2/2012 - Fingrid

2/2012 - Fingrid

2/2012 - Fingrid

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

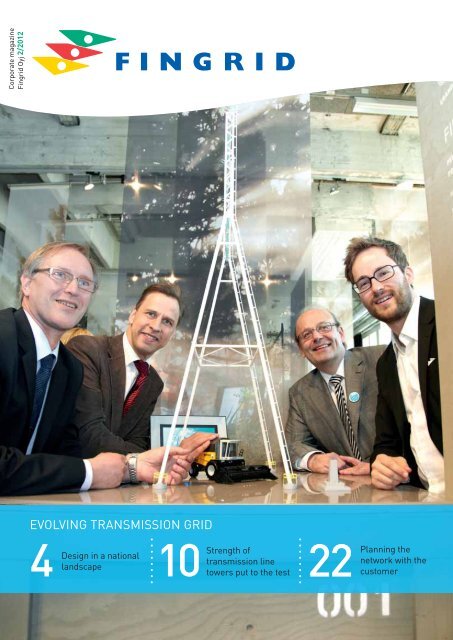

Corporate magazine<strong>Fingrid</strong> Oyj 2/<strong>2012</strong>EVOLVING TRANSMISSION GRID4 10towersDesign in a nationallandscapeStrength of22transmission lineput to the testPlanning thenetwork with thecustomer

EDITORIALCOMPETITIVE TRANSMISSION SYSTEMat competitive tariffsThe energy infrastructure is animportant competitive factor forFinland. We have learned it thehard way that our society requires moreand more from electricity networks. Thisis so because the dependence of societyon electricity and its sensitivity to disturbanceshave increased substantially.The updating of our existing electricitynetworks calls for considerablefinancial input. With <strong>Fingrid</strong>’s system,the price tag is about 1.7 billion eurosduring this decade. A correspondingupdate was carried out most recently inthe 1970s, when electricity consumptiongrew rapidly and large coal andnuclear power plants were connected tothe grid.Our heavy capital investment programmetogether with a rise in marketbasedcosts has created a pressure toincrease the transmission tariffs. Thetariffs were raised by 30 per cent at thebeginning of this year. Our customersreferred to this raise as “huge”, althoughthey understood why the raisewas needed.The reasonableness of the transmissionfees levied by <strong>Fingrid</strong> is monitoredby the Energy Market Authority. In accordancewith the regulation model applied,<strong>Fingrid</strong>’s owners have the rightto a reasonable return on the basis ofthe capital invested in the transmissionsystem. Our owners have decided thata level of return allowed by the regulationmodel will be gradually introducedduring the regulatory period of <strong>2012</strong> to2015. This will translate into annual tariffadjustments.Simply put, the tariffs are determinedby the regulation model and based onthe company’s cost level. A cost-effectivecompany has a lower tariff. <strong>Fingrid</strong>’scost control measures also serveour customers. Our key objective is toretain our transmission prices at a levelwhich is competitive on a Europeanscale. We are determined in improvingour organisational performance. We reporttransparently the trend in factorswhich influence our financial performance.We also measure our cost efficiencyby participating in internationalbenchmarking studies.We do everything we can to avoidunnecessary investments. Firstly, wefollow the principle of transparency interms of our capital investment programme.On the other hand, the programmeschedule is mostly determinedby the completion times of new electricitygeneration facilities. Future investmentsin power generation capacity involvemany political and market-relateduncertainties. This is why we make thedecisions concerning the transmissionsystem investments only after a customerof ours has made its own investmentdecision.Such a just-in-time approach involvesa schedule risk. What if the generationplant is ready before its connection tothe transmission system? In order tocontrol the risk, we carry out the environmentalimpact assessments, permittingprocesses and necessary preliminaryplanning in advance. Thisapproach also facilitates the serviceproviders, because most of the uncertaintiesrelated to the schedules havebeen eliminated through the work carriedout in advance. This is reflected inthe prices of work and equipment. Andultimately it is our customers who drawthe benefit.This year has shown that <strong>Fingrid</strong>’s financesalso involve a number of uncertainties.It is really difficult to forecastelectricity consumption in the currenteconomic situation. The market pricesof power system reserves have increasedrapidly. There should absolutelybe more competition and new playersin the reserve market, both among electricityproducers and users. The volumeof electricity imports from Russiahas dropped dramatically as a result ofthe capacity compensations introducedthere, so our cross-border income hasreduced correspondingly. Somewhatparadoxically, our finances have beenrelieved by the record-high congestionincome resulting from the inadequacyof cross-border transmission connections.On the other hand, these congestionshave also disturbed the electricitymarket mechanisms.In the future, operational and investmentefficiency can be enhancedthrough closer co-operation betweenthe players in the industry and by findingnew kinds of shared procedures. Amore active contribution of electricityconsumption to the security of supplyis one possibility, as are investmentsto be made in reserve power capacity.Co-operation enables us to keep up ahigh level of security of supply costeffectively– to benefit our customersand society.Jukka RuusunenPresident & CEOFINGRID 2/<strong>2012</strong> | 3

12Design inA NATIONAL LANDSCAPEWell designed, thoroughly considered, a beautiful and simple entity. These wereamong the characterisations that won <strong>Fingrid</strong>’s field tower the Grand Prix in theesteemed Fennia Prize <strong>2012</strong> design competition.Text by Ursula Aaltonen | Photographs by Mait Jüriado, Jonna Monola, Muotohiomo and FutureimagebankFINGRID 2/<strong>2012</strong> | 4

The opening ceremonies of theFennia Prize exhibition were held atKaapelitehdas in Helsinki in early June.The field tower was also on display inthe centenary exhibition of the FinnishAssociation of Designers Ornamo.On the next page, the happy winning team behind the field tower in the awardsceremony. The certificate of honour is held by <strong>Fingrid</strong>’s Kari Kuusela (at thefront), and Muotohiomo’s Pekka Toivanen is standing on his right. Also shown isAntti Kuljakka (at the back on the right), CEO of Fennia, which sponsors the prize.The right-hand photograph shows <strong>Fingrid</strong>’s former Environmental ManagerSami Kuitunen, who was also involved in developing the idea of the field tower.line construction rather than a designitem. A transmission line tower modelenabling work close to the tower wasneeded for field areas where transmissionlines run. The guys, or supportwires, of conventional towers preventthe use of agricultural machinery rightnext to the towers and hence reduce theavailable arable field area.In fact, the idea for the design ofthe new tower model originally camefrom feedback received from farmers.The most important target group hasalso been heard in the various stages ofthe design process. “Based on feedbackgiven by farmers, we enlarged the openingsbetween the legs of the tower sothat all agricultural machinery used inFinland can be driven through them,”says Pekka Toivanen, Managing Directorof Muotohiomo, the design agencythat designed the field tower.The design work of the field towertook a total of about 18 months, includingthorough familiarisation with thetopic and background work. The designwork was limited by the strict structural,technical and safety considerations.“The decisive factor was that the designprocess involved <strong>Fingrid</strong>’s own expertsright from the outset. Their contributionwas crucial – as was the fact that wegot a free hand to create ideas and comeup with something new,” Pekka Toivanenpraises the seamless co-operationbetween the various parties.Out to conquer the worldThe World Design Capital Helsinki <strong>2012</strong>project in Finland has generated a lotof positive activity and raised designinto the hub of current debate even ona wider scale. The field tower has alsobenefited from this. It has been presentedin two different places during thissummer – in the Fennia Prize exhibitionerected at Kaapelitehdas in Helsinki andin the centenary exhibition of the FinnishAssociation of Designers Ornamo.Mikko Kalhama predicts that the fieldtower will have a prosperous futureeven after the summer. Next, the exhibitioncomposed of the items awardedin the Fennia Prize competition will bepacked into crates and sent abroad togather international fame. “It is conventionalthat those reaching success inthis competition have done well also inother parts of the world.”FINGRID 2/<strong>2012</strong> | 6

