DRIVE CHAINS - Tsubaki

DRIVE CHAINS - Tsubaki DRIVE CHAINS - Tsubaki

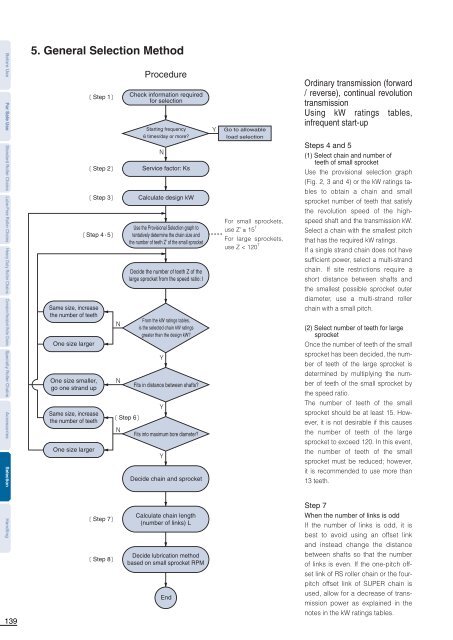

Before Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling1395. General Selection MethodSame size, increasethe number of teethOne size largerOne size smaller,go one strand upSame size, increasethe number of teethOne size largerStep 1Step 2Step 3Step 4 5Step 7Step 8ProcedureCheck information requiredfor selectionService factor: KsCalculate design kWDecide the number of teeth Z of thelarge sprocket from the speed ratio: IStep 6Starting frequency6 times/day or more?Use the Provisional Selection graph totentatively determine the chain size andthe number of teeth Z’ of the small sprocketFrom the kW ratings tables,is the selected chain kW ratingsgreater than the design kW?Fits in distance between shafts?Fits into maximum bore diameter?Decide chain and sprocketCalculate chain length(number of links) LDecide lubrication methodbased on small sprocket RPMEndGo to allowableload selectionFor small sprockets,use Z' ≥ 15 TFor large sprockets,use Z < 120 TOrdinary transmission (forward/ reverse), continual revolutiontransmissionUsing kW ratings tables,infrequent start-upSteps 4 and 5(1) Select chain and number ofteeth of small sprocketUse the provisional selection graph(Fig. 2, 3 and 4) or the kW ratings tablesto obtain a chain and smallsprocket number of teeth that satisfythe revolution speed of the highspeedshaft and the transmission kW.Select a chain with the smallest pitchthat has the required kW ratings.If a single strand chain does not havesufficient power, select a multi-strandchain. If site restrictions require ashort distance between shafts andthe smallest possible sprocket outerdiameter, use a multi-strand rollerchain with a small pitch.(2) Select number of teeth for largesprocketOnce the number of teeth of the smallsprocket has been decided, the numberof teeth of the large sprocket isdetermined by multiplying the numberof teeth of the small sprocket bythe speed ratio.The number of teeth of the smallsprocket should be at least 15. However,it is not desirable if this causesthe number of teeth of the largesprocket to exceed 120. In this event,the number of teeth of the smallsprocket must be reduced; however,it is recommended to use more than13 teeth.Step 7When the number of links is oddIf the number of links is odd, it isbest to avoid using an offset linkand instead change the distancebetween shafts so that the numberof links is even. If the one-pitch offsetlink of RS roller chain or the fourpitchoffset link of SUPER chain isused, allow for a decrease of transmissionpower as explained in thenotes in the kW ratings tables.

