DRIVE CHAINS - Tsubaki

DRIVE CHAINS - Tsubaki

DRIVE CHAINS - Tsubaki

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Tsubaki</strong>: RecognizedProvider forBasic Environmental Policy of the <strong>Tsubaki</strong> Chain GroupThe <strong>Tsubaki</strong> Chain Group recognizes that theprotection of the global environment is one of the chiefresponsibilities of all mankind. It is our goal to showconsideration for the environment in all of ourbusiness activities in order to contribute to a bettertomorrow.1PhilosophyPolicyAlways be aware of the environmental effects ofbusiness activities, products and services, andstrive to reduce the related environmental load fromthe perspective of global environmental protection.Streamline our organization for environmentalprotection and continually improve our environmentalmanagement systems.Comply with environmental laws, regulations andagreements.Help the entire workforce understand our basicenvironmental policy, and enhance their awarenessof global environmental protection via environmentaleducation, internal publication activities, etc.

T S U B A K I D R I V E C H A I NWorldwide as a SolutionsManufacturing EnvironmentsKyotanabe Plant ConceptsKind consideration towards the global environmentHarmony and coexistence with the global environmentPursuit of high efficiency and high qualityInternationally Accredited Plant<strong>Tsubaki</strong>moto Chain aims to make products that are people-friendly,environmentally friendly, and reliable. The Chain Division acquiredISO9001 accreditation in 1995 and ISO14001 accreditation in2003.Courage to look to the future<strong>Tsubaki</strong>moto Chain’s Kyotanabe Plant is astate-of-the-art facility outfitted with thelatest environmental systems to produceenvironment-friendly products that meetthe needs of the times and our customers.ISO 9001 ISO 14001JQA-0911Chain DivisionJQA-EM3392Kyotanabe PlantKyotanabe Plant2

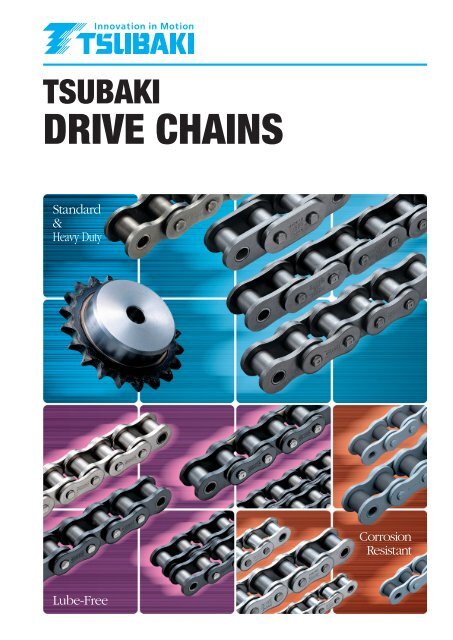

RThe Powerful <strong>Tsubaki</strong> LineBecause it’s <strong>Tsubaki</strong>, customers can select the best products for theirproduction environment from amongst our powerful lineup. Companieslooking to improve their productivity shouldn’t miss trying <strong>Tsubaki</strong>’s drivechains.RS Roller Chain "G7"General PurposeStandard Roller Chains<strong>Tsubaki</strong>’s roller chains greatly improve transmissionpower and deliver performance tailored to size.Lube-FreeLube-Free Drive Chains<strong>Tsubaki</strong>’s lube-free drive chains contribute to lowermaintenance, cleaner work environments, andincreased productivity.* Lambda Chains are also available for conveyor applications.Lambda ChainX-Lambda ChainSurface Treated Lambda ChainHeavy Duty Lambda ChainCurved Lambda ChainBS Lambda ChainRS Roller ChainBS/DIN Standard RS Roller ChainHeavy DutyHeavy Duty Drive Chains<strong>Tsubaki</strong>’s heavy-duty drive chains offer highertransmission capacity and greater allowable loadand tensile strength than RS Roller Chains, thusenabling the use of chains 1 or 2 sizes smaller.Heavy Duty Roller ChainSUPER Roller ChainSUPER-H Roller ChainULTRA SUPER Roller Chain3

T S U B A K I D R I V E C H A I Nfor Boosting ProductivityCorrosion ResistantCorrosion Resistant Drive Chains<strong>Tsubaki</strong>’s corrosion resistant drive chains can beused in a variety of environments.Stainless Steel Drive ChainsSS SpecificationNS SpecificationAS SpecificationSpecialty ChainSpecialty Chains<strong>Tsubaki</strong> also has chains for special applications.Curved Roller ChainCurved Roller ChainStainless Steel Roller ChainSS SpecificationStainless Steel Roller ChainAS SpecificationLeaf ChainLeaf ChainPin Gear Attachment ChainSurface Treated Drive ChainsSurface Treated Drive Chain (NEP)NP SpecificationNEP SpecificationAPP SpecificationTitanium Roller ChainPoly Steel ChainLow Noise Roller ChainCold Resistant Roller ChainAccessoriesChain Elongation ScaleAccessories<strong>Tsubaki</strong>’s chain accessories meet user demands forchain maintenance.Chain TensionerChain Cutting ToolsChain Coupling ToolsEnd FittingsChain Elongation ScalePoly Steel ChainLow Noise Roller Chain4

ContentsBefore UseNotes on Using Roller Chains P7General Comparison of Transmission Elements P8Features and Precautions of P8Roller Chain TransmissionGlossaryRoller Chain ConstructionRoller Chain and SpecialtyChain Line-upSafetyP7P9P11P13P15Ordering RS Roller Chain P16Introduction to RS Roller Chain ’G7’ P19Drive Chain Dimensions / SpecificationsStandard Roller ChainsP19Old-New Chain Number Comparison P21RS Roller Chain P23BS/DIN Standard RS Roller Chain P53P61Lube-Free Roller ChainsOld-New Chain Number Comparison P63Lambda Chain P65Surface Treated Lambda Chain P66X-Lambda Chain P67Lambda Chain KF Series P68Heavy Duty Lambda Chain P71Heavy Duty Lambda Chain NP Specification P72Curved Lambda Chain P73BS Lambda Chain P74Heavy Duty Roller ChainsP77Old-New Chain Number Comparison P79RS-HT Chain P81SUPER Roller Chain P89SUPER-H Roller Chain P96ULTRA SUPER Roller Chain P97Corrosion Resistant Roller ChainsOld-New Chain Number ComparisonP100P102Stainless Steel Roller Chain(SS, NS, AS Specification)Surface Treated Roller Chain P104(NP, NEP, APP Specification)Titanium Roller Chain P107Poly Steel Chain (RS / BS) P107P108Low Noise Roller ChainCold Resistant Roller Chain P112Curved Stainless Steel Roller Chain P112Specialty Roller ChainsP98P113Curved Roller Chain P113Leaf Chain P114Pin Gear Attachment Chain P119RollerCHAIN5

T S U B A K I D R I V E C H A I NAccessories (peripheral instruments) P122Handling Roller Chains and SprocketsP158Old-New Chain Number Comparison P123Chain TensionerP124Chain Cutting Tools P127Chain Connecting Tools P127End FixturesP128Chain Elongation Scale P129Roller Chain SelectionP1301. Selection Guide P1312. Service Factors P1333. Provisional Selection Graph P1344. Selection Formulae P1365. General Selection P1396. Allowable Load Selection P1417. Example of Lifting Transmissions P1468. Calculating Moment of Inertia P1489. Example of Shuttle TractionP14910.Pin Gear Drive Selection P15011.Temperature Selection P15612.Special Selection Method for P156Corrosion-Resistant Roller Chain13.Anti-corrosion Reference Guide for P157Corrosion Resistant Drive Chains and Sprockets1. How to Cut Roller Chain P1582. How to Connect Roller ChainP1593. Roller Chain Lubrication P1604. Layout and Installation P1625. Sprockets P1646. Chain Test Run P1657. Roller Chain Inspection P1658. Cautions on Use in Special Environments P1699. Troubleshooting P170Roller Chain Inquiry SheetP174WARNINGJapan Chain AssociationThe chains, sprockets and other products appearing in this catalog are manufactured with care. However, ifnot properly selected, handled, or maintained, chains may break, resulting in serious accident. Use designmaterials, selection criteria, and instruction manuals as reference for selecting, handling, and maintainingchains and sprockets, and confirm any uncertainties with the manufacturer before proceeding.1.The specifications, dimensions and other particulars specified in this catalog are subject to change for improvement. Before designing your system, please consult with <strong>Tsubaki</strong>moto Chain Co.2. C The contents of this catalog are copyrighted by <strong>Tsubaki</strong>moto Chain Co. with all rights reserved. No part of it may be copied without the written consent of <strong>Tsubaki</strong>moto Chain Co.3.The logos, brand or product names in this catalog are trademarks or registered trademarks of <strong>Tsubaki</strong>moto Chain Co. in Japan and other countries.LINE-UP6

Before UseT S U B A K I D R I V E C H A I NBefore Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingNOTEWith the exception ofendless chains, thetransmission power tablesin this catalog are basedon use with connectingparts (connecting links oroffset links).See page 12 for details onconnecting parts.NOTEThis drive chain catalog explains how to select, install and maintain all listed <strong>Tsubaki</strong> RollerChains. Numerical figures are indicated in both SI and gravimetric units.Read through this catalog before use to ensure proper selection and usage. Also, carefullyinform persons involved in installation and maintenance of all pertinent matters.Ordinary TransmissionShuttle TractionPin Gear DriveNotes on Using Roller ChainsLifting ApplicationsDrumPin gearattachment chainPin gearsprocketWhen using a roller chain in lifting applications, keep clear from underneath the load.If there is the possibility of serious accident or death in the event of roller chainbreakage during lifting or other applications, install reliable safety devices to preventaccidents.Inspect and replace worn roller chain periodically.Roller chains can break and climb up on the sprocket from wear elongation.(Lubrication can extend service life against wear elongation. <strong>Tsubaki</strong> also offers lubefreedrive chains that deliver long-lasting service without lubrication.)Overload may cause roller chain to break. (Avoid breakage by properly selectingproducts with consideration to inertia, etc. <strong>Tsubaki</strong> offers heavy-duty drive chains inidentical sizes that deliver the high strength of larger chains.)Roller chains can break due to corrosion and other environmental conditions. (Avoidbreakage superior by preventing exposure to corrosive liquids, atmospheres, etc.<strong>Tsubaki</strong> offers corrosion-resistant drive chains.)Correctly install roller chain to avoid misalignment or uneven wear and possible breakage.7

