mig welding - Rapid Welding and Industrial Supplies Ltd

mig welding - Rapid Welding and Industrial Supplies Ltd

mig welding - Rapid Welding and Industrial Supplies Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

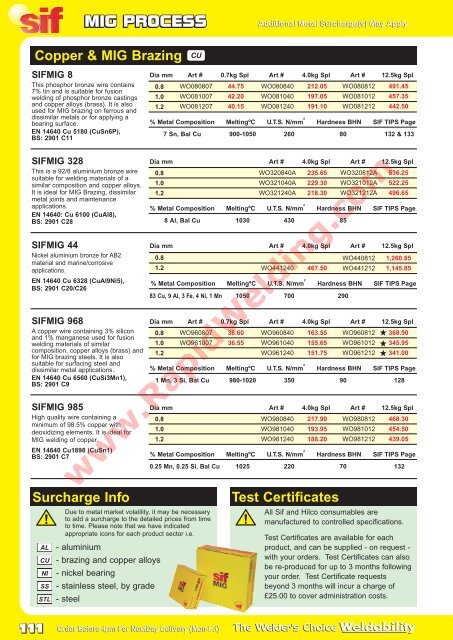

MIG PROCESSAdditional Metal Surcharge(s) May ApplyCopper & MIG Brazing CUSIFMIG 8This phosphor bronze wire contains7% tin <strong>and</strong> is suitable for fusion<strong>welding</strong> of phosphor bronze castings<strong>and</strong> copper alloys (brass). It is alsoused for MIG brazing on ferrous <strong>and</strong>dissimilar metals or for applying abearing surface.EN 14640 Cu 5180 (CuSn6P),BS: 2901 C11SIFMIG 328This is a 92/8 aluminium bronze wiresuitable for <strong>welding</strong> materials of asimilar composition <strong>and</strong> copper alloys.It is ideal for MIG Brazing, dissimilarmetal joints <strong>and</strong> maintenanceapplications.EN 14640: Cu 6100 (CuAl8),BS: 2901 C28SIFMIG 44Nickel aluminium bronze for AB2material <strong>and</strong> marine/corrosiveapplications.EN 14640 Cu 6328 (CuAl9Ni5),BS: 2901 C20/C26SIFMIG 968A copper wire containing 3% silicon<strong>and</strong> 1% manganese used for fusion<strong>welding</strong> materials of similarcomposition, copper alloys (brass) <strong>and</strong>for MIG brazing steels. It is alsosuitable for surfacing steel <strong>and</strong>dissimilar metal applications.EN 14640 Cu 6560 (CuSi3Mn1),BS: 2901 C9SIFMIG 985High quality wire containing aminimum of 98.5% copper withdeoxidizing elements. It is ideal forMIG <strong>welding</strong> of copper.EN 14640 Cu1898 (CuSn1)BS: 2901 C7ALCUNISSSTLDia mm Art # 0.7kg Spl Art # 4.0kg Spl Art # 12.5kg Spl0.81.01.20.81.2WO080807 44.75WO081007 42.20WO081207 40.15Due to metal market volatility, it may be necessaryto add a surcharge to the detailed prices from timeto time. Please note that we have indicatedappropriate icons for each product sector i.e.- aluminium- brazing <strong>and</strong> copper alloys- nickel bearing- stainless steel, by grade- steelWO080840 212.05WO081040 197.05WO081240 191.107 Sn, Bal Cu 900-1050 260 80 132 & 133Dia mm Art # 4.0kg Spl Art # 12.5kg Spl0.81.01.2WO320840AWO321040AWO321240A235.65229.30218.30WO320812AWO321012AWO321212A536.25522.25496.658 Al, Bal Cu 1030 430 8583 Cu, 9 Al, 3 Fe, 4 Ni, 1 Mn 1050 700 290WO080812 491.45WO081012 457.35WO081212 442.50Dia mm Art # 4.0kg Spl Art # 12.5kg SplWO441240 467.50WO440812 1,260.85WO441212 1,145.85Dia mm Art # 0.7kg Spl Art # 4.0kg Spl Art # 12.5kg Spl0.81.01.2WO960807WO96100738.6036.55WO960840WO961040WO961240163.55155.65151.75WO960812WO961012WO961212368.50345.95341.001 Mn, 3 Si, Bal Cu 980-1020 350 90 128Dia mm Art # 4.0kg Spl Art # 12.5kg Spl0.81.01.2WO980840WO981040WO981240217.90193.95188.20WO980812WO981012WO981212468.30454.50439.050.25 Mn, 0.25 Si, Bal Cu 1025 220 70 132www.<strong>Rapid</strong><strong>Welding</strong>.comSurcharge InfoTest CertificatesAll Sif <strong>and</strong> Hilco consumables aremanufactured to controlled specifications.Test Certificates are available for eachproduct, <strong>and</strong> can be supplied - on request -with your orders. Test Certificates can alsobe re-produced for up to 3 months followingyour order. Test Certificate requestsbeyond 3 months will incur a charge of£25.00 to cover administration costs.111Order Before 4pm For NextDay Delivery (Mon-Fri)