DRIVE CHAINS - Tsubaki

DRIVE CHAINS - Tsubaki

DRIVE CHAINS - Tsubaki

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

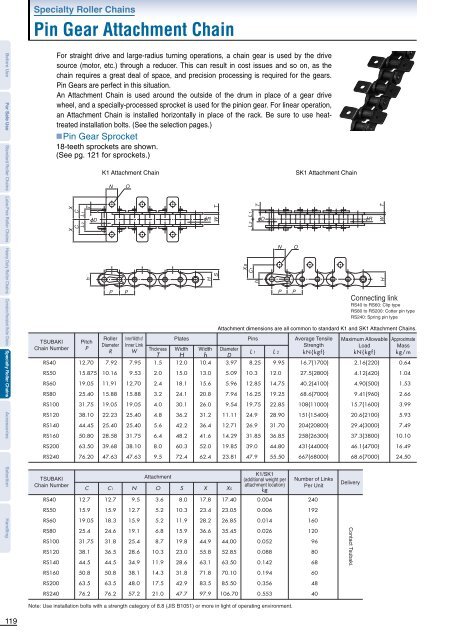

Specialty Roller ChainsPin Gear Attachment ChainBefore Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingFor straight drive and large-radius turning operations, a chain gear is used by the drivesource (motor, etc.) through a reducer. This can result in cost issues and so on, as thechain requires a great deal of space, and precision processing is required for the gears.Pin Gears are perfect in this situation.An Attachment Chain is used around the outside of the drum in place of a gear drivewheel, and a specially-processed sprocket is used for the pinion gear. For linear operation,an Attachment Chain is installed horizontally in place of the rack. Be sure to use heattreatedinstallation bolts. (See the selection pages.)Pin Gear Sprocket18-teeth sprockets are shown.(See pg. 121 for sprockets.)XCXCL 1L 2ThDK1 Attachment ChainNPOPRoller Inner Width ofPlatesPinsAverage Tensile Maximum Allowable ApproximateTSUBAKI PitchDiameter Inner LinkStrengthLoad MassChain Number PR WThickness Width Width DiameterL 1 L 2 kN{kf} kN{kf} k/mT H h DRS40 12.70 7.92 7.95 1.5 12.0 10.4 3.97 8.25 9.95 16.7{1700} 2.16{220} 0.64RS50 15.875 10.16 9.53 2.0 15.0 13.0 5.09 10.3 12.0 27.5{2800} 4.12{420} 1.04RS60 19.05 11.91 12.70 2.4 18.1 15.6 5.96 12.85 14.75 40.2{4100} 4.90{500} 1.53RS80 25.40 15.88 15.88 3.2 24.1 20.8 7.94 16.25 19.25 68.6{7000} 9.41{960} 2.66RS100 31.75 19.05 19.05 4.0 30.1 26.0 9.54 19.75 22.85 108{11000} 15.7{1600} 3.99RS120 38.10 22.23 25.40 4.8 36.2 31.2 11.11 24.9 28.90 151{15400} 20.6{2100} 5.93RS140 44.45 25.40 25.40 5.6 42.2 36.4 12.71 26.9 31.70 204{20800} 29.4{3000} 7.49RS160 50.80 28.58 31.75 6.4 48.2 41.6 14.29 31.85 36.85 258{26300} 37.3{3800} 10.10RS200 63.50 39.68 38.10 8.0 60.3 52.0 19.85 39.0 44.80 431{44000} 46.1{4700} 16.49RS240 76.20 47.63 47.63 9.5 72.4 62.4 23.81 47.9 55.50 667{68000} 68.6{7000} 24.50TSUBAKIChain NumberAttachmentC C1 N O S X XSK1/SK1(additional weight perattachment location)kRS40 12.7 12.7 9.5 3.6 8.0 17.8 17.40 0.004 240RS50 15.9 15.9 12.7 5.2 10.3 23.4 23.05 0.006 192RS60 19.05 18.3 15.9 5.2 11.9 28.2 26.85 0.014 160RS80 25.4 24.6 19.1 6.8 15.9 36.6 35.45 0.026 120RS100 31.75 31.8 25.4 8.7 19.8 44.9 44.00 0.052 96RS120 38.1 36.5 28.6 10.3 23.0 55.8 52.85 0.088 80RS140 44.5 44.5 34.9 11.9 28.6 63.1 63.50 0.142 68RHTWSL 1L 2XsC 1ThDNPOPSK1 Attachment ChainAttachment dimensions are all common to standard K1 and SK1 Attachment Chains.Number of LinksPer UnitHConnecting linkRS40 to RS60: Clip typeRS80 to RS200: Cotter pin typeRS240: Spring pin typeDeliveryContact <strong>Tsubaki</strong>.RTWRS160 50.8 50.8 38.1 14.3 31.8 71.8 70.10 0.194 60RS200 63.5 63.5 48.0 17.5 42.9 83.5 85.50 0.356 48RS240 76.2 76.2 57.2 21.0 47.7 97.9 106.70 0.553 40Note: Use installation bolts with a strength category of 8.8 (JIS B1051) or more in light of operating environment.119