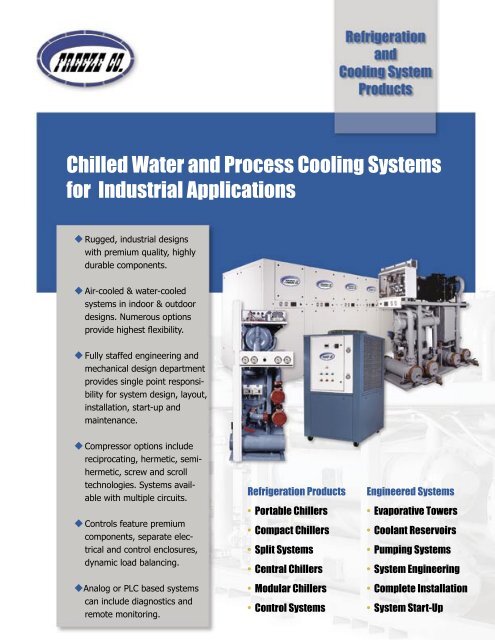

Chilled Water and Process Cooling Systemsfor Industrial Applicationsu Rugged, industrial designswith premium quality, highlydurable components.u Air-cooled & water-cooledsystems in indoor & outdoordesigns. Numerous optionsprovide highest flexibility.u Fully staffed engineering andmechanical design departmentprovides single point responsibilityfor system design, layout,installation, start-up andmaintenance.u Compressor options includereciprocating, hermetic, semihermetic,screw and scrolltechnologies. Systems availablewith multiple circuits.u Controls feature premiumcomponents, separate electricaland control enclosures,dynamic load balancing.uAnalog or PLC based systemscan include diagnostics andremote monitoring.Refrigeration Products• Portable Chillers• Compact Chillers• Split Systems• Central Chillers• Modular Chillers• Control SystemsEngineered Systems• Evaporative Towers• Coolant Reservoirs• Pumping Systems• System Engineering• Complete Installation• System Start-Up

- Page 2: Portable Air-Cooled or Water-Cooled

- Page 5 and 6: Engineered Process Cooling SystemsI

<strong>Chilled</strong> <strong>Water</strong> <strong>and</strong> <strong>Process</strong> <strong>Cooling</strong> <strong>Systems</strong><strong>for</strong> <strong>Industrial</strong> <strong>Applications</strong>u Rugged, industrial designswith premium quality, highlydurable components.u Air-cooled & water-cooledsystems in indoor & outdoordesigns. Numerous optionsprovide highest flexibility.u Fully staffed engineering <strong>and</strong>mechanical design departmentprovides single point responsibility<strong>for</strong> system design, layout,installation, start-up <strong>and</strong>maintenance.u Compressor options includereciprocating, hermetic, semihermetic,screw <strong>and</strong> scrolltechnologies. <strong>Systems</strong> availablewith multiple circuits.u Controls feature premiumcomponents, separate electrical<strong>and</strong> control enclosures,dynamic load balancing.uAnalog or PLC based systemscan include diagnostics <strong>and</strong>remote monitoring.Refrigeration Products• Portable Chillers• Compact Chillers• Split <strong>Systems</strong>• Central Chillers• Modular Chillers• Control <strong>Systems</strong>Engineered <strong>Systems</strong>• Evaporative Towers• Coolant Reservoirs• Pumping <strong>Systems</strong>• System Engineering• Complete Installation• System Start-Up

Portable Air-Cooled or <strong>Water</strong>-Cooled ChillersFCAC, FCWC & FCAC-R Series - 1 to 30 TonsEconomical, Compact <strong>and</strong> Highly RealiableFrom the ground up, Freeze Co equipment is designed to deliver the rightbalance of per<strong>for</strong>mance, ruggedness, operational consistency <strong>and</strong> cost effectivenessdesired by the world’s largest processing environments. Freeze Co is aunique combination of experts in refrigeration engineering, mechanical design& installation, <strong>and</strong> real-world, high productivity processing plants worldwide.Freeze Co gives customers wider “systems” capabilities, innovation <strong>and</strong> attentionto detail, mechanical <strong>and</strong> electrical implementation experience <strong>and</strong> productsof premium quality, yet are economical to own <strong>and</strong> operate.The FCAC models feature air cooled condensing. FCWC models are watercooled. Both use highly reliable reciprocating