Design and technologyhand in handThe first idea of the field tower came about – naturally – in the field.have spent a lot of time in the countryside sincechildhood; my first job was working on the pota-“I to field. My present home is also in the country, inKirkkonummi, next to a transmission line. I have been lookingat the towers for a length of time and thinking whetheror not something could be done to them,” says Muotohiomo’sManaging Director Pekka Toivanen. The tower designproject that lasted a couple of years ended up well. “A successfuloutcome and a satisfied customer are the best thankswe can get. Fennia Prize is a great bonus on top of it all;these things are a rare treat for any designer.””Fennia Prize is a great recognition of persistent work,”said <strong>Fingrid</strong>’s Executive Vice President Kari Kuusela incommenting on the prize. “In this project, we have managedto combine design and technology in a successful manner.The way I see it, this recognition is above all a testament tothat.”Despite the strong presence of design, the planning of thefield tower has been based on the practical aspects. The goalwas to achieve a tower that not only adapts to the landscapebut one that is also as safe and functional as possible. “Thekey objective for us was to accomplish a new tower thatneeds no guys. A tower with no guys not only facilitatescultivation but also adds to safety when moving on fields,”Kari Kuusela says.The field tower to be taken into use in 2013 has passed exactingstrength and safety tests. Kari Kuusela estimates that10 to 20 field towers will be erected on <strong>Fingrid</strong>’s transmissionlines annually.The price of a single field tower is about 60,000 euros,which is roughly twice as high as that of a conventionaltower. “However, if we look at the total costs, the differenceis small, because on average the towers only accountfor about 2 per cent of all the costs of a transmission line.We will use the field towers only where they are necessary,in other words primarily on arable field areas. The parts oftransmission lines traversing forests continue to have conventionaltowers.” FINGRID 2/<strong>2012</strong> | 7

Project Manager Hannu Kuikka following theerection of a 110 kilovolt transmission linetower south of Hyvinkää in early June.Nurmijärvi–Hyvinkää–Hikiätransmission line project in brief• total project budget 13.5 million euros• schedule• completed in September 2013• foundation work Jan <strong>2012</strong> to Feb 2013• 110 kV installation work Apr <strong>2012</strong> to Jun 2013• 400 kV installation work Jan 2013 to Sep 2013• dismantling work in Metsäkalteva areaSep 2013 to Oct 2013FINGRID 2/<strong>2012</strong> | 8

to be constructedto be dismantledFIRST FIELD TOWERto be erected in Hyvinkää<strong>Fingrid</strong> will renew the transmission lines running between Nurmijärvi, Hyvinkää and Hikiä inSouthern Finland. Proximity to urban settlement affects the way in which the transmission line isconstructed: part of the existing line will be transferred to a new route, and new types of towers willbe used to streamline the landscape. <strong>Fingrid</strong>’s first field tower will also be erected in Hyvinkää.Text by Tiina Miettinen | Photograph by Juhani Eskelinen<strong>Fingrid</strong> is strengthening the highvoltagetransmission system inSouthern Finland by building anew 400 kilovolt transmission line fromHyvinkää to Hikiä in Hausjärvi. The110 kilovolt double circuit line originallybuilt in the 1920s between theHikiä and Nurmijärvi substations willbe modernised at the same time, andtransmission line rearrangements willbe carried out in the Metsäkalteva areain Hyvinkää.The renewal of the transmission linebetween Hyvinkää and Hikiä is part ofthe ten-year capital investment programmein the Finnish transmissionsystem. The Hyvinkää switching plantwill be decommissioned, and line rearrangementswill be made at the Hikiäsubstation which forms a node in thenetwork. Preparations will be made atHikiä for a situation where the 400 kilovoltnetwork will be extended further toForssa and later to the east and north.The 110 kilovolt transmission line betweenHikiä and Nurmijärvi also callsfor a renewal, because the old line builtas early as the 1920s is in a poor condition.Around a new residentialarea in HyvinkääThe transmission line work will mostlytake place in existing transmission lineroutes. In some places, the new 400kilovolt transmission line will be locatedin a new route or shift slightlyat the corner points of the line. In Hyvinkää,the 400 kilovolt transmissionline will be transferred to a new routeto give way to the new residential areaof Metsäkalteva and the Kravunharjuhousing fair area.The length of the line section betweenHyvinkää and Hikiä is approx. 17 kilometresand the section between Nurmijärviand Hikiä about 29 kilometres. Thecontractor in the project is the Finnishcompany Eltel Networks Oy.The construction of the transmissionline between Nurmijärvi and Hikiä begunby foundation work in Januarythis year. The dismantling of the existingtransmission line structures and theconstruction of the new lines are progressingin stages so that the entire projectwill be ready by the end of October2013.According to <strong>Fingrid</strong>’s Project ManagerHannu Kuikka, the project adjacentto a residential area is a fairlytypical transmission line constructionproject. However, a few kilometres ofthe line will be built using new types oftower models.“We have taken the impacts on thelandscape into account near residentialareas. On the north side of the Hyvinkääsubstation, we will use streamlined conicaltube towers. They are considerablymore expensive than standard towermodels, but they are also better adaptedto the built-up landscape,” Hannu Kuikkasays.The first field tower designed for <strong>Fingrid</strong>will also be erected in Hyvinkää.“The field towers will primarily beused in the construction of new transmissionlines in field areas. A modeltower will be erected near the Hyvinkäähousing fair area in early 2013,” saysHannu Kuikka. FINGRID 2/<strong>2012</strong> | 9

PUTTING THETOWERS TO THE TEST<strong>Fingrid</strong> testing its mostcommon tower typesA transmission line tower must be able to withstand considerable loadsin the Finnish conditions. It must stand without breaking in heavy windsand burdened by ice loads accumulated on the structures. To securethis, <strong>Fingrid</strong> has launched a comprehensive testing programme, whichcovers all the type towers used in the company’s transmission lines.Text by Maria Hallila | Photographs by Ritva LaineThe testing programme is based ona project aiming to put together a“tower family” of <strong>Fingrid</strong>’s typetowers. It would cover up to 90 per centof the tower types most commonly usedby the company. According to ProjectManager Ritva Laine, the number oftype towers selected in the family isclose to 30.“By having an established basic rangeof towers and by using ready-madeplans, we can intensify and expediteboth the construction of transmissionlines and line maintenance,” she says.Not many testing stationsDuring her career of more than 20years, Ritva Laine has participated inthe testing of 20 or so transmission linetowers. In the past four years the testshave concerned the so-called type towers.The tests for the new towers usedon the overhead line section of the Est-Link 2 transmission interconnection betweenFinland and Estonia have beenconducted under the supervision of ProjectManager Ritva Hauvonen.What makes the testing of the towerscomplicated is the fact that there arenot that many testing stations available.In Europe, there are such facilities onlyin Spain, Italy and Romania, and onlythe one in Romania enables the testingof guyed 400 kilovolt transmission linetowers more than 30 metres in height.<strong>Fingrid</strong> has had towers tested alsoin China, where the testing station isunique in that it can test towers as highas 140 metres.“The testing station in China is lessfavourable than its European competitorsin terms of logistics. There is nopoint in transporting the towers there,so they are manufactured in China,”Ritva Laine says.She says that this is sometimes standardpractice also with European testingstations. Tubular towers are mostlymanufactured in Finland and transportedto the testing site in parts by road.Ritva Laine and Ritva Hauvonencommend the Romanian testing stationfor service flexibility, activity and responseability. The station has acquirednew equipment and facilities specificallyfor <strong>Fingrid</strong>’s needs.Efficiency from ITThe strength requirements applied totowers used in the Finnish high-voltagetransmission system are laid down inEuropean transmission line standards.FINGRID 2/<strong>2012</strong> | 10

