M.J. MAILLIS

M.J. MAILLIS

M.J. MAILLIS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

M.J. <strong>MAILLIS</strong>Stretch Wrapping Machine EUREKAComplete ● End of Line ● Packaging SolutionsM.J. <strong>MAILLIS</strong> GROUP

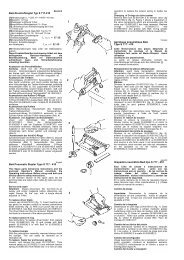

M.J. <strong>MAILLIS</strong>Stretch Wrapping SystemsSemi-automatic Wrapping with Active Roping SystemThe M.J. Maillis EUREKA is the only semi-automaticmachine in the market that can do exactly the same workas a fully automatic wrapper. Thanks to many technicalinnovations this machine allows the customer to complywith the latest European regulations (EN 12195-1)regarding stability of loads during transport.EUREKA Machine Features Standard SIEMENS S7 200 PLC operating system PRO FACE full color touch screen display OMRON J1000 frequency changers Nine individual wrapping programs easily selectable via touchscreen interface Extremely easy program choice via touch screen icons withcustomers product cargo pictures 300% pre-stretch motorized film carriage (Maillis PW type)with unique “No film breaking system” Pre-stretch rollers with life time warranty Active film roping system to make additional reinforcedwrappings at different levels (in accordance with EN 12195-1) Tension on load can be set different at five different places onthe load Waterproof wrapping for top sheet covering Protected against unauthorized access for maintenance andprogram inserts with password entry key lock Automatic alarm for maintenanceComplete ● End of Line ● Packaging Solutions

M.J. <strong>MAILLIS</strong>Semi-automatic Wrapper EUREKAUser Friendly Individual Operation and Program SettingEUREKA is the perfect wrapping machine to make sure you will use the minimum amount of film, reaching the best possible loadstability, without crushing your products, without film breaks (thanks to our “no-film-break” solution) and equipped with manyinteresting options that will allow you to “personalize” your own ideal wrapping pattern and make pallets that will resist the mostdemanding forces as described in the new European directive EN 12195-1 (according to these a load must resist to 0,5 G forceslateral and 0,8 G forces frontal direction).The whole machine has been developed to be 100% user friendly but will also give us the opportunity to guarantee the promisedfilm cost savings thanks to a “closed” program, only accessible for initiated users by two different access codes. All programsettings are done via a “stupid-proof” great dimensioned multicolor electronic operating touch panel in six main Europeanlanguages. The setting processes are done very simple via touch screen fields with logic structure and self explanatory symbols.The whole procedure to define your own personal wrapping parameter for nine different pallet types with a specific “ideal”wrapping pattern will be done in few steps:Six European languages arefreely selectable for easy settingof all parameter (Italian, English,German, French, Spanish andDutch).Three types of wrapping cycles(up and down, waterproof orsingle wrap in one direction)define basic parameters foroptimum load stability.Determination of the essentialcarriage speed regulations tomodify the parameter for layeroverlapping in both directionsand on top.Insert the number of layers youwant to apply in three differentplaces (top, bottom and forreinforcement in the middle) ofthe pallet load.Program settings in case ofwaterproof wrapping cycles withtop sheet, with press plateand without photo-eye mode(wrapping with black film types).In case of unstable loadsdifferent speeds (lower) ofturntable rotations can bemodified depending on the filmcarriage direction.Beyond the fixed standard prestretchparameters the filmtension forces can be modifiedand regulated in a very preciseway.In case of wrapping with filmroping you can activate anddeactivate the carriage ropingdevice and specify the tensionand number of roping cycles.www.maillis.comM.J. <strong>MAILLIS</strong> GROUP