T S U B A K I D R I V E C H A I NGeneral Comparison of Transmission ElementsThe following table compares roller chains to other power transmission mechanisms such astoothed belts, V-belts and gears. Generally speaking, roller chains are often used aseconomical power transmission suited to low speed and high loads. However, it is alsopossible to use chain in high-speed applications such as camshaft drives for automobiles.TransmissionMechanismSynchronicityTransmissionEfficiencyAnti-shockNoise & VibrationAmbient ConditionsSpaceWeightHigh speed,light loadLow speed,heavy loadLubricationLayout FreedomExcess Loadon ShaftRoller Chain Avoid water and dust.(Corrosion-resistantdrive chains available.)Compact,lightweightAvoid heat, oil,water and dust.Avoid heat, oil,water and dust. Slightly heavypulleysRequiredExcellentGoodFairPoorFeatures and Precautions of Roller Chain Transmissions1.2.3.4.5.6.7.8.9.1.2.3.4.FeaturesWide with heavypulleysAccommodetes large speed reductions/increases (usually up to 1:7).Chain can accommodate long shaft center distances (normally less than 4 m), and is more versatile.It is possible to use chain with multiple shafts or drives with both sides of the chain.Easy installation and replacement (easy to cut and connect chains).Drive use is possible even when shafts are vertical, as long as the chain receives support in shortdistances between the shafts.Standardization of chains under the American National Standards Institute (ANSI), the InternationalStandardization Organization (ISO), and the Japanese Industrial Standards (JIS) allow ease ofselection.The sprocket diameter for a chain system may be smaller than a belt pulley while transmitting thesame torque.Sprockets are subject to less wear than gears because sprockets distribute the load over their manyteeth.High shock absorbency compared with gears.PrecautionsToothed Belt V-belt GearNot requiredNot required Chain has speed variation, called chordal action, which is caused by the polygonal effect of thesprockets.(Shock can be reduced under the same speed ratio by either reducing the chain pitch orincreasing the number of sprocket teeth.)During transmission, a method of lubrication suitable to the chain’s speed is necessary.Chain wears and elongates. Measures for adjusting chain slack need to be considered.Chain is weak when subjected to loads from the side. It needs proper alignment.Avoid waterand dust.Needs high strengthdue to low numberof engaging teeth.RequiredBefore Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling8

GlossaryT S U B A K I D R I V E C H A I NBefore Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling1. ANSI Standard Minimum Tensile Strength (Tensile Breakage Strength)2. <strong>Tsubaki</strong> Average Tensile Strength3. <strong>Tsubaki</strong> Minimum Tensile Strength4.Maximum Allowable LoadThis is the minimum tensile strength determined by ANSI Standard. If a roller chain breaksfrom a tensile load below this value, then it is non-compliant. In the case of multi-strand rollerchain, the single strand value is multiplied by the number of strands. (ANSI B 29.100)This is a fracture load reading obtained after a long period of actual tensile strength testing ofa large number of chain strands. Naturally, a roller chain may actually break at a higher orlower value than this, so it does not represent a guaranteed value. This value variesdepending on the manufacturer.This is a minimum value determined bystatistical processing at <strong>Tsubaki</strong>. If anyroller chain fractures by a tensile loadbelow this value, then it is noncompliant.This value varies dependingon the manufacturer.Testing MethodAs shown in Fig. 2, roller chain with over five links is fixed at both ends by clevises and isstretched until breakage occurs (JIS B 1801-2009). The type of fracture is indicated bybreakage of the roller chain or failure of its parts (Fig. 3.)Fig. 2 Tensile strength testThe maximum allowable load of roller chain (excluding Stainless Steel Chain and EngineeringPlastic Chain*) is the value derived from the lowest fatigue limit. When a load lower than thisvalue is repetitively applied to the roller chain, fatigue failure will never occur.According to the former JIS B 1801-1997, the maximum allowable load indicates abreakage load of Pmax = (Pm + Pa) = 2.2Pa at a frequency of 5 10 6 , when a newroller chain with over five links receives a repetitive load in linear operation. (Fig. 4)<strong>Tsubaki</strong> standards and catalog values are for 10 7 repetitions, or 2Pa. In other words, if<strong>Tsubaki</strong>’s maximum allowable load is indicated as maximum load (Pmax), then values in thiscatalog would increase 10%.Fig. 4 Summary chart of repetitive loadLoadFig. 1 Relationship between three tensile strengthsJIS minimum tensile strength<strong>Tsubaki</strong> minimum tensile strengthFrequencyFig. 3 Shape of fractureAverage tensile strengthTensile strength* Stainless steel and engineered plastic chains:Maximum allowable load is determined from specifying the surfacepressure between pins and bushes based on wear performance.Note that strength of offset links may belower than the chain itself.(Refer to each product page for details.)Time9

T S U B A K I D R I V E C H A I N5. Kilowatt Ratings Table6. Moment of Inertia (I / J / GD 2 )7. Total Length Tolerance of Roller Chain8. Elastic Elongation of Chain under LoadRS Roller Chain, SUPER Roller Chain, Heavy Duty Chain, and Low Noise Drive Chainkilowatt ratings tables show kW values for 15,000 hours of operation using a two-shaft driveand 100 pitches of roller chain under conditions 1 - 5 below.The kW ratings table of Lambda Chain is based on conditions 1 - 4 and shows kW ratingvalues when Lambda Chain is used with two shafts. Lambda Chain has more than seventimes the wear elongation of Standard RS Roller Chain operated without lubrication (#120 and#140 are over 2.5 times). X-LAMBDA has more than five times the wear elongation life ofLambda Roller Chain.1) The chains are operated under ordinary conditions where the ambient temperature is -10 - +60(+14F - +140F) and there is no abrasive dust.2) There are no negative effects from corrosive gasses or high humidity.3) The two shafts are level and the chains are properly installed. (See item 4 on pg. 162.)4) There is minimal fluctuation in load during transmission.5) The recommended lubrication system and lubricant shown in the kW ratings tables is used for RS RollerChain and SUPER Roller Chain. (See pgs. 160 - 161.)Moment of inertia is used to show the degree of inertia in rotational movement; in other words,"rotation difficulty", or "rotation ease." This is equivalent to the mass (weight) of the objectbeing used for straight-line transmission.Moment of inertia is shown in the SI units table as:I = mk 2 (kgm 2 m: mass of rotating body k: turning radius)It is shown in the Gravimetric units table as:J = GK 2(kgfms 2 G: mass of rotating body G: gravitational acceleration).GAlthough, GD 2 = 4GJ (D: diameter of rotating body) is generally being used now in place ofmoment of inertia.Length test method and length tolerance are specified in JIS B 1801-2009. The lengthtolerance of any individual size when subjected to a measured load (e.g. 500 N [50.99 kgf] forRS 80) specified in JIS is 0 to +0.15% of the reference length. The reference length iscalculated by multiplying the reference pitch (P) by the number of links. (Applicable toproducts bearing a JIS identification number.)An elastic elongation curve of a chain under load looks as shown below. Values shown hereare the standard references for single-strand RS Roller Chains. Actual values may slightlydiffer. Do not apply loads greater than the maximum allowable load to roller chains.Load: Maximum allowable loadLoad: Maximum allowable loadBefore Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingElongation of 1 m chain (mm)Elongation of 1 m chain (mm)10

T S U B A K I D R I V E C H A I NRoller Chain ConstructionBefore Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling1. Basic Structure (Photo: RS Roller Chain)Offset pinBasic Three DimensionsThe pitch, roller diameter, andinner width of the inner linkare considered the basic threedimensions of a roller chain.When these dimensions areidentical, a roller chain andsprocket are dimensionallycompatible.Cotter pinSpring clips, cotter pins andspring pins are essential partsthat prevent connecting platesfrom falling off, maintainingthe strength of the chain itself.Always install these parts.*Slip FitWhen the shafts and holes arefitted together, there is acontinuous loose fit. This is afit where the range of tolerancefor the hole is larger than therange of tolerance for the shaft(pin or bush).*Press FitWhen the shafts and holes arefitted together, there is acontinuous interferential fit. Thisis a fit where the range oftolerance for the hole is smallerthan the range of tolerance forthe shaft (pin or bush).Slip fitPlateOuter linkRollerdiameterOffset linkInner linkPitchConnecting linkChainWidth between inner link platesThe plate bears the tension placed on the chain. Usually this is a repetitive load, butsometimes it is accompanied by shock. Therefore, the plate must have not only great statictensile strength, but also must hold up to the dynamic forces of load and shock.PinPress fitPress fit*2Press fitSlip fit*1The pin is subject to shearing and bending forces transmitted by the plate. At the same time, itforms a load-bearing part, together with the bush, when the chain flexes during sprocketengagement. Therefore, the pin needs high tensile and shear strength, resistance to bending,and sufficient endurance against shock and wear.BushPinRollerBushConnecting link plateSpring clipInner linkInner plateOuter plateMiddle plateSingle-strandouter linkMulti-strand outer link(Double-strand shown here)chainThe bush is subject to complex forces from all parts, especially from the repetition of shockloads when the chain engages the sprocket. Therefore, the bush needs extremely high shockresistance. In addition, the bush forms a load-bearing part together with the pin, and as suchrequires great wear resistance.RollerThe roller is subject to impact load as it strikes the sprocket teeth during chain engagementwith the sprocket. After engagement, the roller changes its point of contact and balance. It isheld between the sprocket teeth and bush, and moves on the tooth face while receiving acompression load. Therefore, it must be resistant to wear and still have strength againstshock, fatigue and compression. RS11 / 15 / 25 / 35 do not have rollers.Roller LinkTwo bushes are press fit into two inner plates, and rollers are inserted to allow rotation aroundthe outside of the bush. This is the same for single-strand and multi-strand chain.Outer Link and Middle PlateThe pin link consists of two pins that have been press fit into two outer plates. With multistrandroller chain, a middle plate is added to the pin link. The middle plate is slip fit forStandard RS Roller Chain and press fit for SUPER Roller Chain.11

