You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Our new fume cupboards for highthermal loads and working with acids

Safe and cost-effective workingalso under special conditionsWe are a leading supplier in the field of laboratoryequipment and laboratory fume cupboards because weare constantly developing ourselves and our products.To achieve this, we combine our constructive knowhowwith the results of systematic investigation andtesting of the flow technology of laboratory fume cupboards.Energy efficiency and optimum ergonomicsmake our fume cupboards safe and comfortable for thepeople working with them.For years now, we have been introducing our expertisein laboratory design and construction to standardisationcommittees in order to improve the safety inlaboratories even further. In our own certified testinglaboratory, we test our fume cupboards in accordancewith EN 14175 – Part 3, 4, 6 and 7, but also inaccordance with further standards, for example BSR/ASHRAE Standard 110P-2005.We have always been searching for solutions thatwill make our fume cupboards even safer and moreenergy efficient. The energy consumption is extremelylow, whilst high safety standards are maintained, dueto the continual optimisation of our flow technology.

The new standard for working in the fumecupboard for high thermal and acidic loadsThe new standard EN 14175-7:2012 regulates fumecupboards for special application with high thermalload and/or acidic load. The use of these special purposefume cupboards instead of general purpose fumecupboards is usually the result of a risk assessment.The standard is applicable for the following specialpurpose fume cupboards:- Fume cupboards for high thermal loads- Fume cupboards for high thermal loads incombination with acid digestions- Fume cupboards for handling of perchloric acid- Fume cupboards for handling of hydrofluoricacidAdditional objectives that are formulated insection 7 go beyond the safety and performancetargets defined in EN 14175-2, for example:Requirements for materialsIn fume cupboards for high thermal loads, thematerials used must be able to meet the resultingdemands. The materials must be chemically resistantto acids and acidic vapours and resistant to thermaldeformation at the working temperatures.Requirements on the cleanabilityThe construction of the fume cupboard mustsecure the necessary access to all air flow parts forcleaning purposes.Requirements on the air flow and the monitoringImpacts on the air current, caused by thermalloads and installed heating appliances, for example,must be taken into account and limited.In addition to the fume cupboard function displaywith the acoustic and optical alarm, fume cupboardsfor high thermal loads must be equipped with a temperaturesensor that will trigger an alarm when themaximum temperature is reached.While the previous standard series EN 14175defines exclusively isothermal conditions in the fumecupboard, the newly issued part 7 offers the opportunityto evaluate the safety of fume cupboards on incidenceof high thermal loads. This closes a significantgap, as working with heat sources in the fume cupboardis part of the everyday routine work in manylaboratories.

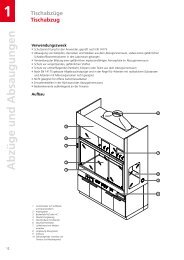

Secuflow EN7 bench-mounted fume cupboard• for high thermal loadsThe Secuflow is especially successful because it canbe operated with lower extract air volumes, whichmeans considerable saving in energy costs and inthe investment costs for the ventilation system. TheSecuflow is the safest and most ecologically soundvariant.We have developed the Secuflow EN7 to securethese benefits also for working with high thermalloads. Due to its sophisticated supply and extractair flow, the fume cupboard secures safe operationwhen working with thermal loads, whilst retaining allthe benefits of the supportive flow fume cupboardSecuflow.When the laboratory is equipped with SecufowEN7 fume cupboards, the user is ideally equipped forany kind of laboratory work: whether this is normaloperation or working with thermal loads.Secuflow EN7 bench-mounted fumecupboards for high thermal loadsIntended use• For work with high thermal loads in the inside of the fumecupboard (Heat sources of 4 KW per meter inner width of thecupboard)• Protective device for the user, tested in accordance withEN 14175-7:2012• Extraction of fumes, aerosols and dust from the internalworkspace to prevent dangerous amounts of pollutants fromescaping into the laboratory• To prevent the formation of dangerous potentially explosiveatmospheres in the internal workspace• Protection from splashes of hazardous substances• Protection from flying particles, bodies or parts escaping fromthe internal workspace• General fume cupboards constructed in acc. with EN14175 are not suited for use with radioactive substances ormicroorganisms• Not suitable for openly breaking down chemicals• Active supportive flow technology (Secuflow technology)reduces the energy consumption while regulations andstandards are observed• Service outlets for sanitary supply in the rear panel of the internalworkspace• Control units located horizontally on the service rail of thesupport unitTechnical dataDimensions 1200 1500 1800Width [mm] 1200 1500 1800Depth [mm] 900Height [mm 2700Clear width, internal workspace [mm] 1150 1450 1750Clear height, internal workspace [mm] 1550Working height [mm] 900

