Linear Actuators - Setec-Group

Linear Actuators - Setec-Group Linear Actuators - Setec-Group

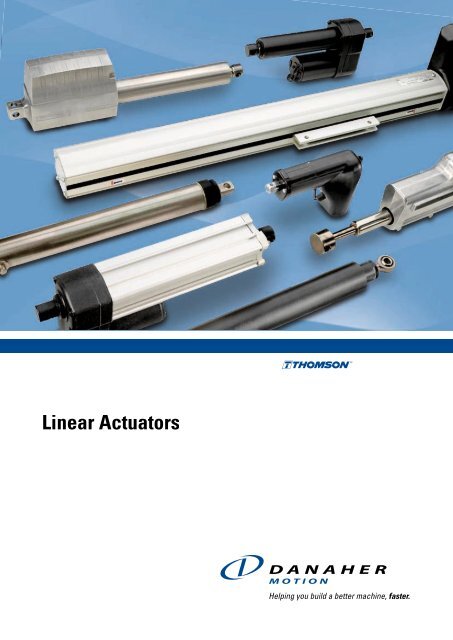

- Page 2: Danaher Motion -Helping you build a

- Page 5 and 6: Linear ActuatorsIntroductionProduct

- Page 7 and 8: Linear ActuatorsIntroductionThe Ben

- Page 9 and 10: Linear ActuatorsIntroductionSelecti

- Page 11 and 12: Linear ActuatorsLIFTING COLUMNS ROD

- Page 13 and 14: Linear ActuatorsPerformance Overvie

- Page 15 and 16: Linear ActuatorsElectrak 112, 24 an

- Page 17 and 18: Linear ActuatorsElectrak 1SP12, 24

- Page 19 and 20: Linear ActuatorsElectrak 05012, 24

- Page 21 and 22: Linear ActuatorsElectrak PPA-DC12,

- Page 23 and 24: Linear ActuatorsElectrak 1012, 24 a

- Page 25 and 26: Linear ActuatorsElectrak Pro12 and

- Page 27 and 28: Linear ActuatorsElectrak PPA-AC115

- Page 29 and 30: Linear ActuatorsElectrak 5230 and 4

- Page 31 and 32: Linear ActuatorsLifting Column TC16

- Page 33 and 34: Linear ActuatorsLifting Column DMD1

- Page 35 and 36: Linear ActuatorsLifting Column DMA2

- Page 37 and 38: Linear ActuatorsRodless Actuator LM

- Page 39 and 40: Linear ActuatorsRodless Actuator LM

- Page 41 and 42: Linear ActuatorsElectrak Non-driven

- Page 43 and 44: Linear ActuatorsElectrak Non-driven

- Page 45 and 46: Linear ActuatorsElectrical Wiring D

- Page 47 and 48: Linear ActuatorsElectrical Wiring D

- Page 49 and 50: Linear ActuatorsActuator ControlsSw

- Page 51 and 52: Linear ActuatorsActuator ControlsEl

Danaher Motion -Helping you build a better machine, fasterDanaher Corporation combined over 30 industry-leading brands such as Kollmorgen, Thomson, Dover, Pacific Scientific,Portescap, Neff, Seidel and Bautz to establish a customer-focused motion control manufacturing company called DanaherMotion. We offer this powerful set of integrated motion control technologies under the Danaher Motion and Thomsonbrand names. We are a $B+ global motion control leader, unique in our ability to marshal decades of application experienceand technical innovation to help you build better machines, faster.Danaher Motion defines high standards of quality, innovation and technology. We enable improved machine performanceand reliability while controlling costs. Our global manufacturing footprint, rapid customization and prototyping capabilitiesdrive quick lead times. Unmatched application experience and design expertise empowers you to commissionmachines faster.Consider your options in today’s market for a motion control partner. Select Danaher Motion and join a team with 600employees, over 60 years of application experience and 2000+ distributor locations around the globe. Danaher Motionserves industries as diverse as semiconductor, aerospace and defense, electric vehicle systems, packaging, printing,medical and robotics. We offer an unparalleled depth and breadth of motion control product solutions through a worldwideservice and support infrastructure, field service engineers and support teams available when and where you needthem.The Danaher Business System -Building sustainable competitive advantage into your businessThe Danaher Business System (DBS) was established to increase the value we bring to customers. It is a mature andsuccessful set of tools we use daily to continually improve manufacturing operations and product development processes.DBS is based on the principles of Kaizen which continuously and aggressively eliminate waste in every aspectof our business. DBS focuses the entire organization on achieving breakthrough results that create competitive advantagesin quality, delivery and performance – advantages that are passed on to you. Through these advantages DanaherMotion is able to provide you faster times to market as well as unsurpassed product selection, service, reliability andproductivity.Local Support Around the GlobeApplication CentersGlobal Manufacturing OperationsGlobal Design & Engineering Centers

IntroductionCompany IntroductionThe history of the Thomson Electrak ® actuator goes back to the developmentof ball screw actuators 40 years ago in Marengo, IL, USA. The first generationof general purpose actuators were developed for control of accessory driveson garden tractors and farm equipment. Since that simple beginning, actuatorsare now used in all types of equipment to automate a process, remove peoplefrom dangerous situations, provide remote control or make difficult, tediousmanual jobs easier.The linear actuators in this catalog represent provendesign concepts found in the entire Electrak series. Fromlight load 050s to the high performance Electrak Pro seriescapable of handling loads up to 9000 N,Thomson offersfeatures unavailable anywhere else.The world’s most versatile actuator selectionThomson combined the clevis to clevis mount Electrakseries, and the trunnion mount Electrak PPA units, toprovide the most versatile selection of linear actuatorsavailable. Our actuator team has solved over 10000 toughapplication challenges with even tougher actuators. Webuilt our reputation in the mobile off highway market inextremely demanding operating conditions. And if youcan’t find the actuator to meet your application, call usfor a cost effective actuator built to your needs. Thomsonbuilds more custom actuators than anyone.You can count on ThomsonThomson linear actuators – rugged, reliable remote linearmotion control with the push of a button. You can count onThomson for worldwide sales, service, application supportand local availability. Please visit www.danahermotion.com for more information.1967 1969 1974 1982 1984 1987 1988 1991The firstgeneration ofactuators foruse in gardentractors andfarm equipmentis released.First line of ballscrew drivenactuators withright angle ACand DC motors isreleased.First line ofactuators withparallel motorsand bothacme and ballscrew drive isreleased.The “Tiger” lineactuators arereleased forOEMs.Electrak 1, 2, 5,10 and 100 arereleased fordistribution.Electrak 205and the firstline of MCScontrols arereleased.Electrak 1SPwith feedbackpotentiometeris released.The first liftingcolumns, DMDand DMA, arereleased.4 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>IntroductionProduct IntroductionThomson actuators are easy to mount and operate, require no maintenance,don’t leak hydraulic fluid, are easy to incorporate into an automated processand once installed they will work reliably under the toughest conditions yearafter year.<strong>Actuators</strong> offer advantages over mechanical and hydraulicsystems in many applications. They are self-contained,rugged, and durable, making them ideal anywhere youwant to lift, lower, push, pull, rotate or position a load.Compact designWith their compact size, actuators can be located inconfined areas. An actuator with a 100 mm stroke lengthcan produce 9000 N of force from a 280 mm package.Electrak 1 and 050 series actuators fit small areas withpackage lengths as short as 153 mm.Rugged and reliableAll Thomson actuators incorporate strong, high qualitycomponents to assure trouble-free service. Rugged spur,worm or helical gearing, aircraft quality lubricants and highperformance motors provide the maximum life and value.The actuators are gasketed and sealed throughout forprotection in wet, dirty and oily environments and are idealfor use on outdoor equipment. The rod style actuatorshave stainless steel or aluminum extension tubes to resistcorrosion.Maintenance-freeAll adjustments and lubrication are made at the factory andno maintenance is required or recommended. Consistent,repeatable performance is provided for the entire lifetimeof the actuator.BidirectionalThomson actuators can push and pull loads ranging fromone to 900 kg, and can extend up to 900 mm. With theThomson series of actuator controls, you can create anactuator control system to meet your particular motioncontrol requirements.Safe operationMotors used on Electrak actuators utilize thermal switchesin their windings or Electronic Load Monitoring to shut theactuator off in case of overheating. A standard overloadclutch or Electronic Load Monitoring will stop the motionif the load is too great or at the end of a stroke. All linearactuators will hold their loads with power removed.VersatileStroke lengths of 25 to 900 mms are available and speedsare as high as 75 mm per second. <strong>Actuators</strong> are easy toapply, quick to install and usually only requiring two wiresfor operation. A wide variety of options and controls makesit easy to find the perfect actuator for your application. Andif you have special needs, cost effective custom solutionsare our speciality.1992 1994 1998 1999 2000 2004 2006A patent for aload lock deviceis granted.Electrak 1LL isreleased.Electrak 150 withtwo patents isreleased. ACcontrol line isreleased.Electrak 050 withpatented designand the firstrotary actuatorsare released.The first LM80rodless actuatoris released.The triple profilelifting columnTC16 and the“sweeper“actuator arereleased.The Electrak Proactuator lineand the DCGcontrol line arereleased.www.danahermotion.com5