T S U B A K I D R I V E C H A I N2. Assembly PartsRoller Chains are usually made up of a number of connected links in an endless formation, or used by fixing the chain ends, butthe need for connecting links will eventually arise. Although offset links can be used when there are an odd number of links inthe roller chain, please use a design that requires an even number of links as much as possible.2.1 Connecting LinksM-type Connecting linkClip typeOuter plateConnecting link plate(RC-processing)Cotter pin typeCotter pin typeMulti-strand (Double-strand shown)Outer plateConnecting link plate(RC-processing)Spring pin type(RS240 only)Connecting link plate(RC-processing)F-type Connecting linkPin Pin Middle platePin Pin PinClipCotter pin1-Pitch Offset Link (OL)Single-strandOffset link plateMulti-strand(double-strand shown)Cotter pinSpring pin2-Pitch Offset LinkSingle-strandMulti-strand(double-strand shown)Offset link plateSpring clipOuter platePin / Connecting ConnectingChain type Connecting link type Notelink plate fitting link plate fasteningRS Roller ChainLambda ChainSUPERRoller ChainSUPER-HRoller ChainHeavy DutyRoller ChainOther rollerchains in catalog2.2 Offset Link1-Pitch Offset LinkFor RS35 to RS60 offset links, allow for a20% reduction in kW (35% less for RS80 toRS240) and 35% less maximum allowableload (same for RS80 to RS240).M-type connecting linkCode: CLF-type connecting link *Code: FCLM-type connecting linkCode: CLM-type connecting linkCode: MCLF-type connecting linkCode: FCLF-type connecting linkCode: CLF-type connecting linkCode: CL M-type connecting linkCode: CL2-Pitch Offset LinksThe pin and offset link plate of a 2POL is pressfit and is fastened by a rivet. They can be usedin accordance with the kW ratings tables.4-Pitch Offset Link4POL can be used with (single-strand) SUPERRoller Chains. Allow for a 10% reduction inmaximum allowable load and kW ratings.Slip fit(M)Press fitSlip fit(M)Slip fit(M)Press fitPress fitPress fitSlip fit(M)PinSpring clipCotter pinSpring pinSpring clip, Cotter pinSpring pinT-pinSpring clipCotter pinSpring pinSpring pinSpring pinCotter pinSpring pinCotter pin, Spring clipSpring pinT-pin, Z-pinPinConnecting link plateSingle-strandCotter pinFor multi-strand chain, make sure the platewith *RC processing is on the outermost sidewhen assembling.Operating speed is indicated by the white areain the kW ratings table.Make sure to use the chain according to the specifiedapplications on page 131 and within the speed regionof the colored area in the kW rating tables.Can be used in all areas of the kW ratingstable for Lambda Chain.Connecting plates are RC-processed.Connecting plates are RC-processed.Use under extreme conditions (e.g., high shock,very high load, possible side force, etc.).Use exclusive connecting link.Use exclusive connecting link.Refer to individual dimension diagrams.Only NP, NEP and Low Noise Roller Chainsuse RC-processed connecting link plates.Note 1. The connecting link plate fastening method for each chain size is indicated in the dimension tables and the table notes.2. The color of F-type connecting links for RS Roller Chain and RS-HT Roller Chain marked with * is black.Remark: Ring Coin (RC) ProcessingThis <strong>Tsubaki</strong> original processing adds an area of plastic deformation around pin holes to generate residual stress around the holes.4-Pitch Offset LinkNote: See the dimensional tables for roller chain types and sizes suitable for offset links.Before Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling See the notes for BS/DIN Standard RS Roller Chains section.12

T S U B A K I D R I V E C H A I NRoller Chain and Specialty Chain LineupBefore Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingSeriesStandardRoller ChainsLube-FreeRoller ChainsHeavy DutyRoller ChainsCorrosionResistantRoller ChainsSpecialtyRoller ChainsProductRS Roller ChainBS/DIN StandardRS Roller ChainLambda ChainSurface TreatedLambda ChainX-Lambda ChainLambda ChainKF SeriesHeavy DutyLambda ChainCurvedLambda ChainBSLambda ChainHeavy DutyRoller ChainSUPERRoller ChainSUPER-HRoller ChainULTRA SUPERRoller ChainStainless SteelRoller ChainSurface TreatedRoller ChainFeatures/ApplicationsJIS-, ISO-compliantISO-compliant seriesLube-free, long-life (Special oil-impregnated bush)Lube-free, long-life (Special oil-impregnated bush)Surface treated (NP and NEP)Operatingtemperaturerange ()—10 to + 60 *1—10 to +150—10 to +230—10 to +150Titanium Roller Chain Made of nonmagnetic titanium, high corrosion resistance —10 to +60Cold Resistant Roller Chain Cold resistance specification —40 to +60Low Noise Roller Chain Spring rollers, low noise —10 to +60Poly Steel Chain Corrosion resistance, wear resistance, low noise, lightweight —10 to +80Curved Roller Chain Side-flexing chain, curved transmissions —10 to +60Curved Stainless Steel Stainless steel, curved transmissionsRoller ChainLeaf ChainPin Gear Attachment ChainSuper long-life via special oil-impregnatedbush and felt sealLube-free, long-life (Special oil-impregnated bush), forhigh temperatures and food processing equipment.Lube-free, long-life (Special oil-impregnated bush),heavy-duty, double-strand onlyLube-free, long-life (Special oil-impregnated bush),for curved linesLube-free, long-life (Special oil-impregnated bush),ISO-compliant BS SeriesHigh tensile strength(Approx. 19% increase over RS)High tensile strength(Approx. 30% increase over RS)High fatigue strength, high tensile strength,for heavy-duty transmissionsMaximum fatigue strength, maximum tensilestrength, for super heavy-duty transmissionsSSNSASNPNEPAPPHigh corrosion resistance, high heat resistanceHigher corrosion resistance and higher heatresistance than SS1.5x maximum allowable load of SS, slightlyless corrosion resistanceLow corrosion resistance, special nickel platingHigh corrosion resistanceAnti-pittingPlate and pin construction, for lifting applications,AL-type, BL-type (AL ), (BL )Used in anchored configuration, gear transmission—10 to +60—20 to +400—10 to +60—20 to +400—10 to +6013

SizesT S U B A K I D R I V E C H A I N111525354050Chain No. (Pitch: mm) *260803.7465 4.7625 6.359.52512.70 15.875 19.05 25.40 31.75 38.10 44.45 50.80 57.15 63.50 76.20 100RF06B RS08B RS10B RS12B RS16B RS20B RS24B RS28B RS32B RS40B RS48B*3 *3 120 140160 180200240 RF06B RS08B RS10B RS12B RS16B RS20B RS24B RS28B RS32B RS40B 4 5 6 8 10 12 14 16Ref. page21617798113Before Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling*1: The operating temperature range of pre-lubricated chains (those coated with oil when delivered) is -10 to +60 (-40 to +60 for KT specification).Chain kW ratings do not decrease until 150. To use in +60 to 150environments, apply a high temperature lubrication. For details and precautions inusage, see "Temperature Selection Method" (page 156) and "Roller Chain Lubrication" (page 160).*2: Sizes marked with are standard products shown in this catalog. For details, see the corresponding section. Blank cells are specialty items and may bespecially ordered. Contact <strong>Tsubaki</strong> for details.*3: RS05B (pitch 8.00) and RS56B (pitch 88.9) are also available.14

Before Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingFor Safe UseWARNING Obey the following points in order to prevent hazardous situations.Do not use chains and accessories (accessories and parts) for anything other than their original purpose.Never perform additional processing on the chain.. Do not anneal the various parts of the chain.. Do not clean the chain with either acid or alkali, as they may cause cracking.. Do not electroplate the chain or its parts, as it may cause cracking due to hydrogen embrittlement.. Do not weld the chain, as the heat may cause cracking or a reduction in strength.. When heating or cutting the chain with a torch, remove the links immediately adjacent and do not use them again.When there is need to replace a lost or damaged portion of a chain, always replace the whole chain witha new product rather than replacing only the lost or damaged portion.When using a chain on suspension equipment, establish a safety perimeter and strictly prevent entry tothe area directly below the suspended object.Always employ hazard protection devices for the chain and sprocket (safety cover, etc.).If a substance that can cause embrittlement cracking (acid, strong alkali, battery fluid, etc.) adheres to thechain, stop using the chain immediately and replace it with a new one.During installation, removal, maintenance inspection and lubrication of the chain:. Perform the operation according to the instruction manual or this catalog.. Always turn off the power switch to the device and make sure that it cannot be turned on accidentally.. Anchor the chain and parts so that they cannot move freely.. Perform cutting and connecting procedures properly using a press or other special tool.. Wear clothing and employ protective devices that are appropriate to the job (safety glasses, gloves, safety shoes, etc.).. Only allow experienced personnel to perform chain replacement procedures.A fail safe back up system is suggested whenever using Leaf Chain to safely support the load in the eventof a chain failure.CAUTIONObey the following points in order to prevent accidents.Only handle the chain after thoroughly understanding its structure and specifications.When installing a chain, inspect it in advance to confirm that it has not been damaged in transport.Be sure to perform regular maintenance inspections on the chain and sprocket.Chain strength varies according to manufacturer. When selecting a chain based on a <strong>Tsubaki</strong> catalog,always use the corresponding <strong>Tsubaki</strong> product.Minimum tensile strength refers to the failure point when the corresponding load is applied to the chain onceand does not refer to the allowable operational load.Warranty1. LIMITED WARRANTYProducts manufactured by Seller: (a) conform to the design andspecifications, if any, expressly agreed to in writing by Seller; and(b) are free of defects in workmanship and materials at the timeof shipment. The warranties set forth in the preceding sentenceare exclusive of all other warranties, express or implied, andextend only to Buyer and to no other person. ALL WARRANTIESOF MERCHANTABILITY OR FITNESS FOR A PARTICULARPURPOSE ARE HEREBY EXCLUDED.2. NON-RELIANCEBuyer is not relying upon any advice, representations orwarranties (except the warranties expressly set forth above) ofSeller, or upon Seller's skill or judgment regarding the Seller'sproducts.Buyer is solely responsible for the design and specifications ofthe products, including without limitation, the determination ofsuitability for Buyer's application of the products.3. CLAIMS(a) Any claim relating to quantity or type shall be made to Seller inwriting within 7 days after receipt of the products; any suchclaim made thereafter shall be barred.(b) Any claim under the above-stated Limited Warranty shall bemade to Seller in writing within three (3) months after receipt ofthe products; any such claim made thereafter shall be barred.(c) Seller's liability for breach of warranty or otherwise is limited torepair or replacement, at Seller's option, of non-conforming ordefective products. Buyer waives all other remedies, including,but not limited to, all rights to consequential, special orincidental damages, including, but not limited to, damagesresulting from personal injury, death or damage to or loss ofuse of property.(d) Repair, alteration, neglect or misuse of the products shall voidall applicable warranties.4. INDEMNIFICATIONBuyer will indemnify, defend and hold Seller harmless from allloss, liability, damage and expense, including attorneys' fees,arising out of any claim (a) for infringement of any patent,trademark, copyright, misappropriation of trade secrets, unfaircompetition or similar charge by any products supplied by Sellerin accordance with the design or specifications furnished byBuyer, or (b) arising out of or connected with the products or anyitems into which the products are incorporated, including, but notlimited to, any claim for product liability (whether or not based onnegligence or strict liability of Seller), breach of warranty, breachof contract or otherwise.5. ENTIRE AGREEMENTThese terms and conditions constitute the entire agreementbetween Buyer and Seller and supersede any inconsistent termsand conditions, whether contained in Buyer's purchase order orotherwise, and whether made heretofore or hereafter.No statement or writing subsequent to the date hereof whichpurports to modify or add to the terms and conditions hereof shallbe binding unless consented to in writing, which makes specificreference hereto, and which has been signed by the partyagainst which enforcement thereof is sought. Seller reserves theright to change these terms and conditions without prior notice.15

