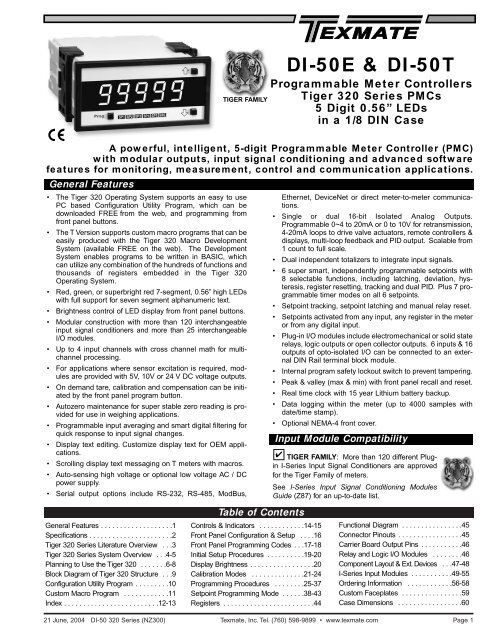

DI-50E Data Sheet - K - Tech, Inc.

DI-50E Data Sheet - K - Tech, Inc.

DI-50E Data Sheet - K - Tech, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Tiger 320 Series Modular Literature OverviewThe Tiger 320 Series, Modular Literaturesystem, makes it easy to select detailedinformation about those specific functionsrequired for your application and theConfiguration of the Tiger 320 you intendusing.Copies of all <strong>Data</strong> <strong>Sheet</strong>s / User Manuals andSupplements can be viewed page-by-pageand/or downloaded from the document serveron our website.Programming Code <strong>Sheet</strong>Generic to all Tiger 320 Series models, the Programming Code<strong>Sheet</strong> is a quick reference document that allows you to quicklyview the meter’s manual programming codes.Shipped with each productordered, copies are alsoavailable on request, or canbe viewed and downloadedfrom the document serveron our website.Model Specific <strong>Data</strong> <strong>Sheet</strong> / User ManualSpecific to each 320 Seriesmeter model, the data sheet /user manual describes thebasic functions of the meterand how to configure themeter for these functions.Shipped with each productordered, copies are also availableon request, or can beviewed and downloaded fromthe document server on ourwebsite.The model specific data sheet / user manual contains:• <strong>Tech</strong>nical Specifications• Overview of Tiger 320 SeriesSoftware and Hardware• Planning Guide• Block Diagram of the Tiger320 Software and Hardware• Configuration Utility Program• Custom Macro Programming• Front and Rear PanelControls• Front Panel Button ManualProgramming Codes Overview• Programming Procedures• Functional Diagram andPinouts• Hardware Layout and AvailableInput and Output Modules• Meter Options, and CustomFaceplates• Ordering InformationSupplements to <strong>Data</strong> <strong>Sheet</strong> / User Manual are Generic to all Tiger 320 ModelsGeneric to all Tiger 320 Seriesmodels, each supplement providesin-depth technical andprocedural information on allindividual meter modules,functions, or applications.Listed are the supplementswhich are currently available:Specific supplements areshipped with each productordered to suit our customer’sapplication. Copies are alsoavailable on request, or can beviewed and downloaded fromthe document server on ourwebsite.Advanced Calibration and On DEMANDModeAnalog Output ModulesBASIC to Tiger 320 MACRO-LanguageProgram Development System, Compilerand TutorialConfiguration Utility Program (Runs on PC)Linearizing FunctionsMeter Registers (for Macro Programming)Serial Communications Output ModulesSetpoints & RelaysTotalizing & Batching FunctionsTiger 320Functional OverviewOther Tiger 320 Series Related LiteratureTiger 320Application ExamplesI-Series Input SignalConditioning ModulesMeters By theCase SizeA Quick Overview of the AwesomePower of the Tiger 320 SeriesDescribes a Selection ofTiger 320 Applications<strong>Inc</strong>ludes all Available Input andOutput Modules for the Tiger,Leopard and Lynx Families of MetersShows all Cases and Lists allAvailable Meters by Each CaseSize and Type21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300) Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.comPage 3

SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6An Overview of the Awesome Power of the Tiger 320 SeriesThe Tiger 320 Series of 32-bit Programmable Meter Controllers incorporates, in one instrument, all thedifferent functions required by today’s automation and process control applications.1 Tiger 320 32-Bit Operating SystemA virtual toolbox of selectable and programmable applicationsoftware functions are embedded in the Tiger 320Operating System. They integrate seamlessly with a trulyvast array of modular input and output hardware options.Embedded Application Software <strong>Inc</strong>ludes:• Multi-channel Inputs In Many Combinations• Full Floating-point Maths• Cross Channel Math (A+B, A-B, AxB, A/B)• Square Root, Inverse and Log of Input• 4 x 32 Point Or 1 x 125 Point Linearization Table• Smart Auto Zero with Programmable Capture Band, Rateof Change and Aperture Window for Weighing Applications• Set Tare Reset Tare for Batching• Smart Quick Response Averaging• Smart Timer and Time Integration Functions• Time and Event-based Sequencing• Polynomial Calculations• Remote Reset of Any Function• Dual Totalizers• Dual PID4 Powerful Custom Macro Programming CapabilityTexmate’s BASIC to Tiger 320 Macro-language Compiler can quicklyConvert your special metering, control and automation ideas into reality.This powerful easy to use development system enables programs to be written in BASICutilizing any combination of the hundreds of functions and thousands of registers embeddedin the Tiger 320 Operating System. When your BASIC program is compiled into theTiger 320 Macro-language it is error checked and optimized. There are also numerous offthe-shelfapplication specific programs available. Many only need the blanks to be filled into use them and this does not require any knowledge of BASIC.F1PF22 <strong>Data</strong> Logging and Memory OptionsUp to 1MB of non-volatile on-board memory can beinstalled for (Black Box) endless loop recording. Upto 4000 data records can be continuously stored toprovide before and after analysis of any process faultcondition.• <strong>Data</strong> log from 4 channels.• <strong>Data</strong> log from 2 channelswith date & time stamp.• Log / print from setpointor timer.Scrolling annunciator messages can beprogrammed to appear with any setpoint activation,selected events or logic inputs.A Plug-in I/O Module is availablewith removable Flash CardMemory for high-capacity orlong-term data logging.Flash Cards areavailable from 4to 128 Meg.3Real-time ClockOptional Real-time clockwith date and time stamp.15 year lithium battery.5 Programmable Front Panel ControlsProgrammable Front Panel ControlsThe front panel buttons can be used tocontrol or program any standard functions.They can also be programmed to onlyaccess and display specifically designatedfunctions, such as Tare, Auto-Cal or Print on Demand.6Configuration & Programming from a PCPC ProgrammingProgram the meter froma PC with Texmate’s easy to useTiger 320 Configuration Utility Program.Prog. SP1 SP2 SP3 SP4 SP5 SP67A Wide Selection of Display Formats & 8 Case Sizes to Suit any Application144x72mm 9/32 <strong>DI</strong>NSingle or multiple LED or LCD displaysNumeric, Alpha Numeric and Bargraph96x48 mmShort Depth CaseRemoteDisplay PCB96x48 mm Case36x144mm9/64 <strong>DI</strong>N648x144mm 4”LEDRemote Display5 or 6 digitDriven by RS485from any Tiger 32048x96mm1/8 <strong>DI</strong>N96x48mm1/8 <strong>DI</strong>N6-wire DisplayConnectorPage 4Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.com21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300)

