physical characteristics of cotton/polyester core spun yarn made

physical characteristics of cotton/polyester core spun yarn made

physical characteristics of cotton/polyester core spun yarn made

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

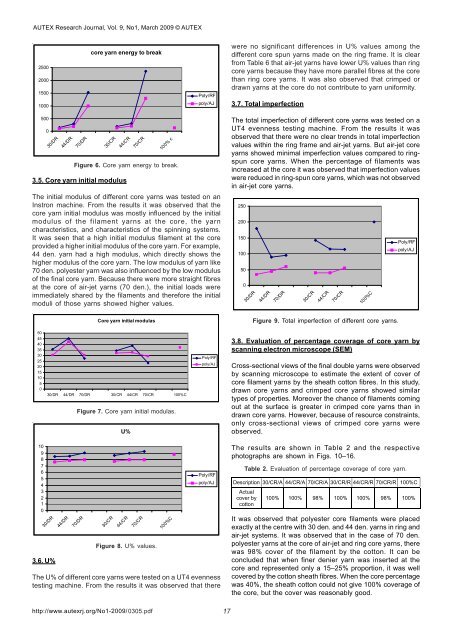

AUTEX Research Journal, Vol. 9, No1, March 2009 © AUTEX2500200015001000<strong>core</strong> <strong>yarn</strong> energy to breakPoly/RFpoly/AJwere no significant differences in U% values among thedifferent <strong>core</strong> <strong>spun</strong> <strong>yarn</strong>s <strong>made</strong> on the ring frame. It is clearfrom Table 6 that air-jet <strong>yarn</strong>s have lower U% values than ring<strong>core</strong> <strong>yarn</strong>s because they have more parallel fibres at the <strong>core</strong>than ring <strong>core</strong> <strong>yarn</strong>s. It was also observed that crimped ordrawn <strong>yarn</strong>s at the <strong>core</strong> do not contribute to <strong>yarn</strong> uniformity.3.7. Total imperfection500030/DR44/DR70/DR3.5. Core <strong>yarn</strong> initial modulus30/CR44/CR70/CR100% cFigure 6. Core <strong>yarn</strong> energy to break.The initial modulus <strong>of</strong> different <strong>core</strong> <strong>yarn</strong>s was tested on anInstron machine. From the results it was observed that the<strong>core</strong> <strong>yarn</strong> initial modulus was mostly influenced by the initialmodulus <strong>of</strong> the filament <strong>yarn</strong>s at the <strong>core</strong>, the <strong>yarn</strong><strong>characteristics</strong>, and <strong>characteristics</strong> <strong>of</strong> the spinning systems.It was seen that a high initial modulus filament at the <strong>core</strong>provided a higher initial modulus <strong>of</strong> the <strong>core</strong> <strong>yarn</strong>. For example,44 den. <strong>yarn</strong> had a high modulus, which directly shows thehigher modulus <strong>of</strong> the <strong>core</strong> <strong>yarn</strong>. The low modulus <strong>of</strong> <strong>yarn</strong> like70 den. <strong>polyester</strong> <strong>yarn</strong> was also influenced by the low modulus<strong>of</strong> the final <strong>core</strong> <strong>yarn</strong>. Because there were more straight fibresat the <strong>core</strong> <strong>of</strong> air-jet <strong>yarn</strong>s (70 den.), the initial loads wereimmediately shared by the filaments and therefore the initialmoduli <strong>of</strong> those <strong>yarn</strong>s showed higher values.The total imperfection <strong>of</strong> different <strong>core</strong> <strong>yarn</strong>s was tested on aUT4 evenness testing machine. From the results it wasobserved that there were no clear trends in total imperfectionvalues within the ring frame and air-jet <strong>yarn</strong>s. But air-jet <strong>core</strong><strong>yarn</strong>s showed minimal imperfection values compared to ring<strong>spun</strong><strong>core</strong> <strong>yarn</strong>s. When the percentage <strong>of</strong> filaments wasincreased at the <strong>core</strong> it was observed that imperfection valueswere reduced in ring-<strong>spun</strong> <strong>core</strong> <strong>yarn</strong>s, which was not observedin air-jet <strong>core</strong> <strong>yarn</strong>s.25020015010050030/DR44/DR70/DR30/CR44/CR70/CR100%CPoly/RFpoly/AJCore <strong>yarn</strong> initial modulasFigure 9. Total imperfection <strong>of</strong> different <strong>core</strong> <strong>yarn</strong>s.5045403530252015105030/DR 44/DR 70/DR 30/CR 44/CR 70/CR 100%CFigure 7. Core <strong>yarn</strong> initial modulas.U%Poly/RFpoly/AJ3.8. Evaluation <strong>of</strong> percentage coverage <strong>of</strong> <strong>core</strong> <strong>yarn</strong> byscanning electron microscope (SEM)Cross-sectional views <strong>of</strong> the final double <strong>yarn</strong>s were observedby scanning microscope to estimate the extent <strong>of</strong> cover <strong>of</strong><strong>core</strong> filament <strong>yarn</strong>s by the sheath <strong>cotton</strong> fibres. In this study,drawn <strong>core</strong> <strong>yarn</strong>s and crimped <strong>core</strong> <strong>yarn</strong>s showed similartypes <strong>of</strong> properties. Moreover the chance <strong>of</strong> filaments comingout at the surface is greater in crimped <strong>core</strong> <strong>yarn</strong>s than indrawn <strong>core</strong> <strong>yarn</strong>s. However, because <strong>of</strong> resource constraints,only cross-sectional views <strong>of</strong> crimped <strong>core</strong> <strong>yarn</strong>s wereobserved.1098765432103.6. U%30/DR44/DR70/DR30/CR44/CR70/CRFigure 8. U% values.100%CPoly/RFpoly/AJThe U% <strong>of</strong> different <strong>core</strong> <strong>yarn</strong>s were tested on a UT4 evennesstesting machine. From the results it was observed that thereThe results are shown in Table 2 and the respectivephotographs are shown in Figs. 10–16.Table 2. Evaluation <strong>of</strong> percentage coverage <strong>of</strong> <strong>core</strong> <strong>yarn</strong>.Description 30/CR/A 44/CR/A 70/CR/A 30/CR/R 44/CR/R 70/CR/R 100%CActualcover by<strong>cotton</strong>100% 100% 98% 100% 100% 98% 100%It was observed that <strong>polyester</strong> <strong>core</strong> filaments were placedexactly at the centre with 30 den. and 44 den. <strong>yarn</strong>s in ring andair-jet systems. It was observed that in the case <strong>of</strong> 70 den.<strong>polyester</strong> <strong>yarn</strong>s at the <strong>core</strong> <strong>of</strong> air-jet and ring <strong>core</strong> <strong>yarn</strong>s, therewas 98% cover <strong>of</strong> the filament by the <strong>cotton</strong>. It can beconcluded that when finer denier <strong>yarn</strong> was inserted at the<strong>core</strong> and represented only a 15–25% proportion, it was wellcovered by the <strong>cotton</strong> sheath fibres. When the <strong>core</strong> percentagewas 40%, the sheath <strong>cotton</strong> could not give 100% coverage <strong>of</strong>the <strong>core</strong>, but the cover was reasonably good.http://www.autexrj.org/No1-2009/ 0305.pdf17