Ordering RS Roller ChainT S U B A K I D R I V E C H A I NBefore Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling3. Ordering an odd number of linksBe sure to indicate "configuration specification". If no specification is made for an oddnumber of links, both end links will be inner links (both RL) as in [4].1 9 links (including CL and OL)2 9 links (specified to include 2POL)3 9 links (both ends with CL)4 9 links (both ends inner links)5 9 links (both ends outer links)After installing the equipment, use a riveting punch (see theaccessories section) to fasten the pin ends of the rivets inthe outer links on both ends.Product codeA110018 RS50-1-RP 7A115018 RS50-1-CL 1A116013 RS50-1-OL 1Configuration specificationProduct codeA110018 RS50-1-RP 5A115018 RS50-1-CL 2A116080 RS50-1-2POL 1Configuration specification9LX1H CL,OLLKK9LX1H2POL,CLNote: To specify that parts be installed, an assembly specificationsuch as CL - OL (2POL) is required.Product codeChainnumberCountA110018 RS50-1-RP 7A115018 RS50-1-CL 2Configuration specificationProduct codeChainnumberChainnumberCountCountUnits9LX1H CL-CLNote: To specify that parts be installed, an assembly specificationsuch as CL - OL (2POL) is required.A110018 RS50-1-RP 9 LConfiguration specificationProduct codeChainnumberChainnumberCountLKKUnitsUnitsLKUnits9LX1HRL-RLCountUnitsA110018 RS50-1-RP 9 LConfiguration specificationNote: To specify that parts be installed, an assembly specificationsuch as CL - OL (2POL) is required.9LX1HPL-PLThe photograph in each example order shows CL and OL assembled. In an actual order, CL and OL aredelivered unassembled. If you wish parts to be assembled, a configuration specification is necessary.17

T S U B A K I D R I V E C H A I N4. Matched and tagged chainDeviations in chain length exist due to the manufacturingtolerances of the parts. When chains are to be used in paralleland minimizing the relative difference in the lengths is necessary,request a "matched and tagged" chain.Note: A separate charge is required for a length matching.5. Long length formation6. Reel chainSingle-strand RS25 to RS80 chain (see table below) is available on long-length reels.7. Replacement precautionsWhen you do not know the roller chain numberFor example, if you need three sets of two single-strand,120-link RS80 chains, the entry should be:When a chain s total length exceeds 3.048m (10ft), it is called a long length formation. Please consult a <strong>Tsubaki</strong> representativefor information regarding chains exceeding the lengths below. A separate super long length formation fee and wooden box feeapplies.Example orderOrdering one reel of RS50-1-RP Roller ChainProduct codeChainnumberCount UnitsA110089 RS50-1-RP-10UR 1 RProduct codeA110083A110084A110085A110086A110087A110088A110089A110090A110091Chain number Units per reel Number of links (unit: L)Number of accessory CL(M-type connecting links)RS25-1-RP-150UR 15023999 150RS35-1-RP-20UR 206399 20RS37-1-RP-20UR 20479920RS38-1-RP-20UR 20479920RS41-1-RP-20UR 20479920RS40-1-RP-15UR 15359915RS50-1-RP-10UR 10191910RS60-1-RP-10UR 10159910RS80-1-RP-5UR 559951 2 3Verification of theroller chain specifications(strength type, material, etc.)is important. Check with themanufacturer.Check the roller chainsize and specifications thatare engraved on the rollerchain plate.Example entry in special mention columnRS80-1-RP 720 linksMatched and tagged chain: 120 L x 2 H x 3 DMeasure the pitch,roller diameter, inner widthof inner link, and platethickness of the roller chain.Before Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling18

groovebushesTwo timesthe wear lifeing oil between the pin and bush longer than theWith G7, our newly-developed LG solid bushwith seamless bush for lastingFour times betterthe wear lifeLG Solid BushIncreasesuperior

"World’s No. 1"kilowatt ratings by 25%."World’s No.1kW ratingsgroove, the connecting link achieves the same strength as thechain itself.

Before Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingStandard Roller Chains Old-New Chain Number ComparisonProduct codes have been assigned to all products (except customized products) and chain numbers have been rewritten.The following clarifies the differences between old and new chain numbers.RS Roller ChainOld chain numbers for single-strand chains indicated size only. Add "-1" to all new chain numbers.Double-and higher multi-strand chains will still use the current numbering.RP and CP type needs to be stated with new chain numbers.RPA chain that uses rivets to connect RL and RL with PL.RS80 -1 -RP -UApplicable sizesChain number with connecting link (CL)Chain number with OL/2POLRS11-SS-1RF320-T-1RF400-T-1New chain number15, 25, 37, 38, 41, 40, 50,60, 80, 100, 120, 140,160, 180, 200, 240BF25-H-1-RP-UBF25-H-1-RPor CPRequired for standardstocked products (units).Not required for linksonly.Note: RS11SS, RF320T and RF400T numbers are as follows.New chain numberNote: BF25H numbers are as follows.New chain numberRS80Applicable sizes15, 25, 37, 38, 41, 40, 50, 60,80, 100, 120, 140, 160, 180,200, 240RS80-1-CLFor FCL: RS80-1-FCLRS80-1-OL, RS80-1-2POLOld chain numberRS11SSRF320TRF400TOld chain numberBF25HCPA chain that uses cotter pins to connect RL and RL with PL.Old chain number21

Standard Roller ChainsOld-New Chain Number ComparisonBS Roller Chain (ISO606-compliant B Series)RF06B-1New chain numberRS 08B -1RS Roller ChainOld chain numbers for single-strand chains indicated size only. Add "-1" to all new chain numbers.For double and higher multi-strand chains, confirm size and then simply change the strand listing.Chain number with connecting link (CL)Chain number with OL/2POLApplicable sizes08B, 10B, 12B, 16B, 20B,24B, 28B, 32B, 40BRF06BRS08BRS08B-1-CLRS08B-1-OL, RS08B-1-2POLOld chain numberApplicable sizes08B, 10B, 12B, 16B, 20B,24B, 28B, 32B, 40BBefore Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling22

Standard Roller Chains RS Roller ChainRS11-SS-1Before Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingTSUBAKIChain Number3.345 2.2750.383.5RS11-SS-1 780{80} 50{5} 52 134Standard Roller ChainsRS11SS SprocketSprocket NumberTypeChain numberAverageTensile StrengthN{kf}Stainless steelNumber of teeth1.57MaximumAllowable LoadN{kf}Note: 1. Made of SUS 304 stainless steel. 2. No offset links available.3. Bushed chain.3.7465 3.7465Non-stepped teeth1B typeNumber ofteethTypeApproximateMass/mPitch circulardiameter(DP )Stepped teethSprocket outerdiameter(DO)2.285Non-stepped teeth 1C type12 14.475 16.26 9.415 18.020 19.9 9 13416 B or C 19.204 21.1 9 14M30.518 (non-stepped 21.575 23.5 11 1620teeth)23.949 25.924 28.703 30.7 6 13 19 M40.728 33.462 35.530 35.842 37.934 B or C 40.604 42.736 (stepped 42.986 45.1 6 13 19 M40.740 teeth) 47.751 49.848 57.283 59.40.381.83Drawing Scale 2/1Number ofLinks Per UnitBore diameter (d )Min.Max.Hub Set screwdiameter hole(DH )Stepped teethApprox. weight ()1B type 1C type5.9 7.411.5 14.713.5 17.317.7 22.823.3 30.325.7 32.728.7 35.729.7 39.337.9 48.940.7 52.446.5 59.960.5 77.8MaterialStainlesssteelStainlesssteelNote: 1. Bore diameter is customizable within the above ranges. However, the finishing hole tolerance is H8 fordiameters of less than 8 and H7 for diameters of 8 and above.2. Unless bore diameter is specified, sprockets are made to the above minimum size with an H10 tolerance.23