<strong>Fingrid</strong>’s type towers havepassed the strength testswithout any major problems.The load has been raised to justover 100 per cent of the testload, whereby the steel bendssomewhat in accordance with itscharacteristics.The tests model a range of forces exertedon the towers – for example ice,wind, installation and safety loads – bymeans of pull wires, pulleys and winchesattached to the structures. The testsverify that the strength calculations ofthe tower hold true and that all jointsare correctly designed.Ritva Laine says that it typically takesabout four months for a single tower tobe manufactured, transported, erected,tested and dismantled. The actual testingby the current methods can be carriedout within one working day.Information technology has gained anincreasingly important role in the testingprocess in recent years. “As a result,the testing times are now shorter andthe work stages have become easier.Information technology has also improvedthe manageability and safety ofthe tests,” she adds.The testing programme detects, forexample, if the tower bends too muchat some point. “In such a case, the loadis released automatically, and there isno damage or accident.”Solid structuresThe testing of transmission line towerscomplies with the relevant Europeanstandard. According to Ritva Laine andRitva Hauvonen, <strong>Fingrid</strong>’s towers havepassed the strength tests without anymajor problems.“There have been slight problems afew times during the tests, but the testshave been completed successfully aftercorrecting these problems,” they say.The testing takes place in stages: theload is first adjusted to 50 per cent andthen gradually to 75, 90, 95 and finallyto 100 per cent of the limit value set forthe capacity of the tower.The testing can continue even afterthe 100 per cent load level has beenreached. “This is not mandatory on thebasis of the standards, but it is a way offinding out what the tower really withstands.The information may be usefulwhen the goal is to optimise materialcost-effectiveness, for example,” RitvaLaine says.After testing, the tower is dismantled,and it is examined whether the deflectionshave remained within the prescribedlimits. A tower that passes thetest is included in <strong>Fingrid</strong>’s type towerfamily.FINGRID 2/<strong>2012</strong> | 11

1.Stages of testing oftransmission line towerBefore testing, the designer of thetower and the testing station drawup a test programme. The test programmecontains information on theloads that the tower is designed towithstand, and the proposed testingsequence and testing method, includingthe fixing points of pull wires.Manufacture of the tower, transport tothe testing station, and erection.2. 3.The load sensors are calibrated to ensurethe accuracy of the results.Pull wires and load sensors, whichmeasure the load exerted on the towerby the wires, are attached to thetower.If the testing also covers the measurementof stresses occurring in thesteel, strain gauges are attached tothe towers.4.The guys of the tower are providedwith measuring instruments used formonitoring the forces created in theguys.The load situations are examined inaccordance with the test programme.Displacements are measured at eachload step (50%, 75%, 90%, 95%, 100%)and also when the load has comedown to zero (permanent deflection).Material samples are taken from thetower, used for ensuring that the steelin the tested tower is of the right quality.After the tests, the tower is scrappedand recycled. The towers are testedwith no zinc coating, because galvanizingis expensive, and it does notchange the strength properties of thesteel.1. The tests model a variety of forces exerted on the towers. The forcesare directed to the tower structures via portals by means of pull wires.2. The loads are created by means of automatically-controlled winches.3. The load sensors of the test equipment are provided with a directoptical fibre connection to the computer in the control room of the testingstation.4. Before testing, the pull wires are secured to the tower structuresand tightened. The tapes on the tower are used for fastening the straingauges, which measure the tensions occurring in the steel.FINGRID 2/<strong>2012</strong> | 12

Asset management dayfocused on occupational safety<strong>Fingrid</strong> arranged the traditional assetmanagement seminar for its serviceproviders at the end of May. Thistime the seminar concentrated onsafety at work.The topic was covered in a number ofspeeches and in a panel discussion.In recent years, there have been bothsuccesses and failures in occupationalsafety. The number of serious injurieshas decreased, but at the same time theaccident frequency has grown. The primarygoal therefore is to change the attitudesand working culture.In the seminar, <strong>Fingrid</strong>’s ExecutiveVice President Kari Kuusela describedthe company’s extensive constructionprogramme. The year 2011 was arecord year in the number of personworkyearsalone: a total of 625 personworkyearswere performed at <strong>Fingrid</strong>’swork sites, while the normal figure isabout 500. There were as many as 160people working at the Forssa reservepower plant. Some of the increase in thenumber of accidents is explained by thehigher amount of work, but despite thisthe goal must be to reach zero accidents.In the asset management seminar,awards were presented to the builderof the year and to the maintenanceperson of the year. These are serviceproviders’ representatives who haveexcelled themselves. The builder of theyear award was given to Infratek’s KariLikander, who served as the projectmanager for the Uusnivala, Tuovila andHuutokoski 400 kilovolt substation projectsin 2011. Kari Likander’s efforts insubstation projects are characterised bythorough and detailed technical knowledgeand expertise, also as regards installationwork and switching planning.The maintenance person of the yearaward went to Empower’s Juha Laukkola,who is responsible for <strong>Fingrid</strong>’stransmission line maintenance in Westernand South-Western Finland. JuhaLaukkola was credited for improvingthe quality of maintenance service. Hiscontribution has been flexible, and thework has been completed well evenwith a short notice. The developmentproposals presented by <strong>Fingrid</strong> havebeen received positively, and they havebeen put into practice.Photographs by Juhani EskelinenElering and Litgridbecome Nord PoolSpot shareholdersThe Estonian and Lithuanian electricitytransmission system operatorsElering and Litgrid each acquired a 2per cent share of Nord Pool Spot, Europe’slargest power market, at thebeginning of August.In addition, it has been agreed that theright of the Latvian TSO, AugstspriegumaTkls (AST), to acquire a 2 percent share of Nord Pool Spot will begranted when the new Latvian powermarket opens.Once all three Baltic TSOs are establishedas shareholders, existing shareholdersStatnett and Svenska Kraftnätwill each hold 28.2 per cent of NordPool Spot, and Energinet.dk and <strong>Fingrid</strong>will both hold 18.8 per cent.The four Nordic TSOs see the extensionof ownership to the Baltic TSOs asan important and natural step in thefurther integration of the Baltic andNordic electricity markets.For the Baltic TSOs, part ownershipof Nord Pool Spot is a strategic investment.It will enable their participationin the decision-making process, ensuringthat the market interests of therespective Baltic countries are discussedand accommodated. It also allows theBaltic TSOs to contribute to Nord PoolSpot’s corporate activities in developingthe regional and European power markets.Meanwhile Nils Nygren has been appointedthe new chairman of Nord PoolSpot, effective from the same date. MrNygren was previously responsible forpublic affairs at the Nordic energy businessFortum and now works as a privateconsultant.Juha Laukkola and Kari Likander emphasised the importance of teamwork intheir speeches.FINGRID 2/<strong>2012</strong> | 13

RESPONSIBLYfor the futureAs a result of more than a year’s work, <strong>Fingrid</strong>’s land use andenvironmental policy is now compiled into a single volume. “Theprinciple was that we will not record anything to which we cannot trulycommit ourselves,” says Land Use Manager Ilkka Alm.Text by Ursula Aaltonen | Photograph by Valtteri KantanenFINGRID 2/<strong>2012</strong> | 14

The compilation work was undertaken,because the fragmentedprinciples pertaining to land useand environmental matters needed to beput together and given a concrete substance.“The basic idea was to make itwork right from the outset so that everythingis reallywell thought out.No wishy-washystatements, butthings we canvouch for,” Ilkka Alm points out.Even though the land use and environmentalpolicy principles were toa large extent already in place, it wasnot an easy task to record them. “Whenwe build and maintain transmissionlines, we usually work on other people’slands, so the very starting point is fairlyunenviable. What we do and how wedo it are under strict scrutiny, which iswhy we need to think especially carefullywhat we say of these things.”The land use and environmentalpolicyis part of <strong>Fingrid</strong>’sCode of Conduct,which has also beenrecently published asa separate publication.“Even thoughwe are in a certaintype of a special positionbecause we arethe Finnish transmissionsystem operator,it is really important tous that whatever we dois socially acceptable inevery way. We want todevelop all of our activitiesin this direction – and also serve asa trailblazer here.”Into practice right awayThe practical application of the landuse and environmental policy principleswill begin with the company’s ownpersonnel in the autumn. The personnelwill be arranged for example groupwork sessions, where each businessunit can consider the importance of theprinciples and their implementation asregards their own work.Another major target group are <strong>Fingrid</strong>’spartners, contractors and serviceproviders. “Forus, this is themost challengingtarget group,because they arethe very people with whom landownersand our other stakeholders commonlycome into contact.”In the future, the land use and environmentalissues will be incorporatedmore closely into <strong>Fingrid</strong>’s contractterms. The relevant matters will also bebrought regularly to the agendas of sitemeetings. “We intend to monitor thatthings make progress as agreed. Therewill also be more regular environmentalaudits at the worksites than before.”All these efforts stemfrom a genuine desire toenhance the company’sAll efforts stem from a genuinedesire to enhance the company’senvironmental policy.environmental policy.“Land use and environmentalissues giveus more feedback thanany other sector,” saysIlkka Alm.This is why, he adds,it is of paramount importanceto make allthe partners committedto the implementationof these principles.“No matterhow strong our strategicintent is, we can never reach asituation where everyone would alwaysbe happy with the way in which wework. And of course we sometimes givecause for criticism – but so that we cando something about it, we need to knowabout the problems. Therefore, it is veryimportant for us to receive feedback.”Whenever transmission lines are constructed,the goal is always to produceas little inconvenience as possible tothe environment, landowners and localresidents. This is why the heaviest constructionwork on arable land is preferablyscheduled for the winter season,when the ground is frozen and the workcauses less damage to fields. However,this is not always possible, but sometimesthe timing of construction work isdetermined for example by power plantoutages. “The most important thing is ofcourse to ensure uninterrupted electricitysupply,” Ilkka Alm says.Wisdom of forethoughtThe changes in <strong>Fingrid</strong>’s ownership lastyear have also increased the need forenvironmental reporting. Ilkka Alm issatisfied that the process to launch thereforms was started in good time – infact, even before there was any knowledgeof the coming changes. “The stateowner requires from us accurate environmentalreporting. We had some sortof wisdom of forethought, so now wecan be really satisfied.”The long-term goal is to progresstowards more comprehensive environmentalmanagement – one where theenvironmental matters are perceived asa natural part of all corporate managementand operations. This requires thatthere is genuine commitment to thegoals, throughout the organisation. “Weworked on these principles for over ayear. There were some 15 persons activelyinvolved in the work, includingthe executive management. Of course,much more have been able to give theircomments, so all who have been willingto contribute have certainly had theirvoice heard,” Ilkka Alm sums up. <strong>Fingrid</strong>’s land use and environmentalpolicy can be found on our website atwww.fingrid.fi under Environment.FINGRID 2/<strong>2012</strong> | 15