Planning to Harness the Power of Tiger 320 Programmable Meter ControllersA combination of modular hardware and software resourcesenable Tiger 320 Series Programmable Meter Controllers(PMCs) to be easily configured as a cost effective solution forthe most simple or the most complex of applications.A review of your Project’s objectives, its physical layout, theproposed sensors and control outputs will enable you to selectthe optimum configuration of the Tiger 320 PMC’s unique hardwareand software capabilities.Input Signals & SensorsDECISION4-20 mA or Sensor DirectUnless sensors are located at a far distance, the greatestaccuracy and best performance is usually obtained byconnecting sensors directly to the Tiger 320, which will thenfunction as the primary measurement device.PLANNINGTIPThere are more than 120 Tiger compatible input signalconditioning modules, with the appropriate excitationoutputs, to suit almost any type of sensor or combinationsof up to 4 sensors.In most cases, sensors with a 4-20 mA output are more costly,and when a separate 4-20 mA transmitter is used, signal conversion,drift, and calibration inaccuracies are introduced.PLANNINGTIPDECISIONSome Tiger input modules combine direct sensor inputswith 4-20 mA inputs, enabling both local and far distantsensor inputs to be combined.Sensor Linearization or CompensationThe performance of many sensors can be greatlyenhanced or expanded with linearization and or compensation.Sensors may be compensated for temperature, frequency,altitude, humidity and mechanical position, to namejust a few parameters.PLANNINGTIPPLANNINGTIPTiger PMCs with 32 kilobits or more of memory provideup to four 32-point user defined linearization tables orone combined 125-point table.Many compensation methods can be implemented withthe standard cross channel math capabilities of theTiger’s 32-bit operating system. Complex three-dimensionalcompensation can also be implemented using the powerfulmacro programming capability.PLANNINGTIPThe serial number and calibration date of a sensor canbe loaded into the meter. The serial number, linearizationtables, and compensation factors of a newly calibratedsensor can then be saved for future reloading, eitherserially through a PC or directly through the web via anEthernet port.PLANNINGTIPAlthough there are numerous input modules with combinationsof various input signals, some inputs such aswatts or pH are provided on input modules dedicated toa single function. Combining these inputs with each other signalstwo or more Tiger meters can serially communicate, andbe configured to share their data and processing resources.Display OptionsTiger PMCs have a large range of display options, including digitaland alphanumeric LCDs, LEDs and Touch Panel HMIs.4” 7-Segment RemoteShort Depth Remote Display96x48 mmShort Depth CaseRemoteDisplay PCB96x48 mm Case6-wire DisplayConnector5.7” & 10.4” HMIsColor or MonocolorDECISIONLED or LCD DisplaysLED displays are a lower cost and popular display option.They operate over the largest temperature range, havebetter viewing angles and viewing distances, and have thelongest operational life. However, red LEDs are difficult to readin direct sunlight without a shade hood and consume morepower. Green LEDs and backlit LCD displays can be more easilyread in direct sunlight.PLANNINGTIPDECISIONProg.Prog.The Tiger range can be ordered with red or green LEDs.LCD displays are also available, with or without backlighting.Numeric or Alphanumeric DisplaysGenerally, numeric displays are a lower cost option thanalphanumeric displays. The Tiger range supports a full 7-segment numeric and 14-segment alphanumeric alphabet ofEnglish letters and Arabic numerals. Where complex text messagingor alarm annunciation is required, we recommendusing the 14-segment alphanumeric option.DECISIONSingle or Multiple DisplayThe Tiger meter has four input channels and can be configuredto display many different inputs or results. Thesecan be viewed constantly on the operational display, or ondemand in one of the view modes by pressing a button. Someapplications require multiple values to be displayed simultaneously.With single, dual, or triple displays, and single displayswith 51 or 101-segment bargraph combinations, we have alarge range of display options to choose from.PLANNINGTIPTiger meters can communicate with each other to sharetheir data and processing resources and be stack or twinmounted to provide a wider range of display options.SP1 SP2 SP3 SP4 SP5 SP6SP1 SP2 SP3 SP4 SP5 SP6taretareStack mountingfor greater displayoptionsDECISIONPush Button or Membrane Touch PadsTiger PMCs are shipped as standard with high usage hardplastic push buttons. An optional clear lens cover thatopens on a cam hinge with a key lock can provide full NEMA 4or IP65 dust and water proofing. Alternatively, an optional membranetouch pad faceplate can be ordered.PLANNINGTIPFaceplates can be customizedto suit anyOEM application, andbe quickly produced in large orsmall quantities for push buttonsor membrane touch pads.Twin or triple mountingfor greater displayoptionsControl Outputs & I/O LogicDECISIONElectromechanical Relays or SolidState Control OutputsTiger PMCs have a wide selection of control outputs tochose from. The decision on which control output to choosedepends on the current and the switching frequency.Electromechanical relays are a popular choice for most controloutputs. Tiger output modules are available with combinationsof two 10 amp form C and two to six 5 amp form A relays thatcan be used to directly drive fractional HP motors or actuators.PLANNINGTIPTIMETEMPNo OF LABELS100SP 901802703 604 5040530620100The limitation of electromechanical relays is switchingspeed. If a relay needs to operate in less than 30 mS, orbe cycled faster than .5 cpm, it is advisable to select anoutput module with solid state relays (SSR) or open collectoroutputs (OC), that can drive external high current SSRs.P100806040200SP654321100806040200SP654321Page 6Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.com21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300)

Pri P r i n t P r i n t**Planning to Harness the Power of Tiger 320 Programmable Meter Controllers continuedDECISIONPID or On/Off ControlDepending on the process to be controlled, either PID oron/off control should be selected. If the process variablesare reasonably consistent, then the on/off control is generallymore than adequate and easier to implement. Supersmart setpoint control software supports many selectable functions,such as Hi or Lo activation, Latching, Hysteresis,Tracking, Register Resetting and 7 Multi-function internalTimers on all setpoints.PLANNINGTIPControl systems with large lag and lead times are notsuitable for on/off control and tend to overshoot andundershoot. PID is needed to stabilize and control thesesystems. One of the many powerful setpoint functions providedby the Tiger 320 Operating System is single or dual PID.DECISIONRetransmission 0-10V or 4-20mATiger PMCs can have an optional single (0-10 V or 0/4-20mA) or dual (0-10 V) analog output module installed. Theisolated 16-bit output is fully scalable and highly accurate.With a compliance of up to 500Ω at 20mA, the 4-20 mA outputcan be used over very long distances and still drive more thanone output device, such as a PID controlled valve positioner.PLANNINGTIPThe analog outputs can be reversed to output 20mA to4/0 or 10 to 0VDC. They can be scaled across any portionof the digital range, up to full scale. The output canbe programmed to swing 0 to 20mA or 0 to 10V in one digitalcount to drive external logic or SSRs as additional setpoints.Under Macro Program Control, the analog outputs can be programmedto produce pulses or even sinewaves.DECISIONI/O Logic, Rear Panel or Breakout BoxThe Tiger Operating System has many built-in logic functionsthat can be used to develop sophisticated controlPLANNINGTIPsystems. The Tiger PMC has three logic inputs/outputs availablevia the LOCK, HOLD, and CAPTURE pins, and three logicI/Os are available for input module use via pins D1, D2 and D3.More complex I/O intensive applications require an opto-isolatedI/O plug-in module, which supports six inputs and upto 16 outputs. This module can connect to an externalBreakout Box that is <strong>DI</strong>N Rail mountable with screw terminalblocks. There are also compatible <strong>DI</strong>N Rail mountingelectromechanical relays and SSR modules.• 6 Inputs & 16 Outputs or 6 Inputs & 6 Outputs• Fully ProgrammableConnects to <strong>DI</strong>N Railterminal block modulewith 3M IDC cableSerial CommunicationThe easiest way to configure or program a Tiger PMC is withthe free user-friendly Configuration or Macro DevelopmentSoftware. Serial I/O is provided via an optional Plug-in outputcarrier board, which supports RS-232 or RS-485 output modules.If serial I/O is not required by the application, the serialcarrier board can be removed for reuse. The Tiger 320Operating System supports several serial protocols, includingASCII, Modbus RTU and Print Mode (which includes a printerdriver and support for direct meter to meter communications).Also supported is DeviceNet, which requires a special dedicatedcarrier board, and Ethernet (TCP/IP), which requires anexternal converter box.DECISION<strong>DI</strong>N RailBreakout Box<strong>DI</strong>N RailRelayModuleRS-232 or RS-485Except for DeviceNet, all serial communication modessupported by the Tiger can function with either RS-232 orRS-485. The limitations of RS-232 are that only one meter at atime can be connected to the serial port of a computer, and thedistance from the computer to the meter is limited in practicalterms to around 30 meters (100 feet).PLANNINGTIPUp to 32 meters can be connected on an RS-485 bus.The differential current drive of the RS-485 bus ensuressignal integrity in the most harsh environments to distancesup to 1230 meters (4000 feet). However, RS-485 generallyrequires a special RS-485 output card to be installed inthe computer or an external RS-232 to RS-485 converter hasto be used.DECISIONSelect the Communication Mode BestSuited to Your Application:Modbus (RTU)Modbus is widely used in industry. It has alarge base, and most SCADA and HMI softwarepackages support it. See also ModbusWrapped in Ethernet (Modbus/TCP) below.PLANNINGTIPThere are 100s of HMI Touch PanelScreens that are compatible with theTiger 320 Modbus interface.ASCIIThe meter configuration utility program and the developmentsoftware use the ASCII protocol. The ASCII protocol allows youto write your own driver for your own application via the developmentsoftware and should provide the quickest developmenttime.Print ModeThis is an ASCII based printerdriver output that enables theserial port to be directly connectedto any serial printer with Epson compatibility. Printeroutput can be configured to occur from a setpoint or ondemand, and can be date or time stamped.PLANNINGTIPThe print mode can also be used for computer data loggingapplications. The meter can be connected directlyto a computer, set up in Microsoft Hyperterminal mode,with the meter programmed to output directly into a MicrosoftExcel spreadsheet format. (Also see <strong>Data</strong> Logging).Print Mode for Meter to Meter CommunicationTwo or more Tiger PMCs can be connected together allowingdata to be transferred from the master meter (in print mode) tothe slave meter (in ASCII mode). This enables the meters toshare input data and control output functions.Master ModeThis mode is for use with macro programming to expand themeter to meter communication capability to multiples of TigerPMCs. This is useful for building an entire system of TigerPMCs, sharing information and control output resources.EthernetEthernet has become a popularautomation and control protocol. Wesupply an ethernet output option and severalexternal ethernet converters that are compatiblewith the serial outputs of Tiger PMCs.DECISIONPLANNINGTIPEthernet ASCII Wrap - The ethernet output carrierboard option wraps the ASCII output into the Ethernetprotocol, and provides a T-base 10/100 Ethernet outputsocket. This allows the Configuration Utility Program or theMacro Development Software to run over a standard Ethernetnetwork. This enables the Tiger meter to be configured ormacro programmed from anywhere in the world via the web.PLANNINGTIPPLANNINGTIPProg. SP1 SP2 SP3 SP4 SP5 SP6Up to 32 Tiger PMCs can be connected by RS-485 to asingle Ethernet Converter, which will support up to 32separate IP addresses.Ethernet Modbus Wrap - This converter accepts theTiger PMC’s modbus protocol and outputs Modbus/TCPthrough an Ethernet T-base 10 port. This has become astandard for Ethernet on the factory floor. Many SCADA andHMI software packages connect directly to Modbus/TCP.***E P S O NT M - U 2 1 0* ***2 4 : 0 7 : 0J o b . 143 2 J o b . . 1 43 221 June, 2004 <strong>DI</strong>-50 320 Series (NZ300) Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.comPage 7