Selecting a Roller ChainSelection example using the general selection method(Step 1) Required dataMachine used : AgitatorType of shock : Moderate shockSource of Power : MotorRated power : 11 kW 1800 r/minHigh speed shaft: Shaft diameter 45mm 90 r/minLow speed shaft : Shaft diameter 60mm 30 r/minDistance between shafts: 350 mmSpace limitation : 700 mm(Step 2) Determine the service factorService factor Ks = 1.3 from Table 2 Service Factor(Step 3) Determine the design kWDesign kW = 11 kW X 1.3 = 14.3 kW(Steps 4 and 5) Determine the chain and the numberof teeth for the sprocketDecide on the chain number and number of teeth of thesmall sprocket derived from the speed of the high speedshaft, at 90 r/min, and the design kW (14.3 kW).(1)17 T of the single strand RS100 is derived from the basicselection figure and the kilowatt ratings table. Since thespeed ratio is 1/3, the number of teeth will be 17T and 51T ofRS100. But, with an outer diameter of 17T at 189 mm and51T at 534 mm, these are not adequate because they do notfit in the required space. 189 + 534 > 700(2) Checking multi-strand chains:19T and 57T of the RS80-2 is derived for double-strand, andthe outer diameter of its sprockets are 167 mm and 476 mm,which is within limits. Check RS80 kilowatt ratings table forthe kW ratings of 19T of RS80-2.The kW ratings for the small sprocket number of teeth 19T is5.06 kW at 50 r/min, and 9.44 kW at 100 r/min. By calculatingproportionally using the tabular difference between them,drive kW for 90 r/min is 8.56 kW.(3) This 8.56 kW is the kilowatt rating of single-strand chain, andthe kilowatt rating of double-strand chain that will be used isderived from the multi-strand factor in Table 1.8.56 kW X 1.7 = 14.6 kWMotorAgitator(Step 6) Check the bore diameter(1) Check the bore diameter on the dimension table. Maximumbore diameter for RS80-2-19T is 63 mm, and it can be usedfor the required bore diameter of 45 mm.Maximum bore diameter for RS80-2-57T is 80 mm, and it canbe used for the 60 mm.(Step 7) Determine the distance between shaftsWith a distance between shafts of 350 mm,1674762350 , and it will fit into the required space.Number of the links is calculated as( )57 19L571922 350 6.2825.4 35068.225.4In order to have an even number of links, raise the valuebelow the decimal point to an integer to get 70.(Step 8) Check lubrication methodSince the small sprocket is RS80-2-19T at a speed of 90 r/min,according to the kilowatt ratings table, lubrication method A willbe used. It is necessary to have an oil bath lubrication orlubrication with a slinger disc.For selecting lifting or shuttle traction applications, do not use theGeneral Selection method. Use the Allowable Load Selection method.Reason: It is assumed that the braking force will be large when abalance weight is used, even if the motor capacity is small.2Before Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling(4) This kW rating, 14.6 kW, satisfies the design kW (14.3 kW).140