MONEY ISA SCARCE COMMODITYFollowing several months of intense and thorough preparations, <strong>Fingrid</strong> issued a public bond of300 million euros at the beginning of April this year. <strong>Fingrid</strong>’s Treasury Manager Katrina Klinge-Sonninen played a key role in the arrangement which consolidates the funding base of thecompany’s capital investment programme of 1.7 billion euros.Text by Maria Hallila | Photographs by Juhani Eskelinen and Heidi Sonninenuncertainty shadowing theglobal economy and financialmarkets has influenced “Thecorporate funding activities. ‘Cash isking and money talks’, but now, if ever,you can say that money is a scarcecommodity,” Katrina Klinge-Sonninensays.“Only change remains constant”Katrina Klinge-Sonninen says that turbulenttimes are testing the strength andreliability of companies’ debt financingbase. “<strong>Fingrid</strong>’s financial policy isfounded on a long-term approach. Weassume that only change remains constant.”<strong>Fingrid</strong>’s principles of financing areapproved by the Board of Directors, andthe financial exposure and financialrisks of the company are reported regularlyto the Board.“The risks and their limits are set at<strong>Fingrid</strong> so that they are not changedfrequently. Within the framework ofrisks, it must be possible to executefinancing in a sustainable manner; financingmust not cause fluctuation inthe company’s financial performance orcompromise liquidity and financial position.”According to Katrina Klinge-Sonninen,the recent market volatility hasproved clearly that <strong>Fingrid</strong>’s financingprinciples are sustainable. It has notbeen necessary to change the principleseven during great instability.Katrina Klinge-Sonninen considers it meaningful to have close co-operationwith the company’s Board of Directors in financial solutions. The principles offinancing adopted by the Board guide the efforts, and the Board also receivesregular reports of the financing situation.Money at the right price<strong>Fingrid</strong>’s capital structure is heavilydebt-based. The company has an in-FINGRID 2/<strong>2012</strong> | 16

A GOOD SERVANTbut a poor masterThe man cage of a personnel hoist is ascending underneath an electricity transmission line. Theominous music in the background and the coffin awaiting in the hearse make the viewer anticipatethat the man holding an iron bar in the man cage is not in for anything good. The videos of a recentcampaign induce people to pay attention to the dangers of electricity.Text by Suvi Artti | Photographs by GoodMood, Juhani Eskelinen and Valtteri KantanenThe undertaker played by the actorVille Virtanen has plenty ofcustomers in the videos of thecampaign “BEWARE BEFORE ACTIONnear electrical networks”: Felling of atree next to a power line does not govery well. The bucket of an excavatorhits an underground cable, and an electricshock kills a man standing besidethe pit. A farmer concentrating on findinghis mobile phone drives his tractoragainst a transmission line tower withdisastrous consequences. The videoson the campaign website at www.hengenvaara.fiindicate in a harsh mannerwhat implications the neglecting ofsafety instructions can have.According to the accident statisticsof Tukes, the Finnish Safety TechnologyAuthority, there have been as manyas 42 serious accidents when workingclose to overhead power lines or undergroundcables during the period of 2000to 2011. Fatal accidents resulting fromelectricity work have decreased significantlysince the 1970s, but one to twofatal accidents still happen in Finlandannually.Goal: zeroelectricity accidentsThe campaign stems from a concernshared by the entire electricity industryregarding the safety of work conductednear transmission networks. “In recentyears, there have been many near misssituations and also unfortunately someoccupational accidents, which are oftencaused by sheer thoughtlessness,” says<strong>Fingrid</strong>’s Marcus Stenstrand, whoworks as the Project Manager of thecampaign.Work sites located close to powerlines are commonplace. In addition toelectricity professionals, many otherpeople work close to transmission lines:civil engineering contractors, homeowners, forest workers and farmers.Typical hazards comprise the casespresented in the videos, where a treeis felled on a transmission line, a workmachine reaches too close to a powerline, or an excavator bucket hits anFINGRID 2/<strong>2012</strong> | 18

“All accidents can be prevented,” said<strong>Fingrid</strong>’s Executive Vice President KariKuusela in the press conference of thecampaign. He pointed out that electricitycompanies and <strong>Fingrid</strong> welcome anyobservations of abnormalities concerningelectricity networks.Campaign shared by the electricity industryThe website of the campaign “BEWARE BEFORE ACTION near electricalnetworks” at www.hengenvaara.fi contains basic informationabout how to take an electricity network into account at work sites,and instructions for situations where a power line is damaged.The campaign material also covers a pocket-sizesafety brochure and training materials in Power-Point format.The two-year campaign launched in May<strong>2012</strong> is backed by ten electricity companiesand organisations: Elenia Verkko Oy, FinnishEnergy Industries, EPV AlueverkkoOy, <strong>Fingrid</strong> Oyj, Fortum Sähkönsiirto Oy,Helen Sähköverkko Oy, INFRA ry, aconsortium of electricity companiesin Eastern Finland, Tukes, and VantaanEnergia Sähköverkot Oy.TIEDÄENNEN KUIN TOIMITsähköverkon läheisyydessäunderground cable. Blasting work tooclose to lines as well as constructionand storage in the power line right-ofwayare also prohibited as dangerousoperations.Undertaker on amuddy fieldThe startling videos on the campaignwebsite have been designed and filmedby the video production companyGoodMood. Instead of direct bans, thevideos wish to show what can happenif you work contrary to the safety instructions.“From the outset, we thought of unconventionalways to make safety videos,”says Otto Hietaharju of Good-Mood. The idea of the undertaker cameabout as a result of creative brainstorming.“There are plenty of prohibitions,commands and orders in Finland. Maybepeople have become accustomed tothinking in the lines of: ‘OK, there is aprohibition sign, but that’s quite alright,nothing has happened to me before’.”The videos were directed by TeemuNikki, who has previously directed muwww.hengenvaara.fiFINGRID 2/<strong>2012</strong> | 19