SP1 SP2 SP3 SP4 SP5 SP6Planning to Harness Use the the Tiger Power 320 Series of Tiger of 320 Programmable Meter Meter Controllers continuedDECISIONDeviceNetDeviceNet was originally developed by Allen Bradley toconnect sensors from the factory floor to PLCs. It is adeterministic real-time system, typically used to connect to networksusing Allen Bradley PLCs. An optional carrier board isrequired for DeviceNet which replaces the standard serial outputwith a dedicated DeviceNet output connector.<strong>Data</strong> LoggingThe Tiger 320 Operating System has built-in, sophisticateddata logging software. <strong>Data</strong> logging can be triggered from thePROGRAM button, digital inputs, time or alarm functions. Upto 1MB of optional extra on-board memory provides a powerful,multichannel data capture and acquisition system.PLANNINGTIPTiger PMCs can be configured to log in an endless loop,overwriting the oldest data first and utilizing the maximumamount of memory available. Similar to the BlackBox on an aircraft, the data can be downloaded for analysisafter a problem event occurs.PLANNINGTIPDECISION<strong>Data</strong> logging can be combined with an Ethernet converterto provide an individual Web Page with data thatcan be accessed by a browser over the internet.Real-time ClockThe Tiger meter has an optional real-time clock with a 15year lithium battery backup, ensuring that time informationis not lost in the event of a power failure. It can be configuredin 12 or 24-hour modes for printing and data logging applications.PLANNINGTIPDECISIONOther applications of the real-time clock include activatinga setpoint or control action at fixed times of the hour,day, week, month or year.Flash Card Memory ModuleFor long term data logging, a FlashCard Memory Module that plugs into the carrier board output socket isavailable. Flash Cards are available from4 to 128 meg. They can be removed andread by a standard card reader, or thedata can be downloaded through the serial port or over theinternet with an Ethernet converter. The module also has anSSR setpoint output to trigger an external event.Configuration and Programming witha PCDECISIONWith a serial output module installed, Tiger 320 PMCs aremost easily configured using the Tiger 320 ConfigurationUtility, which can be downloaded free from the web andrun on any Windows-based PC. The utility also enables theuser to access some special capabilities of the Tiger 320 whichcannot be programmed manually by the front panel buttons.Code BlankingCheck only thecodes you wantto seeDisplay Text EditingEdit display text tosuit your applicationPLANNINGTIPDevelopment SoftwareDECISIONCustom Macro ProgrammingThis powerful, easy to use development system enablesprograms to be written in BASIC, utilizing any combinationof the hundreds of functions and thousands of registersembedded in the Tiger 320 Operating System. When yourBasic program is compiled into the Tiger 320 Macro-languageit is error checked and optimized. There are also numerous offthe-shelfapplication specific programs available. Many onlyneed the blanks to be filled in to use them and do not requireany knowledge of BASIC programming.PLANNINGTIPMacros are useful when implementing any specializedcontrol system that cannot be achieved by the standardconfiguration capability of the Tiger 320 OperatingSystem. Using the development software, functions can bealtered or added in a standard meter to perform the requiredjob. This may typically include logic sequencing functions andmathematical functions.PLANNINGTIPDeveloping a Macro is much easier and quicker thanprogramming a PLC, because the basic code requiredto customize the Tiger meter is considerably less thanthe ladder logic programming required for PLCs. This is due tothe hundreds of functions built into the Tiger meter that can bemanipulated or invoked by a macro, to fulfill the requirementsof almost any application.Scrollingannunciatormessagescan be programmedPLANNINGTIPThe Configuration Utility requires that an RS-232 interfaceboard be installed in a Tiger 320 for programming.However, if the final application does not require a serialoutput, the RS-232 board can be easily removed, after programmingis completed, and kept for future use.PLANNINGTIPWhen a Tiger 320 is to be used in a custom application,the utility enables all or any of the front panel programmingfunctions to be disabled (code blanking).Customized descriptive text can also be entered to appear withany setpoint action or event.PLANNINGTIPDifferent configurations can be stored in a PC for fastdownloading into a meter by the user. Custom configurationscan also be issued a serial number and preloadedat the factory.Macro in thewriting stageto appear with any setpoint activation, selected events or logicinputs. Easy to read, plain text prompts can be programmed toreplace the manual programming codes and provide a userfriendlyinterface for any custom application.F1PF2Page 8Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.com21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300)