- Page 90 and 91: Heavy Duty Roller Chains SUPER Roll

- Page 92 and 93: Heavy Duty Roller Chains SUPER Roll

- Page 94 and 95: Heavy Duty Roller Chains SUPER Roll

- Page 96 and 97: Heavy Duty Roller Chains SUPER Roll

- Page 98 and 99: Heavy Duty Roller Chains ULTRA SUPE

- Page 100 and 101: T S U B A K I D R I V E C H A I NBe

- Page 102 and 103: Corrosion Resistant Roller ChainsOl

- Page 104 and 105: Corrosion Resistant Roller Chains S

- Page 106 and 107: Corrosion Resistant Roller Chains S

- Page 108 and 109: Corrosion Resistant Roller ChainsTi

- Page 110 and 111: Corrosion Resistant Roller Chains L

- Page 112 and 113: Corrosion Resistant Roller ChainsLo

- Page 114 and 115: Before Use For Safe UseStandard Rol

- Page 116 and 117: Specialty Roller ChainsLeaf ChainsB

- Page 118 and 119: Specialty Roller ChainsLeaf ChainsB

- Page 120 and 121: Specialty Roller ChainsPin Gear Att

- Page 122 and 123: Pin Gear SprocketBefore Use For Saf

- Page 124 and 125: Before Use For Safe UseStandard Rol

- Page 126 and 127: 2 ETS Type: Straight type, with idl

- Page 128 and 129: Before Use For Safe UseStandard Rol

- Page 130 and 131: Before Use For Safe UseStandard Rol

- Page 132 and 133: Roller Chain SelectionBefore Use Fo

- Page 134 and 135: Before Use For Safe UseStandard Rol

- Page 136 and 137: Before Use For Safe UseStandard Rol

- Page 138 and 139: Before Use For Safe UseStandard Rol

- Page 142 and 143: Before Use For Safe UseStandard Rol

- Page 144 and 145: Before Use For Safe UseStandard Rol

- Page 146 and 147: Before Use For Safe UseStandard Rol

- Page 148 and 149: Before Use For Safe UseStandard Rol

- Page 150 and 151: Before Use For Safe UseStandard Rol

- Page 152 and 153: Before Use For Safe UseStandard Rol

- Page 154 and 155: Before Use For Safe UseStandard Rol

- Page 156 and 157: Before Use For Safe UseStandard Rol

- Page 158 and 159: Before Use For Safe UseStandard Rol

- Page 160 and 161: Before Use For Safe UseStandard Rol

- Page 162 and 163: Before Use For Safe UseStandard Rol

- Page 164 and 165: Before Use For Safe UseStandard Rol

- Page 166 and 167: Before Use For Safe UseStandard Rol

- Page 168 and 169: Before Use For Safe UseStandard Rol

- Page 170 and 171: Before Use For Safe UseStandard Rol

- Page 172 and 173: Before Use For Safe UseStandard Rol

- Page 174 and 175: Before Use For Safe UseStandard Rol

- Page 176 and 177: 175MEMO

Before Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling1395. General Selection MethodSame size, increasethe number of teethOne size largerOne size smaller,go one strand upSame size, increasethe number of teethOne size largerStep 1Step 2Step 3Step 4 5Step 7Step 8ProcedureCheck information requiredfor selectionService factor: KsCalculate design kWDecide the number of teeth Z of thelarge sprocket from the speed ratio: IStep 6Starting frequency6 times/day or more?Use the Provisional Selection graph totentatively determine the chain size andthe number of teeth Z’ of the small sprocketFrom the kW ratings tables,is the selected chain kW ratingsgreater than the design kW?Fits in distance between shafts?Fits into maximum bore diameter?Decide chain and sprocketCalculate chain length(number of links) LDecide lubrication methodbased on small sprocket RPMEndGo to allowableload selectionFor small sprockets,use Z' ≥ 15 TFor large sprockets,use Z < 120 TOrdinary transmission (forward/ reverse), continual revolutiontransmissionUsing kW ratings tables,infrequent start-upSteps 4 and 5(1) Select chain and number ofteeth of small sprocketUse the provisional selection graph(Fig. 2, 3 and 4) or the kW ratings tablesto obtain a chain and smallsprocket number of teeth that satisfythe revolution speed of the highspeedshaft and the transmission kW.Select a chain with the smallest pitchthat has the required kW ratings.If a single strand chain does not havesufficient power, select a multi-strandchain. If site restrictions require ashort distance between shafts andthe smallest possible sprocket outerdiameter, use a multi-strand rollerchain with a small pitch.(2) Select number of teeth for largesprocketOnce the number of teeth of the smallsprocket has been decided, the numberof teeth of the large sprocket isdetermined by multiplying the numberof teeth of the small sprocket bythe speed ratio.The number of teeth of the smallsprocket should be at least 15. However,it is not desirable if this causesthe number of teeth of the largesprocket to exceed 120. In this event,the number of teeth of the smallsprocket must be reduced; however,it is recommended to use more than13 teeth.Step 7When the number of links is oddIf the number of links is odd, it isbest to avoid using an offset linkand instead change the distancebetween shafts so that the numberof links is even. If the one-pitch offsetlink of RS roller chain or the fourpitchoffset link of SUPER chain isused, allow for a decrease of transmissionpower as explained in thenotes in the kW ratings tables.