Standard Products Catalog - Omni Metalcraft Corp.

Standard Products Catalog - Omni Metalcraft Corp. Standard Products Catalog - Omni Metalcraft Corp.

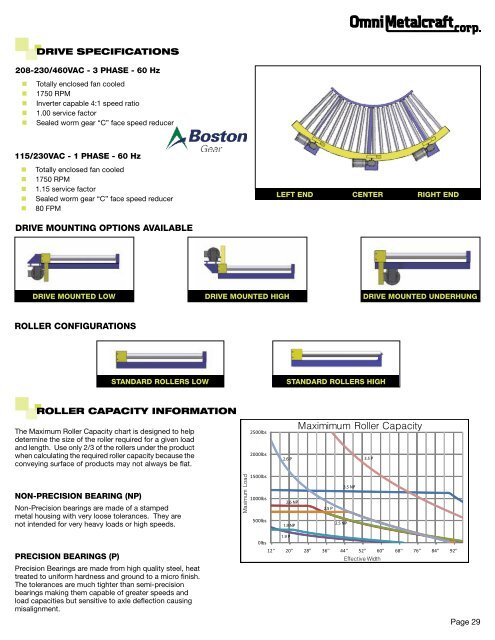

DRIVE SPECIFICATIONS208-230/460VAC - 3 Phase - 60 Hz• Totally enclosed fan cooled• 1750 RPM• Inverter capable 4:1 speed ratio• 1.00 service factor• Sealed worm gear “C” face speed reducer115/230VAC - 1 Phase - 60 hz• Totally enclosed fan cooled• 1750 RPM• 1.15 service factor• Sealed worm gear “C” face speed reducer• 80 FPMLeft end Center right endDRIVE MOUNTING OPTIONS AVAILABLEDRIVE MOUNTED LOWDRIVE MOUNTED HIGHDRIVE MOUNTED UNDERHUNGROLLEr configurationsSTANDARD ROLLERS LOWSTANDARD ROLLERS HIGHROLLER CAPACITY INFORMATIONThe Maximum Roller Capacity chart is designed to helpdetermine the size of the roller required for a given loadand length. Use only 2/3 of the rollers under the productwhen calculating the required roller capacity because theconveying surface of products may not always be flat.non-precision BEARING (NP)Non-Precision bearings are made of a stampedmetal housing with very loose tolerances. They arenot intended for very heavy loads or high speeds.precision Bearings (P)Precision Bearings are made from high quality steel, heattreated to uniform hardness and ground to a micro finish.The tolerances are much tighter than semi-precisionbearings making them capable of greater speeds andload capacities but sensitive to axle deflection causingmisalignment.Page 29

SCISSOR LIFTSSCISSOR LIFTSShop Aid Series Scissor Lifts are a versatileproduction tool. Offered in multiple capacities,these scissor lifts are constructed with qualityin mind and make ideal work stations forassembly or welding processes putting theergonomics of the worker first. Scissor Liftsalso integrate within a conveyor line whenelevation changes are needed.specifications• 2000, 4000 and 6000 lbs. load capacities• 8" lowered height• 24", 36" and 48" travel• 32", 44" and 56" raised height• 1 HP internal power unit standard• Hand pendant controller with 10’ leads• Hand-tool removable pins and bushings forease of maintenance• Guarded foot pedal, external power unitsand accordion skirting available*Expanded product parameters availableABA = Platform WidthB = Platform LengthC = Raised HeightD = Lowered HeightE = TravelCEDScissor Lift Shown in Raised PositionScissor Lift Shown in Lowered PositionLOAD CAPACITY, DIMENSIONAL SPECIFICATIONS AND OPTIONSSERIESLOADCAPACITY(lbs.)LOWEREDHEIGHT(D)TRAVEL(E)RAISEDHEIGHT(C)PLATFORM DIMENSIONS(A x B)Standard MaximumLIFTINGSPEEDSTANDARDVOLTAGE/PHASE/HzHS Series24" TravelHS Series36" TravelHS Series48" Travel2000 8" 24" 32" 30" x 50" 54" x 74" 14 sec. 115/1/604000 8" 24" 32" 30" x 50" 54" x 74" 28 sec. 115/1/606000 8" 24" 32" 30" x 50" 54" x 74" 42 sec. 115/1/602000 8" 36" 44" 30" x 54" 54" x 78" 21 sec. 115/1/604000 8" 36" 44" 30" x 54" 54" x 78" 42 sec. 115/1/606000 8" 36" 44" 30" x 54" 54" x 78" 63 sec. 115/1/602000 8" 48" 56" 30" x 66" 54" x 96" 24 sec. 115/1/604000 8" 48" 56" 30" x 66" 54" x 96" 48 sec. 115/1/606000 8" 48" 56" 30" x 66" 54" x 96" 72 sec. 115/1/60OPTIONAL ACCESSORIESFOOT PEDAL HAND PENDANT POWER UNITS LUBE MANIFOLD SKIRTINGMOBILITYPage 30