Block Diagram of the Tiger 320 Software and Hardware StructureP and UP Buttonsto enter setupmenu.PROGRAM LOCKIf Program lock is ON values aredisplayed, but cannot be changedSERIAL COMMUNICATIONRead and write into all registersCALP and DOWNButtons to entersetpoint menu.VIEW MODEto viewselectedfunction valuesRESETwith UP/DOWNPeak, Valley,Tare, TotalizersON DEMAND CALFUNCTIONSHold down thePROGRAMbutton for 4 secsto initiate Autotare, AutoCalibration,Manual Loader orInput ChannelCompensationProgPROGRAMBUTTONMACRO_PROCESSING<strong>Inc</strong>ludingE<strong>DI</strong>T MACROF1_BUTTONMACRO_PROCESSINGF2_BUTTONMACRO_PROCESSINGF3_BUTTONMACRO_PROCESSINGF1 F2 F3FLASHRegisters 5120 to 614416 bit unsigned. May beaccessed by macros orSerial Port.SETPOINT LOCKIf Program lock is ON values aredisplayed, but cannot be changed6144 REGISTERSRegisters are comprised of 8, 16 or32 bit signed, unsigned or floatingpoint registers, implemented in eitherFlash RAM, RAM, FeRAM, EEPROMor NVRAM (Real time clock option).See the Register Supplement fordetailed information on ALL registersAll registers may be accessed, andread or written to via the serial port,and by user developed macros.The registers used for the operatingsystem should not be written into, asmodification of their data may renderthe meter inoperative.Registers 1 to 244Registers from 1 to 244 may be selectedmanually as a data source for setpointor output processing. However onlythose registers shown below containdata applicable for use as data source.Setpoints6 to 11- SP1,2,3,4,5,6 value65 to 70- SP1,2,3,4,5,6 Hysteresis,71 to 76- delay on make SP1,2,3,4,5,677 to 82- delay on break SP1,2,3,4,5,6Input Channels18,19,20,41,42- Raw Result,CH1,2,3,421 to 23,43,44- Scaled Result,CH1,2,3,445,46- Prescaler CH1,2Smart modules54 to 60- Smart Output 1,2,3,4,5,6,7Analog Outputs83, 84 - Analog Output 1 & 2Variables (Used with Macro Only)85 to 94 - Variable 1 to Variable 10Timers95 & 96 - Timer 1, 2Real time Clock213 to 219 - Real Time ClockAuto Zero Offset227 to 231 - Auto Zero Offset for Result,CH1, CH2, CH3 & CH4Operating SystemNOT USABLE as a data source.15,38,47,48,52,53,61-64,123-128,140,141,160,161,234-244Registers 257 to 512Linearization24 bit registers in EEPROM that storethe four 32 point LIN tables.Registers 513 to 1124Multi function, multi type Registersthat may only be accessed throughthe serial port or by macros. Theirfunctions are detailed in the RegisterSupplement.Registers 1125 to 2048OPERATING SYSTEM USE ONLYDO NOT write to these registers, asany alteration to their data may makethe meter inoperative.Registers 2049 to 4096Macro Code Storage16 bit unsigned. In Flash RAMRegisters 4097 to 5120OPERATING SYSTEM USE ONLYDO NOT write to these registers, asany alteration to their data may makethe meter inoperative.<strong>DI</strong>SPLAY FORMATTINGI 2 CBUS<strong>DI</strong>SPLAY DRIVECode1BRIGHTNESS, ANNUNCIATORS, TRENDCUSTOM TEXT FOR CH1, 2, 3, 4, RESULT, PEAK, VALLEY,TOTALIZER 1, TOTALIZER 2, SP1, SP2, SP3, SP4, SP5, SP6SCALE, OFFSET FOR CH1, 2, 3, 4 AND RESULTLOG BARGRAPH <strong>DI</strong>SPLAY, dB <strong>DI</strong>SPLAY, OCTAL.DECIMALS, , RIGHT HAND CHARACTER, AND ROUN<strong>DI</strong>NGFOR CH1, 2, 3, 4, RESULT AND DEFAULT <strong>DI</strong>SPLAYDEFAULT<strong>DI</strong>SPLAYCHANNEL D R 1 2 3 4Select data source forOUTPUT PROCESSINGSelect data source for: Setpoint 1, 2, 3, 4, 5, 6;Analog output 1, 2; <strong>Data</strong> loggingSelect from R, 1, 2, 3, 4, Totalizer 1, 2, Peak,Valley, Tare or any usable registers from 1 to 244DEFAULT<strong>DI</strong>SPLAYCHANNEL DRESULTCHANNEL RResult of CrossChannel Math RCross Channel Math1+2, 1-2, 1x2, 1/2, 1=R1 2RAW DATAPrescalerChannel 1 & 2LOGIC I/OFROMMODULESR11CHANNELS 1 22 3 4Select data source forCode1<strong>DI</strong>SPLAY PROCESSINGSelect data source for:Display 1 (Default Display Channel D), Display 2,Display 3, Peak, Valley, Totalizer 1, Totalizer 2,Select from R, 1, 2, 3, 4, Totalizer 1, 2, Peak,Valley, Tare or any usable registers from 1 to 2442 3 4RESULT PROCESSINGof Cross Channel MathAVERAGING, CALIBRATION (SCALE & OFFSET),INVERSE of R, LOG OF R (Bargraph display only)LINEARIZING of R,SMART AUTO ZERO,SQUARE ROOT of R,3 4<strong>DI</strong>GITAL PROCESSINGAVERAGING,CALIBRATION (SCALE and OFFSET),INVERSE OF INPUT, LINEARIZATION,LOG OF INPUT (Bargraph display only)RTD, SAMPLE RATE, SMART AUTO ZERO,SQUARE ROOT, THERMOCOUPLESCHANNELS 1 2 3 417 BIT ON BOARDDUAL SLOPE A to DREF INSPC_1 to 6Code7CALCode2Code4Code5Code6CALANALOG, <strong>DI</strong>GITALAND LOGIC I/OASCII, MODBUS, DEVICENETMeter TO Meter Communication,ETHERNET (TCP/IP), Epson CompatibleSerial Printer DriverDATA LOGGING Code8Manual or auto, Up to 4000samples, Date and Timestamp, endless loop record,Burst downloadingSETPOINTS SPC_1 to 6Up to 6 relay, SSR,TTL or open collector.PID, deviation, trigger, pulse,tracking, hysteresis, latching,timer modes, reset,High/low/deviation activationPLUG IN OPTO-ISOLATE<strong>DI</strong>/O 6 IN 6 OUT OR 6 IN 16 OUTANALOG OUTPUTVoltage or current,single or dualMACRO PROCESSINGA macro can access all functions and readand write into all registers. Macro Timer1,Macro Timer2 have 0.1 second resolution.Macros allow a user to customize the meterfor a specific application using the Tiger 320Development system.Macros may be locked to prevent access byanyone.LinearizingCAL4 Tables of 32 Points eachor 1 Table of 125 PointsTOTALIZER 1CALTOTALIZER 2Two independent totalizersOptional Real-time clockwith date and time stampCALCALInternal System ClockDownloads from Real Time Clockor starts from 12:00 on power up.Can be displayed on CH3, CH4RESIDENT TIMER 1 Code5RESIDENT TIMER 2 Code6Runs ONLY if selected on CH3,or CH4. Resolution 1 secRear PinsCode9Hold, Test, Lock & Capture.The Lock, Hold and Capturepins can be reprogrammedfor use as Digital Logic I/O pins.SP1SP2SP3SP4SP5SP6I 2 CI 2 CMICROSigma DeltaA to D16 to 24 BitREFREFSigConMICROREFSigConPULSEMUXREFSignalConditioningREFREFSignalConditioningSSRSSRSignalConditioningSSR SSRSignalConditioningZEROSPANSMART MODULES WITH MULTICHANNEL INPUTS,AN ON-BOARD A TO D CONVERTER,MICROPROCESSOR, AND TWOSOLID STATE RELAY OUTPUTSSMART MODULES WITH AN ON BOARDMICROPROCESSOR AND TWO SOLID STATERELAY OUTPUTS WITH PULSE, OR QUADRATUREENCODER INPUTS FOR COUNTING, FREQUENCY OR POSITIONMULTI-INPUT MODULESW/<strong>DI</strong>GITAL SCALINGSINGLE INPUT MODULESWITH ANALOG SCALING12-30-02 4:00 PM21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300) Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.comPage 9

Configuration Utility ProgramThe Easiest and Fastest Way to Configure the Tiger 320 is to Usea PC with the Free Downloadable Configuration Utility ProgramThe diagrams and instructions provided in this data sheet/ user manual are intended to enable the Tiger meter to beconfigured and programmed manually using the frontpanel buttons. A system of Programming Codes isrequired to facilitate this type of manual programming andthese are explained in detail with diagrams and examples.However, when the Tiger meter is configured and programmedvia the optional RS-232 serial port and a PC using theConfiguration Utility, the system of Programming Codes isbypassed. The Configuration Utility enables all the programmingoptions to be clearly identified by their functions for directon-screen selection. The Configuration Utility requires that anRS-232 interface board be installed in a Tiger 320 for programming.However, if the final application does not require a serialoutput, the RS-232 board can be easily removed, after programmingis completed, and kept for future use.The Configuration Utility Program (which may be freely downloadedfrom the web) is designed to simplify and speed up theconfiguration and programming of any Tiger 320. Pull downmenus facilitate the selection of different options and theassignment of values. A “Help” explanation is provided just byholding the cursor over any function box.The configuration utility enables the user to accesssome special capabilities of the Tiger 320 which cannotbe selected manually by the front panel buttons.Source ForDisplayOFFPrimary DisplayResultChannel 1Channel 2Channel 3Channel 4Totalisator 1Totalisator 2PeakValleyTareSetpoint 1Setpoint 2Setpoint 3Setpoint 4Setpoint 5PID 1PID 2RegisterSource ForPeak and ValleyOFFPrimary DisplayResultChannel 1Channel 2Channel 3Channel 4Totalisator 1Totalisator 2PeakValleyTareSetpoint 1Setpoint 2Setpoint 3Setpoint 4Setpoint 5PID 1PID 2RegisterAnnunciatorsAnnunciators On - Relay ONAnnunciators On - Relay OFFAnnunciators OFFAnnunciators show tendencyCode BlankingCode BlankingCheck only the codesyou want to seeDisplay ModeNormal Display ModeManual Display ModeFast Display ModeDecimals andDisplay FormatNo decimal pointX.XX.XXX.XXXX.XXXXX.XXXXXExternal decimal point12 Hour Clock24 Hour ClockHrs : Mins : SecsDays : Hrs : MinsOctalDisplay Text EditingEdit display text tosuit your applicationLast Digit RightRounding HandNoneSide2 x5 xCharacter10 xWhen a custom configuration is created for any specializedapplication, the Tiger 320 can be programmed to blank out anddisable all or any manual programming codes that you do notwish the user to be able to view or access by de-selecting themin the appropriate check box.Display Text EditingThe meter can be programmed to display customized text toappear for any setpoint or event to suit any application requirements.Easy Installation of Linearization TablesThe configuration utility facilitates the storage and downloadingof complex linearization tables. Tables can be created in anymathematical or spreadsheet program, and copied into the utility.Linearization tables can be created to precisely match aparticular sensor so that they can be installed and downloadedas part of an annual calibration procedure.Source ForSetpoints 1-6OFFPrimary DisplayResultChannel 1Channel 2Channel 3Channel 4Totalisator 1Totalisator 2 Latching ForPeakValleySetpoints 1-6TareNoneSetpoint 1Latch ONSetpoint 2Latch OFFSetpoint 3Setpoint 4Setpoint 5 Activation ForSetpoint 6 Setpoints 1-6PID 1PID 2AboveLock PinBelowHold PinCapture Pin Mode ForDigital Input 1Setpoints 1-6Digital Input 2Digital Input 3OFFRegisterHysteresisDeviationPIDDestinationOFFDisplayTimer ForResultSetpoints 1-6Channel 1OFFChannel 2NormalChannel 3One ShotChannel 4PulseTotalisator 1RepeatTotalisator 2PeakValleyTareSetpoint 1 Reset ModeSetpoint 2Reset ValueSetpoint 3ConstantSetpoint 4Input-SP+Const.Setpoint 5Dest.+Const.Setpoint 6DisplayPID 1ResultPID 2Channel 1Register:Channel 2Channel 3Channel 4Totalisator 1Totalisator 2PeakValleyTarePID 1PID 2Register:OFFReset ValueEasy Setpoint ConfigurationThe Tiger 320 supports an incredible range of setpoint optionsand functions. The utility makes is quick and easy to select anddownload any combination you may require.Configuration <strong>Data</strong> Copying and LoadingThe configuration utility program allows you to store a recordof a meter’s configuration for later referral, or for the restorationof a desired configuration. Macros can be combined with aconfiguration file so they can be downloaded together andlocked at the same time. When a file is locked after downloading,it cannot be copied. It can only be erased and reloadedfrom a master file.Also included is the ability for the user to make notes about theconfiguration that can be stored as part of the file.Page 10Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.com21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300)