IntroductionThe Benefits of ElectrificationElectrification is converting manual, hydraulic and pneumatic operations toelectromechanical motion. Substantially improved machine performanceand cost advantages can be gained through electrification.Reduce costs• Electric actuation components cost less thancomparable hydraulic and pneumatic systems.• One electric linear actuator is faster and easierto install than the multiple hydraulic and pneumaticcomponents required to achieve the same function.• Electric actuators feature quick and predictable systemtuning when compared to the headaches of configuringhydraulic systems and their components which contendwith power variation, temperature variation, and nonlinearperformance profiles.• Compare zero maintenance electric actuators againstthe fluid replacement, leak repairs and other routinemaintenance needed to support hydraulic systems.• Eliminate the environmental problems and costsassociated with hydraulic fluid leaks and fluid disposal.Boost productivity and efficiency• Improve control over critical machine operations with:- Multiple digital and analog feedback options- Fixed and programmable limit switches for “teach andrepeat” positions- Low voltage switching options that can interfacedirectly with programmable PC/PLC controllers- Pulse width modulation for variable speed control• Superior accuracy and repeatability• Link and automate simultaneous processes• Reduce down time with:- Zero maintenance- Longer component life- Redundancy through manual override• Improve safety and reduce costs by removing peoplefrom danger with convenient remote controlMaking jobs easier• Raising and lowering a deck on a mower, paver or floor scrubber.• Shifting manual transmission.• Lifting wheelchairs into a vehicle.• Opening and closing doors on buses or vans.Automating a process• Moving twine across a round bale of hay for consistent wrap.• Varying the chute opening on a salt/sand spreader based on speedfor consistent application.• Lift and lower pantographs on electrical trains and trams.Providing remote control• Throttle control from the rear of garbage trucks.• Positioning the discharge spout on a large chipper, snowblower orcombine.• Opening a chute on a salt/sand spreader.• Positioning of solar energy panels and wind power plant turbines.• Opening/closing the engine hatch on boats.• Positioning boat, handicap vehicle seats.• Belt tensioning.Removing people from danger• Sliding a cover over the stairs in a recreational vehicle.• Throttle control for a tree stump grinder to keep the operator awayfrom moving parts or flying debris.• Medical waste/refuse compacting.Replacing hydraulics or pneumatics• Power steering.• Dump beds on ATVs.• Positioning mower decks on golf course equipment.Great opportunities for electric conversionwww.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>IntroductionThe Benefits of ElectrificationReplacing hydraulic or pneumatic cylinders with electrical linear actuatorsmeans a simpler and smaller installation, easier control, lower energy costs,higher accuracy, less maintenance, less noise and a cleaner, healthierenvironment.432516Single acting, uni-directional hydraulic cylinder system1. Hydraulic cylinder2. Electric pump motor3. Hydraulic pump4. Hydraulic oil resevoir5. Check valve6. Operator push button box7. Relay cabinet8. Unloading valve7You can design, purchase and install all these componentsor you can select and install an actuator and control.8This single acting, uni-directional hydraulic cylinder systemis one of the simplest hydraulic solutions. This system onlyallows consistent performance in one direction. In orderto get consistent performance in both directions a bidirectionalsystem would be required which is even morecomplex and costly.12Electric linear actuator system1. <strong>Linear</strong> actuator2. Actuator control3. Hand held control pendantPlug and play type of connections, simple installation andno need for any set up or adjustments ensures accurate,clean and trouble free operation within the hour.3This simple electrical actuator system will ensure consistentoperation in both directions. It will also give you addedfeatures such as electronic load monitoring, end of strokelimit switches, mid stroke protection and manual overrideoperation in case of power failure. Optional features suchas analog or digital position feedback, adjustable end ofstroke limit switches, end of stroke indication outputs andsignal following capability are also available. Anotheradvantage is that a system like this is easy to integrate withother control systems normally found in industrial systemsor vehicles such as PLC’s, micro-controllers, computers orsimple relay based systems.www.danahermotion.com

IntroductionActuator ApplicationsThomson Electrak actuators can be found in the most diverse applications,ranging from agricultural to industrial, ventilation and medical equipment.Anywhere you want to lift, lower, push, pull, rotate or position a load - onlyyour imagination will set the limit.Mobile-off-highway<strong>Actuators</strong> are widely used in agricultural, construction,mining, forestry, road work and railway equipment for thecontrol of seats, hoods, doors, covers, balers, pantographs,sprayer booms, throttles and much more.Turf and garden<strong>Actuators</strong> can be found on riding lawn mowers, golf carts,garden tractors, cleaning machines, sky lifts and otherutility vehicles.Industrial equipment<strong>Actuators</strong> are used on conveyor belts, for adjustablework tables/platforms and in the opening and closingof hatches, doors and locks. They are also common inmachines for dispensing, cutting, packaging, labeling,scanning or printing.Health and fitness<strong>Actuators</strong> are commonly used in patient lifts/beds,handicap adapted vehicles and wheel chairs to positionpatients or equipment. Other applications include hospitaldevices, examination chairs/tables and work out/gymapparatus.Office, domestic and entertainment equipmentAt home, in the office and in the entertainment businessactuators are used in automatic doors, lifts, garage doors,gates, satellite dishes, beds, reclining chairs, adjustableoffice desks, arcade games, vending machines, theatre/TV/movie props and theme park attractions.MarineOn boats, ships and oil rigs actuators are used in seats,hatches, fire doors, rescue equipment, valves and throttles.Ventilation and process control<strong>Actuators</strong> are used for valve control in ventilation andprocess equipment.8 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>IntroductionSelection ProcedureThomson actuators have been divided into good, better and best groups tohelp you select the appropiate actuator for your application. By using thesimple selection procedure described below and the Performance Overviewon the next few pages, the process will be even easier.GoodThese actuators are the lowest cost solution, providecapable, reliable performance and have some flexibilityof options and configurations. If you just need a basicactuator, this is the best choice.Selection procedureStep 1 - Determine VoltageDC actuators can be operated by battery, a rectifier oran actuator control with 230 Vac input. AC actuators areeither 230 or 400 Vac.Step 2 - Determine Load/SpeedSelect the actuator which has the load and speed ratingthat suits your application.BetterThese actuators have more flexibility in options,configurations and modifications. They have passed thetest of time in the toughest agriculture and constructionapplications. Choose from this group if you need a rugged,heavy duty actuator customized to your application.BestThese robust and strong actuators are the market leaderswith state of the art technology and flexibility. They aresmaller, lighter and have a shorter retracted length thanother actuators on the market. If you need electronic loadmonitoring, programmable limit switches, digital feedbackor signal following, this is the group for you.Step 3 - Select Stroke LengthChoose the desired stroke length from either thePerformance Overview pages or the individual productpages.Step 4 - Verify Design ConsiderationsDo you need a very short retracted length, adjustable,fixed or programmable limit switches, electronic loadmonitoring, digital or analog feedback, low voltage powerswitching, manual override, signal following, clevismounting, tube mounting or trunnion mounting? If youneed an actuator to take side loads or cantilever loads,select from the TC16, DMD, DMA or LM80 actuators.Step 5 - Select ControlThe controls in the catalog are designed for use withElectrak actuators and range from a simple switch to acontrol with membrane switches and feedback display orwith a hand pendant.On-line selection softwareOn www.danahermotion.com/linear_actuator_advisoryou can select an actuator by using the actuator productadvisor. This easy to use software lets you play with allthe parameters and will give you all the relevant data andthe correct ordering information for your choice.Can’t find what you are looking for?If you are an OEM customer and can’t find exactly whatyou need, contact customer service at +46 (0)44 24 67 90for a custom solution.www.danahermotion.com

Performance OverviewStandard Actuator Range SP 050 2 PPA-DC 0ELECTRAKProduct availabilityNorth America / Europe / Asia 1 • / • / • • / • / • • / • / • • / / • / • / • • / • / •General performanceProduct group rating good good better better good betterInput voltage - Vdc / Vac [V] 12, 24, 36 2 / 12, 24, 36 2 / 12, 24, 36/ 12 / 12, 24, 36, 90 3 / 12, 24, 36/Maximum dynamic load [N] 340 340 500 1100 6670 6800Maximum speed [mm/s] 75 75 48 30 33 60Maximum stroke length [mm] 150 150 200 610 914 610Restraining torque [Nm] 2,3 0 0 7,3 23 12Protection class IP65 IP65 IP56 IP65 IP52 IP65FeaturesMounting configuration clevis clevis clevis clevis trunnion clevisScrew type - acme / worm / ball • / / •/ / / • / • / / / / • • 2 / / •Overload clutch • • • •Motor overload protection • • • • • •End of stroke limit switches • •Potentiometer feedback•Electronic load monitoringDynamic braking • 7Manual overrideOptional featuresEnd of stroke limit switches • 3 • • 3Potentiometer feedback • • • •Encoder feedback•Programmable limit switchesEnd of stroke indication outputsLow voltage power switchingSignal follower inputPWM speed control monitoringManual override • • 3 •More informationSee page 1 14 16 18 – 20 22Actuator ControlsRecommended control AC-247 ELS AC-247 ELS DCG-150 DPDT Switch AC-063 AC-0631Products not available in this region are not further described in this catalog. Contact customer support for more information.2Not available in North America.0www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>LIFTING COLUMNS RODLESS OTHERPro PPA-AC 5 205 TC6 DMD DMA LM80-H LM80-V• / • / • •/ • / • •/ • / • •/ / • / • / • •/ • / • •/ • / • •/ • / • •/ • / •best good better better best better better better better12, 24 / / 115, 230 / 115 3 , 230, 400 2 / 115, 230 24 / 12, 24, 36 / / 115 3 , 230, 400 2 12, 24 / 12, 24 /9000 6670 6800 6800 2000 6800 6800 2000 4 2000 551 15 60 53 19 60 60 110 110300 914 610 610 400 610 610 1500 150017 / 0 6 23 12 12 0 0 0 0 0On the nextpages youcan findinformationon thefollowingtype ofactuators:• Non-driven• Rotary• Legacy• CustomIP66 IP45 IP45 IP45 IP44 IP65 IP45 IP44 IP44clevis trunnion clevis clevis/tube base mount base mount base mount T-slot T-slot• / / • / / • • 2 / / • / / • • 8 / / • / / • •/ / • • 8 / / • • 8 / / •• • • •• • • • • •• • •••• ••• • 3• • • • 2 • 2• • ••••••• 3 • • •24 26 28 – 30 32 34 36 38DCG-190 DPDT Switch DPDT Switch MCS-2051(2) DCG-180 AC-063 DPDT Switch DCG-170 DCG-1603 4 5 6 7 8Not available in Europe. For horizontal operation only. For vertical operation only. Without / with anti-rotation option. At end of stroke only. Trapezoidal screw.www.danahermotion.com

Performance OverviewNon-driven and Rotary <strong>Actuators</strong>PPA-MFA4ROTARYDGBProduct availabilityNorth America / Europe / Asia 1 • / • / • / • / •General performanceProduct group rating goodbestProduct availabilityNorth America / Europe / AsiaGeneral performanceProduct group rating• / / •betterMax. input torque [Nm] 9 1,8Max. input speed [rpm] 100 3000Maximum dynamic load [N] 6670 6800Maximum speed [mm/s] 8 37Maximum stroke length [mm] 914 600Restraining torque [Nm] 23 0Standard featuresMounting configuration trunnionclevis/trunnionScrew type - acme / worm / ball / / • • / / •Overload clutchOptional featuresManual overrideProtective bellowsExternal magnetic position sensorsMore informationSee page 1 40 421Products not available in this region are not further described in this catalog.Contact customer support for more information.••••Input voltage - Vdc / Vac [V] 12, 24, 36 /Maximum torque [Nm] 20Maximum speed [rpm] 200Maximum duty cycle [%] 25Protection classStandard featuresMounting configurationOverload clutchMotor overload protectionOptional featuresDual ouput shaftsManual overrideMore informationIP56clevis/tapped holesSee page 1 –1Products not available in this region are not further described in this catalog.Contact customer support for more information.••••2www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Performance OverviewLegacy <strong>Actuators</strong>ELECTRAK LEGACY ACTUATORSLL 50 00 LA4 LA24Product availabilityNorth America / Europe / Asia • / / • / • / • • / / / • / • / • / •General performanceProduct group rating good better better better betterInput voltage - Vdc / Vac [V] 12, 24 / 12, 24, 36 / 115 1 24 / 12, 24, 36 / / 230, 400Maximum dynamic load [N] 340 2000 6800 6800 6800Maximum speed [mm/s] 76 71 48 60 60Maximum stroke length [mm] 152 406 609 600 600Restraining torque [Nm] 0 0 12 0 0Protection class IP65 IP56 IP65 IP65 IP45Standard featuresMounting configuration clevis clevis tube clevis/trunnion clevis/trunnionScrew type - acme / worm / ball • / / / • / / / • • / / • • / / •Overload clutch • •Motor overload protection • • • •Potentiometer feedback•Fixed end of stroke limit switches•Adjustable end of stroke limit switches•Internally restrained • • • •Optional featuresAdjustable end of stroke limit switches•Potentiometer feedback • • •Manual override • •External magnetic position sensors • •1 Not available in Europe.About Legacy <strong>Actuators</strong>The legacy products will not be further described in thiscatalog. We recommend you choose one of the productson the preceding pages, especially when designing newequipment. However, the legacy actuators can still bepurchased and we fully support them. Please contactcustomer support if you need more information.About Custom <strong>Actuators</strong>The actuators you see on these pages are some of thebuilding blocks we use to create cost effective custom actuatorsfor OEMs. If you can’t find the actuator that meetsyour needs, call customer service at +46 (0) 44 24 67 90 for acustom solution. Thomson is the industry leader in customactuator design.www.danahermotion.com3