Standard Roller ChainsRS25, BF25-H Sprocket HLRS37-1RS38-1RS41-191011121314151617181920212223242526283032354045d10 20.55 23.5 6H8 8H8 13 14 4 M3X6 1311 22.54 25.5 6H8 8H8 15 14 4 M3X8 1612 24.53 27.5 8H8 10H8 17 14 4 M4X8 2013 26.53 29.5 8H8 10H8 18 14 4 M4X8 2314 28.54 31.5 8H8 10H8 19 14 4 M4X8 2615 30.54 33.5 8H8 10H8 20 14 4 M4X10 3116 32.55 35.5 8H8 10H8 21 16 5 M4X10 3817 34.56 37.5 8H8 10H8 23 16 5 M4X10 4518 36.57 39.5 8H8 10H8 25 16 5 M4X12 5219 38.58 41.5 8H8 10H8 26 16 5 M4X12 6020 40.59 43.5 8H8 10H8 28 16 5 M4X14 6821 42.61 45.5 8H8 10H8 30 18 7 M4X14 8022 44.62 48.0 8H8 10H8 30 18 7 M4X14 8423 46.63 50.0 8H8 10H8 30 18 7 M4X14 8824 48.65 52.0 8H8 10H8 30 18 7 M4X14 9325 50.66 54.0 8H8 10H8 30 18 7 M4X14 9826 52.68 56.0 10H8 12H8 30 18 7 M4X14 9828 56.71 60.0 10H8 12H8 30 18 7 M4X14 10330 60.75 64.0 10H8 12H8 30 18 7 M4X14 11032 64.78 68.0 10H8 12H8 30 18 7 M4X14 117T1 T2 T3 D L1+L2 L1 L2 LRS37-1 12.70 7.80 3.40 1.0 1.0 1.2 3.63 11.0 5.1 5.9 12.45RS38-1 12.70 7.80 4.80 1.1 1.1 1.2 3.63 13.1 6.0 7.1 14.1RS41-1 12.70 7.77 6.38 1.251.251.253.59 14.7 6.757.9515.1RS37-1 8.14{ 830} 9.41{ 960} 1.67{170} 0.29 240RS38-1 8.14{ 830} 9.41{ 960} 1.67{170} 0.35 240RS41-1 7.4{755} 10.3{1050} 11.8{1200} 2.26{230} 0.41 24010 25 50 100 200 300 400 500 700 900 1000 1200 1400 1600 1800 2100 2400 2700 3000 3500 4000 5000 6000 7000 80000.020.030.030.030.030.040.040.040.050.050.050.050.060.060.060.070.070.070.080.080.090.100.120.13SD HD PD OSintered alloy specification (1B type)Sprocket NumberL1Small SprocketNo. of TeethChain numberL2T1T3DType0.050.060.070.070.080.080.090.100.100.110.120.120.130.140.140.150.160.170.180.190.210.230.260.30Notes:1. Bores are finishedand fittedwith a screw.0.100.110.120.140.150.160.170.180.190.210.220.230.240.260.270.280.300.310.330.360.380.430.490.560.180.200.230.250.270.290.320.340.360.390.410.430.460.480.500.530.550.570.620.670.720.790.921.04Bore diameter (d)Number of teethA B C0.340.380.430.470.510.550.590.630.680.720.760.810.850.890.940.981.031.071.161.251.341.481.711.94R0.490.550.610.670.730.790.850.910.981.041.101.161.231.291.351.421.481.541.671.801.932.132.462.792TW0.640.710.790.870.951.021.101.181.261.341.421.511.591.661.751.831.922.002.172.332.512.763.183.62Number ofTeethL0.780.870.971.061.161.251.351.451.551.641.741.841.942.042.142.242.342.452.652.853.063.373.894.42Pitch CircularDiameter(DP )Standard Roller Chains RS Roller Chain1.051.181.311.441.571.701.831.962.092.222.362.492.632.762.903.043.173.313.593.864.144.565.275.991.321.481.641.801.962.132.292.462.622.792.963.133.293.463.633.813.984.154.504.845.195.726.617.50Sprocket OuterDiameter(DO)RS41-1 Maximum Kilowatt Ratings Table (kW Ratings for Single Strand Chain)Lubrication Type1.251.471.691.932.162.342.522.702.883.073.253.443.623.814.004.184.374.564.945.325.716.297.268.250.951.111.281.451.641.842.042.252.452.682.903.163.403.643.894.154.414.685.235.806.397.318.569.72Cross-recessed HeadBore Diameter (d ) HubMachine ScrewDiameter Length Position1 type 2 typeS(DH) (L )(H )TSUBAKIChain NumberTSUBAKIChain Number0.750.881.011.161.311.451.621.781.952.132.312.482.682.873.073.273.483.694.124.575.045.767.048.430.610.720.830.951.071.191.321.451.601.741.892.042.192.352.512.682.843.023.373.744.124.725.766.87PitchPSmall Sprocket Max r/min0.510.600.690.790.901.001.111.221.331.451.581.711.831.972.102.252.392.532.833.133.453.954.835.76Roller Inner Width ofDiameter Inner LinkR W0.410.480.550.630.710.790.880.971.061.161.251.351.451.561.671.781.902.012.252.482.743.133.834.570.340.400.460.510.580.650.720.790.870.951.031.111.191.281.371.451.551.641.842.042.252.573.133.740.280.330.380.430.480.540.600.660.730.790.860.931.001.071.151.221.301.381.541.711.882.152.633.130.240.280.320.370.420.460.510.570.620.680.730.790.850.920.981.041.111.181.311.451.601.842.252.68PlatesANSI Standard <strong>Tsubaki</strong> Minimum <strong>Tsubaki</strong> AverageMin. Tensile Strength Tensile Strength Tensile StrengthkN{kf} kN{kf} kN{kf}0.190.220.250.290.330.370.410.450.490.540.580.630.680.720.780.830.880.931.041.161.281.451.782.13MaximumAllowable LoadkN{kf}0.160.180.210.240.270.300.340.370.400.440.480.510.550.600.630.680.720.760.850.951.041.191.451.740.110.130.150.170.190.220.240.260.290.310.340.370.400.430.460.480.510.540.610.680.750.851.040Approx.Mass()PinsApproximateMassk/m0.080.100.110.130.150.160.180.200.220.240.260.280.300.320.340.370.400.420.460.510000.070.080.090.100.120.130.140.160.170.190.210.220.240.250.28Material0.290000Sintered alloyMachine-structuralcarbon steelNumber of LinksPer UnitNote: 1. Maximum allowable load when using a one-pitch offset link (OL) is 65% of the above.2. Number of links per unit = 2400.050.060.070.080.100.100.120.130.140000000Before Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingNote: 1. Please consult TSUBAKI prior to use of kW ratings in the colored area of the table.LubricationmethodABCManual lubrication or drip lubricationOil bath or slinger disc lubricationForced pump lubricationDetailsonPg. 16126

Standard Roller Chains RS Roller ChainRS35Before Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingL11LSmall SprocketNo. of TeethL1L2RS35-1 1 12.7 5.85 6.85 13.58.7 {887} 9.81{1000} 11.3{1150} 2.16{220} 0.33RS35-2 2 22.8 10.9 11.9 24.5 10.1 Riveting 17.4{1774} 19.6{2000} 22.6{2300} 3.63{370} 0.69RS35-3 3 32.9 16.0 16.9 34.6 26.1{2661} 29.4{3000} 33.8{3450} 5.39{550} 1.05910111213141516171819202122232425262830323540451.257.83.5950 100 300 500 700 900 1200 1500 1800 2100 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000 7500 8000 8500 9000 100000.090.100.120.130.140.150.160.170.190.200.210.220.230.240.260.270.280.290.320.340.370.400.470.530.170.190.220.240.260.280.300.320.350.370.390.410.430.460.480.500.520.550.590.640.680.750.870.99Single strand9.525 9.5250.470.520.580.640.700.750.810.870.930.991.051.111.171.231.291.351.411.471.591.721.842.032.342.66A B C0.740.830.921.011.101.191.281.381.471.561.661.751.851.942.042.132.232.332.522.722.913.213.714.21L1.001.121.241.371.491.611.741.861.992.122.252.372.502.632.762.893.023.153.413.683.944.345.025.701.261.411.561.711.872.022.182.342.502.662.812.983.143.303.463.623.793.954.284.614.945.456.297.141.631.822.022.222.422.622.833.033.233.443.653.854.064.274.484.694.905.125.545.976.407.058.159.255.089.01.254.781.992.232.472.712.963.213.453.703.954.214.464.714.975.225.485.746.006.266.787.307.838.629.9611.32.342.632.913.203.493.784.074.364.664.955.255.555.856.156.466.767.077.377.988.609.2210.211.713.3L12LC2.693.023.343.674.014.344.675.015.355.696.036.386.727.077.427.778.128.479.179.8810.611.713.515.32.112.502.883.283.704.144.595.055.536.036.547.067.608.158.689.099.509.9110.711.612.413.715.817.91.621.902.182.502.803.143.473.804.174.544.925.325.726.206.627.067.517.968.909.8710.912.415.218.1Double strandRS35-1 Maximum Kilowatt Ratings Table (kW Ratings for Single Strand Chain)Lubrication TypeSmall Sprocket Max r/min1.291.511.731.982.232.492.763.043.333.633.944.254.574.915.265.595.966.317.077.838.589.8512.014.41.051.231.421.621.832.032.262.492.732.973.223.483.744.014.304.574.885.165.786.397.048.059.8511.80.881.041.181.361.531.711.892.092.282.492.702.913.143.363.603.844.094.334.845.355.906.768.289.850.750.881.011.161.301.461.621.781.952.122.302.492.682.873.083.273.493.704.144.585.045.767.058.430.660.770.881.011.121.271.401.541.691.842.002.162.322.492.672.833.023.213.593.974.375.006.117.30L12LC C0.570.670.770.880.991.111.231.361.481.621.751.892.032.182.342.492.662.813.153.483.834.385.366.410.510.600.680.780.870.981.091.201.321.431.561.681.801.942.082.212.362.492.793.093.403.894.755.690.460.530.610.700.780.880.981.071.181.281.391.501.621.741.861.972.102.232.502.763.043.484.255.09Triple strandOffset Pin TransverseANSI Standard <strong>Tsubaki</strong> Minimum <strong>Tsubaki</strong> Average Maximum ApproximateTSUBAKI Number Pin Length Dimensions DimensionsLength Pitch Pin Type Min. Tensile Strength Tensile Strength Tensile Strength Allowable Load MassChain Number of Strands L1+L2 L1 L2L CkN{kf} kN{kf} kN{kf} kN{kf} k/mNote: 1. Maximum allowable load when using a one-pitch offset link (OL) is 65% of the above.2. Number of links per unit = 320 3. Bushed chain.Note: 1. KW rating when using a one-pitch offset link (OL) is 80% of the above.2. Please consult TSUBAKI prior to use of kW ratings in the colored area of the table.0.410.480.550.630.700.790.880.971.061.151.251.361.461.561.681.781.902.012.252.492.743.143.830Drawing Scale 1/1.20.370.430.500.570.640.720.800.880.961.051.141.231.321.421.521.621.721.832.042.262.492.853.480.340.400.450.520.580.650.730.800.880.961.031.121.211.301.391.481.571.671.872.062.272.6000.310.370.420.480.540.600.670.740.800.880.951.031.111.191.281.361.451.531.721.892.092.390.270.310.360.410.460.510.570.620.690.750.810.880.951.011.091.151.231.301.461.6200Multi-strandfactorNumber of chain strandsDouble strandTriple strandQuadruple strandMulti-strand factor Number of chain strands Multi-strand factor1.7 Quintuple strand 3.92.5 Sextuple strand 4.63.3 LubricationmethodABCManual lubrication or drip lubricationOil bath or slinger disc lubricationForced pump lubricationDetailsonPg. 16127