sic videos and short films. He joinedthe project when the initial manuscriptswere ready. “The basic setup was there,and I started to take the idea a bit towardsa Gothic ambience,” Teemu Nikkisays. Although the outcome is not funnyin any way, the team spirit was good.“It was terribly cold, wet and fun,” hesays in recalling the November shootingsessions on a muddy field with sleetpouring from the sky.When the completed videos wereshown for the first time to the campaignpeople, the makers were excited to seehow the audience would react. “Peoplestared at the videos with amazement,and they had serious expressions ontheir faces,” Otto Hietaharju says.However, after initial bewildermenteveryone agreed that the videos accomplishexactly what they should: makepeople see that electricity involves a realdanger to life.Project Manager Marcus Stenstrandhopes that the campaign messagereaches as many people aspossible. The electricity companiesand organisations involved in thecampaign convey the message forinstance in various events.Accidents to zero<strong>Fingrid</strong>’s new work sites have applied a stringent policy since the beginningof this year: an employee who does not have appropriate protective equipmentsuch as helmet, safety shoes or high-visibility clothing will be removedfrom the site for the rest of the day. If the same employee repeats the offense, theemployee will have to leave the entire project. The main contractor will also be subjectto a written complaint and a fine of 250 euros. The penalty is less severe in oldprojects: there is no fine, and the employee will receive one warning before beingremoved from the work site.“The penalties were introduced as part of our new development project for occupationalsafety,” says Development Manager Suvi Lokkinen, who heads the project.She says that the service providers have been mostly positive about the new practice.On the other hand, the planned reward system for good occupational safetyhas not received as enthusiastic reception. “Some service providers feel that sincetaking care of occupational safety is self-evident, there is no reason to reward for itseparately,” Suvi Lokkinen says.The new penalty and reward systems are just a small part of a sizeable projectlaunched at the beginning of this year by <strong>Fingrid</strong> to reduce the number of serviceproviders’ accidents at work. <strong>Fingrid</strong> has paid special attention to occupationalsafety for several years now, but the index indicating the frequency of accidents at<strong>Fingrid</strong>’s construction sites has still not come down to the targeted level. “However,what is positive is that the index describing the seriousness of accidents inflicted onthe service providers has taken a downward turn,” says Suvi Lokkinen.<strong>Fingrid</strong> has outsourced its construction and maintenance operations, so in practicethe service suppliers carry out the work at <strong>Fingrid</strong>’s sites.The Finnish Occupational Safety and Health Act stipulatesthat both the party ordering a service and the serviceprovider have the right and the obligation to ensurethe safety of work sites.The safety project aims at influencing attitudesin particular. One example of the power of attitudesgiven by Suvi Lokkinen is the construction industry,where the number of occupational accidentsvaries greatly between different companies.Some companies get close to the goal ofzero accidents while in others the accidentfigures are continuously too high. “Thisreflects the fact that the working culturehas an important role in the number ofaccidents.” <strong>Fingrid</strong> considers occupationalsafety as a key component ofhigh-quality project execution,says Development ManagerSuvi Lokkinen.FINGRID 1/<strong>2012</strong> | 20

KNOW THE TERMSThis column presents and defines terminology in theelectricity transmission business and related fields.Step voltageText by Juhani Mäkelästep voltage which is dangerousA to people may emerge in conjunctionwith earth faults in the high-voltagesystem between two points undera person’s feet. An earth fault occurswhen, during a fault, a conductor in acircuit gets into a conducting connectionwith the earth. As an example, electricityflowing into the ground from atree which has fallen on an energisedtransmission line or from a machinewhich has hit a line causes step voltage:legs which are apart from each otherhave a different potential, and some ofthe electric current gets into the body.The step voltage is at its highestright next to the earth fault. In order toavoid an electric shock, you must leavethe fault area either by jumping withyour legs kept together or boundingso that only one foot at a time touchesthe ground. It is important that onlyone point of you is in contact with theground at a time. The safe area startsat a distance of approx. 20 metres fromthe fault location. FINGRID 2/<strong>2012</strong> | 21

Planning the networkwith the customerThe planning of an electricity network calls for expertise innetwork technology, economic matters and environmental issues.The skills of a clairvoyant would also come in handy, as a networkplanner should see some 20 years ahead.Text by Maarit Kauniskangas | Photographs by Juhani Eskelinen, Helsinki City PlanningDepartment and Futureimagebankplans the transmissionsystem one region at a time,“<strong>Fingrid</strong>because a plan encompassingthe whole of Finland would be way toocomprehensive. This work is not carriedout solely at <strong>Fingrid</strong>, but our customers– local network companies, electricityproduction companies and manufacturingindustries – are also actively involvedin the planning work,” says AnteroReilander, who works as SpecialAdviser in <strong>Fingrid</strong>’s grid planning.<strong>Fingrid</strong>’s grid plan consists of 13regional plans. Of these, the plans forLapland, South-Western Finland, Kymenlaakso/SouthKarelia and the Helsinkiarea are currently being updated.About three to five such extensive regionalplans are made each year, whichmeans that the whole of Finland iscovered in about four years. However,the plans are flexible and the planningprocess is continuous, because in manycases there are events in the operatingenvironment compelling modificationsto the plans.Information from customersAntero Reilander says that gridplanning work is much aboutdialogue and about letting ideasevolve.tives of our customer network enterprisesare involved in drawing up theregional plan from the outset,” AnteroReilander says.<strong>Fingrid</strong>’s planning team also keepscontact with the representatives of electricityproduction companies and localmanufacturing industries. New resi-“We need local information about electricityconsumption, and estimates offuture developments. The representadentialareas, factories, logistics centresetc. add to the need for electricity. It ischallenging to foresee the electricitydemand of manufacturing industries inparticular, because a single productionplant may consume as much electricityas a medium-sized town.“As an example, if an industrial companyis planning to build a new factoryor shut down an existing plant, it wouldbe good for us to know about it so thatwe can take the matter into account innetwork planning. The changes may beswift, but years should be reserved forthe upgrading of the network. On theother hand, the companies themselvesrarely know about these things severalyears in advance. Still, it would be goodto be informed of these cases as early aspossible,” Antero Reilander hopes.Electricity production anticipation,in turn, is complicated by factors suchas uncertainties involved in the constructionof wind power capacity. Thechanges caused by wind power in thetransmission system have been rathermoderate to date, but now there areplans for more than 300 wind farm projects,totalling about 15,000 megawatts.The original target set for wind powerwas only about 2,500 megawatts. However,it is still uncertain how many ofFINGRID 2/<strong>2012</strong> | 22

these projects will actually become reality.From ideas to solutionsTransmission system planners use initialinformation acquired by them tosketch various scenarios for the futureprospects in a certain area and explorewhat kinds of impacts these have onthe transmission network. Will there bea need for new high-voltage transmissionlines or substations? How couldwind power capacity be connected tothe system? Does a network companyneed a new transmission line connectionbecause of the expansion of itsown network?The regional plans also take into accountthe management of the ageingof the transmission system. The systemmay contain parts that should be dismantled,repaired, or rebuilt entirely.“We always aim to use the existingnetwork as optimally as possible. Wecannot and should not make preparationsfor every eventuality by overbuildingthe system. It is our goal tofind flexible as well as technically andeconomically correct solutions in atimely fashion. This is so because networkconstruction is very expensive,Electricity productionanticipation iscomplicated by factorssuch as uncertaintiesinvolved in theconstruction of windpower capacity.and the network also has environmentalimpacts,” Antero Reilander says.The planning team works together,but each member also works independently.After joint meetings for creatingideas, it is time to return to the computerto simulate the possible solutions.Antero Reilander says that the work ismuch about dialogue and about lettingideas evolve.The plans are modified on the basisof feedback received during the discussions.A regional plan shaped andhoned in co-operation with the customersis distributed to all parties ina shared event arranged by <strong>Fingrid</strong>. Ifnecessary, customer-specific confidentialreports address the developmentneeds involved in the network and gridconnections of a particular customer. Ittakes about a year to draw up the regionalplan.“When we can do things for the regionalplans in advance with no hurryand when we have proper discussionswith all stakeholders, the actual implementationof the projects is also mucheasier,” says Antero Reilander.FINGRID 2/<strong>2012</strong> | 23