SP1 SP2 SP3 SP4 SP5 SP6Custom Macro ProgrammingNever Before has the Customization of such a Powerful Measurement,Control and Automation Product been Made so Fast, Free and EasyThe Tiger 320 Macro Development System is sopower packed and feature rich that you canbuild a completely custom designed controllerin 1/50th of the time it would take to program amicroprocessor or a PC, and 1/20th of the timeit can take to program a PLC.Quickly convert any special metering or controland automation idea into your own proprietaryproduct, CE approved and ready to ship indays, with custom multicolor faceplates, labels,shipping boxes and instruction manuals.This powerful, easy to use Development System can be downloadedfree from the web. It enables programs to be written inBASIC, which can utilize any combination of the hundreds offunctions and thousands of registers embedded in the Tiger320 Operating System.When your BASIC program is compiled into the Tiger 320Macro-language it is error checked and optimized. When yourMacro is downloaded into a Tiger 320 and locked, it is lockedforever. It cannot be read or duplicated, it can only be erased.There is no back-door access. A Tiger 320 running your Macrowill remain your exclusive proprietary product.There is also a growing library of off-the-shelf application specificmacro programs available. Many only need the blanks tobe filled in to use them and this does not require any knowledgeof BASIC. The source code is provided with these programs sothey can easily be customized and/or integrated into any proprietaryapplication-specific Macro.On request, any custom Macro can be issued a serial numberand pre-installed at the factory to operate on power-up.Tiger Development System screen showing Macro being written.Double clicking onregister label in theleft hand side frameautomatically inserts the function inthe code window at the cursor insertionpoint.Tiger Development System screen showing the Macro codebeing compiled successfully.F1PF2Scrolling annunciator messages can be programmed to appearwith any setpoint activation, selected events or logic inputs.Easy to read, plain text prompts can be programmed to replacethe manual programming codes and provide a user-friendlyinterface for any custom application.Tiger Development System - Code Writing ScreenRegister LabelsCode Writing AreaTiger Development System screen showing the compiledMacro being downloaded into a Tiger 320 Series PMC.21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300) Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.comPage 11

Index32-Bit Operating System ....................................................4Analog Output / Analog Retransmission ..........................21-22Calibration of Analog Output............................................21Dual (0-10V) Analog Output ............................................21Location of Analog Output Module ..................................47Pinout of Analog Output ..................................................46Scaling of Analog Output ................................................21, 22Select Source for Analog Output ....................................21Auto Zero Maintenance for Weighing Applications..........22Set Parameters for CH1, CH2, CH3 & CH4 ....................21Averaging - Digital Filtering................................................22Set Parameters for CH1, CH2, CH3 & CH4 ....................21Block Diagram of Software & Hardware............................9Brightness Display ..............................................................20Calibration ............................................................................21-24Calibration Thermocouple or RTD ..................................21Manual Calibration ..........................................................23Single-Point Calibration....................................................23Two-Point Calibration ......................................................23Case Dimensions ................................................................60Modular Construction ......................................................47Other Case Sizes ............................................................3, 4Channel 1 Settings ..............................................................31-3232 Point Linearization ......................................................32Analog Input Signal Sample Rate....................................31Counter/Resident Timer/Clock ........................................31Measurement Task ..........................................................31Post Processing ..............................................................32Print Mode........................................................................32Sampling Rate ................................................................31Serial Mode......................................................................32Smart Input Module ........................................................31Channel 2 Settings ..............................................................33Channel 3 Settings ..............................................................34Channel 4 Settings ..............................................................35Channel 1 & Channel 2 Results Processing32 Point Linearization ......................................................36Maths Functions ..............................................................36Code 1 - Display Configuration ..........................................25-30Configure <strong>Data</strong> Source Procedure ..................................27Configure Display Format Mode Procedure ....................28Configure Last Digit Text Char. Procedure ......................29Configure Setpoint Annunciators Procedure ..................30Configure Update at Sample Rate Procedure ................30<strong>Data</strong> Source - 2nd Digit [X5X] ........................................25Display Format - 2nd Digit [X6X] ....................................25Display Functions Mode ..................................................25Manual Loader Mode ......................................................25Setpoint Annunciators Mode............................................25Text Character - 2nd Digit [X7X] ......................................25Update Display at Selected Sample Rate........................25Code 2 - Channel 1 Measurement Taskand Sampling Rate ........................................................31Code 3 - Channel 1 Post Processingand Serial Mode Functions ..........................................32Code 4 - Channel 2 Measurement Taskand Sampling Rate ........................................................33Code 5 - Channel 3 Functions............................................34Code 6 - Channel 4 Functions............................................35Code 7 - Result Processing ................................................36Code 8 - <strong>Data</strong> Logging & Print Mode ................................37Code 9 - Functions for Digital Input Pins..........................37Code Blanking......................................................................19-20Clock/TimerConfiguration....................................................................31, 34, 35Optional Real-time Clock ................................................4Real-time Clock Configuration ........................................31, 34, 35Real-time Clock Date ......................................................37Time Stamp......................................................................37Component Layout & External Devices ............................47-48Modular Construction ......................................................47Component Layout ..........................................................48Configuration and Programming from a PC ....................4, 8Configuration Utility ProgramCode Blanking and Display Text Editing ..........................10Configuration <strong>Data</strong> Copying ............................................10Installation of Linearization Tables ..................................10Setpoint Configuration ....................................................10ConnectionsCarrier Board Output Pinouts ..........................................46Connector Pinouts ..........................................................45DeviceNet ........................................................................46External Devices ..............................................................48Ordering Information, Connectors ..................................58Rear Panel Pinout Diagram ............................................45Controls & Indicators ..........................................................14-15Annunciator LEDs ............................................................14Down Button ....................................................................14Error Message ................................................................15LED Display ....................................................................14Program Button................................................................14Program Lockout Switch ..................................................15Scrolling Display Text Messaging ....................................14Setpoint Lockout Switch ..................................................15Seven Segment LED Displays ........................................14Up Button ........................................................................14Control Outputs ..................................................................6-7Electromechanical Relaysor Solid State Control Outputs ........................................6I/O Logic, Rear Panel or Breakout Box............................7PID or ON/OFF Control ..................................................7Retransmission 0-10V or 4-20mA....................................7Custom Macro ProgrammingMacro Compiling and Loading ........................................11<strong>Data</strong> Logging........................................................................4, 8, 37Downloading Logged <strong>Data</strong> from Meter ............................37Flash Card Memory Module ............................................8Printing Logged <strong>Data</strong> ......................................................37Real-time Clock................................................................8, 37Development SoftwareWhen to Use Macros ......................................................8DeviceNet..............................................................................8, 46Digital Input Pins ................................................................37Display Brightness Setting ................................................20Display Functions................................................................25-30<strong>Data</strong> Source ....................................................................27Display Format and Decimals..........................................28Display Rounding ............................................................28Last Digit Text Character..................................................29Other Display Formats ....................................................4Setpoint Annunciator Mode..............................................30Update at Sample Rate ..................................................30Page 12Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.com21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300)