Electrak 12, 24 and 36 Vdc - load up to 340 N» Ordering Key - see page 64» Glossary - see page 72» Electric Wiring Diagram - see page 44Performance SpecificationsStandard Features and Benefits• Very compact and lightweight• Integrated end of stroke limit switches• Corrosion resistant housing• Self-locking acme screw drive system• Maintenance free• Ideal for replacement of comparable size pneumaticand hydraulic cylindersGeneral SpecificationsParameterScrew typeInternally restrainedManual overrideDynamic brakingHolding brakeEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionacmenononono, self-lockingElectrak end of stroke limit switchesnoauto reset thermal switchflying leads and connectorParameterMaximum load, dynamic / staticS • • -09A04S • • -09A08S • • -17A08S • • -17A16Speed, at no load / at maximum loadS • • -09A04S • • -09A08S • • -17A08S • • -17A16[N][mm/s]Electrak 110 / 1300225 / 1300340 / 1300340 / 130075 / 5245 / 3326 / 1714 / 7Available input voltages [Vdc] 12, 24, 36Standard stroke lengths [inch] 1, 2, 3, 4, 5, 6Operating temperature limits [°C] -25 – +65Full load duty cycle @ 25 °C [%] 25End play, maximum [mm] 0,9Restraining torque [Nm] 2,3Lead cross section [mm 2 ] 1Lead length [mm] 110Protection classCompatible ControlsControl modelIP65See pageDPDT switch 48DPDT switch box 49AC-247 ELS 52DCG-150 54Motor connectorCertificatesOptionsPackard Electric Pack-Con male8911773 with terminal 6294511.Mating connector: 8911772 withterminal 8911639 (p/n 9300-448-001)CEnone4www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak 112, 24 and 36 Vdc - load up to 340 NS: strokeA: retracted lengthA1: installation must include at least this much coast beyond limit switch shut offA2: black lead for 12 Vdc units, white lead for 24 Vdc unitsA3: yellow leadOrdering stroke [inch] 1 2 3 4 5 6Actual stroke (S) [mm (inch)] 20,8 (0,82) 46,2 (1,82) 71,6 (2,82) 97,0 (3,82) 122,4 (4,82) 147,8 (5,82)Retracted length (A) [mm] 134,5 159,9 185,3 210,7 236,1 261,5Weight [kg] 0,52 0,54 0,60 0,63 0,66 0,68Performance DiagramsSpeed and Current vs. LoadSpeed and Current vs. Load12 and 24 Vdc 36 VdcV: speed I: current F: load1: speed S • • -09A042: speed S • • -09A083: speed S • • -17A084: speed S • • -17A165: current 12 Vdc, S12-09A046: current 24 Vdc, S24-09A047: current 12 Vdc, S12-09A088: current 24 Vdc, S24-09A089: current 12 Vdc, S12-17A0810: current 24 Vdc, S24-17A0811: current 12 Vdc, S12-17A1612: current 24 Vdc, S24-17A16V: speed I: current F: load1: speed S36-09A042: speed S36-09A083: speed S36-17A084: speed S36-17A165: current 36 Vdc, S36-09A046: current 36 Vdc, S36-09A087: current 36 Vdc, S36-17A088: current 36 Vdc, S36-17A16www.danahermotion.com15

Electrak SP12, 24 and 36 Vdc - load up to 340 N» Ordering Key - see page 64» Glossary - see page 72» Electric Wiring Diagram - see page 44Performance SpecificationsStandard Features and Benefits• Very compact and lightweight• Potentiometer feedback• Corrosion resistant housing• Self-locking acme screw drive system• Maintenance free• Internally restrained extension tube• Ideal for replacement of comparable size pneumaticand hydraulic cylindersGeneral SpecificationsParameterScrew typeInternally restrainedManual overrideDynamic brakingHolding brakeEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionMotor connectoracmeyesnonono, self-lockingnonoElectrak SPauto reset thermal switchflying leads and connectorPackard Electric Pack-Con male8911773 with terminal 6294511.Mating connector: 8911772 withterminal 8911639 (p/n 9300-448-001)ParameterMaximum load, dynamic / staticSP • • -09A04SP • • -09A08SP • • -17A08SP • • -17A16Speed, at no load / at maximum loadSP • • -09A04SP • • -09A08SP • • -17A08SP • • -17A16[N][mm/s]Electrak SP110 / 1300225 / 1300340 / 1300340 / 130075 / 5245 / 3326 / 1714 / 7Available input voltages [Vdc] 12, 24, 36Standard stroke lengths [inch] 2, 4, 6*Operating temperature limits [°C] -25 – +65Full load duty cycle @ 25 °C [%] 25End play, maximum [mm] 0,9Restraining torque [Nm] 0Lead cross section [mm 2 ] 1Lead length [mm] 110Protection classIP65Potentiometer [kOhm] 10*** Six inch stroke lenght not possible for SP • • -17A16.** See table on page 17 for resistance change per mm.Compatible ControlsControl modelSee pageDPDT switch 48DPDT switch box 49AC-247 ELS 52DCG-150 54CertificatesOptionsCEnone6www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak 1SP12, 24 and 36 Vdc - load up to 340 NS: strokeA: retracted lengthA1: cable for potentiometer feedback, length = 635 mmA2: black lead for 12 Vdc units, white lead for 24 Vdc unitsA3: yellow leadOrdering stroke [inch] 2 4 6*Actual stroke (S) [mm (inch)] 58,7 (2,31) 115,1 (4,53) 171,5 (6,75)Retracted length (A) [mm] 197,9 254,3 310,7Weight [kg] 0,54 0,64 0,68Potentiometer resistance change [ohm/mm] 94 47 31* Six inch stroke lenght not possible for SP • • -17A16.Performance DiagramsSpeed and Current vs. LoadSpeed and Current vs. Load12 and 24 Vdc 36 VdcV: speed I: current F: load1: speed SP • • -09A042: speed SP • • -09A083: speed SP • • -17A084: speed SP • • -17A165: current 12 Vdc, SP12-09A046: current 24 Vdc, SP24-09A047: current 12 Vdc, SP12-09A088: current 24 Vdc, SP24-09A089: current 12 Vdc, SP12-17A0810: current 24 Vdc, SP24-17A0811: current 12 Vdc, SP12-17A1612: current 24 Vdc, SP24-17A16V: speed I: current F: load1: speed SP36-09A042: speed SP36-09A083: speed SP36-17A084: speed SP36-17A165: current 36 Vdc, SP36-09A046: current 36 Vdc, SP36-09A087: current 36 Vdc, SP36-17A089: current 36 Vdc, SP36-17A16www.danahermotion.com17

Electrak 05012, 24 and 36 Vdc - load up to 510 N» Ordering Key - see page 65» Glossary - see page 72» Electric Wiring Diagram - see page 44Performance SpecificationsParameter Electrak 050Maximum load, dynamic / staticDE • • • 17W41DE • • • 17W42DE • • • 17W44[N]510 / 1020275 / 550140 / 280Standard Features and Benefits• Designed for office or medical applications• Small, quiet and lightweight• Very short retracted length• Low cost• Durable and corrosion free plastic housing• Color molded into the plastic, no painting required• End of stroke limit switches with dynamic braking• Maintenance free• Internally restrained extension tube• Estimated life is minimum 40000 cycles• Q-version for noise sensitive applicationsGeneral SpecificationsParameter Electrak 050Screw typeInternally restrainedManual overrideDynamic brakingHolding brakeEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionMotor connectorCertificatesOptionswormyesnoyes, at end of strokeno, self-lockinginternal limit switchesoverload clutchauto reset thermal switchflying leadsnoCE• potentiometer 10 kOhm*• cross holes rotated 90°• white housing* See performance specification table for resistance change per mm of travel.Speed, at no load / at maximum loadDE • • - 17W41DE • • - 17W42DE • • - 17W44DE • • Q17W41DE • • Q17W42DE • • Q17W44[mm/s]12 / 924 / 1848 / 379 / 7,518 / 1438 / 30Available input voltages [Vdc] 12, 24, 36Standard stroke lengths [mm] 25, 50, 75,100, 125, 150,175, 200Operating temperature limits [°C] -30 – +80Full load duty cycle @ 20 °C [%] 25End play, maximum [mm] 1,5Restraining torque [Nm] 0Lead cross section [mm 2 ] 1Lead length [mm] 500Protection classstandar versionQ-versionPotentiometer resistance changeDE • • • 17W41DE • • • 17W42DE • • • 17W44Compatible ControlsControl model[ohm/mm]IP56IP5122,021,921,2See pageDPDT switch 48DPDT switch box 49DCG-150 52AC-247 ELS 548www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak 05012, 24 and 36 Vdc - load up to 510 NS: stroke (tolerances: 17W41 = ± 3,23 mm, 17W42 = ± 4,25 mm, 17W44 = ± 5,26 mm)A: retracted lengthA1: Ø 6 mm +0,15/ -0 mounting cross holes (2 ×) in standard positionA2: red leadA3: yellow leadA4: vent tube Ø 3 mmStroke (S) [mm] 25 50 75 100 125 150 175 200Retracted length (A) [mm] 114,2 139,2 164,2 189,2 214,2 239,2 264,2 289,2Retracted length, with potentiometer (A) [mm] 145,7 170,7 195,7 220,7 245,7 270,7 295,7 - *Weight [kg] 0,59 O,64 0,69 0,73 0,78 0,82 0,87 0,91Weight with potentiometer [kg] 0,69 0,74 0,79 0,83 0,88 0,92 0,97 - ** 200 mm stroke not possible with potentiometer (PO, MP, PF options)Performance Diagrams050, standard version 050, Q-versionSpeed and Current vs. LoadSpeed and Current vs. LoadV: speed I: current F: load1: speed DE • • • 17W412: speed DE • • • 17W423: speed DE • • • 17W444: current 12 Vdc, DE12 • 17W415: current 24 Vdc, DE24 • 17W416: current 12 Vdc, DE12 • 17W427: current 24 Vdc, DE24 • 17W428: current 12 Vdc, DE12 • 17W449: current 24 Vdc, DE24 • 17W44www.danahermotion.com19