Regional grid planning in the Helsinki regionChallenge: growth and compaction<strong>Fingrid</strong>’s regional grid plan for the Helsinki regionis currently being updated in a thorough manner.The representatives of the network company HelenSähköverkko Oy in Helsinki in the planning process are AttePihkala, who works in network planning, and Markku Hyvärinen,head of the unit for network development.“Helen’s network is connected to <strong>Fingrid</strong>’s system at severalpoints; it is a meshed, ring-like network. This is whyall solutions related to our network development must becarried out together with <strong>Fingrid</strong>,” says Markku Hyvärinen.What makes the development work challenging is that theHelsinki region is growing and becoming increasingly compact.A dense urban structure calls for new electricity transmissioninfrastructure. The projects require much preparationin issues such as land use and technical solutions.“New people keep moving to the Helsinki region, and newresidential houses and business premises are built. Eventhough the per capita energy efficiency has improved, thisimprovement only mitigates but does not cancel out the increasein electricity consumption,” Markku Hyvärinen pointsout.When more electricity is needed, more transmission capacityis also needed. One of the factors complicating networkplanning is the uncertain situation with the Hanasaari powerplant. The decision on the future of the plant will be made inearly 2015. Before that decision, preparations must be madein network planning for various alternative scenarios. Markku Hyvärinen (left) and Atte Pihkala say thatnetwork projects within a compact urban structurecall for much preparatory work, both in terms ofland use and technical solutions.A visualisation of the Kalasatama area adjacent to theheart of Helsinki. The area will provide a home for about20,000 people by the early 2030s.FINGRID 2/<strong>2012</strong> | 24

<strong>Fingrid</strong> remains atthe top of internationalcomparison<strong>Fingrid</strong> ranked at the top in the internationalITOMS* maintenancebenchmarking study for the ninthconsecutive time. The benchmarkingcovering the years 2010 and 2011concerned 27 transmission systemoperators from around the world.In the cost-effectiveness comparison,<strong>Fingrid</strong>’s placing was slightly lowerthan in the previous study. The resultreflects <strong>Fingrid</strong>’s considerable inputin the restoration of guy structures intransmission line towers in recent yearsso as secure safety and system security.<strong>Fingrid</strong> did particularly well in circuitbreaker maintenance and in the managementof vegetation in the rights-ofways.In both of these sectors, the qualitylevel was very high, while the costswere among the lowest in the referencegroup.The ITOMS study compares theperformance quality, efficiency andeconomy in the electricity transmissionindustry every two years. The goal is tofind best practices and methodologies aswell as to learn from other companies.*International Transmission andMaintenance Study<strong>Fingrid</strong> in socialmedia<strong>Fingrid</strong> has expanded its communicationsin Finnish to social media. Thecompany is now on both YouTube andFacebook.<strong>Fingrid</strong>’s YouTube website shows presentationfilms of issues such as theoperations of the transmission systemoperator, its compliance with the principlesof corporate social responsibility,and its role as an employer. You canalso get to meet <strong>Fingrid</strong> people workingwith various duties, see the video materialof a topical electricity safety campaign,and learn about the principles ofthe Finnish power system.The company’s Facebook site (www.facebook.com/fingridfi) is the basic informationchannel for the general publicin the Finnish language. In additionto current news, the site contains informationon issues such as all vacanciesGRID QUIZCompetition to the readers of <strong>Fingrid</strong> MagazineAnswer the below questions and send your reply by fax (number+358 (0)30 395 5196) or mail to <strong>Fingrid</strong> no later than 30 September <strong>2012</strong>.Address: <strong>Fingrid</strong> Oyj, PL 530, 00101 HELSINKI, FINLAND. Mark theenvelope with “Verkkovisa”. You can also send your reply to Grid Quizonline. The link can be found on the home page of our website www.fingrid.fi. Among all those who have given right answers, we will give fivelanterns powered by a solar cell as prizes by drawing lots.The answers to the questions can be found in the articles of this magazine.1. <strong>Fingrid</strong>’s first field tower will be erected inHyvinkääHikiäForssa2. The testing of a single transmission line tower at the testing station takesin all approximately2 months4 months6 months3. Last April, <strong>Fingrid</strong> issued a bond with a value of200 million euros300 million euros400 million euros4. The undertaker in the videos of the campaign “Beware before action nearelectrical networks” is played byAntti ReiniTapio LiinojaVille Virtanen5. If a machine part has hit the transmission line or if a tree has fallen on theline, you need to leave the siterunning as fast as you canjumping with your legs kept together or bounding so that only one foot ata time touches the groundcreeping while crouched6. Of the electricity used on the Åland Islands, how much is produced onmainland Finland?approx. 7 per centapprox. 15 per centapprox. 20 per cent7. What was the first country in the world to introduce the 400 kilovoltvoltage in electricity transmission?JapanRussiaSwedenWinners of prizes of the Grid Quiz in the previous <strong>Fingrid</strong> magazine (1/<strong>2012</strong>):Jarmo Henriksson, Turenki; Lidia Lybek, Helsinki; Kimi Patja, Turku; ArtoKöykkä, Muhos; Tuomo Jokinen, Helsinki.in the company. FINGRID 2/<strong>2012</strong> | 25

Planning of networksolutions:ADVANCES THROUGHANTICIPATIONIn July 2010, the Finnish Parliament adopted decisions in principleconcerning the construction of two new nuclear power plants. <strong>Fingrid</strong>is making preparations for connecting these new nuclear power unitsto the Finnish transmission system. Analyses of the grid upgradesrequired by the plants have been launched.Text by Maria Hallila | Photographs by Juhani Eskelinen and Esko Keski-OjaThe grid reinforcements will requirethat the planning and environmentalsurveys of the projectsare carried out in stages. The environmentalimpact assessment (EIA) of the400 kilovolt transmission line routesrelated to Teollisuuden Voima’s (TVO)Olkiluoto 4 nuclear power plant unitin Western Finland unit was launchedtowards the end of 2011. The EIA procedurefor the transmission lines requiredby Fennovoima’s Hanhikivi 1 nuclearpower plant further up north is also beingprepared.<strong>Fingrid</strong> will make the decisions on thefurther planning and construction of thetransmission lines later on the basis ofthe decisions made by the companiesresponsible for the nuclear power projects.Far-reaching developmentIn just over one year after the decisionby Parliament, <strong>Fingrid</strong> presented theEIA programme concerning the transmissionline projects required by theOlkiluoto 4 plant unit. The swift reactionwas enabled by the company’slong-term and flexible approach tonetwork development plans. This modeof operation has also become standardprocedure as a result of experience accumulatedfrom numerous transmissionline projects.“We have been thinking about therough outlines of network solutions foradditional nuclear power capacity for alength of time. Routes were introducedin regional land use plans as early as2007 and 2008,” says <strong>Fingrid</strong>’s ProjectManager Mika Penttilä.He says that connecting a generationfacility the size of the Olkiluoto 4 nuclearpower plant unit to the transmissionsystem always calls for new 400kilovolt transmission lines. Preparationsare being made to build a double circuit400 kilovolt transmission line fromOlkiluoto to Rauma and a new 110 kilovoltline to run parallel with it.Moreover, the transmission grid needsto be reinforced by new transmissionlines from Rauma to Ulvila, Forssa andLieto.The transmission lines will be locatedin the area of 19 towns and municipalitiesin the regions of South-WesternFinland, Satakunta and Kanta-Häme.In accordance with the national landuse objectives, the goal is to plan andbuild the new transmission lines parallelwith existing lines or to replace them,using existing transmission line areaswherever possible.Surveys aheadMika Penttilä says that the total lengthof the transmission line routes coveredby the EIA of the project is 390 kilometres.Numerous nature and archaeologicalsurveys have already been conductedin the routes.“There is much to survey, because thewest coast of Finland has been settledsince times immemorial, and the areacontains many historical sites. Some naturevalues have also been investigatedover several years.”Visualisations will be drawn up ofsites along the line routes. These give anunderstanding of what the new transmissionlines will look like in a familiarFINGRID 2/<strong>2012</strong> | 26