hermetic compressors (semi-hermeticon larger models), large insulated stainless-steel tank, efficient brazedplateevaporator, <strong>and</strong> dual, bronze-fitted process <strong>and</strong> recirculation pumps.Controls include common chiller functions <strong>and</strong> safeties as st<strong>and</strong>ard, <strong>and</strong> a widevariety of both equipment <strong>and</strong> control options, including PLC control, hot gasbypass, <strong>and</strong> special materials of construction.Model Shown includes semi-hermetic compressor, oversizedtank, separate process <strong>and</strong> recirc pump, outdoor aircooled condenser <strong>and</strong> analog controls.Generous St<strong>and</strong>ard Features <strong>and</strong> Widest OptionsSt<strong>and</strong>ardOptionalEpoxy coated steel cabinet Stainless steel cabinetNEMA-12 electrical enclosure Other NEMA, explosion proofRelay-logic control system PLC controls, diagnostics, remoteInsulated stainess-steel tank Hot gas bypass capacity controlCondenser fan cyclingSemi-hermetic compressorsHigh/Low pressure safeties Diagnostic color display screen<strong>Water</strong> flow safety switch Remote control using serial outputTemp <strong>and</strong> freeze control Outdoor models with fan controlsAnti-recycling timerHeat traced pipingOperation <strong>and</strong> fault indicators High ambient modelsBronze-fitted pump impellers Low chilled water temp modelsOversized liquid receiver Oversized water reservoirsPortableChillersCapacityBTU/HRFlowGPMTankGallonsComp HPAir CooledComp HP<strong>Water</strong> CooledNominal Capacity in BTUH based on R-22 refrigerant. <strong>Chilled</strong> water at 2.4 GPM from 60°F to 50°F.Ambient air at 95°F. Condenser water at 3 GPM/ton <strong>and</strong> 85°F to 95°FChillerPump<strong>Process</strong>PumpAC DimLxHxWWC DimLxHxWFCAC/WC-001 12,000 2.4 30 1.5 1.0 .50 1.0 36x60x40 36x60x40FCAC/WC-002 24,000 4.8 30 2.5 2.0 .50 1.0 36x60x40 36x60x40FCAC/WC-003 36,000 7.2 30 3.5 3.0 .50 1.0 36x60x40 36x60x40FCAC/WC-004 48,000 9.6 30 4.5 4.0 .50 1.0 36x60x40 36x60x40FCAC/WC-005 60,000 12 50 5.5 5.0 .50 1.5 40x75x48 40x75x48FCAC/WC-008 90,000 19.2 50 8 7.5 .75 3.0 40x75x48 40x75x48FCAC/WC-010 120,000 24 50 10.5 10 .75 3.0 40x75x48 40x75x48FCAC/WC-015 180,000 36 100 20 15 1.0 5 40x75x72 40x75x72FCAC/WC-020 240,000 48 100 25 20 2.0 7.5 40x75x72 40x75x72FCAC/WC-025 300,000 60 100 30 25 2.0 7.5 40x96x72 40x75x72FCAC/WC-030 360,000 72 100 35 30 3.0 10 40x96x72 40x75x72Specifications subject to change without notice

Central <strong>Process</strong> ChillersWCT-Series - 40 to over 400 TonsDesigned <strong>for</strong> High Reliability, Flexibility <strong>and</strong> Tight Equipment RoomsHigh productivity plants require abundant amounts of chilled water <strong>for</strong> critical pro cess es.We designed our central chiller line after considerable up-front plan ning, con sult ing with partnersin processing plants <strong>and</strong> ex perts in refrigeration <strong>and</strong> me chan i cal system de sign. The re sultis a unique <strong>and</strong> very practical design, eas i er to in stall <strong>and</strong>main tain <strong>and</strong> has pre mi um fea tures <strong>for</strong> consistent per<strong>for</strong>mance<strong>and</strong> high er reliablility. Avail able with semi-hermetic,open-drive or screw com pres sors, air or wa ter cooled <strong>and</strong> ava ri ety of con trols.System