Standard Roller ChainsRS35 Sprocket LdMechanically machined(1B type)DHDPDOSprocket Number1B typePitch CircularNumber ofSprocket OuterNumberDiameterBore Diameter (dTeethDiameter)Hub Approx.of(DP )(DO)MassPilot BoreMaterial TeethDiameterMaximum Diameter (DH ) Length (L ) (k)9 27.85 32 8 11 22 20 0.06 910 30.82 34 8 12 25 20 0.08 1011 33.81 38 8 14 27 20 0.09 1112 36.80 40 8 16.5 31 20 0.12 1213 39.80 44 9.5 18 32 20 0.12 1314 42.80 46 9.5 16.5 30 20 0.12 1415 45.81 51 9.5 19 35 20 0.16 1516 48.82 53 9.5 20 37 20 0.19 1617 51.84 57 9.5 24 41 20 0.22 1718 54.85 60 12.7 24.5 44 20 0.25 1819 57.87 63 12.7 28.5 47 20 0.28 1920 60.89 66 12.7 30 50 20 0.32 2021 63.91 69 12.7 32 53 20 0.36 2122 66.93 72 12.7 32 53 20 0.37 2223 69.95 75 12.7 32 53 20 0.40 2324 72.97 78 12.7 32 53 22 0.43 2425 76.00 81 12.7 32 53 22 0.44 2526 79.02 83 12.7 32 53 22 0.45 2627 82.05 87 12.7 32 53 22 0.46 2728 85.07 90 12.7 32 53 22 0.48 2830 91.12 96 12.7 32 53 22 0.51 3032 97.18 102 12.7 32 53 22 0.54 3234 103.23 109 12.7 32 53 22 0.57 3435 106.26 112 12.7 32 53 22 0.59 3536 109.29 115 12.7 32 53 22 0.61 3638 115.34 121 13 42 63 25 0.82 3840 121.40 127 13 42 63 25 0.854042 127.46 133 13 42 63 25 0.914245 136.55 142 13 42 63 25 0.95 4548 145.64 151 13 42 63 25 1.04850 151.69 157 13 42 63 25 1.15054 163.82 169 13 42 63 25 1.2 5460 182.00 187 13 42 63 25 1.36065 197.15 203 16 45 68 25 1.56570 212.30 218 16 45 68 25 1.7 7075 227.46 233 16 45 68 25 1.8 75Note: 1. Maximum bore diameter is the typical range. Determine bore diameter and keybearing pressure based on general mechanical design.2. Models in shaded areas have hardened teeth.3. Sprockets marked with an * have an outer groove around the hub. Groove outer diameter is 16 for9T, 22 for 10T, 24 for 12T and 28 for 13T.4. Sprockets with 42 or more teeth do not have hardened teeth, but the Strong Series ofsprocket with hardened teeth can be made-to-order.Mechanically machined: machine-structural carbon steelNumber of teethTypeChain numberExample ofgrooved sprocketBefore Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling28

Standard Roller Chains RS Roller ChainRS40Before Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection Handling1 L1LRS40-1 1 18.2 8.25 9.95 18.215.2 {1550} 17.7 {1800} 19.1 {1950} 3.63 {370} 0.64RS40-2 2 32.6 15.45 17.15 33.5 30.4 {3100} 35.3 {3600} 38.2 {3900} 6.18 {630} 1.27RS40-3 3 46.8 22.65 24.15 47.9 45.6 {4650} 53.0 {5400} 57.4 {5850} 9.12 {930} 1.9014.4 RivetingRS40-4 4 61.2 29.9 31.3 62.3 70.6 {7200} 76.5 {7800} 12.0 {1220} 2.53RS40-5 5 75.7 37.1 38.6 76.8 88.3 {9000} 95.6 {9750} 14.1 {1440} 3.16RS40-6 6 90.1 44.3 45.8 91.2 106 {10800} 115 {11700} 16.7 {1700} 3.7991011121314151617181920212223242526283032354045L1L21.510.4TSUBAKIChain NumberSmall SprocketNo. of Teeth10 25 50 100 200 300 400 500 700 900 1000 1200 1400 1600 1800 2100 2400 2700 3000 3500 4000 5000 6000 7000 80000.050.050.060.070.070.080.080.090.100.100.110.120.120.130.130.140.150.150.170.180.190.210.240.283.970.110.120.140.150.170.180.190.210.220.230.250.260.280.290.310.320.330.350.380.410.440.480.560.630.210.230.260.280.310.330.360.390.410.440.460.490.520.540.570.600.620.650.710.760.810.901.041.18Single strand12.70 12.700.390.430.480.530.570.620.670.720.770.820.870.920.961.011.061.111.161.211.321.421.521.671.932.20LA B C0.720.810.900.981.071.161.251.341.431.521.621.711.801.891.992.082.172.272.462.652.843.133.614.101.041.161.291.421.541.671.801.932.062.202.332.462.592.732.863.003.133.273.543.814.094.505.205.911.351.511.671.842.002.172.342.502.672.843.023.193.363.533.713.884.064.234.584.945.295.836.747.6512.01.57.927.951.641.842.042.242.452.652.863.063.273.483.693.904.114.324.534.744.965.175.606.046.477.138.249.352.232.492.763.043.313.593.874.144.424.714.995.275.565.856.136.426.717.007.588.178.769.6511.112.7L1L2C2.793.133.473.814.154.504.855.205.555.906.266.616.977.337.698.058.418.789.5110.211.012.114.015.93.073.443.814.194.574.955.335.716.106.496.887.277.668.068.458.859.259.6510.511.312.113.315.417.5Double strandRS40-1 Maximum Kilowatt Ratings Table (kW Ratings for Single Strand Chain)Lubrication TypeNumberof StrandsNote: 1. Maximum allowable load when using a one-pitch offset link (OL) is 65% of the above.2. Number of links per unit = 240Small Sprocket Max r/min3.624.054.494.935.385.836.286.737.197.648.108.579.039.499.9610.410.911.412.313.314.215.718.120.63.764.405.085.676.186.697.217.738.268.789.319.8410.410.911.412.012.513.114.215.216.318.020.823.63.073.624.164.745.345.976.627.307.998.709.4410.211.011.812.613.414.114.716.017.218.420.323.526.62.573.013.483.964.475.005.546.106.697.287.838.289.249.8610.511.211.912.714.215.717.319.824.228.82.042.392.763.153.553.964.394.845.305.786.276.777.287.838.368.889.4810.111.212.513.715.719.222.81.671.962.262.572.903.253.603.964.344.735.135.545.966.396.837.287.768.219.1810.111.212.815.718.7L1L2C C1.401.641.902.162.432.723.013.323.643.964.304.645.005.365.736.106.496.897.688.519.4010.713.115.71.191.401.601.842.082.322.572.843.113.393.673.964.274.574.895.225.545.886.577.288.069.1811.213.40.951.111.281.461.651.842.042.252.472.692.923.153.393.633.884.134.394.665.225.786.377.288.8810.6Triple strand0.780.911.051.191.351.511.671.842.022.212.392.572.772.973.183.393.603.824.274.735.225.967.288.73Drawing Scale 1/1.6Offset Pin TransverseANSI Standard <strong>Tsubaki</strong> Minimum <strong>Tsubaki</strong> Average Maximum ApproximatePin Length Dimensions DimensionsLength Pitch Pin Type Min. Tensile Strength Tensile Strength Tensile Strength Allowable Load MassL1+L2 L1 L2L CkN{kf} kN{kf} kN{kf} kN{kf} k/m0.560.650.750.850.961.081.191.321.451.571.711.841.982.132.282.422.572.733.053.393.734.275.2200.430.490.570.650.730.820.911.001.101.191.301.401.511.621.731.841.962.062.322.570000.340.400.460.510.580.650.720.800.870.951.031.111.191.281.371.4600000.280.320.370.430.480.530.590.650.720000000Note: 1. KW rating when using a one-pitch offset link (OL) is 80% of the above.2. Please consult TSUBAKI prior to use of kW ratings in the colored area of the table.Multi-strandfactorNumber of chain strandsDouble strandTriple strandQuadruple strandMulti-strand factor Number of chain strands Multi-strand factor1.7 Quintuple strand 3.92.5 Sextuple strand 4.63.3 LubricationmethodABCManual lubrication or drip lubricationOil bath or slinger disc lubricationForced pump lubricationDetailsonPg. 16129