<strong>Fingrid</strong>’s online map service can be used forproviding feedback on the transmission linesolutions required by the Olkiluoto 4 nuclearpower plant project. The feedback page (inFinnish) can be found on the website of theEIA project, which can be reached by clicking“Ympäristö” in the top menu of <strong>Fingrid</strong>’swebsite, or using search “fingrid.navici.com/ol4/”.The transmission line projects required byOlkiluoto 4 and their environmental impacts werethe topic in the three public events arrangedby <strong>Fingrid</strong> in early <strong>2012</strong>. Mika Penttilä (on theright) and Hannu Ylönen (in the middle) hadplenty of questions to answer also in coffee tableconversations.landscape.The impacts of transmission linesrequired by Fennovoima’s Hanhikivi 1nuclear power plant on the environmentand people will be investigated ina similar manner within an EIA procedureto be launched at a later date. Thetransmission line routes to be examinedwithin this project total over 100 kilometres.Opinions expressed in public eventsWithin the first stage of the EIA procedurein South-Western Finland, <strong>Fingrid</strong>arranged public meetings in threeplaces in January: Alastaro, Harjavaltaand Mynämäki.The events presented the project ingeneral, the planned transmission lineroutes, and the environmental impactassessment programme. In addition to<strong>Fingrid</strong>’s experts, the questions were answeredby representatives of the Centrefor Economic Development, Transportand the Environment in South-WesternFinland, the EIA consultant as well asTVO, the nuclear power company.“The purpose of these events is tomake people involved and share information,”Mika Penttilä says.However, information supplied inthe early stages of the EIA project didnot appear to attract too much interestamong the local residents. The threeevents gathered a total audience ofabout 100.“The attendance was low consideringthat the planned transmissionline routes traverse the land of a totalof 1,500 to 2,000 landowners. On theother hand, people tend to become moreinterested in the projects as the workmakes progress, and we have receivedsome questions and comments also bytelephone and through the map feedbackservice on our website.”Mika Penttilä says that landownersand local residents are typicallyinterested in issues such as the projectschedule, land use impacts, expropriationcompensations, and the tower locations,which, however, are only decidedlater during the more detailed planningof the line routes.EIA results to beexpected in the autumnThe environmental impact assessmentwork continues, and the assessment reportcompiling its results is expected tobe ready in the autumn. This is anotheropportunity for the general public toobtain more information, present theirviews and discuss the transmission lineproject face to face with the relevantexperts. The statement of the co-ordinationauthority will close the EIA processin early 2013.“The construction of the transmissionlines will take about three years. Thelaunching of the actual constructionand the progress of the work will dependon TVO’s schedule for the Olkiluoto4 nuclear power plant unit,” saysMika Penttilä. The plant is expected tobe complete in the 2020s. FINGRID 2/<strong>2012</strong> | 27

Åland Islands producea quarter of theirelectricityThe Åland Islands, an autonomous region of Finland, use approximately 300 gigawatt hours ofelectricity per year, in other words just under one per cent of the total electricity consumptionin Finland. About a quarter of the electricity is produced on the Åland Islands, over two thirdsis imported from Sweden, and the remainder seven per cent from Finland. Kraftnät Åland, thetransmission system operator of Åland, takes care of electricity transmission.Text by Antti Lagus | Photographs by Kraftnät Åland’s archivesThere is a 110 kilovolt submarinecable from the Åland Islands toSenneby in Sweden, from wherethere is a connection to the Swedishhigh-voltage grid through Vattenfall’snetwork. From the submarine cable,electricity is transmitted on an overheadtransmission line to the Tingsbackasubstation, from where Kraftnät Ålandsupplies electricity further along four45 kilovolt branch lines to the eastern,western and northern parts of the ÅlandIslands and to the town of Mariehamn.One 45 kilovolt transmission connectiontraverses the archipelago of Turkuto Kustavi.Of the energy used on Åland, 26 percent is derived from renewable energysources. In addition to 20 wind turbines,energy is produced in a thermal powerplant firing bioenergy.“Our goal on the Åland Islands is toraise the share of renewables of totalenergy to at least 38 per cent, whichis the national objective in Finland.We already have the permits for newwind turbines which would elevate theshare of renewable energy to about 70per cent, but their construction is stillwaiting for subsidy decisions,” says JanKahlroth, CEO of the transmission systemoperator Kraftnät Åland.The demand for energy continues togrow. On Åland, the growth rate hasbeen 1.8 per cent a year in the past tenyears. Jan Kahlroth also thinks that thegrowth in population on Åland will influencethe need for additional energy.Åland now has about 28,000 inhabitants.The portion of wind poweris growing in electricitygeneration on Åland in thecoming years.FINGRID 2/<strong>2012</strong> | 28

Kraftnät Åland uses its own transmission grid, which covers the Åland Islands completely, with about 300 kilometres of110 and 45 kilovolt lines, substations and interconnections to mainland Finland and Sweden.Alternatives to reserve powerThe transmission connection from Swedencan in practice cater for the fullelectricity supply of the Åland Islands.This is needed especially when thereis not enough wind to propel the windturbines. If the Swedish connection isnot available, the current archipelagoconnection can supply nine megawattsof energy. The rest of the electricity demandis due to be covered by reservepower machinery.Kraftnät Åland has an agreementwith a local electricity producer on itproducing energy for Kraftnät Ålandwhenever necessary. The company’s twogas turbines can produce 24 megawattsof energy, and the same amount usingtwo diesel engines. Moreover, KraftnätÅland has a 25 megawatt gas turbineof its own.Ring in the makingÅland has 17 substations, some ofwhich are currently being connectedinto a ring to safeguard continued operation.In addition, the old substationsbuilt in the 1970s are being upgraded toimprove system security.“We are renewing the substationspartly because they are so old that thereSven-Anders Eriksson and JanKahlroth: The transmission systemoperator of Åland is facing somesignificant changes.have been some problems in acquiringspare parts for them. Personal safety isalso an important consideration, sincemodern substations are safer to workin,” says Sven-Anders Eriksson, NetworkManager of Kraftnät Åland.Another problem with old technologyis that there are fewer and fewerprofessionals left to use it. Sven-AndersEriksson compares the situation to ataxi driver having a car from the 1970s.Full ownership toregional governmentAccording to the EU’s third ElectricityMarket Directive, an electricity distribu-tion company cannot be an owner in atransmission system operator. The regionalgovernment of Åland redeemedthe ownership of all the other major coownersof Kraftnät Åland in the summer.The regional government alreadyhas a majority of the shares.Kraftnät Åland will face even othersignificant changes in the near future.“The gas turbines of the local electricitycompany are old, and they musteventually be withdrawn from operation.Moreover, the demand for energyis constantly on the increase; as it is, wehave a risk of a power shortage in thewinter. As a result of the decommissioningof the reserve power machines andincreasing electricity consumption, wehave been planning a submarine cableconnection to the Finnish mainland,”says Jan Kahlroth.The new cable will enable Åland tobuy its electricity either from Finlandor Sweden. At present, there are discussionsabout what type of a model willbe introduced in the procurement ofmarket electricity, and no final decisionhas been made yet as to the directionfrom which the majority of the electricitywill be imported.FINGRID 2/<strong>2012</strong> | 29

Submarine cable linkingthe Åland Islands and mainland FinlandThe transmission cable connectionplanned between the ÅlandIslands and mainland Finlandwould start in Finland in Naantali withan AC/DC converter substation andwould reach the Åland Islands in thevillage of Ytterby in Jomala. The connectionwould continue via the DC/ACtransformer substation in Ytterby as a110 kilovolt overhead transmission lineto the Tingsbacka substation, where thepresent connection from Sweden is alreadyoperated.The cable could also be operated inthe other direction. If wind power productionincreases on Åland as planned,surplus electricity could be supplied tothe mainland on windy days. The importantthing in the utilisation of windpower is that there is a strong grid,which can be used for reserve powersupply whenever necessary and throughwhich any excess electricity can be deliveredfurther.The cable connection is used fortransmitting electricity on a market basis,in other words from a less expensivearea to a more expensive area.“The connection also provides yetanother opportunity to integrate thetransmission grids in Finland and Sweden.A submarine cable connects Ålandto Sweden and to mainland Finland,and on Åland the connection would runon overhead lines. Such an additionalconnection could be used for electricitytransmission between Finland and Sweden,”says Kraftnät Åland’s CEO JanKahlroth.According to him, the practical solutionswill be agreed upon at a later datebetween Kraftnät Åland, Svenska Kraftnät,<strong>Fingrid</strong> and Nord Pool Spot.Kraftnät Åland will be responsible forthe cable investment, and the companyhas applied for an investment subsidyfrom the regional government of Åland.The regional government, in turn, canapply for a subsidy for this type of specialexpenditure from the budget ofFinland. The Delegation of Åland is responsiblefor this process.The state of Finland has given a subsidyof 40 per cent to the earlier infrastructureinvestments on Åland – theelectricity transmission connectionto Sweden and the gas turbine powerplant. The state has granted a subsidy of40 per cent or a maximum of 50 millioneuros for the cable costing a total of125 million euros. The final agreementon the construction of the cable can bemade in the autumn after the EU hasapproved the subsidy package. FINGRID 2/<strong>2012</strong> | 30