Electrak PPA-DC12, 24 and 36 Vdc - load up to 6670 N» Ordering Key - see page 65» Glossary - see page 72» Electric Wiring Diagram - see page 45Performance SpecificationsParameterMaximum load, dynamic / staticPPA • • -18B65PPA • • -58B65[N]PPA-DC3330 / 133506670 / 13350Standard Features and Benefits• Strong and versatile heavy duty actuator• High duty cycle• Highly efficient ball screw drive system• Overload clutch for mid and end of stroke protection• Stroke lengths up to 36 inch (914 mm)• Three different input voltages to choose from• Motor with thermal switch• Maintenance free• Large range of optionsGeneral SpecificationsParameterScrew typeInternally restrainedManual overrideDynamic brakingHolding brakeEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionMotor connectorCertificatesOptionsballnono, optionalnoyesoverload clutchoverload clutchElectrak PPA-DCauto reset thermal switchflying leadsnoCE• end of stroke limit switches• potentiometer• encoder• protective bellowsSpeed, at no load / at maximum loadPPA12(24/36)-18B65PPA12(24/36)-58B65[mm/s]32 / 2812 / 9Available input voltages [Vdc] 12, 24, 36Standard stroke lengths [inch] 4, 8, 12,18, 24, 36Operating temperature limits [°C] -25 – +65Full load duty cycle @ 25 °C [%] 30End play, maximum [mm] 1Restraining torquePPA • • -18B65PPA • • -58B65[Nm]Lead cross section [mm 2 ] 21122Lead length [mm] 420Protection classCompatible ControlsControl modelIP52See pageDPDT switch 48DPDT switch box 49AC-063 50DCG-190 5420 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak PPA-DC12, 24 and 36 Vdc - load up to 6670 NS: strokeA: retracted lengthB: retracted length to trunnionsA1: housing dimensions for limit switch, encoder or potentiometer optionsStroke (S) [inch (mm)] 4 (101,6) 8 (203,2) 12 (304,8) 18 (457,2) 24 (609,6) 36 (914,4)Retracted length (A) without options [mm] 348,0 449,6 551,2 754,4 906,8 1211,6Retracted length (A) with limit switch,[mm]encoder or potentiometer398,8 500,4 602,0 805,2 957,6 1262,4Retracted length to trunnions (B) [mm] 223,5 352,1 426,7 629,9 782,3 1087,1Weight [kg] 4,5 5,3 6,0 7,2 8,4 10,8Add on weight for limit switch,[kg]encoder or potentiometer0,5 0,5 0,5 0,5 0,5 0,5Performance DiagramsSpeed and Current vs. LoadV: speed I: current F: load1: speed PPA • • -18B652: speed PPA • • -58B653: current 12 Vdc, PPA12-18B654: current 12 Vdc, PPA12-58B655: current 24 Vdc, PPA24-18B656: current 24 Vdc, PPA24-58B657: current 36 Vdc, PPA36-18B658: current 36 Vdc, PPA36-58B65www.danahermotion.com21

Electrak 012, 24 and 36 Vdc - load up to 6800 N» Ordering Key - see page 66» Glossary - see page 72» Electric Wiring Diagram - see page 44Performance SpecificationsParameter Electrak 0Standard Features and Benefits• Robust, strong and reliable• Withstands very harsh environments• Stainless steel extension tube• Acme or ball screw models• Overload clutch for mid and end of stroke protection• Motor with thermal switch• Maintenance freeGeneral SpecificationsParameter Electrak 0Screw typeInternally restrainedManual overrideDynamic brakingHolding brakeacme screw modelsball screw modelsEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionMotor connectorCertificatesacme or ballnono, optionalnono, self-lockingyesoverload clutchoverload clutchauto reset thermal switchflying leads and connectorAMP connectorwith housing p/n 180908-5with male terminals p/n 42098-2CEMaximum load, dynamic / staticD • • -05A5 (acme screw)D • • -10A5 (acme screw)D • • -20A5 (acme screw)D • • -05B5 (ball screw)D • • -10B5 (ball screw)D • • -20B5 (ball screw)D • • -21B5 (ball screw)Speed, at no load / at maximum loadD • • -05A5 (acme screw)D • • -10A5 (acme screw)D • • -20A5 (acme screw)D • • -05B5 (ball screw)D • • -10B5 (ball screw)D • • -20B5 (ball screw)D • • -21B5 (ball screw)[N][mm/s]1100 / 113502250 / 113502250 / 113502250 / 180004500 / 180004500 / 180006800 / 1800054 / 3230 / 1815 / 1261 / 3730 / 1915 / 1215 / 11Available input voltages [Vdc] 12, 24, 36Standard stroke lengths [inch] 4, 6, 8, 10,12, 14, 16,18, 20, 24Operating temperature limits [°C] -25 – +65Full load duty cycle @ 25 °C [%] 25End play, maximum [mm] 1,0Restraining torque [Nm] 11,3Lead cross section [mm 2 ] 2Lead length [mm] 165Protection classCompatible ControlsControl modelIP65See pageDPDT switch 48DPDT switch box 49AC-063 50DCG-190 54Options• potentiometer• manual override22 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak 1012, 24 and 36 Vdc - load up to 6800 NS: stroke, tolerance acme / ball screwA: retracted length, tolerance acme / ball screwA1: black leadA2: red leadA3: manual override input (optional)A4: housing dimensions for potentiometer optionStroke (S) [inch (mm)] 4 (101,6) 6 (152,4) 8 (203,2) 10 (254,0) 12 (304,8) 14 (355,6) 16 (406,4) 18 (457,2) 20 (508,0) 24 (609,6)Retracted length, acme screw models (A) [mm] 262,3 313,1 363,9 414,7 465,5 567,1 617,9 668,7 719,5 821,1Retracted length, ball screw models (A) [mm] 302,3 353,1 403,9 454,7 505,5 607,1 657,9 708,7 759,5 861,1Add on length for potentiometer* [mm] 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0Weight, acme screw models [kg] 4,5 4,7 4,9 5,0 5,2 5,4 5,5 5,7 5,8 6,2Weight, ball screw models [kg] 5,1 5,3 5,5 5,6 5,8 5,9 6,1 6,3 6,4 6,8Add on weight for potentiometer* [kg] 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3Potentiometer resistance change* [ohm/mm] 39 39 39 39 20 20 20 20 20 10* Potentiometer is optionalPerformance DiagramsAcme Screw ModelsSpeed and Current vs. LoadBall Screw ModelsSpeed and Current vs. LoadV: speedI: currentF: load1: speed D • • -05A52: speed D • • -10A53: speed D • • -20A54. current 12 Vdc, D12-05A55: current 24 Vdc, D24-05A56: current 12 Vdc, D12-10A57: current 24 Vdc, D24-10A58: current 12 Vdc, D12-20A59: current 24 Vdc, D24-20A5V: speedI: currentF: load1: speed D • • -05B52: speed D • • -10B53: speed D • • -20B54: speed D • • -21B55. current 12 Vdc, D12-05B56: current 24 Vdc, D24-05B57: current 12 Vdc, D12-10B58: current 24 Vdc, D24-10B59: current 12 Vdc, D12-20B510: current 24 Vdc, D24-20B511: current 12 Vdc, D12-21B512: current 24 Vdc, D24-21B5www.danahermotion.com23

Electrak Pro12 and 24 Vdc - load up to 9000 N» Ordering Key - see page 67» Glossary - see page 72» Electric Wiring Diagram - see page 44Performance SpecificationsParameterElectrak ProStandard Features and Benefits• Designed for heavy duty operation, IP66 protection• Optimized overall envelope with minimal retracted length• Durable and corrosion resistant aluminum housing• Cover tube and extension tube in stainless steel 2/5• Acme or ball screw models• Maintenance free• Electronic load monitoring (ELM)• Manual override• Wide range of optionsGeneral SpecificationsParameterScrew typeacme or ballInternally restrained no / yes 1Manual overrideDynamic brakingyesyesElectrak ProMaximum load, dynamic / staticPR • • 02-2A65 (acme screw)PR • • 05-4A65 (acme screw)PR • • 07-8A65 (acme screw)PR • • 05-2B65 (ball screw)PR • • 10-4B65 (ball screw)PR • • 15-8B65 (ball screw)PR • • 20-8B65 (ball screw)Speed, at no load / at maximum loadPR • • 02-2A65 (acme screw)PR • • 05-4A65 (acme screw)PR • • 07-8A65 (acme screw)PR • • 05-2B65 (ball screw)PR • • 10-4B65 (ball screw)PR • • 15-8B65 (ball screw)PR • • 20-8B65 (ball screw)[N][mm/s]1125 / 22502250 / 45003375 / 67502250 / 33754500 / 90006800 / 136009000 / 1800050 / 4328 / 2314 / 1250 / 3825 / 2014 / 1114 / 10Available input voltages [Vdc] 12, 24Standard stroke lengths 7 [mm] 100, 150, 200,300Operating temperature limits [°C] -40 – + 85Full load duty cycle @ 25 °C [%] 25End play, maximum [mm] 1,0Restraining torque, maximum [Nm] 17 / 0 1Protection classIP66Holding brakeacme screw modelsball screw modelsEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionno, self-lockingyeselectronic load monitoringelectronic load monitoringelectronic load monitoringconnector integrated in housingMotor connector Delphi Metri-Pack 280CertificatesCEOptions • linear potentiometer 2• encoder• programmable limit switches 2• low voltage power switching 3• end of stroke indication outputs 2• ELM trip indication output• signal follower input 2/3• PWM speed control monitoring 4• IP67 5• black paint 6Compatible ControlsControl modelSee pageDPDT switch 48DPDT switch box 49DCG-190 54AC-063 501Without / with anti-rotation option. When the anti-rotation option is being used, thefront adapter cross hole can’t be freely rotated. Instead the front cross hole mustbe ordered in standard postion (shown in the drawing) or rotated 90°.2<strong>Actuators</strong> with linear potentiometer, programmable limit switches or signalfollower input option must have the anti-rotation option and an aluminumcover tube. Note that a programming unit is neccessary for the programmablelimit swich option, see page 62.3 Only possible on models with 12 Vdc input voltage.4PWM speed control monitoring requires the ELM to be set from factory to matchthe customer’s PWM source. Contact customer support for more information.5IP67 requires the mating connector be installed and the factory sealing,including the manual override cover, must not be compromised.6Black paint requires a carbon steel or an aluminum cover tube.7For longer stroke length, contact customer support.24 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak Pro12 and 24 Vdc - load up to 9000 NS: strokeA: retracted lengthA1: manual override cover (manual override requires 5 mm or 3/16 hexagon key to operate)A2: motor connectorA3: knock out plug for signal wire exitA4: adapter / extension tube diam. for 1125 - 6800 N models = 28,58 ±0,13 mm,for 9000 N model diam. = 30,16 ±0,13 mm.A5: front adapter cross hole shown in standard positionStroke (S) [mm] 100 150 200 300Retracted length, acme screw models (A) [mm] 257,5 307,5 357,5 457,5Retracted length, ball screw models (A) [mm] 289,5 339,5 389,5 489,5Weight, acme screw models [kg] 3,0 3,2 3,4 3,9Weight, ball screw models [kg] 3,4 3,6 3,8 4,1Potentiometer resistance change* [ohm/mm] 36,2 26,5 41,7 29,3* Potentiometer is optionalPerformance DiagramsAcme Screw ModelsSpeed and Current vs. LoadBall Screw ModelsSpeed and Current vs. LoadV: speedI: currentF: load1: speed PR • • 02-2A652: speed PR • • 05-4A653: speed PR • • 07-8A654. current 12 Vdc, PR1202-2A655: current 24 Vdc, PR2402-2A656: current 12 Vdc, PR1205-4A657: current 24 Vdc, PR2405-4A658: current 12 Vdc, PR1207-8A659: current 24 Vdc, PR2407-8A65V: speedI: currentF: load1: speed PR • • 05-2B652: speed PR • • 10-4B653: speed PR • • 15-8B654: speed PR • • 20-8B655. current 12 Vdc, PR1205-2B656: current 24 Vdc, PR2405-2B657: current 12 Vdc, PR1210-4B658: current 24 Vdc, PR2410-4B659: current 12 Vdc, PR1215-8B6510: current 24 Vdc, PR2415-8B6511: current 12 Vdc, PR1220-8B6512: current 24 Vdc, PR2420-8B65www.danahermotion.com25