designs allow plants to op er ate <strong>and</strong> monitor banks ofmul ti ple Freeze-Co chiller skids within a single con trol environment.This can provide the benefit of sys tem re dun dan cy <strong>for</strong>assured up-time, <strong>and</strong> dynamic load bal anc ing by stag ing chill ers<strong>and</strong> their re frig er a tion circuits. Entire systems, in clud ing the chilledwa ter <strong>and</strong> ser vice wa ter loops can be re mote ly mon i tored <strong>for</strong> prop erfunc tion, tem per a ture vari ance, pro cess <strong>and</strong> tow er water pres suredrop, <strong>and</strong> respond in real-time to load changes.200 ton re cip ro cat ingcompressor modular chillerwith PLC controlsCentral<strong>Water</strong> CooledCapacityBTU/HR<strong>Chilled</strong> <strong>Water</strong>Flow - GPMCondenserFlow - GPMCompressorHPFull Load Amps208 460 575DimLxHxWFCWCT-040 480,000 96 120 40 107 49 39 84 x 70 x 52 3,700FCWCT-050 600,000 120 150 50 133 61 49 84 x 70 x 52 4,100FCWCT-060 720,000 144 240 60 151 69 56 120 x 70 x 52 4,300FCWCT-080 960,000 192 240 80 167 76 61 120 x 70 x 52 4,800FCWCT-100 1,200,000 240 300 2 x 50 266 121 98 120 x 70 x 52 5,800FCWCT-120 1,440,000 288 360 2 x 60 302 137 112 120 x 70 x 52 6,300FCWCT-150 1,800,000 360 450 3 x 50 399 181 147 168 x 70 x 52 7,400FCWCT-180 1,920,000 384 480 4 x 40 428 193 156 168 x 70 x 52 7,900FCWCT-200 2,400,000 480 600 4 x 50 532 241 196 168 x 70 x 52 9,900WeightLbsRemoteAir CooledCapacityBTU/HRChillerGPMRemoteCond FansCompHPFull Load Amps208 460 575Chiller DimsLxHxWCond DimsLxHxWChillerWeightFCACT-040R 440,000 88 4 x 1.0 40 123 56 45 84 x 70 x 52 144 x 60 x 40 3,500 1,800FCACT-050R 546,000 110 4 x 1.0 50 156 71 57 84 x 70 x 52 144 x 60 x 40 3,800 2,300FCACT-060R 645,000 129 8 x 1.0 60 175 80 64 120 x 70 x 52 144 x 72 x 76 4,300 2,600FCACT-080R 880,000 176 8 x 1.0 80 195 88 71 120 x 70 x 52 144 x 72 x 76 4,900 2,950FCACT-100R 1,092,000 219 12 x 1.0 2 x 50 312 141 114 120 x 70 x 52 216 x 72 x 76 5,200 3,100FCACT-120R 1,320,000 264 12 x 1.0 3 x 40 369 167 135 168 x 70 x 52 216 x 72 x 76 5,700 4,200FCACT-150R 1,638,000 328 16 x 1.0 3 x 50 468 212 171 168 x 70 x 52 288 x 72 x 76 6,500 4,700FCACT-160R 1,760,000 352 16 x 1.0 4 x 40 492 223 180 168 x 70 x 52 288 x 72 x 76 7,100 5,600FCACT-200R 2,184,000 436 20 x 1.0 4 x 50 624 282 228 168 x 70 x 52 360 x 72 x 76 8,700 5,800Capacity in BTUH based on R-22 refrigerant. <strong>Chilled</strong> water at 2.4 GPM from 60°F to 50°F. Ambient air at 95°F. Condenser water at 3 GPM/ton <strong>and</strong> 85°F to 95°F.Air cooled models require remote condenser. FLA does not include remote condenser. Consult factory <strong>for</strong> selections above 200 tons.CondWeight

Engineered <strong>Process</strong> <strong>Cooling</strong> <strong>Systems</strong>Implementing New & Re-engineered Thermal <strong>Systems</strong>Integrating the knowledge <strong>and</strong> practical experience from experts inrefrigeration, me chan i cal design <strong>and</strong> construction <strong>and</strong> large-scale system userspro vides Freeze Co customers with significant advantages. It pro vides agreat er depth of expertise supporting high production environments <strong>and</strong> a sin glesource responsibility. Freeze Co is unique ly qualified to pro videinitial system or ex pan sion de signs, installation <strong>and</strong> on go ingservice. We provide a prop er blend of ex per