IndexDisplay OptionsLED or LCD Displays ......................................................6Numeric or Alphanumeric Displays..................................6Push Button or Membrane Touch Pads ..........................6Remote Display................................................................6Single or Multiple Displays ..............................................6FaceplatesCustom Faceplates ..........................................................59Optional Caption <strong>Sheet</strong>s..................................................59Custom Faceplate Design Template ................................59FilteringSee Averaging Samples & Averaging WindowFront Panel Controls ..........................................................4, 14-15Front Panel Programming Codes ......................................17-18Main Programming Mode ................................................17On Demand Modes..........................................................18Setpoint Programming Mode ..........................................17View Modes ....................................................................18Functional Diagram ............................................................45General Features ................................................................1HMI Touch Panel Graphic Displays ....................................7Hysteresis and Deviation ....................................................39-40, 42Initial Setup Procedures......................................................19-20Code Blanking and Macro Check ....................................19-20Model and Software Code Version Check ......................19Input Signal Conditioning Modules ..................................5, 49-55Input Module Component Glossary ................................55Input Module Index ..........................................................49Input Modules ..................................................................50-54Modular Position ..............................................................47Ordering Information, Input Modules ..............................56-57Input Signals & Sensors4-20mA or Sensor Direct ................................................6Sensor Linearization or Compensation............................6I/Os (Opto Isolated & Logic Ports) ....................................5, 48LinearizationChannel 1 Temperature Sensors ....................................31Channel 1 User Loaded Tables........................................32Channel 2 Temperature Sensorsand User Loaded Tables ..................................................33Channel 3 Temperature Sensorsand User Loaded Tables ..................................................34Channel 4 Temperature Sensorsand User Loaded Tables ..................................................35Result of CH1 & CH2 User Loaded Tables......................36Table Settings ..................................................................22, 36Literature OverviewModel Specific <strong>Data</strong> <strong>Sheet</strong>s / User Manuals ..................3Other Tiger 320 Series Related Software........................3Programming Code <strong>Sheet</strong> ..............................................3Supplements to <strong>Data</strong> <strong>Sheet</strong>s / User Manuals..................3Macros ..................................................................................4, 8, 11Macro Check....................................................................19-20Manual Loader ....................................................................25Maths FunctionCross Channel Maths ......................................................9, 36Result Processing ............................................................36Modbus ................................................................................7, 22Model Type Check................................................................19On Demand Functions ........................................................21Ordering Information ..........................................................56-58Panel Cutout ........................................................................60PID Control Settings............................................................39, 42Power Supply ......................................................................5, 45PrescalingChannel 1 ........................................................................31Channel 2 ........................................................................33Print Mode ............................................................................7, 32Programming Codes............................................................17-18Programming Conventions ................................................16Programming via PC ..........................................................4, 10-11RegistersRegisters That Can Be Selected ....................................44Registers That Should Not Be Selected ..........................44Resetting and <strong>Inc</strong>rementing Using Setpoints ..................44Relay & Logic Output Modules ..........................................46Serial Communication ........................................................5, 7-8ASCII................................................................................7Configuration....................................................................32DeviceNet ........................................................................8Ethernet ..........................................................................7Master Mode ....................................................................7Modbus ............................................................................7Pinouts ............................................................................46Print Mode........................................................................7RS-232 or RS-485 ..........................................................7Setpoint Programming Mode..............................................38-43<strong>Data</strong> Logging....................................................................39<strong>Data</strong> Printing to PC ..........................................................39<strong>Data</strong> Printing to Serial Printer ..........................................39Display Flashing ..............................................................39Hysteresis or Deviation ....................................................39-40, 42Level 1 - Basic Mode - Prog. Procedures ........................41PID Control Settings ........................................................39, 42Real-time Clock Option ....................................................39Real Time Control Modes ................................................40Relay Energize Functions ................................................39Relay Output Modules ....................................................38Setpoint & Relay Control Settings ..................................38, 42Setpoint Activation Source ..............................................39Setpoint Activation Values................................................38Setpoint Latching ............................................................39Setpoint Reset & Trigger ..................................................39, 43Setpoint Tracking..............................................................39Timer Modes ....................................................................39, 43Smart Input ModulesSetting Up ........................................................................31SupplementsSee Literature OverviewTable of Contents ................................................................1Timers ..................................................................................5, 39Configuration....................................................................31, 34, 35Delay Settings..................................................................43Modes ..............................................................................40TotalizersSetting..............................................................................21-2221 June, 2004 <strong>DI</strong>-50 320 Series (NZ300) Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.comPage 13

Controls and IndicatorsFront Panel Controls and IndicatorsProg. SP1 SP2 SP3 SP4 SP5 SP6PROGRAMButtonPLED Annunciatorsfor Setpoints 1- 6Display with Faceplate and BezelOptional Membrane Touch Pad FaceplateP.N.: 76-<strong>DI</strong><strong>50E</strong>G-N4 for green display & 76-<strong>DI</strong><strong>50E</strong>R-N4 for red displayUPButtonDOWNButtonOnce into the viewing routine, pressing the button movesthrough each displayed parameter.See Display with Faceplate and Bezel diagram.Annunciator LEDsThe annunciator LEDs can be programmed to indicate thealarm status.Setpoint 1 can be configured to indicate the rising signaltrend. Setpoint 2 can be configured to indicate the falling signaltrend. They are labeled from left to right: SP1, SP2, SP3,SP4, SP5, SP6.See Display with Faceplate and Bezel diagram.Seven Segment LED DisplaysThe six, seven segment LED displays are used to display themeter input signal readings.They also display the programming codes and settings duringprogramming. The display is available in red, green, or superbright red LEDs.UPButtonSeven SegmentLED DisplayON1 2PROGRAMLOCKOUTSwitchSETPOINTLOCKOUTSwitchProgPROGRAMButtonSP1 SP2 SP3 SP4 SP5 SP6PLED Annunciatorsfor Setpoints 1-6Display with Faceplate and BezelProgram ButtonDOWNButtonWhile programming, pressing the P button saves the currentprogramming settings and moves to the next programmingstep.You can move through the programming codes using the programbutton. The codes you pass are not affected, unless youstop and make changes using the or buttons.Pressing the P and button at the same time initiates themain programming mode. To save a new configuration settingand return to the operational display, press the P buttononce and then press the P and button at thesame time.Pressing the P and button at the same time initiates thesetpoint programming mode. To save a new configurationsetting and return to the operational display, press the P buttononce and then press the P and button at thesame time.See Display with Faceplate and Bezel diagram.Up ButtonWhen setting a displayed parameter during programming,press the button to increase the value of the displayedparameter.When in the operational display, pressing the button initiatesa viewing mode that allows you to view the readings onchannels 1 and 3, setpoints 1, 3, and 5, peak, and total 1.Once into the viewing routine, pressing the button movesthrough each displayed parameter.See Display with Faceplate and Bezel diagram.Down ButtonWhen setting a displayed parameter during programming,press the button to decrease the value of the displayedparameter.When in the operational display, pressing the button initiatesa viewing mode that allows you to view the readings onchannels 2 and 4, setpoints 2, 4, and 6, valley, and total 2.Display PCB without Faceplate and BezelLED DisplayThe meter has a 5-digit, 7-segment, 0.56” (14.2 mm) standardred, or optional green or superbright red LED numeric display.The LED displays are used to display the meter input signalreadings. They also display the programming codes and settingsduring meter programming.Display Text Editing with 7 SegmentAlphanumeric Display CharactersDisplay text, such as setpoints, can be easily edited to suit yourapplication, by connecting the meter to a PC running the freedownloadable Configuration Utility program.For Example:Instead of [SP_1]Prog. SP1 SP2 SP3 SP4 SP5 SP6could be used forTANK LOWORInstead of [SP_2]Prog. SP1 SP2 SP3 SP4 SP5 SP6could be used forBRAKE OFFScrolling Display Text MessagingScrolling display text messaging can be configured to run witha simple macro.Prog. SP1 SP2 SP3 SP4 SP5 SP6Display Text CharactersThe following text characters are used with the 7-segment display.7-SEGMENT <strong>DI</strong>SPLAY CHARACTERSPage 14Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.com21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300)