Electrak PPA-AC115 and 230 Vac - load up to 6670 N» Ordering Key - see page 68» Glossary - see page 72» Electric Wiring Diagram - see page 46Performance SpecificationsStandard Features and Benefits• Strong and versatile heavy duty actuator• High duty cycle• Highly efficient ball screw drive system• Overload clutch for mid and end of stroke protection• Stroke lengths up to 36 inch (914,4 mm)• Motor with thermal switch• Integrated motor capacitor• Maintenance free• Large range of optionsGeneral SpecificationsParameterScrew typeInternally restrainedManual overrideDynamic brakingHolding brakeEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionMotor connectorCertificatesOptionsballnono, optionalnoyesoverload clutchoverload clutchElectrak PPA-ACauto reset thermal switchflying leadsnoCE• end of stroke limit switches• potentiometer• encoder• protective bellows• anti-coast brake• electrical brake *ParameterMaximum load, dynamic / staticPPA • • -18B65PPA • • -58B65Speed, at no load / at maximum loadPPA11-18B65PPA22-18B65PPA11-58B65PPA22-58B65Available input voltagesSingle phaseInput frequency1 × 115 Vac model1 × 230 Vac model[N][mm/s][Vac][Hz]PPA-AC2220 / 133506670 / 1335016 / 1514 / 134,3 / 4,34,3 / 4,3115, 23050/6050/60Standard stroke lengths [inch] 4, 8, 12,18, 24, 36Operating temperature limits [°C] -25 – +65Full load duty cycle @ 25 °F [%] 30End play, maximum [mm] 1,0Restraining torquePPA • • -18B65PPA • • -58B65[Nm]11,322,6Lead cross section [mm 2 ] 0,75Lead length [mm] 500Protection classCompatible ControlsControl modelIP45See pageDPDT switch 48DPDT switch box 49* Only possible on 115 Vac models26 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak PPA-AC115 and 230 Vac - load up to 6670 NS: strokeA: retracted lengthB: retracted length to trunnionsC: motor lengthA1: housing dimensions for limit switch, encoder or potentiometer optionsStroke (S) [inch (mm)] 4 (101,6) 8 (203,2) 12 (304,8) 18 (457,2) 24 (609,6) 36 (914,4)Retracted length (A) without options [mm] 348,0 449,6 551,2 754,4 906,8 1211,6Retracted length (A) with limit switch, [mm]encoder or potentiometer398,8 500,4 602,0 805,2 957,6 1262,4Retracted length (B) [mm] 223,5 352,1 426,7 629,9 782,3 1087,1Motor length (C) without electrical brake [mm] 213,6 213,6 213,6 213,6 213,6 213,6Motor length (C) with electrical brake [mm] 277,4 277,4 277,4 277,4 277,4 277,4Weight [kg] 6,0 6,7 7,5 8,7 9,8 12,2Weight with electrical brake [kg] 6,6 7,3 8,1 9.3 10,4 12,9Add on weight for limit switch,[kg]encoder or potentiometer0,8 0,8 0,8 0,8 0,8 0,8Performance DiagramsSpeed and Current vs. LoadV: speed I: current F: load1: speed 115 Vac, PPA11-18B652: speed 230 Vac, PPA22-18B653: speed 115 Vac, PPA11-58B65 and 230 Vac, PPA22-58B654: current 115 Vac, PPA11-18B655: current 230 Vac, PPA22-18B656: current 115 Vac, PPA11-58B657: current 230 Vac, PPA22-58B65www.danahermotion.com27

Electrak 5230 and 400 Vac - load up to 6800 N» Ordering Key - see page 68» Glossary - see page 72» Electric Wiring Diagram - see page 46Performance SpecificationsParameter Electrak 5Standard Features and Benefits• Robust, strong and reliable• Stainless steel extension tube• Acme or ball screw models• Overload clutch for mid and end of stroke protection• Heavy duty motor with thermal switch• Anti-coast brake for repeatable positioning on all ballscrew models. Optional on acme screw models.• Maintenance freeGeneral SpecificationsParameter Electrak 5Screw typeInternally restrainedManual overrideDynamic brakingHolding brakeacme screw modelsball screw modelsEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionMotor connectorCertificatesOptionsacme or ballnono, optionalnono, self-lockingyesoverload clutchoverload clutchauto reset thermal switchcablenoUL, CSA, CE• potentiometer• manual overrideMaximum load, dynamic / staticA • • -05A5 (acme screw)*A • • -10A5 (acme screw)A • • -20A5 (acme screw)A • • -05B5 (ball screw)A • • -10B5 (ball screw)A • • -20B5 (ball screw)A • • -21B5 (ball screw)Speed, at no load / at maximum loadA • • -05A5 (acme screw)*A • • -10A5 (acme screw)A • • -20A5 (acme screw)A • • -05B5 (ball screw)A • • -10B5 (ball screw)A • • -20B5 (ball screw)A • • -21B5 (ball screw)Available input voltagesSingle phaseThree phaseInput frequency1 × 230 Vac model3 × 400 Vac model[N][mm/s][Vac][Hz]1100 / 113502250 / 113502250 / 113502250 / 180004500 / 180004500 / 180006800 / 1800048 / 3830 / 1815 / 1261 / 3730 / 1915 / 1215 / 11230**40050/6050Standard stroke lengths [inch] 4, 6, 8, 10,12, 14, 16,18, 20, 24Operating temperature limits [°C] -25 – +65Full load duty cycle @ 25 °C [%] 25Maximum on time [s] 45End play, maximum [mm] 1,0Restraining torque [Nm] 11,3Lead cross section [mm 2 ] 1,5Cable length [mm] 600Protection class* Not possible with 400 Vac input voltage.** 10 µF capacitor required to run the actuator, p/n 9200-448-003Compatible ControlsControl modelIP45See pageDPDT switch 48DPDT switch box 4928 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak 5230 and 400 Vac - load up to 6800 NS: stroke, tolerance acme / ball screwA: retracted length, tolerance acme / ball screwA1: cableA2: manual override input (optional)A3: housing dimensions for potentiometer optionStroke (S) [inch (mm)] 4 (101,6) 6 (152,4) 8 (203,2) 10 (254,0) 12 (304,8) 14 (355,6) 16 (406,4) 18 (457,2) 20 (508,0) 24 (609,6)Retracted length, acme screw models (A) [mm] 262,3 313,1 363,9 414,7 465,5 567,1 617,9 668,7 719,5 821,1Retracted length, ball screw models (A) [mm] 302,3 353,1 403,9 454,7 505,5 607,1 657,9 708,7 759,5 861,1Add on length for potentiometer* [mm] 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0Weight, acme screw models [kg] 5,9 6,1 6,3 6,5 6,7 6,9 7,1 7,3 7,5 7,8Weight, ball screw models [kg] 6,5 6,7 6,9 7,1 7,3 7,5 7,7 7,9 8,1 8,4Add on weight for potentiometer* [kg] 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3Potentiometer resistance change* [ohm/mm] 39 39 39 39 20 20 20 20 20 10* Potentiometer is optional (NPO, BPO option)Performance DiagramsAcme Screw ModelsSpeed and Current vs. LoadBall Screw ModelsSpeed and Current vs. LoadV: speedI: currentF: load1: speed A22 -05A52: speed A• • -10A53: speed A• • -20A54. current 230 Vac, A22-05A55: current 230 Vac, A22-10A56: current 400 Vac, A42-10A57: current 230 Vac, A22-20A58: current 400 Vac, A42-20A5V: speedI: currentF: load1: speed A22-05B5, A42-05B52: speed A22-10B5, A42-10B53: speed A22-20B5, A42-20B54: speed A22-21B5, A42-21B55. current 230 Vac, A22-05B56: current 400 Vac, A42-05B57: current 230 Vac, A22-10B5, A22-20B58: current 400 Vac, A42-10B5, A42-20B59: current 230 Vac, A22-21B510: current 400 Vac, A42-21B5www.danahermotion.com29