Standard Roller ChainsRS40 Sprocket LdDHDPDOMechanically machined1B typeLWelded construction1C typedDHDPDOLdDHDPDO20 81.18 88 12.7 45.5 67 25 0.76 12.7 46 67 40 1.3 16 0.2621 85.21 92 12.7 45.5 71 25 0.85 12.7 47 71 40 1.4 16 0.2922 89.24 96 12.7 50 75 25 0.95 12.7 50 75 40 1.6 16 0.3223 93.27 98 12.7 50 77 25 1.0 12.7 50 77 40 1.716 0.35222324 97.30 104 12.7 42 63 25 0.84 12.7 55 83 40 1.9 16 0.38 2425 101.33 108 12.7 42 63 25 0.88 12.7 59 87 40 2.1 16 0.41 2526 105.36 112 12.7 42 63 25 0.92 12.7 62 91 40 2.316 0.45 2627 109.40 116 12.7 42 63 25 0.9612.7 65 95 40 2.416 0.52 2728 113.43 120 12.7 42 63 25 1.0 16 48 73 45 1.8 12.7 67 99 40 2.616 0.56 2830 121.50 128 12.7 42 63 25 1.1 16 48 73 45 1.9 12.7 73 106 40 3.016 0.60 3032 129.57 137 16 45 68 28 1.3 16 48 73 45 2.0 12.7 55 115 50 4.316 0.68 3234 137.64 145 16 45 68 28 1.3 16 48 73 45 2.0 12.7 55 124 50 5.016 0.77 3435 141.68 149 16 45 68 28 1.4 16 48 73 45 2.1 16 63 93 50 3.9 16 63 93 70 4.9 16 0.82 3536 145.72 153 16 45 68 28 1.4 16 48 73 45 2.2 16 63 93 50 4.0 16 63 93 70 5.1 16 0.87 3638 153.79 161 16 45 68 28 1.5 16 48 73 45 2.3 16 63 93 50 4.3 16 63 93 70 5.4 16 0.96 3840 161.87 169 16 45 68 28 1.6 16 48 73 45 2.4 16 63 93 50 4.7 16 63 93 70 5.7 16 1.1 4042 169.94 177 18 48 73 32 2.0 18 48 73 45 2.4 16 63 93 50 5.0 16 63 93 70 6.0 18 1.2 4245 182.06 189 18 48 73 32 2.1 18 48 73 45 2.6 18 63 93 50 5.5 18 63 93 70 6.6 18 1.4 4548 194.18 201 18 48 73 32 2.3 18 48 73 45 2.8 18 63 93 50 6.1 18 63 93 70 7.2 18 1.5 4850 202.26 209 18 48 73 32 2.5 18 48 73 45 2.9 18 63 93 50 6.7 18 63 93 70 7.8 18 1.7 5054 218.42 226 18 48 73 32 2.8 18 48 73 45 3.3 18 63 93 50 7.4 18 63 93 70 8.4 18 2.0 5460 242.66 250 18 48 73 32 3.2 18 48 73 45 3.8 18 63 93 50 8.9 18 63 93 70 9.9 18 2.4 6065 262.87 270 23 55 83 32 3.9 23 55 83 50 4.723 2.8 6570 283.07 290 23 55 83 32 4.3 23 55 83 50 5.2 23 3.2 7075 303.28 311 23 55 83 32 4.8 23 55 83 50 5.723 3.7 75LMechanically machined Welded construction2B typedDHDPDOLWelded construction2C typedDHDPDO dDPDO1B type1C type2B type2C type1A typeBore Diameter(d ) Hub Approx. Bore Diameter(d ) Hub Approx. Bore DiameterBore DiameterApprox.(d ) Hub Approx.(d ) Hub Approx.PilotDiameter LengthMassPilotDiameter LengthMassPilotDiameter LengthMassPilotDiameter LengthMassMassBore MaximumDiameter (DH ) (L ) (k)Bore MaximumDiameter (DH ) (L ) (k)Bore Maximum Bore MaximumDiameter (DH ) (L ) (k)Diameter (DH ) (L ) (k)(k)9 37.13 42 9.5 15 28 22 0.11 910 41.10 46 9.5 16.5 32 22 0.14 1011 45.08 51 9.5 20 37 22 0.19 1112 49.07 53 9.5 22 40 22 0.22 9.5 18 32 35 0.3416 0.10 1213 53.07 58 12.7 20 37 22 0.23 12.7 20 37 35 0.3916 0.11 1314 57.07 63 12.7 24 42 22 0.28 12.7 24 42 35 0.47 16 0.13 1415 61.08 67 12.7 28.5 46 22 0.34 12.7 29 46 35 0.56 16 0.14 1516 65.10 71 12.7 30 50 22 0.40 12.7 30 50 35 0.65 16 0.16 1617 69.12 75 12.7 32 54 22 0.46 12.7 32 54 35 0.75 16 0.19 1718 73.14 78 12.7 35 57 22 0.51 12.7 35 57 35 0.85 16 0.21 1819 77.16 83 12.7 39.5 62 22 0.59 12.7 40 62 35 0.98 16 0.24 19Number ofTeeth(DP )Pitch CircularDiameterSprocket Outer Diameter(DO)MaterialMechanically machined: machine-structural carbon steelNote: 1. Maximum bore diameter is the typical range. Determine bore diameter and key bearing pressure based on general mechanical design.2. Models in shaded areas have hardened teeth.3. The outer diameters above are given for the 1B type. Diameters vary slightly for all other types.4. 1B-type sprockets marked with an * have an outer groove around the hub. Groove outer diameter is 21 for 9T, 25 for 10T, 30 for 11T and 32 for 12T.5. For single-strand sprockets without hardened teeth, the Strong Series of sprocket with hardened teeth can be made-to-order.MaterialWelded specification: machine-structuralcarbon steel (teeth) and structural rolled steel (hub)MaterialPrecut specification: machine-structural carbon steelWelded specification: machine-structuralcarbon steel (teeth) and structural rolled steel (hub)MaterialWelded specification: structural rolled steelPilot BoreDiameterdMaterialMachine-structural carbon steelNumber ofTeeth2021Before Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingSprocket NumberNumber of teethTypeChain number30

Standard Roller Chains RS Roller ChainRS50Before Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingL1L1RS50-1 1 22.2 10.3 11.9 22.624 {2447} 28.4 {2900} 31.4 {3200} 6.37{650} 1.04RS50-2 2 40.5 19.35 21.15 41.8 48 {4895} 56.9 {5800} 62.8 {6400} 10.7{1100} 2.07RS50-3 3 58.6 28.4 30.2 59.9 72 {7342} 85.3 {8700} 94.1 {9600} 16.0{1630} 3.0918.1 RivetingRS50-4 4 76.7 37.45 39.25 78.1 114 {11600} 126 {12800} 21.1{2150} 4.11RS50-5 5 94.8 46.5 48.3 96.2 142 {14500} 157 {16000} 24.9{2540} 5.14RS50-6 6 113.0 55.6 57.4 114.4 171 {17400} 188 {19200} 29.3{2990} 6.1691011121314151617181920212223242526283032354045L1L22.013.0TSUBAKIChain NumberSmall SprocketNo. of Teeth5.0910 25 50 100 200 300 400 500 700 900 1000 1200 1400 1600 1800 2100 2400 2700 3000 3500 4000 4500 5000 5500 60000.100.110.120.140.150.160.170.190.200.210.230.240.250.260.280.290.300.320.340.370.400.440.500.570.230.260.280.310.340.370.400.430.460.490.510.540.570.600.630.660.690.720.780.840.900.991.151.300.430.480.530.580.640.690.740.800.850.910.961.011.071.121.181.241.291.351.461.571.691.862.142.44Single strand15.875 15.8750.800.900.991.091.191.291.391.491.591.691.791.892.002.102.202.302.412.512.722.933.143.464.004.54LA B C1.491.671.852.032.222.402.592.782.963.153.343.533.723.914.114.304.494.695.085.475.876.467.478.482.152.412.672.933.193.463.734.004.274.544.815.095.365.645.926.196.476.757.327.888.459.3110.812.215.02.783.123.463.804.144.484.835.185.535.886.246.596.957.317.668.038.398.759.4810.210.912.113.915.82.010.169.533.403.814.224.645.065.485.916.336.767.197.628.068.498.939.379.8110.310.711.612.513.414.717.019.34.605.165.726.286.857.427.998.579.159.7310.310.911.512.112.713.313.914.515.716.918.120.023.126.2L1L2C5.776.477.177.888.599.3010.010.711.512.212.913.714.415.215.916.717.418.219.721.222.725.028.932.86.357.117.888.669.4410.211.011.812.613.414.215.015.816.717.518.319.120.021.623.325.027.531.836.1Double strandRS50-1 Maximum Kilowatt Ratings Table (kW Ratings for Single Strand Chain)Lubrication TypeNumberof StrandsNote: 1. Maximum allowable load when using a one-pitch offset link (OL) is 65% of the above.2. Number of links per unit = 192Small Sprocket Max r/min5.666.637.658.729.8311.012.213.414.715.816.817.718.719.620.621.622.523.525.527.429.432.437.542.54.495.266.076.917.768.739.7210.711.712.713.814.916.017.218.419.620.822.124.727.430.134.542.148.93.674.304.965.666.387.137.918.739.5510.411.312.213.114.015.016.017.018.120.122.424.828.434.641.13.083.604.164.745.345.986.637.307.988.739.4810.211.011.812.613.414.315.116.918.720.723.628.934.42.442.873.303.764.254.745.265.796.346.917.468.068.739.3310.010.711.312.013.414.816.418.722.927.32.002.342.703.083.473.884.304.745.195.666.136.637.147.618.218.739.259.8511.012.213.415.418.722.4L1L2C C1.681.962.272.582.913.253.603.974.354.745.145.555.986.416.857.307.768.219.1810.211.312.815.718.71.431.681.932.202.482.783.083.393.724.044.394.745.105.475.856.236.637.037.838.739.6211.013.416.01.131.331.541.751.972.202.442.692.953.213.483.764.044.344.644.955.265.576.236.917.618.7310.70Triple strand0.931.091.251.431.611.812.002.202.412.632.853.083.313.553.804.044.304.575.105.666.237.1300.780.911.051.201.351.511.681.842.022.202.392.582.782.983.193.393.603.834.28000Drawing Scale 1/2Offset Pin TransverseANSI Standard <strong>Tsubaki</strong> Minimum <strong>Tsubaki</strong> Average Maximum ApproximatePin Length Dimensions DimensionsLength Pitch Pin Type Min. Tensile Strength Tensile Strength Tensile Strength Allowable Load MassL1+L2 L1 L2L CkN{kf} kN{kf} kN{kf} kN{kf} k/m0.660.780.901.021.161.291.431.571.721.882.042.202.372.54000000.570.670.780.891.001.121.241.371.50000000.510.590.690.7800000Note: 1. KW rating when using a one-pitch offset link (OL) is 80% of the above.2. Please consult TSUBAKI prior to use of kW ratings in the colored area of the table.Multi-strandfactorNumber of chain strandsDouble strandTriple strandQuadruple strandMulti-strand factor Number of chain strands Multi-strand factor1.7 Quintuple strand 3.92.5 Sextuple strand 4.63.3 LubricationmethodABCManual lubrication or drip lubricationOil bath or slinger disc lubricationForced pump lubricationDetailsonPg. 16131