POWERED BYELECTRICITYIn this column, <strong>Fingrid</strong> employees share their experiences ofappliances driven by an electric motor. Corporate Adviser RistoLindroos tested the Kalkhoff 8C HS electric bicycle.Electric partner ofcommuter cyclistText by Risto Lindroos | Photograph by Juhani EskelinenIhad been thinking of buying anelectric bicycle for quite some timewhen I saw an article in the springissue of magazine “Latu & Polku”, comparingelectric bicycles. The comparisonwas won by Kalkhoff 8C HS. The bikehas a 540 Wh lithium battery and a 250watt electric motor. The bike is given arange of 120 kilometres with a singlecharge.I soon found myself as a happyowner of an electric bike, and I usedthe bike on the next morning to ride towork. Switching on the electricassist by the switch on the handlebar,and the LEDs indicate thatthe battery is full. This is reallyeasy to ride! The riding positionis erect, so it is effortless to followthe traffic. The bike negotiatescurves very well, althoughin the lower position the pedaltends to scratch the asphalt.It is speedy going, but stillsomeone tries to pass. “Oh,you’ve got a doping bike,” a passer-bysays. It’s like being a dogowner: it is easy for like-minded peopleto start talking. “I had to electrify mybike, because there was so much snowin the winter. I used a self-install kit,”the passer-by continues.On the second day, the trip to workgoes as smoothly as dancing 30 yearsago. Following an easier ride, I cometo work feeling refreshed, and I returnhome less tired. On the third day, I feellike a pro. But why is that LED blinking?Maybe I should have read themanual after all. And behold, the batterygoes dead on the way to work. NowI understand why this needs a transmissionof eight speeds. There is no otheroption than to pedal harder! When Iget home from work, I am exhausted,although riding without the electric assistis not any heavier than riding a bikewith a single speed.After one month’s experience, I beginto be convinced. An electric bike ismost competitive over distances of 15to 25 kilometres, with relatively muchurban routes and hills. In an urban environment,an electric bike is faster thanconventional bicycles thanks to its betteracceleration. During the test period,my electric bike was an estimated 20per cent faster than my hybrid bike. Theaverage speed was approx. 25 kilometresper hour. The greatest benefit camefrom the fact that I was not tired in theevenings after the way home. This iswhy I can use the electric bike for relativelylong distances more often thanthe hybrid bike. I figured out that theelectric bike will pay itself back in timesavings and savings in travel costs in aperiod of two to three years.If you want, you can use the electricbike for exercise purposes just like anyother bike, because the electric assist isdisengaged when the speed goes over25 km/h. On the other hand, you canalso use it for leisurely ride, becausepedalling with the assist is child’s play.The electric bike equipped with studdedtyres is definitely also a competitive alternativein the winter.The speed of an electric bicycle ismore stable than when riding a hybridbike. There is really no speed loss in aclimb. Being quite heavy, the electricbike runs downhill a little faster thana regular bike. A cyclist with an electricbike is the first to shoot from trafficlights, because the electric motorkicks in at start.One of the foremost technicalcharacteristics of an electric bicycleis sufficient battery capacity.The brakes must also be effective.The bike must not assist pedallingin a jerky fashion. These characteristicswere fine in the biketested. However, the transmissionratio seemed to be too small athigh speeds. Other drawbacks includethe greater need for serviceand a relatively high price.A few years ago, an electric bicyclewas primarily just an aid for the disabledand aged. Electric bikes were notthat commonplace mainly due to theexpensive batteries. The prices of electricbicycles have come down in a fewyears and made them more popular.This is why electric bikes will probablybecome common in Finland, too, andfind users among cyclists aged 50+, especiallyin the Helsinki region, wherecycling is often a faster way of commutingthan motoring and public transportanyway. FINGRID 2/<strong>2012</strong> | 31

Grid ABCThis article series deals with the main operating principles,equipment units and components in the main grid. The articlespublished in the series previously can be viewed on our websiteat www.fingrid.fi.Voltage in electricity transmissionand distribution systemsText by Jarmo Elovaara | Photograph by Juhani EskelinenThe technology applied to electricitytransmission is relativelyyoung: It was not until the early1880s that the conditions were createdfor the transmission of electricity overlonger distances. The alternating currentmotor was developed in those days, anda patent was granted for an idea wherethe voltage provided by a generator waschanged to a higher voltage for electricitytransmission, and back to a lowervoltage at the point of consumption sothat the electricity could be used.Since the generation and transmissionof electricity require considerablecapital, the related investments havehad a long life. In some countries, suchas Sweden, this has been reflected in therelatively great diversity of the voltagelevels used. Only in the past 40 to 50years has the electricity distribution systembeen rationalised by reducing thenumber of voltage levels used.The magnitude of the power transmittedas electricity is determined bythe voltage used and the current transmitted(P~ U·I). As electricity consumptionand transmission distanceshave increased, a need for higher andhigher transmission voltage levels hasemerged. The most viable voltage dependson both the power transmissionneed and the transmission distance.The general principle is: the longer thetransmission distance, the higher thetransmission voltage, but the voltagevalues are case-specific. The nature ofthe most advantageous voltage is suchthat it is better to overdimension ratherthan to underdimension the voltage (Figure1). As an example, when the voltageneeded to transmit a certain poweris doubled, the current value drops to ahalf, and the resistance losses occurringin the transmission line are reduced in asquare (~I 2 ), in other words to a quarterof the original. This improves the transmissionand distribution efficiency. Asmaller current also translates into asmaller cross-sectional area of the conductorand hence lighter and less expensiveconductors and towers, but inother respects an increase in the voltageincreases the size of the equipmentand also raises their price. Moreover, ahigher voltage usually also means fewerparallel lines in a certain link.The current travelling in the linecauses losses, which are manifested inboth power losses (heat) and in a voltagereduction in the line. Electricity distributionnetworks are so designed thatthe sum of the investment costs and losscosts needed to transmit the necessarypower is minimised. In high-voltagetransmission networks, however, thedistances are long, and attention mustbe paid to many other factors dependenton the voltage, such as the maximumtransmittable power without disturbingthe synchronous operation of differentgenerators in the network. This dependson the product of voltages affecting atthe ends of the transmission connection.The highest voltage used anywherein the world is usually also the highestoption that is technically and economicallyavailable. The technical constraintsare generally manifested in the currentbreaking capability of circuit breakersand in the maximum voltage withstandcapability of the insulations of equipment(including overhead lines). As thevoltages and currents increase, so do theenvironmental disadvantages and safetyrisks, such as the risk of a short circuitand earth fault. These must be kept undercontrol.In the early days of electricity use,there was limited technical knowledge,and the construction of large networkswas not mastered. This is why the decisivefactor in the selection of the voltagelevel was that the consumptiondevices would work as well as possible.Before the advent of alternating current(AC) motors, electricity was primarilyused for illuminating major cities. Thelamps were arc lamps powered by directcurrent, and a voltage of approx. 120volts (V) was optimal for them. The ACsystem devised in 1883 enabled highervoltage levels and the use of electricityin manufacturing industries. As theAC systems developed further, lampsequipped with a metallic glow filamentwere introduced in lighting. These couldbe used at a voltage about twice thevoltage of arc lamps. Nevertheless, thevoltage of the low-voltage network inmany Finnish towns in the early 20thcentury was still 110 volts.Arc lamps were apparently morecommon in America than in Europe.This is why low-voltage distributionin Europe and the USA started to usedifferent voltages, which are still inuse: The standard voltage in Europe is230/400 V, while in the United Statesand in countries that use the technologydeveloped there the standard voltage is120/208 or 120/240 V. The standardvoltage series for high voltage were notharmonised between Europe and Americauntil 2006.Figure 2 shows the transmission voltagein the AC network over the years,expressed as the rated voltage of thenetwork. The figure shows that whenmoving over to the use of a higher voltage,the ratio of voltages in consecutivevoltage levels is in the order of two dueFINGRID 2/<strong>2012</strong> | 32