Lifting Column TC624 Vdc - load up to 2000 N» Ordering Key - see page 69» Glossary - see page 72» Electric Wiring Diagram - see page 45Performance SpecificationsStandard Features and Benefits• Designed for domestic, office and medical applications• Self supporting column in extruded anodized aluminum• Low weight and quiet operation• Smooth operating telescopic screw drive• High load torque capability• Very short retracted length• Very low stroke to retracted length ratio• Maintenance free• Dynamic braking and load holding brake• Integrated end of stroke limit switches• EMC recognized for medical applicationsParameterTC6Maximum load [N] 2000Maximum load torque, dynamic / static [Nm] 150 / 500Speed, at no load / at maximum load [mm/s] 19 / 15Available input voltages [Vdc] 24Maximum standard stroke* [mm] 400Minimum standard stroke [mm] 200Operating temperature limits [°C] 0 – +40Full load duty cycle @ 20 °C [%] 15Maximum on time [s] 60Restraining torque [Nm] 0Lead cross section [mm 2 ] 1,5Cable length [mm] 2000Protection class* For longer stroke length, contact customer support.Compatible ControlsIP44General SpecificationsParameterScrew typeInternally restrainedManual overrideDynamic brakingHolding brakeEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionMotor connectorCertificatesOptionstrapezoidalyesnoyesyesTC6end of stroke limit switchesnonocableDIN 41524 8 pin plugCEEMC for medical applications*encoder* Emission: EN 61000-6-3:2001, EN 60601-1-2:1993, EN 55011 Class B,Immunity: EN 61000-6-2:2001, EN 61000-4-2, EN 61000-4-3Control modelSee pageDPDT switch 48DPDT switch box 49DCG-180 54DCG-280 54AC-247 ELS 5230 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Lifting Column TC1624 Vdc - load up to 2000 NS: strokeL: retracted lengthStroke (S), minimum and maximumMin. possible stroke (Smin) = 200 mm, Max. possible stroke (Smax) = 400 mmRetracted length (L), minimum and maximum Min. retracted length (Lmin) = 250 mm, Max. retracted length (Lmax) = 400 mmStroke / retracted length relationship Longest possible stroke (S) for a given retracted length (L) [mm] = L [mm] × 2 - 282Retracted length / stroke relationship Shortest possible retracted length (L) for a given given stroke (S) [mm] = (S [mm] + 282) / 2Weight Weight of unit [kg] = 3,4 + L × 0,0203 + S × 0,000755Performance DiagramsSpeed and Current vs. LoadV: speed I: current F: load1: speed2: currentwww.danahermotion.com31

Lifting Column DMD12, 24 and 36 Vdc - load up to 6800 N» Ordering Key - see page 69» Glossary - see page 72» Electric Wiring Diagram - see page 47Performance SpecificationsStandard Features and Benefits• Designed for industrial use• Rugged, robust and strong• Self supporting column in extruded anodized aluminum• Acme or ball screw drive• High load torque capability• Overload clutch for mid and end of stroke protection• T-slot grooves along the entire profile• Maintenance freeGeneral SpecificationsParameterScrew typeInternally restrainedManual overrideDynamic brakingHolding brakeacme screw modelsball screw modelsEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionMotor connectorCertificatesOptionsacme or ballyesnonono, self-lockingyesoverload clutchoverload clutchDMDauto reset thermal switchcablenoCEpotentiometerParameterMaximum load, dynamic / staticDMD • • -05A5 (acme screw)DMD • • -10A5 (acme screw)DMD • • -20A5 (acme screw)DMD • • -05B5 (ball screw)DMD • • -10B5 (ball screw)DMD • • -20B5 (ball screw)DMD • • -21B5 (ball screw)Maximum load torque, dynamic / staticacme screw modelsball screw modelsSpeed, at no load / at maximum loadDMD • • -05A5 (acme screw)DMD • • -10A5 (acme screw)DMD • • -20A5 (acme screw)DMD • • -05B5 (ball screw)DMD • • -10B5 (ball screw)DMD • • -20B5 (ball screw)DMD • • -21B5 (ball screw)[N][Nm][mm/s]DMD1100 / 113502250 / 113502250 / 113502250 / 180004500 / 180004500 / 180006800 / 18000565 / 565710 / 71054 / 3230 / 1815 / 1261 / 3730 / 1915 / 1215 / 11Available input voltages [Vdc] 12, 24, 36Standard stroke lengths [in] 4, 6, 8, 10,12, 14, 16,18, 20, 24Operating temperature limits [°C] -25 – +65Full load duty cycle @ 25 °C [%] 25End play, maximum [mm] 1,0Restraining torque [Nm] 0Lead cross section [mm 2 ] 2,5Cable length [mm] 2000Protection classCompatible ControlsControl modelIP65See pageDPDT switch 48DPDT switch box 49DCG-190 54AC-063 5032 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Lifting Column DMD12, 24 and 36 Vdc - load up to 6800 NOff Center Load CapacityFmax: maximum load operated La: length of lever arm1: acme screw models2: ball screw modelsS: stroke L: retracted lengthStroke (S) [inch (mm)] 4 (101,6) 6 (152,4) 8 (203,2) 10 (254,0) 12 (304,8) 14 (355,6) 16 (406,4) 18 (457,2) 20 (508,0) 24 (609,6)Retracted length (L), acme screw models [mm] 329,6 380,4 431,2 482,0 532,8 633,6 684,4 735,2 786,0 887,6Retracted length (L), ball screw models [mm] 369,6 420,4 471,2 522,0 572,8 673,6 724,4 775,2 826,0 927,6Add on length for potentiometer* [mm] 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0Weight, acme screw models [kg] 18,7 20,2 21,6 23,1 24,6 27,3 28,7 30,2 31,7 34,6Weight, ball screw models [kg] 20,4 21,9 23,4 24,8 26,3 29,0 30,4 31,9 33,4 36,3Add on weight for potentiometer* [kg] 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3* Potentiometer is optionalPerformance DiagramsSpeed and Current vs. Load - Chart 1 Speed and Current vs. Load - Chart 2 V: speed I: current F: load1: speed DMD • • -05A5 - chart 12: speed DMD • • -05B5 - chart 13: speed DMD • • -10A5 - chart 14: speed DMD • • -10B5 - chart 25: speed DMD • • -20A5 - chart 26: speed DMD • • -20B5 - chart 27: speed DMD • • -21B5 - chart 28: current DMD12-05A5 - chart 19: current DMD24-05A5 - chart 110: current DMD12-05B5 - chart 111: current DMD24-05B5 - chart 112: current DMD12-10A5 - chart 113: current DMD24-10A5 - chart 114: current DMD12-10B5 - chart 215: current DMD24-10B5 - chart 216: current DMD12-20A5 - chart 217: current DMD24-20A5 - chart 218: current DMD12-20B5 - chart 219: current DMD24-20B5 - chart 220: current DMD12-21B5 - chart 221: current DMD24-21B5 - chart 2www.danahermotion.comContact customer service fordata on 36 Vdc models.33

Lifting Column DMA230 and 400 Vac - load up to 6800 N» Ordering Key - see page 69» Glossary - see page 72» Electric Wiring Diagram - see page 47Performance SpecificationsStandard Features and Benefits• Designed for industrial use• Rugged, robust and strong• Self supporting column in extruded anodized aluminum• Acme or ball screw drive• High load torque capability• Overload clutch for mid and end of stroke protection• T-slot grooves along the entire profile• Maintenance freeGeneral SpecificationsParameterScrew typeInternally restrainedManual overrideDynamic brakingHolding brakeacme screw modelsball screw modelsEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionMotor connectorCertificatesOptionsacme or ballyesnonono, self-lockingyesoverload clutchoverload clutchDMAauto reset thermal switchcablenoCEpotentiometerParameterMaximum load, dynamic / staticDMA22-05A5 (acme screw)*DMA • • -10A5 (acme screw)DMA • • -20A5 (acme screw)DMA • • -05B5 (ball screw)DMA • • -10B5 (ball screw)DMA • • -20B5 (ball screw)DMA • • -21B5 (ball screw)Maximum load torque, dynamic / staticacme screw modelsball screw modelsSpeed, at no load / at maximum loadDMA22-05A5 (acme screw)*DMA • • -10A5 (acme screw)DMA • • -20A5 (acme screw)DMA • • -05B5 (ball screw)DMA • • -10B5 (ball screw)DMA • • -20B5 (ball screw)DMA • • -21B5 (ball screw)Available input voltagesSingle phase**Three phaseInput frequency1 × 230 Vac model3 × 400 Vac model[N][Nm][mm/s][Vac][Hz]DMA1100 / 113502250 / 113502250 / 113502250 / 180004500 / 180004500 / 180006800 / 18000565 / 565710 / 71048 / 3830 / 1815 / 1261 / 3730 / 1915 / 1215 / 1123040050/6050Standard stroke lengths [in] 4, 6, 8, 10,12, 14, 16,18, 20, 24Operating temperature limits [°C] -25 – +65Maximum on time [s] 45Full load duty cycle @ 25 °C [%] 25End play, maximum [mm] 1,0Restraining torque [Nm] 0Lead cross section [mm 2 ] 2,5Cable length [mm] 2000Protection class* Not possible with 400 Vac input voltage** 10 µF capacitor required to run the actuator, p/n 9200-448-003Compatible ControlsIP45Control modelSee pageDPDT switch 48DPDT switch box 4934 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Lifting Column DMA230 and 400 Vac - load up to 6800 NOff Center Load CapacityFmax: maximum load operated La: length of lever arm1: acme screw models2: ball screw modelsS: stroke L: retracted lengthStroke (S) [inch (mm)] 4 (101,6) 6 (152,4) 8 (203,2) 10 (254,0) 12 (304,8) 14 (355,6) 16 (406,4) 18 (457,2) 20 (508,0) 24 (609,6)Retracted length (L), acme screw models [mm] 329,6 380,4 431,2 482,0 532,8 633,6 684,4 735,2 786,0 887,6Retracted length (L), ball screw models [mm] 369,6 420,4 471,2 522,0 572,8 673,6 724,4 775,2 826,0 927,6Add on length for potentiometer* [mm] 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0 55,0Weight, acme screw models [kg] 20,9 22,4 23,8 25,3 26,8 29,5 30,9 32,4 33,9 36,8Weight, ball screw models [kg] 22,6 24,1 25,6 27,0 28,5 31,2 32,6 34,1 35,6 38,6Add on weight for potentiometer* [kg] 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3* Potentiometer is optionalPerformance DiagramsSpeed and Current vs. Load - Chart 1 Speed and Current vs. Load - Chart 2V: speed I: current F: load1: speed DMA22-05A5 - chart 12: speed DMA • • -05B5 - chart 13: speed DMA • • -10A5 - chart 14: speed DMA • • -10B5 - chart 25: speed DMA • • -20A5 - chart 16: speed DMA • • -20B5 - chart 27: speed DMA • • -21B5 - chart 28: current DMA22-05A5 - chart 19: current DMA22-05B5 andDMA22-10A5 - chart 110: current DMA42-05B5 - chart 111: current DMA42-10A5 - chart 112: current DMA22-10B5 andDMA22-20B5 - chart 213: current DMA42-10B5 - chart 214: current DMA22-20A5 - chart 115: current DMA42-20A5 - chart 116: current DMA42-20B5 - chart 217: current DMA22-21B5 - chart 218: current DMA42-21B5 - chart 2www.danahermotion.com35

