DRIVE CHAINS - Tsubaki

DRIVE CHAINS - Tsubaki

DRIVE CHAINS - Tsubaki

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

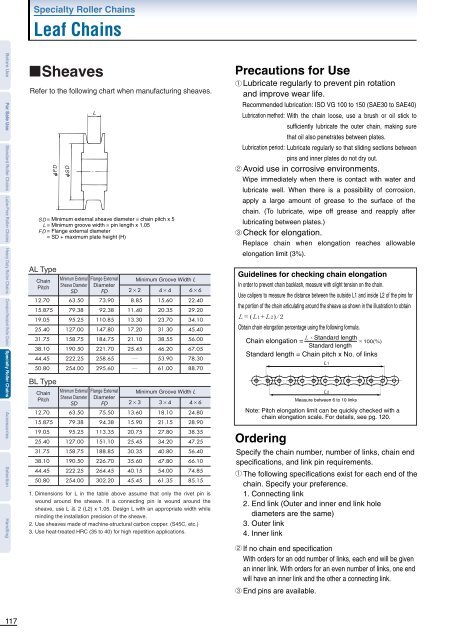

Specialty Roller ChainsLeaf ChainsBefore Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingSheavesRefer to the following chart when manufacturing sheaves.FDSDLSD= Minimum external sheave diameter = chain pitch x 5L = Minimum groove width = pin length x 1.05FD= Flange external diameter= SD + maximum plate height (H)AL TypeChainMinimum External Flange External Minimum Groove Width LPitchSheave Diameter DiameterSD FD 22 44 6612.70 63.50 73.90 8.85 15.60 22.4015.875 79.38 92.38 11.40 20.35 29.2019.05 95.25 110.85 13.30 23.70 34.1025.40 127.00 147.80 17.20 31.30 45.4031.75 158.75 184.75 21.10 38.55 56.0038.10 190.50 221.70 25.45 46.20 67.0544.45 222.25 258.65 53.90 78.3050.80 254.00 295.60 61.00 88.70BL TypeChainMinimum External Flange External Minimum Groove Width LPitchSheave Diameter DiameterSD FD 23 34 4612.70 63.50 75.50 13.60 18.10 24.8015.875 79.38 94.38 15.90 21.15 28.9019.05 95.25 113.35 20.75 27.80 38.3525.40 127.00 151.10 25.45 34.20 47.2531.75 158.75 188.85 30.35 40.80 56.4038.10 190.50 226.70 35.60 47.80 66.1044.45 222.25 264.45 40.15 54.00 74.8550.80 254.00 302.20 45.45 61.35 85.151. Dimensions for L in the table above assume that only the rivet pin iswound around the sheave. If a connecting pin is wound around thesheave, use L 2 (L2) x 1.05. Design L with an appropriate width whileminding the installation precision of the sheave.2. Use sheaves made of machine-structural carbon copper. (S45C, etc.)3. Use heat-treated HRC (35 to 40) for high repetition applications.Precautions for UseLubricate regularly to prevent pin rotationand improve wear life.Recommended lubrication: ISO VG 100 to 150 (SAE30 to SAE40)Lubrication method: With the chain loose, use a brush or oil stick tosufficiently lubricate the outer chain, making surethat oil also penetrates between plates.Lubrication period: Lubricate regularly so that sliding sections betweenpins and inner plates do not dry out.Avoid use in corrosive environments.Wipe immediately when there is contact with water andlubricate well. When there is a possibility of corrosion,apply a large amount of grease to the surface of thechain. (To lubricate, wipe off grease and reapply afterlubricating between plates.)Check for elongation.Replace chain when elongation reaches allowableelongation limit (3%).Guidelines for checking chain elongationIn order to prevent chain backlash, measure with slight tension on the chain.Use calipers to measure the distance between the outside L1 and inside L2 of the pins forthe portion of the chain articulating around the sheave as shown in the illustration to obtain Obtain chain elongation percentage using the following formula. - Standard lengthChain elongation =100(%)Standard lengthStandard length = Chain pitch x No. of linksNote: Pitch elongation limit can be quickly checked with achain elongation scale. For details, see pg. 120.OrderingL 1L 2Measure between 6 to 10 linksSpecify the chain number, number of links, chain endspecifications, and link pin requirements.The following specifications exist for each end of thechain. Specify your preference.1. Connecting link2. End link (Outer and inner end link holediameters are the same)3. Outer link4. Inner linkIf no chain end specificationWith orders for an odd number of links, each end will be givenan inner link. With orders for an even number of links, one endwill have an inner link and the other a connecting link.End pins are available.117