- Page 2: TABLE OF CONTENTSPages 2-7BELT CONV

- Page 8 and 9: DRIVE SPECIFICATIONS208-230/460 VAC

- Page 10 and 11: DRIVE SPECIFICATIONS208-230/460VAC

- Page 12 and 13: CURVE SPECIFICATIONS45° CURVE 60°

- Page 14 and 15: SPUR DETAILSETrunk Line BFF45°CDAN

- Page 16 and 17: ASPUR DETAILSETrunk Line BFC45°DFG

- Page 18 and 19: DRIVE SPECIFICATIONS208-230/460VAC

- Page 20 and 21: CURVE SPECIFICATIONS1 3/8" Diameter

- Page 22 and 23: SPUR DETAILS45°CDBETWEENFRAMEWIDTH

- Page 24 and 25: power supply• 24 VDC fixed output

- Page 26 and 27: MDR STRAIGHT DRIVESPECIFICATIONSpow

- Page 28 and 29: DRIVE SPECIFICATIONS208-230/460VAC

- Page 32 and 33: BALL TABLESBBall Tables are used wh

- Page 34 and 35: 2 3/8"3"2 11/32"1 3/4"1 3/4"1 3/4"S

- Page 36 and 37: ROLLER SPECIFICATIONSROLLER DIAMETE

- Page 38 and 39: ROLLER SPECIFICATIONSROLLER DIAMETE

- Page 40 and 41: CONVEYOR SPECIFICATIONSWHEEL HEIGHT

- Page 42 and 43: CONVEYOR SPECIFICATIONSWHEEL HEIGHT

- Page 44 and 45: NOTESPage 43

- Page 46: THE OPTIONSOffered in Powder Coat F

DRIVE SPECIFICATIONS208-230/460VAC - 3 Phase - 60 Hz• Totally enclosed fan cooled• 1750 RPM• Inverter capable 4:1 speed ratio• 1.00 service factor• Sealed worm gear “C” face speed reducer115/230VAC - 1 Phase - 60 hz• Totally enclosed fan cooled• 1750 RPM• 1.15 service factor• Sealed worm gear “C” face speed reducer• 80 FPMLeft end Center right endDRIVE MOUNTING OPTIONS AVAILABLEDRIVE MOUNTED LOWDRIVE MOUNTED HIGHDRIVE MOUNTED UNDERHUNGROLLEr configurationsSTANDARD ROLLERS LOWSTANDARD ROLLERS HIGHROLLER CAPACITY INFORMATIONThe Maximum Roller Capacity chart is designed to helpdetermine the size of the roller required for a given loadand length. Use only 2/3 of the rollers under the productwhen calculating the required roller capacity because theconveying surface of products may not always be flat.non-precision BEARING (NP)Non-Precision bearings are made of a stampedmetal housing with very loose tolerances. They arenot intended for very heavy loads or high speeds.precision Bearings (P)Precision Bearings are made from high quality steel, heattreated to uniform hardness and ground to a micro finish.The tolerances are much tighter than semi-precisionbearings making them capable of greater speeds andload capacities but sensitive to axle deflection causingmisalignment.Page 29