Rodless Actuator LM80-H12 and 24 Vdc - load up to 2000 N» Ordering Key - see page 70» Glossary - see page 72» Electric Wiring Diagram - see page 45Performance SpecificationsStandard Features and Benefits• Rodless actuator for horizontal operation• For use in domestic, office or medical applications• Rigid self supporting extruded aluminum profile• Durable and corrosion free• Lightweight and quiet operation• Safety nut on ball screw versions• Easy and fast T-slot mounting• Maintenance freeGeneral SpecificationsParameterScrew typeInternally restrainedManual overrideDynamic brakingHolding brakeEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionwith motor enclosureno motor enclosureMotor connectorwith motor enclosureno motor enclosureCertificatesOptions* Contact customer supportLM80-Htrapezoidal or ballyesnononospring loaded soft stopnonocableno cable, clips on motorDIN 41524 8 pin plugclips on motorCE• no motor enclosure• manual override• alternative motor positions• stroke over 1500 mm*• encoder *ParameterLM80-HMaximum load (Fb) [N] 2000Maximum load torque (Mb)DT• • -T68M • • • • • HDT• • -B61M • • • • • HDT• • -B62M • • • • • HDT• • -B65M • • • • • HSpeed, at no load / at maximum loadDT• • -T68M • • • • • HDT• • -B61M • • • • • HDT12 -B62M • • • • • HDT24 -B62M • • • • • HDT• • -B65M • • • • • H[Nm][mm/s]25040018075044 / 3755 / 50110 / 73110 / 8728 / 28Available input voltages [Vdc] 12, 24Standard stroke lengths [mm] 500, 600,700, 800,900, 1000,1100, 1200,1300, 1400,1500Operating temperature limits [°C] 0 – +40Full load duty cycle @ 20 °C [%] 15Maximum on time [s] 120End play, maximum [mm] 1,0Restraining torque [Nm] 0Lead cross sectionwith / without motor enclosureCable lengthwith / without motor enclosureProtection classwith / without motor enclosureCompatible ControlsControl model[mm 2 ][mm]1,5 / –2000 / –IP44 / IP33See pageDPDT switch 48DPDT switch box 49DCG-170 54AC-247 ELS 5236 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Rodless Actuator LM80-H12 and 24 Vdc - load up to 2000 N!Note: this unit may only be mounted horizontaly.S: strokeL: length of profileA1: motor shown in position A (standard position)Stroke (S) [mm] 500 600 700 800 900 1000 1100 1200 1300 1400 1500Dimensions (A) / (B)DT• • -T68M • • • • • HDT• • -B61M • • • • • HDT• • -B62M • • • • • HDT• • -B65M • • • • • H[mm]54,0 / 77,0102,0 / 77,0102,0 / 77,079,0 / 77,0WeightDT• • -T68M • • • • • HDT• • -B61M • • • • • HDT• • -B62M • • • • • HDT• • -B65M • • • • • H[kg]11,212,112,111,713,113,913,913,514,815,715,715,316,617,517,517,118,119,319,318,920,221,021,020,622,022,922,922,423,824,624,624,225,526,326,326,027,428,228,227,829,130,030,029,6Performance DiagramsDefinition of ForcesSpeed and Current vs. LoadDeflection of ProfileV: speed I: current F: load1: speed DT • • -T68M • • • • • H2: speed DT • • -B61M • • • • • H3: speed DT12-B62M • • • • • H4: speed DT24-B62M • • • • • H5: speed DT • • -B65M • • • • • H6: current DT12-T68M • • • • • H7: current DT24-T68M • • • • • Hand DT24-B61M • • • • • H8: current DT12-B61M • • • • • H9: current DT12-B62M • • • • • H10: current DT24-B62M • • • • • H11: current DT12-B65M • • • • • H12: current DT24-B65M • • • • • HF: load Lf: distance between mounting points1: maximum allowed deflectionwww.danahermotion.com37

Rodless Actuator LM80-V12 and 24 Vdc - load up to 2000 N» Ordering Key - see page 70» Glossary - see page 72» Electric Wiring Diagram - see page 45Standard Features and Benefits• Rodless actuator for vertical operation with motor down• For use in domestic, office or medical applications• Rigid self supporting extruded aluminum profile• Durable and corrosion free• Holding brake prevents downward motion at power off• Lightweight and quiet operation• Safety nut on ball screw versions• Easy and fast T-slot mounting• Optional spline safety function• Maintenance freeGeneral SpecificationsParameterScrew typeInternally restrainedManual overrideDynamic brakingHolding brakeEnd of stroke protectionMid stroke protectionMotor protectionMotor connectionwith motor enclosureno motor enclosureMotor connectorwith motor enclosureno motor enclosureCertificatesOptions* Contact customer supportLM80-Vtrapezoidal or ballyesnonoyesspring loaded soft stopnonocableno cable, clips on motorDIN 41524 8 pin plugclips on motorCE• no motor enclosure• manual override• alternative motor positions• spline safety function• stroke over 1500 mm*• encoder *Performance SpecificationsParameterMaximum load (Fa)DT• • -T68M • • • • • V(F)DT• • -B61M • • • • • V(F)DT• • -B62M • • • • • V(F)DT• • -B65M • • • • • V(F)Maximum load torque (Ma)DT• • -T68M • • • • • V(F)DT• • -B61M • • • • • V(F)DT• • -B62M • • • • • V(F)DT• • -B65M • • • • • V(F)Speed, at no load / at maximum loadDT12 -T68M • • • • • V(F)DT24 -T68M • • • • • V(F)DT12 -B61M • • • • • V(F)DT24 -B61M • • • • • V(F)DT12 -B62M • • • • • V(F)DT24 -B62M • • • • • V(F)DT12 -B65M • • • • • V(F)DT24 -B65M • • • • • V(F)LM80-V38 www.danahermotion.com[N][Nm][mm/s]6501000450200025040018075044 / 2944 / 3555 / 3755 / 43110 / 67110 / 8328 / 1928 / 22Available input voltages [Vdc] 12, 24Standard stroke lengths [mm] 500, 600,700, 800,900, 1000,1100, 1200,1300, 1400,1500Operating temperature limits [°C] 0 – +40Full load duty cycle @ 20 °C [%] 15Maximum on time [s] 120Restraining torque [Nm] 0Lead cross sectionwith / without motor enclosureCable lengthwith / without motor enclosureProtection classwith / without motor enclosureCompatible ControlsControl model[mm 2 ][mm]1,5 / –2000 / –IP44 / IP33See pageDPDT switch 48DPDT switch box 49DCG-160 54AC-247 ELS 52

<strong>Linear</strong> <strong>Actuators</strong>Rodless Actuator LM80-V12 and 24 Vdc - load up to 2000 N!Note: this unit may only be mounted vertically with the motor down even if drawingshows it horizontaly.S: strokeL: length of profileA1: motor shown in position A (standard position)Stroke (S) [mm] 500 600 700 800 900 1000 1100 1200 1300 1400 1500Dimensions (A) / (B)DT• • -T68M • • • • • VDT• • -B61M • • • • • VDT• • -B62M • • • • • VDT• • -B65M • • • • • VDT• • -T68M • • • • • FDT• • -B61M • • • • • FDT• • -B62M • • • • • FDT• • -B65M • • • • • F[mm]50,0 / 71,053,0 / 120,053,0 / 120,053,0 / 97,050,0 / 90,053,0 / 144,053,0 / 144,053,0 / 126,0Weight*DT• • -T68M • • • • • VDT• • -B61M • • • • • VDT• • -B62M • • • • • VDT• • -B65M • • • • • V[kg]11,111,611,612,012,913,413,413,814,715,215,215,6* Add 0,5 kg to the below weights to get the weights for DT• • -T68M • • • • • F, DT• • -B61M • • • • • F, DT• • -B62M • • • • • F and DT• • -B65M • • • • • F.16,517,017,017,618,218,718,719,320,020,520,521,121,822,322,322,923,624,124,124,725,425,925,926,527,227,727,728,228,929,529,530,1Performance DiagramsDefinition of ForcesSpeed and Current vs. LoadV: speed I: current F: load1: speed DT12-T68M • • • • • V(F)2: speed DT24-T68M • • • • • V(F)3: speed DT12-B61M • • • • • V(F)4: speed DT24-B61M • • • • • V(F)www.danahermotion.com5: speed DT12-B62M • • • • • V(F)6: speed DT24-B62M • • • • • V(F)7: speed DT12-B65M • • • • • V(F)8: speed DT24-B65M • • • • • V(F)9: current DT12-T68M • • • • • V(F)10: current DT24-T68M • • • • • V(F)11: current DT12-B61M • • • • • V(F)12: curent DT24-B61M • • • • • V(F)13: current DT12-B62M • • • • • V(F)14: current DT24-B62M • • • • • V(F)15: current DT12-B65M • • • • • V(F)16: current DT24-B65M • • • • • V(F)39

Electrak Non-driven Actuator PPA-MLoad up to 6670 N» Ordering Key - see page 71» Glossary - see page 72Performance SpecificationsStandard Features and Benefits• Actuator with double input shafts to which a customersupplied motor or/and an intermediate shaft can bemounted• Can be operated manually• Robust and versatile• Withstands very harsh environments• Highly efficient ball screw drive system• Holding brake prevents back driving• Trunnion to clevis mounting• Maintenance freeParameterPPA-MMaximum load, dynamic / static [N] 6670 / 13350Maximum speed at max. load [mm/s] 8Maximum input torque [Nm] 9Maximum input speed [rpm] 100Standard stroke lengths [in] 4, 8, 12, 18,24, 36Operating temperature limits [°C] -25 – +65End play, maximum [mm] 1,0Restraining torque [Nm] 23General SpecificationsParameterScrew typeInternally restrainedManual overrideHolding brakeEnd of stroke protectionMid stroke protectionCertificates –Optionsballnono*yesnonoElectrak PPA-Mprotective bellows* Either of the two input shafts can be used for manual operation if both shaftsare not connected to a motor or an intermediate shaft.40 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak Non-driven Actuator PPA-MLoad up to 6670 NS: strokeA: retracted lengthB: retracted length to trunnionsStroke (S) [inch (mm)] 4 (101,6) 8 (203,2) 12 (304,8) 18 (457,2) 24 (609,6) 36 (914,4)Retracted length (A) [mm] 375,9 477,5 579,1 782,3 934,7 1239,5Retracted length to trunnions (B) [mm] 223,5 325,1 426,7 629,9 782,3 1087,1Weight [kg] 3,4 4,2 4,8 6,1 7,3 9,7Synchronous OperationTwo or more PPA-M actuators can easily be mechanically linked for synchronous operation by usingintermediate shafts. The intermediate shafts and necessary couplings are provided by the customer.www.danahermotion.com41