Controls and Indicators continuedProgram Lockout SwitchWhen the PROGRAM LOCKOUT switch is set to position 2, allprogrammable meter functions can be changed.When set to the ON position, the PROGRAM LOCKOUTswitch prevents any programming changes being made to themeter. If programming is attempted, the meter displays 'LOC'.The ON position allows programming parameters to be viewedbut not changed.See Display without Faceplate and Bezel diagram.Setpoint Lockout SwitchWhen the SETPOINT LOCKOUT switch is set to position 1, thesetpoints can be programmed. Once the setpoint values havebeen entered and the SETPOINT LOCKOUT switch set to theON position, the setpoints can be viewed but not changed.See Display without Faceplate and Bezel diagram.Error Message [Err]Error messages usuallyoccur during calibration procedures.The three mostlikely causes of an errormessage are:Prog. SP1 SP2 SP3 SP4 SP5 SP6Display Showing [Err] Message1) The full scale and zero signals were too similar.Note, the high input (full scale) signal must be at least 1000counts greater than the low input (zero) signal (positive andnegative values are allowed).2) The scaling requirement exceeded the capability of themeter (–199999 to +999999).3) No input signal present, or incorrect connections.The LOCK pin can also be configured in Code 9 to carry outthe following functions (see Front Panel Programming Codeson Page 17):• Reset channel 1 [XX1].• Reset channel 2 [XX2].• Reset channel 3 [XX3].• Reset channel 4 [XX4].• Reset tare [XX5].• Reset total 1 [XX6].• Unlatch (de-energize) all setpoints [XX7].Hold PinConfigure Code 9 to [X0X]. When the HOLD pin (pin 9) is connectedto the COMMON pin (11) the displayed reading isfrozen. However, A/D conversions and all control functionscontinue and as soon as pin 9 is disconnected from pin 11 bythe switch, the updated reading is instantly displayed.The HOLD pin can also be configured in Code 9 to carry outthe following functions (see Front Panel Programming Codeson Page 17):• Reset channel 1 [X1X].• Reset total 1 and total 2 [X2X].• Reset total 2 [X3X].• Reset peak and valley [X4X].• Reset tare [X5X].• Set tare [X6X].• Unlatch (de-energize) all setpoints [X7X].Rear Panel External Switched InputsRelay Outputs32 31 30 29 28 27 26 25 18 17 16Input Module(See I-Series Input ModuleGuide for Connection Details)1 2 3 4 5 6LOCKLock PinBy configuring Coe 9 to [XX0],connecting the LOCK pin (pin8 on the main PCB) to theCOMMON pin (pin 11 on themain PCB), both the main andsetpoint programming modesare locked out. All meter programmingcodes and setpointscan be viewed but notchanged.HOLDSerial Output24 23 22 21 20 19 Analog OutputFunction PinsDual AnalogOutput ONLY8 9 10 11 12LOCK HOLD TEST COM CAPTURERear PanelTESTCOMMONAC/DC POWER14 15CAPTUREProg. SP1 SP2 SP3 SP4 SP5 SP6Display Showing [LocK] MessageThe main programming mode can be entered, but only the brightnesssetting adjusted. After adjusting the brightness setting, pressingthe P button displays [LocK].Test PinConfigure Code 9 to [0XX]. When the TEST pin (pin 10) is connectedbriefly to the COMMON pin (pin 11) all segments of the displayand setpoint annunciators light up. Five eights and five decimalpoints (8.8.8.8.8.) are displayed for a short period. The microprocessoris also reset during this time, losing all RAM settingssuch as peak and valley, and any digital input pin settings set up inCode 9.The TEST pin can also be configured in Code 9 to carry out the following(see Front Panel Programming Codes on Page 17):• Reset counter channel 1 and total 2 at power-up [1XX].• Reset counters, CH1, CH2, CH3, CH4, total 1, and total 2 atpower-up [2XX].• Reset total 1 and total 2 at power-up [3XX].Capture PinWhen the CAPTURE pin (pin 12) is connected to the COMMONpin (pin 11), the CAPTURE pin can be programmed forsetpoint/relay activation or macro control applications in the setpointcontrol settings mode of the setpoint programming mode[SPC_X] [X2X] .Common PinTo activate the LOCK, HOLD, TEST and CAPTURE pins from therear of the meter, the respective pins have to be connected to theCOMMON pin (pin 11).21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300) Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.comPage 15

SP1 SP2 SP3 SP4 SP5 SP6Front Panel Push Button Configuration and Setup for Programming ConventionsThe meter uses a set of intuitivesoftware codes to allow maximumuser flexibility while maintaining aneasy programming process. Toconfigure the meter’s programmingcodes, the meter uses the threeright-hand side display digits.These are known as the first, second,and third digits and can beseen in the diagram opposite.To explain software programming procedures, diagrams are usedto visually describe the programming steps. The following conventionsare used throughout the range of Tiger 320 Series documentdiagrams to represent the buttons and indicators on the meter, andthe actions involved in programming the meter:Prog.SymbolOperational DisplayProg.ExplanationOperational DisplayFirstDigitSP1 SP2 SP3 SP4 SP5 SP6SecondDigitThirdDigitThis symbol represents the OPERATIONAL<strong>DI</strong>SPLAY. After the meter has been poweredup, the display settles and indicates the calibratedinput signal. This is known as the operationalmode and is generally referred to as theoperational display throughout thedocumentation.Programming procedures are graphic based with little descriptivetext.Each procedure shows a number of meter panel displays runningin procedural steps from the top to the bottom of the page.If need be, the procedure may run into two columns with the leftcolumn running down the page and continuing at the top of theright-hand column. Each action performed by the user is shown asa numbered step.Each procedural step shows the meter display as it looks before anaction is performed.The hand or hands in the procedural step indicatethe action to be performed and also how many times, or forhow long, the button is to be pressed.For example, the diagram below shows the meter in the operationaldisplay. With a left hand pressing the P button and a righthand pressing the button, the user is entering the main programmingmode. This is indicated by the next diagram displaying[bri] and [5].This is the display brightness mode and is the first submenuof the main programming mode.Step 1Pressat sametimeOperational DisplayProg. SP1 SP2 SP3 SP4 SP5 SP6Pressat sametimeAll programming modes are entered from this level.PPress2[Span][10000]This symbol represents the PROGRAM button.In a procedure, pressing the program button isalways indicated by a left hand. A number indicateshow many times it must be pressed andreleased, or for how long it must be pressedbefore releasing.Prog. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6Press4 secsOperational DisplayProg. SP1 SP2 SP3 SP4 SP5 SP6This symbol represents the UP button.Shown in a diagram, pressing the UP button isalways indicated by a right hand.This symbol represents the DOWN button.Shown in a diagram, pressing the DOWN buttonis always indicated by a right hand.Where two right hands are shown on the samediagram with the word OR between them, thisindicates that both the and buttons canbe used to adjust the display: UP for increase,DOWN for decrease.Text or numbers shown between square bracketsin a description or procedure indicate the programmingcode name of the function or the valuedisplayed on the meter display.Where a left and right hand are shown on separate buttons onthe same diagram, this indicates that the buttons must bepressed at the same time.The exceptions to this rule are when carrying out the Model andSoftware Code Version Check, or the Code Blanking and MacroCheck.Prog. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6XXProg. SP1 SP2 SP3 SP4 SP5 SP6Step 2ORPress2Prog. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6When two displays are showntogether as black on grey, thisindicates that the display is toggling(flashing) between thename of the function and thevalue or configuration setting.Where a number is not definable,the default setting [000] isshown.If an X appears in the description of a 3-digitprogramming code or in a configuration procedure,this means that any number displayedin that digit is not relevant to the functionbeing explained, or more than one choicecan be made.Page 16Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.com21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300)