tise in chill ing,tow er ser vice, pumping, con trols <strong>and</strong> pip ing in fra struc tureto maximize overall ef fi cien cy.Freeze Co offers pre-plumbed, pre-wired <strong>and</strong> test edthermal systems designed by ex perts us ing state of theart CAD <strong>and</strong> pipe lay out soft ware to as sure that yourexpectations <strong>for</strong> consistent per <strong>for</strong> mance <strong>and</strong> exp<strong>and</strong>abilityare fully met. Industry stan dard components are avail able internationally to easeservice <strong>and</strong> reduce downtime. Capabilities in clude design, turn-key in stal la tion,start-up <strong>and</strong> on go ing ser vice.Single <strong>and</strong> multiple cell tanks to 10,000 gal lonsavailable with or without insulation. Pumps aregen er ous ly sized <strong>and</strong> fully trimmed <strong>and</strong> valved.Tank shown has full-flow strainer.Fiberglass or Steel Evaporative <strong>Cooling</strong> TowersProper evaporative tower selection involves many factors including site layout, loadbear ing mem bers, prevailing wind direction, wet bulb rating, distance to othercomponents <strong>and</strong> other con sid er ations. It takes experts to do it right, meetingcurrent pro cess needs <strong>and</strong> variables, yet allowing a practical path to modify orexp<strong>and</strong> the system. Freeze Co can pro vide all types of cooling towers from ourown eco nom i cal fiberglass models, to steel crossflow, counterflow <strong>and</strong> <strong>for</strong>ceddraft technologies to meet in di vid u al con di tions. <strong>Cooling</strong> tower sys tems areavail able with closed-loop <strong>and</strong> free-cooling op tions, side-stream or full-flowfil tra tion, heat trace, insulation, elevating struc tures <strong>and</strong> other ther mal <strong>and</strong>me chan i cal requirements.Fiberglass tower cells are available from 40 tons to 200 tons based on CTIrating st<strong>and</strong>ards <strong>and</strong> includes the following features:Typical Tower <strong>Applications</strong>• Chiller condenser cooling• Plantwide heat exchanger cooling• HVAC <strong>and</strong> controlled environments• Compressor <strong>and</strong> reactor jackets• Free-cooling chiller bypass systems• Die-cast mold cooling• Other industrial process needs• Fan motor is weatherproofed <strong>for</strong> protection <strong>and</strong> to reduce noise.• Housing panels <strong>and</strong> water basin are built from fiberglass re in <strong>for</strong>ced plas tic<strong>for</strong> rust-free operation even under harsh conditions.• Sprinkler pipes are sturdy PVC material with closely spaced, self-clearingnozzles al low ing thorough water distribution in a self-pow ered ro tat ingspray cov er ing the entire fill area.• Round design permits maximum air intake regardless of pre vail ing winddirection. Intakes include wind screen.• Large capacity, water basin constructed from rust proof materials