Electrak Non-driven Actuator FA4Load up to 6800 N» Ordering Key - see page 71» Glossary - see page 72Performance SpecificationsParameterFA4Standard Features and Benefits• Actuator with a flange where a customer suppliedmotor can be mounted• Rugged and robust• Withstands very harsh environments• Stainless steel extension tube• Corrosion free aluminium cover tube• Acme or ball screw drive• Trunnion mounting possible• Overload clutch for mid and end of stroke protection• T-slot grooves in the cover tube for magnetic sensors• Maintenance freeMaximum load, dynamic / staticFA14-05A65 (acme screw)FA14-10A65 (acme screw)FA14-20A65 (acme screw)FA14-05B65 (ball screw)FA14-10B65 (ball screw)FA14-20B65 (ball screw)FA14-21B65 (ball screw)Maximum speed at max. load*FA14-05A65 (acme screw)FA14-10A65 (acme screw)FA14-20A65 (acme screw)FA14-05B65 (ball screw)FA14-10B65 (ball screw)FA14-20B65 (ball screw)FA14-21B65 (ball screw)[N][mm/s]1100 / 113502250 / 113502250 / 113502250 / 180004500 / 180004500 / 180006800 / 1800032181237191211Maximum input torque [Nm] 1,8Maximum input speed [rpm] 3000Standard stroke lengths [mm] 50, 100, 150,200, 250, 300,350, 400, 450,500, 550 ,600General SpecificationsParameterScrew typeacme or ballInternally restrainedyesFA4Operating temperature limits [°C] -25 – +65End play, maximum [mm] 1,0Restraining torque [Nm] 0* Recommended maximum speedManual overrideHolding brakeacme screw versionsball screw versionsEnd of stroke protectionMid stroke protectionCertificatesOptions* Contact customer supportnono, self-lockingyesoverload clutchoverload clutchCE• manual override• alternative adaptor positions• custom color*42 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrak Non-driven Actuator FA14Load up to 6800 NS: stroke, tolerance acme / ball screwA: retracted length, tolerance acme / ball screwA1: minimum/maximum input shaft bore in the couplingStroke (S) [mm] 50 100 150 200 250 300 350 400 450 500 550 600Retracted length (A), acme screw models [mm] 216,7 266,7 316,7 366,7 416,7 466,7 566,7 616,7 666,7 716,7 766,7 816,7Retracted length (A), ball screw models [mm] 269,6 319,6 369,6 419,6 469,6 519,6 619,6 669,6 719,6 769,6 819,6 869,6Weight, acme screw models [kg] 3,5 3,7 4,0 4,2 4,5 4,7 5,0 5,2 5,5 5,7 6,0 6,3Weight, ball screw models [kg] 4,2 4,5 4,7 5,0 5,2 5,5 5,7 6,0 6,2 6,5 6,7 7,0www.danahermotion.com43

Electrical Wiring DiagramsDC-actuatorsElectrak 1 and 1SP Electrak 10DPDT SwitchRetractOffExtendDPDT SwitchRetractOffExtend(–)(–)InputVoltageYellowActuatorInputVoltageBlackActuator(+)(+)Black*Red* Black for 24 Vdc supply voltageWhite for 12 Vdc supply voltageBlue for 36 Vdc supply voltagePotentiometerOutput onElectrak 1SPWhiteConnect the black or white* lead to positive and yellowto negative to extend the actuator. Change polarityto retract the actuator. The potentiometer output has0 ohm between white and red when the actuator isfully retracted. The actuator should be protected fromoverload conditions by a customer provided fuse in thecircuit (6 A for 12 Vdc, 3 A for 24 Vdc and 2 A for 36 Vdc).RedBlackOptionalPotentiometerOutput onElectrak 1OGreyYellowGreenConnect the red lead to positive and black to negativeto extend the actuator. Change polarity to retract theactuator. The potentiometer output has 0 ohm betweengrey and yellow when the actuator is fully extended.Electrak 050DPDT SwitchRetractOffExtendElectrak ProDPDT SwitchRetractOffExtendInputVoltage(–)RedActuatorInputVoltage(–)AActuator(+)(+)BlackBOptionalPotentiometerOutputWhiteConnect the black lead to positive and red to negative toextend the actuator. Change polarity to retract theactuator. The potentiometer output has 0 ohm betweenwhite and red when the actuator is fully retracted.RedBlueConnect pin B in the connector to positive and A tonegative to extend the actuator. Change polarity toretract the actuator. Consult the actuator manual forinformation on the wiring of the control options.44 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrical Wiring DiagramsDC-actuatorsElectrak PPA-DCDMDDPDT SwitchDPDT SwitchRetractOffExtendActuatorRetractOffExtend(–)Black(–)InputVoltageRedInputVoltageBlueActuator(+)BlackRed4With Optional Endof Stroke Limit 5Switches Output6BlackRedWith OptionalPotentiometerOutput456BlackRedWith OptionalEncoderOutputBlackRed1WithOptional 2Encoder3and4End of StrokeLimit Switches 5Outputs6Connect the black lead to positive and red to negativeto extend the actuator. Change polarity to retract theactuator. The encoder is supplied with 4,5 - 12 Vdcbetween terminals 4 or 1 and 6 or 3 and the pulse trainsignal is generated on terminal 5 or 2. The potentiometeroutput has 0 ohm between terminal 4 and 5 when theactuator is fully retracted.456(+)(–)(+)S(–)(+)BrownConnect the brown lead to positive and blue to negativeto extend the actuator. Change polarity to retract theactuator.TC16, LM80-H and LM80-VInputVoltage(–)(+)DPDT SwitchPin Configuration(solder view)RetractOffExtendOptionalEncoderOutput2416357RedGreenWhiteBlackBrownPurpleActuator(+)(-)S18YellowS2Connect the green lead to positive and red to negativeto extend the actuator. Change polarity to retract theactuator. If using the connector supplied with the actuator,each motor lead must be connected to two pins in theconnector. The encoder is supplied with 5 - 18 Vdc on pin 3and 5 and the two pulse train signals are generated on pin7 and 8.www.danahermotion.com45

Electrical Wiring DiagramsAC-actuatorsElectrak PPA-ACWithout anti coast or electrical brakeElectrak 5 and DMA - 1 × 230 VacWithout anti coast brake*DPDT SwitchL1RetractOffExtendBlueActuatorCapacitor*L1RetractOffExtendCapacitor**Black (1)ActuatorInputVoltageRedInputVoltageRed (2)L2YellowL2White (3)PEGreenPEYellow/GreenWith anti coast brake or electrical brakeWith anti coast brake*DPDT SwitchDPDT SwitchL1RetractOffExtendBlueActuatorCapacitor*L1RetractOffExtendCapacitor**Black (1)ActuatorInputVoltageRedInputVoltageRed (2)BlackBrake**Orange (4)Brake*L2YellowL2White (3)PEGreenPEYellow/Green* The actuator comes with prewired capacitor from factory.** Anti coast brake or electrical brake (electrical brake only possible on 115 Vac models).Connect the red lead to L1 and white to L2 to extend theactuator. Change L1 from red to blue lead to retract theactuator. If the actuator is equipped with an anti coastbrake, release the brake by connecting black lead to L1.* Anti coast brake is standard on Electrak 5 for ball screw models and optional for acme screwmodels.On DMA there are no anti coast brake on acme models while ball screw modelsalways are equipped with an anti coast brake.** 10 µF capacitor required to run the actuator, p/n 9200-448-003.Leads can be either color or number marked. Connectblack (1) lead to L1 and white (3) lead to L2 to extend theactuator. Change L1 from lead black (1) to lead red (2) toretract the actuator. If the actuator is equipped with an anticoast brake, release the brake by connecting orange (4)lead lead to L1.46 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Electrical Wiring DiagramsAC-actuatorsElectrak 5 and DMA - 3 × 400 VacWithout anti coast brake*L1L2L3RelaysExtendWhite (1)Red (2)Black (3)ActuatorInputVoltageRetractPEYellow/GreenWith anti coast brake*InputVoltageL1L2L3NRelaysExtendRetractWhite (1)Red (2)Black (3)Orange (4)ActuatorBrake*PEYellow/Green* Anti coast brake is optional on Electrak 5 on both acme and ball screw models. On DMAthere are no anti coast brake on acme models while ball screw models always are equippedwith an anti coast brake.Leads can be either color or number marked. Connectwhite (1) lead to L1, red (2) lead to L2 and black (3) lead toL3 to extend the actuator. Change the places of white (2)lead and black (3) to to retract the actuator. If the actuatoris equipped with an anti coast brake, release the brake byconnecting orange (4) lead to N.www.danahermotion.com47

Actuator ControlsSwitchesDPDT SwitchSpecificationsParameterDPDT SwitchMaximum voltage [Vac] 270Maximum current [A] 15Part number 830-8004-016• Robust switch• Double pole, double throw (DPDT)• 15 A rating at 270 Vac• Center “off”• Two momentary contacts• Wiring diagram on labelActuator CompatibilityElectrak 1, Electrak 1SP, Electrak 050, Electrak PPA-DC,Electrak 10, Electrak Pro, Electrak PPA-AC, Electrak 5, TC16,DMD, DMA, LM80-H, LM80-V, DGBWiring DiagramDimensions48 www.danahermotion.com

<strong>Linear</strong> <strong>Actuators</strong>Actuator ControlsSwitchesDPDT Switch BoxSpecificationsParameterDPDT BoxMaximum voltage [Vac] 270Maximum current [A] 15Protection class NEMA 1Part number 6932-101-054• Robust rocker switch mounted in an enclosure• Double pole, double throw (DPDT)• 15 A rating at 270 Vac• Center “off”• Two momentary contacts• Mounting bracket included• Wiring diagram on labelActuator CompatibilityElectrak 1, Electrak 1SP, Electrak 050, Electrak PPA-DC,Electrak 10, Electrak Pro, Electrak PPA-AC, Electrak 5, TC16,DMD, DMA, LM80-H, LM80-V, DGBWiring DiagramDimensions!Note: some AC actuators require a capacitor in the wiring to run.This capacitor will not fit in this box due to space limitations.!Note: the DPDT switch box is not RoHS compliant.www.danahermotion.com4

Actuator ControlsElectronic ControlsControl AC-063DimensionsAC-O63B• Rugged and robust control designed to operate underthe hardest conditions• Robust plastic enclosure• Versions for DC or AC supply voltage• Versions with or without limit switch inputs• Versions with or without control pendantAC-O63BCActuator CompatibilityAC-063BAC-063BCAC-063CElectrak PPA-DC, Electrak 10, DMDElectrak PPA-DC, Electrak 10, DMDElectrak PPA-DC, Electrak 10, DMDAC-O63C50 www.danahermotion.com