Standard fume cupboard with heating sourceSecuflow EN7 with heating sourceFlow pattern in the Secuflow EN7 with heating sourceDesign characteristics 1200 1500 1800Supporting constructionSelf-supporting underbench units or H-frame with push-in underbench unitsSash 2 horizontal sashes 3 horizontal sashesMax. number of devices for scaffold points, ø 12 mm to 13 mm 9 12Service modules 2 3ElectricsElectrical supplyFuse box, Sash controller SCExternal sockets in service panelsOptionalSanitary technologySanitary supplyService modules with take-off valves for vacuum, gases and/or waters and integrated sink (PP) as an optionVentilation technology 1200 1500 1800Air flow range without / with thermal load [m³/h] 1) 360 / 600 450 / 750 540 / 900Airflow damper, variable, including detector of sash positionAirflow-Controller ACFunction display with temperature monitoringFAZConnection height [mm] for AC with extract manifold Ø 250 mm 2950Underbench exhaustAs an option, depending on requirements and regulations1)All air volume specifications refer to an opening height of the sash window of 500 mm (test opening in acc. with EN 14175) and the maximum tracer gas values recommended by German Standard (BG Chemie).A maximum admission pressure of 600 Pa should not be exceeded in the case of fume cupboards with airflow dampers. The indicated minimum air exchange rates were determined under specified test conditions in acc.with EN 14175-3. These minimum air exchange rates must be adapted when dimensioning the ventilation system.If on-site extract air monitoring systems or airflow dampers are used, the required air volumes may be different. The operating limitations must be agreed upon with Waldner.Material/surfaceWorktopInternal liningStoneware, Polypropylene, Stainless steel, EpoxyMelamine resin facing, Solid grade laminate, Stoneware

EN7 Bench-mounted fume cupboards• for high thermal loads incombination with acid digestions• Fume cupboards for handlingof perchloric acid• Fume cupboards for handlingof hydrofluoric acidThese three types of fume cupboards are designedfor safe operation under high thermal load incombination with acidic digestions and for thehandling of perchloric and hydrofluoric acid.The special cladding of the inside of the fumecupboards is resistant to extreme strain. A compactfume scrubber and a neutralisation unit can beoptionally integrated into our fume cupboards atany time.If the maximum admissible temperature isexceeded, the integrated alarm can be relayed tothe building management system.Fume cupboards for high heatand acidic loadsIntended use• Protective device for the user, tested in accordance withEN 14175-7:2012• Suitable for open, thermal processes of breaking downchemicals with aggressive media such as e. g. sulphuric acid,perchloric acid, hydrofluoric acid or aqua regia• The construction of the fume cupboard and the materials ofthe inner lining of the internal workspace determine whichaggressive media the device can be used for• Extraction of fumes and aerosols from the internal workspaceto prevent dangerous amounts of pollutants from escaping intothe laboratory• To prevent the formation of dangerous potentially explosiveatmospheres in the internal workspace• Protection from splashes of hazardous substances in the internalworkspace• Protection from flying particles, bodies or parts escaping fromthe internal workspace• Fume cupboards constructed in accordance withEN 14175-7:2012 are not approved for working with radioactivesubstances and for working with microorganisms• For work with high thermal loads in combination with aciddigestions in the inside of the fume cupboaed (Heat sourcesof 4 KW per meter inner width of the cupboard)Technical dataDimensions 1200 1500 1800Width [mm] 1200 1500 1800Depth [mm] / Height [mm 900 / 2700Clear width, internal workspace [mm] 1150 1450 1750Clear height, internal workspace [mm] / Working height [mm] 1125 / 900Design characteristics 1200 1500 1800Supporting constructionFume-scrubber, Extract manifold, Extract manifold with sprinkler (forworking with perchloric acid), Neutralisation unit underbench unitH-frame with push-in underbench unitsOptional

Velocity vectors within the workspace in fume cupboardswith heat sourceVelocity vectors within the workspace in fume cupboardswithout heat sourceElectricsElectrical supplyFuse box, Sash controller SCExternal sockets in service panelsOptionalSanitary technologySanitary supplyWith take-off valves for vacuum, gases and/or waters and drip cup integrated in the worktop as an optionVentilation technology 1200 1500 1800Minimum air exchange rate [m³/h] 1) 600 750 900Function display with temperature monitoringAirflow damper, constant with temperature monitoringConnection height [mm] for FAZ and AC with extract air spigotØ 250 mm with fume-scrubberConnection height [mm] for FAZ with extract manifoldØ 250 mm without fume-scrubberConnection height [mm] for AC with extract manifoldØ 250 mm without fume-scrubberUnderbench exhaustFAZAirflow-Controller AC314524102640As an option, depending on requirements and regulations1)All air volume specifications refer to an opening height of the sash window of 500 mm (test opening in acc. with EN 14175) and the maximum tracer gas values recommended by German Standard (BG Chemie).A maximum admission pressure of 600 Pa should not be exceeded in the case of fume cupboards with airflow dampers.The indicated minimum air exchange rates were determined under specified test conditions in acc. with EN 14175-3. These minimum air exchange rates must be adapted when dimensioning the ventilation system.If on-site extract air monitoring systems or airflow dampers are used, the required air volumes may be different. The operating limitations must be agreed upon with Waldner.Material/surfaceInternal liningincluding worktopPolypropylene for working with hydrofluoric acidStoneware, for working with perchloric acid, with sulphuric acid, withhydrochloric acid and aqua regia, for example

BMSBMSTemperature monitoringVariable extract air volume control dependenton sash setting and extract air temperatureTemperature monitoringand extract air volume controlAn optical and acoustic alarm is activated when themaximum admissible temperature in the top of thefume cupboard is exceeded, which can be relayed tothe building management system if desired.The extract air of the Secuflow EN7 can be controlledwith our variable Airflow Controller AC dependent onthe setting of the sash and the extract air temperatureinside the fume cupboard.<strong>WALDNER</strong> Laboreinrichtungen GmbH & Co. KGHaidoesch 1 · 88239 Wangen · GermanyPhone +49 7522 986-480 · Fax +49 7522 986-418info@waldner-lab.com · www.waldner-lab.com1530 ∙ 0612 ∙ Konzeption und Gestaltung: Büro für Gestaltung, Isny im Allgäu