Refrigeration & <strong>Process</strong> <strong>Cooling</strong> ProductsPortable Air-Cooled ChillersModels are available from 1 to 30 tons in highly compact design. Models feature re cip ro -cat ing hermetic compressors. Features include gen er ous ly sized insulated stain less steeltank <strong>and</strong> separate process <strong>and</strong> chiller pumps. <strong>Systems</strong> avail able with an a log or PLC basedcontrols. Side panels re move <strong>for</strong> easy ac cess to com po nents. All mod els are run testedunder load <strong>and</strong> ship with a full re frig er ant charge.Refer to Product Type FCAC, FCWC or FCAC-R.Compact, Low Cost, <strong>Water</strong> Cooled ChillersModels are available from 40 to 80 tons in highly compact design. Open frame reducescost <strong>and</strong> improves component access. Models fea ture re cip ro cat ing semi-hermetic compressors. Ideal <strong>for</strong> split systems with re mote tank <strong>and</strong> pumping sys tem. Sys tems avail ablewith analog or PLC based con trols. All models are run tested under load <strong>and</strong> ship witha full re frig er ant charge.Refer to Product Type FCCAC or FCCWC or FCCAC-R.Central Air or <strong>Water</strong> Cooled ChillersModels are available from 40 to over 400 tons in compact, rugged design. Open frameimproves component access <strong>and</strong> maximizes floorspace. Models equipped with in di vid u al lycircuited reciprocating semi-her met ic or screw compressors, ideal <strong>for</strong> split sys tems withre mote tank <strong>and</strong> pump ing sys tem. Up to 12 unloading in cre ments. <strong>Systems</strong> avail ablewith an a log or PLC con trols <strong>and</strong> re mote com mu ni ca tion port. All mod els are run testedunder load <strong>and</strong> ship with a full re frig er ant charge.Refer to Product Type FCWCT <strong>and</strong> FCACT-R.Central <strong>Cooling</strong> Tower & Pumping <strong>Systems</strong>There is virtually no limit to how we can approach <strong>and</strong> implement cooling system de signs.In-house design capability includes piping sys tems, service drop stations, evap o ra tivetowers, free cooling <strong>and</strong> heat recovery, <strong>for</strong>ced air sys tems, air <strong>and</strong> liquid fil tra tion, el e -vat ed equip ment mezzanines, <strong>and</strong> remote di ag nos tics. With our own me chan i cal crews,we design, install <strong>and</strong> service cooling systems world wide.NEW! MODULAR CHILLER SYSTEMSA new range of air <strong>and</strong> water cooled modular chillers is now available!Compact modules can be assembled in equipment rooms or roof tops.<strong>Industrial</strong> construction throughout. Scroll, semi-hermetic <strong>and</strong> screwmodels from 20 to 120 tons per module. Single point piping <strong>and</strong> electricalconnections. Innovative easy-access strainer cleaning system.Brazed plate or servicable shell & tube condensers. Master/Slave controlsystem. Refer to Product Type FC MCS104,000 Sq.Ft. Refrigeration <strong>and</strong> Mechanical System CenterPerhaps no other manufacturer of industrial process cooling equip ment has so much tooffer under one roof. In addition to refrigeration equip ment assembly <strong>and</strong> testing, we havestaff who spe cial ize in designing <strong>and</strong> installing HVAC <strong>and</strong> process cool ing systems. Systemen gi neer ing, industrial pip ing sys tems, sheet met al fab ri ca tion, specialized equip ment <strong>and</strong>skilled per son nel, complete in stal la tion, start-up <strong>and</strong> service are all available..Represented By:Freeze Co <strong>Systems</strong>, Ltd.2100 Steeles Avenue E.Brampton, ON L6T 1A7Phone: (905) 789-9988Fax: (905) 789-9989www.freezeco.comForm 192.01.09 Jan. 2004© 2004 Freeze-Co <strong>Systems</strong>, Ltd.