Front Panel Programming CodesThe meter’s manual programming codes are divided into twomodes: the main programming mode, and the setpoint programmingmode (See diagram below).Each mode is accessible from the operational display.Main Programming ModeThe main programming mode provides access to program allmeter functions, except setpoints.Operational DisplayProgramming TipThe easiest and fastest way to configure theTiger 320 is to use a PC with the free downloadableconfiguration utility program. (see page 10)Setpoint Programming ModeThe setpoint programming mode provides access to programall setpoint and relay functions.To enter or exit the MainProgramming Mode, pressP and at the same timeMain Programming ModeProg.SP1 SP2 SP3 SP4 SP5 SP6To enter or exit the SetpointProgramming Mode, press P andat the same timeSetpoint Programming Mode[bri]P[CAL]P[Cod_1]P[Cod_2]P[Cod_3]P[Cod_4]P[Cod_5]P[Cod_6]P[Cod_7]P[Cod_8]P[Cod_9]Display BrightnessCalibration Modes for Input and OutputCode 1 – Display ConfigurationCode 2 – CH1 Measurement Task & Sampling RateCode 3 – CH1 Post Processing & Serial Mode FunctionsCode 4 – CH2 Measurement Task & Sampling RateCode 5 – CH3 FunctionsCode 6 – CH4 FunctionsCode 7 – Result ProcessingCode 8 – <strong>Data</strong> Logging & Print ModeCode 9 – Functions for Digital Input PinsProgramming TipSave Code Settings & ExitTo save a new main programmingmode configurationsetting and return tothe operational display atany point, press the Pbutton once.Then press the P andbutton at the same time toexit.Programming TipSave SP Settings & ExitTo save a new setpointconfiguration setting andreturn to the operationaldisplay at any point,press the P buttononce.Then press the P andbutton at the sametime to exit.Setpoint Activation ValuesEnter these menus to adjustSP activation values[SP_1]P[SP_2]P[SP_3]P[SP_4]P[SP_5]P[SP_6][SPC_1]Setpoint 1Setpoint 2Setpoint 3Setpoint 4Setpoint 5Setpoint 6Setpoint & Relay Control Function SettingsPEnter these menus to configureSP control values[SPC_2]P[SPC_3]P[SPC_4]P[SPC_5]PSetpoint 1Setpoint 2Setpoint 3Setpoint 4Setpoint 5The Setpoint andRelay ControlSettings diagramon Pages 42 and43 shows thethree digit configurationsettingsthat are appliedindividually toeach setpoint.See Page 41 for anexample procedureto configure asetpoint for simplerelay functions.P[SPC_6]Setpoint 6[Cod10]PCode 10 – Bargraph SetupCode 10 applies to Tiger 320 Series meters with bargraph displaysonly. See user manuals for <strong>DI</strong>-50B51, FI-B101D50, andGI-50B101.POperational DisplayProg.SP1 SP2 SP3 SP4 SP5 SP621 June, 2004 <strong>DI</strong>-50 320 Series (NZ300) Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.comPage 17

Front Panel Programming Codes continuedView ModesWhile in the operational display, pressing the button allowsyou to view but not change the following parameters:• Channel 1.• Channel 3.• Setpoint 1.• Setpoint 3.• Setpoint 5.• Peak (of CH1).• Total 1 (total of CH1).While in the operational display, pressing the button allowsyou to view but not change the following parameters:• Channel 2.• Channel 4.• Setpoint 2.• Setpoint 4.• Setpoint 6.• Valley (of CH1).• Total 2 (total of CH2).On Demand ModesThe meter can be programmed to activate the following functionson demand by pressing the P button for 4 seconds:• Tare.• Single-point calibration.• Two-point calibration.• Primary input compensation.• Manual loader (manual offset).• Print.The on demand function is selected in the calibration mode.Press4 secsOperational DisplayProg.SP1 SP2 SP3 SP4 SP5 SP6On Demand ModesAfter configuring an ondemand function in theCalibration On DemandMode, press the P button for4 seconds to activate one ofthe following selected ondemand modes.TareOROperational DisplayOperational DisplaySingle-point calibrationORProg.SP1 SP2 SP3 SP4 SP5 SP6To view, pressthe button:View ModeCH1Press1Prog.SP1 SP2 SP3 SP4 SP5 SP6To view, pressthe button:View ModeCH2Press1Two-point calibrationORPrimary input compensationORManual loader (manual offset)CH3CH4ORPrintSP_1SP_2PSP_3SP_4Operational DisplaySP_5SP_6Prog.SP1 SP2 SP3 SP4 SP5 SP6PEAKVALEYTOT_1PTOT_2PFor a full breakdown of all programming codes, see theTiger 320 Series Programming Code <strong>Sheet</strong> (NZ101). Seepage 3 for more information.Operational DisplayOperational DisplayProg.SP1 SP2 SP3 SP4 SP5 SP6 Prog.SP1 SP2 SP3 SP4 SP5 SP6Page 18Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.com21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300)

Initial Setup ProceduresBefore configuring the meter, carry out the following meter configurationchecks:• Model and software code version check.• Code blanking and macro check.After powering-up the meter, check the model and softwarecode version number and note this in your user manual.Model and Software Code Version CheckThe meter model and software code version number can bechecked at any time while in the operational display using thefollowing procedure.STARART T HEREMODEL &SOFTWARE CODEVERSION CHECKStep 1Press and holdthe andbuttonsStep 2While holding bothbuttons, press the Prog.button then releaseall three buttonsbPressoncethenreleaseExampleStep 3The displays toggle threetimes. If a macro is installedand turned on, the customer IDand the macro ID scroll across thedisplay before returningto the operational display.Operational DisplayProg. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6TEXMATEProg. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6aPressandholdcReleaseafterpressingProg.ModelNumberTypicalSoftwareVersionNumberCode Blanking and Macro CheckTiger 320 Series meters have the ability to hide (blank out) all orsome programming codes, making them tamper-proof. This canonly be done using the Meter Configuration program.With code blanking turned ON, all main and setpoint codes thathave been blanked out during factory programming are hidden,preventing them from being reprogrammed. Any codes thathave not been blanked out are still visible and can be reprogrammed.Turning code blanking OFF means all meter programmingcodes are visible when you enter the programming modes andcan be reprogrammed.A macro is a set of commands that run automatically when themeter is powered up. We have a growing library of macros tosuit a wide range of standard customer applications.Macros can be installed in the meter at the factory during initialprogramming or by the customer at some later date. Macros arewritten and compiled using the BASIC Compiler program, andloaded into the meter using either the BASIC Compiler programor the Meter Configuration program.Turning the macro OFF means that the meter will not performthe automatic commands pre-programmed to run with themacro.Unless requested to blank out all or some programming codesand/or run a macro, we will program the meter in the codeblanking OFF and macro OFF (default) setting.To turn the code blanking and macro settings from ON to OFF:STARART T HERECODE BLANKING &MACRO CHECKPROCEDUREStep 1Press and holdthe andbuttonsStep 2While holding bothbuttons, press the Prog.button.bPressOperational DisplayProg. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6aPressandholdcReleaseafterpressingProg.Prog. SP1 SP2 SP3 SP4 SP5 SP6Programming TipOperational DisplayModel No: ............................................................................Software Version No: ..................................................Customer ID: ......................................................................Macro ID: ..............................................................................The Model and Software Code Versionchecking procedure can be performed atany time without interfering with other configurationsettings.Step 3Release thethe andbuttons and holdthe Prog. buttonfor approx. 1 secthen releaseStep 4ExampledPress the button to switchcode blanking OFFReleaseafter 1secNOTE: Unless otherwiserequested, the factorydefault setting is oFFProg. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6Code Blanking & MacroCheck Procedurecontinued on next page(Step 5)CodeBlankingPress121 June, 2004 <strong>DI</strong>-50 320 Series (NZ300) Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.comPage 19

Initial Setup Procedures continuedInitial [bri] - Setup Display Procedures Brightnesscontinued from Step 4Step 5Press the Prog. button.Step 6ExampleStep 7Press the Prog. button.Press1NOTE: Unless otherwiserequested, the factorydefault setting is oFFPress the button to switchthe macro OFFPress1Prog. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6MacroPress1The display brightness mode is accessed when entering themain programming mode. It allows you to adjust the brightnessof the display LEDs and setpoint annunciators without interferingwith other configuration settings. It is always available, evenwith the PROGRAM LOCK switch set to ON, or the externalLOCK pin connected to the COMMON pin, locking out the programmingmodes.The display brightness can be set between 0 and 7, with 0being dull and 7 being bright. 5 is the default setting.Example Procedure:Configure the display brightness setting to 7 (bright).STARART T HERE<strong>DI</strong>SPLAYBRIGHTNESSMODEStep 1Enter Brightness ModePressat sametimeOperational DisplayProg. SP1 SP2 SP3 SP4 SP5 SP6Pressat sametimeProg. SP1 SP2 SP3 SP4 SP5 SP6Prog. SP1 SP2 SP3 SP4 SP5 SP6Operational DisplayStep 2Adjust brightness to 7Prog. SP1 SP2 SP3 SP4 SP5 SP6ORProgramming TipCode Blanking and Macro ON/OFF settingsrevert to the meter’s original configurationsettings when the meter is poweredoff and on.Step 3Save brightness setting.Exit Brightness Mode.Return to OperationalDisplayExamplePressat sametimeProg. SP1 SP2 SP3 SP4 SP5 SP6Pressat sametimeProg. SP1 SP2 SP3 SP4 SP5 SP6Operational DisplayProgramming TipThe Display Brightness setting procedurecan be performed at any time without interferingwith other configuration settings byentering the main programming mode.Page 20Texmate, <strong>Inc</strong>. Tel. (760) 598-9899 • www.texmate.com21 June, 2004 <strong>DI</strong>-50 320 Series (NZ300)