Standard Roller ChainsRS50 Sprocket LdDHDPDOLMechanically machined Welded construction1B type dDHDPDOLWelded construction1C typeMechanically machined: machine-structural carbon steeldDHDPDOLdDHDPDOMechanically machined Welded construction2B type25 126.66 135 15.9 47.5 73 28 1.5 15.9 75 109 50 4.0 18 0.78 2526 131.70 140 18 48 73 28 1.5 18 63 93 50 3.7 18 63 93 75 5.3 18 0.84 2627 136.74 145 18 48 73 28 1.5 18 63 93 50 3.9 18 63 93 75 5.5 18 0.91 2728 141.79 150 18 48 73 28 1.6 18 55 83 50 2.7 18 63 93 50 4.1 18 66 98 80 5.7 18 0.98 2830 151.87 161 18 48 73 28 1.8 18 55 83 50 2.9 18 63 93 50 4.6 18 66 98 80 6.1 18 1.1 3032 161.96 171 18 48 73 28 1.9 18 55 83 50 3.1 18 63 93 50 5.1 18 66 98 80 6.6 18 1.3 3234 172.05 181 18 48 73 28 2.1 18 55 83 50 3.2 18 63 93 50 5.6 18 66 98 80 7.2 18 1.4 3435 177.10 186 18 48 73 28 2.2 18 55 83 50 3.3 18 63 93 50 5.9 18 66 98 80 7.4 18 1.5 3536 182.15 191 23 55 83 35 2.7 23 55 83 50 3.4 18 63 93 50 6.2 18 66 98 80 7.7 23 1.6 3638 192.24 201 23 55 83 35 2.9 23 55 83 50 3.6 18 63 93 50 6.8 18 66 98 80 8.3 23 1.8 3840 202.33 211 23 55 83 35 3.1 23 55 83 50 3.8 23 66 98 56 7.8 23 66 98 80 9.1 23 2.0 4042 212.43 221 23 55 83 35 3.3 23 55 83 50 4.0 23 66 98 56 8.5 23 66 98 80 9.8 23 2.2 4245 227.58 237 23 55 83 35 3.6 23 55 83 50 4.4 23 66 98 56 9.5 23 66 98 80 10.9 23 2.5 4548 242.73 252 23 55 83 35 4.0 23 55 83 50 4.8 23 66 98 56 10.7 23 66 98 80 12.0 23 2.9 4850 252.82 262 23 55 83 35 4.3 23 55 83 50 5.0 23 66 98 56 11.5 23 66 98 80 12.8 23 3.1 5054 273.03 282 23 55 83 35 4.8 23 55 83 50 5.6 23 66 98 63 13.5 23 66 98 80 14.5 23 3.6 5460 303.33 312 23 55 83 35 5.6 23 63 93 60 7.5 23 66 98 63 16.3 23 66 98 80 17.3 23 4.6 6065 328.58 338 23 63 93 40 6.9 23 63 93 60 8.323 5.3 6570 353.84 363 23 63 93 40 7.7 23 63 93 60 9.3 23 6.1 7075 379.10 388 23 63 93 40 8.6 23 63 93 60 10.323 7.1 75Note 7LdDHDPDOLWelded construction2C type1B type1C type2B type2C type1A typeBore Diameter(d ) Hub Approx. Bore Diameter(d ) Hub Approx. Bore DiameterBore DiameterApprox.(d ) Hub Approx.(d ) Hub Approx.PilotDiameter LengthMassPilotDiameter LengthMassPilotDiameter LengthMassPilotDiameter LengthMassMassBore MaximumDiameter (DH ) (L ) (k)Bore MaximumDiameter (DH ) (L ) (k)Bore Maximum Bore MaximumDiameter (DH ) (L ) (k)Diameter (DH ) (L ) (k)(k)9 46.42 53 9.5 19 34 25 0.20 910 51.37 58 9.5 22 40 25 0.27 1011 56.35 63 12.7 25 46 25 0.33 1112 61.34 68 12.7 32 51 25 0.41 12.7 24 42 40 0.60 18 0.18 1213 66.33 73 12.7 32 51 25 0.46 12.7 28.5 47 40 0.73 18 0.22 1314 71.34 79 12.7 32 52 25 0.52 12.7 32 52 40 0.87 18 0.24 1415 76.35 84 12.7 35 57 25 0.62 12.7 35 57 40 1.0 18 0.27 1516 81.37 89 12.7 40 62 25 0.72 12.7 40 62 45 1.3 18 0.31 1617 86.39 94 12.7 45.5 67 25 0.83 12.7 45.5 67 45 1.5 18 0.35 1718 91.42 100 12.7 47.5 72 28 1.0 12.7 47.5 72 45 1.7 18 0.40 1819 96.45 105 15.9 47.5 73 28 1.1 15.9 52 79 45 2.0 18 0.44 1920 101.48 110 15.9 47.5 73 28 1.2 15.9 55 82 45 2.2 18 0.49 2021 106.51 115 15.9 47.5 73 28 1.2 15.9 60 89 45 2.5 18 0.54 2122 111.55 120 15.9 47.5 73 28 1.3 15.9 63 92 50 2.9 18 0.60 2223 116.59 125 15.9 47.5 73 28 1.3 15.9 67 99 50 3.318 0.66 2324 121.62 130 15.9 47.5 73 28 1.4 15.9 70 102 50 3.6 18 0.71 24Number ofTeeth(DP )Pitch CircularDiameterSprocket Outer Diameter(DO)MaterialNote: 1. Maximum bore diameter is the typical range. Determine bore diameter and key bearing pressure based on general mechanical design.2. Models in shaded areas have hardened teeth.3. The outer diameters above are given for the 1B type. Diameters vary slightly for all other types.4. 1B-type sprockets marked with an * have an outer groove around the hub. Groove outer diameter is 27 for 9T, 37 for 11T, 42 for 12T and 47 for 13T.5. For single-strand sprockets without hardened teeth, the Strong Series of sprocket with hardened teeth can be made-to-order.6. Welded specifications, machine-structural carbon steel (teeth) and structural rolled steel (hub).MaterialWelded construction: machine-structuralcarbon steel (teeth) and structural rolled steel (hub)MaterialMechanically machined: machine-structural carbon steelWelded construction: machine-structuralcarbon steel (teeth) and structural rolled steel (hub)dDHMaterialWelded construction: machine-structuralcarbon steel (teeth) and structural rolled steel (hub)DPDOPilot BoreDiameterddDP1A typeMaterialMachine-structural carbon steelDONumber ofTeethBefore Use For Safe Use Standard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingSprocket NumberNumber of teethTypeChain number32

Standard Roller Chains RS Roller ChainRS60Before Use For Safe UseStandard Roller Chains Lube-Free Roller Chains Heavy Duty Roller Chains Corrosion Resistant Roller Chains Specialty Roller Chains Accessories Selection HandlingL1L1LRS60-1 1 27.6 12.85 14.75 28.2L1L2CRS60-3 3 73.8 35.65 38.15 75.5 102.6{10462} 121 {12300} 132 {13500} 22.1 {2250} 4.5422.8RS60-4 4 96.6 47.05 49.55 98.3 Riveting 161 {16400} 177 {18000} 29.1 {2970} 6.04RS60-5 5 119.5 58.5 61.0 121.2 201 {20500} 221 {22500} 34.4 {3510} 7.54RS60-6 6 142.4 69.9 72.5 144.0 241 {24600} 265 {27000} 40.6 {4140} 9.05L1L2CC34.2 {3487} 40.2 {4100} 44.1 {4500} 8.83 {900} 1.53RS60-2 2 50.5 24.25 26.25 52.6 68.4 {6975} 80.4 {8200} 88.3 {9000} 15.0 {1530} 3.0491011121314151617181920212223242526283032354045L1L22.415.6TSUBAKIChain NumberSmall SprocketNo. of Teeth10 25 50 100 150 200 300 400 500 600 700 800 900 1000 1100 1200 1400 1600 1800 2000 2500 3000 3500 4000 45000.180.200.220.240.260.290.310.330.350.380.400.420.440.470.490.510.540.560.610.650.700.770.891.015.960.410.450.500.550.600.650.700.750.810.860.910.961.011.061.121.171.221.281.381.491.601.762.032.310.760.850.941.031.131.221.311.411.501.601.701.791.891.992.082.182.282.382.582.782.983.283.794.30Single strand19.05 19.05A B C1.411.581.751.932.102.282.452.632.812.983.163.343.533.713.894.074.264.444.815.185.566.127.078.032.032.282.532.773.033.283.533.794.044.304.564.825.085.345.605.876.136.406.937.468.008.8210.211.62.632.953.273.593.924.254.574.905.245.575.906.246.586.927.267.607.948.298.989.6710.411.413.215.03.794.254.715.185.656.126.597.067.548.028.518.999.489.9610.510.911.411.912.913.914.916.519.021.62.411.9118.112.704.925.516.116.717.317.928.549.159.7710.411.011.612.312.913.514.214.815.516.718.019.321.324.628.06.016.737.468.208.949.6910.411.211.912.713.514.215.015.816.617.318.118.920.522.123.726.130.134.27.087.948.809.6610.511.412.313.214.115.015.916.817.718.619.520.421.322.324.126.027.930.735.540.38.149.1210.111.112.113.114.115.116.217.218.219.320.321.422.423.524.525.627.729.932.035.340.746.3Double strandRS60-1 Maximum Kilowatt Ratings Table (kW Ratings for Single Strand Chain)Lubrication TypeNumberof StrandsSmall Sprocket Max r/min9.1710.311.412.513.614.815.917.118.219.420.621.722.924.125.326.527.728.931.333.736.139.845.952.210.111.412.713.915.216.417.719.020.321.622.924.225.526.828.129.430.732.134.837.440.144.251.158.08.6210.111.613.315.016.718.520.422.323.725.126.628.029.430.932.333.835.338.241.244.148.656.263.87.458.7910.111.613.014.516.117.719.421.122.924.726.628.530.532.534.636.741.044.948.153.061.269.56.547.688.8810.111.312.714.015.617.118.620.221.823.525.226.928.530.332.236.039.943.950.361.473.35.196.087.027.989.0310.111.212.313.514.716.017.218.519.821.222.624.025.528.531.634.839.849.058.54.254.985.746.547.388.289.1810.111.012.013.114.115.116.317.418.519.720.923.425.928.532.639.947.53.574.174.815.486.196.917.688.439.2510.110.911.812.713.614.515.516.517.519.521.723.927.333.439.8Triple strandOffset Pin TransverseANSI Standard <strong>Tsubaki</strong> Minimum <strong>Tsubaki</strong> Average Maximum ApproximatePin Length Dimensions DimensionsLength Pitch Pin Type Min. Tensile Strength Tensile Strength Tensile Strength Allowable Load MassL1+L2 L1 L2L C kN{kf} kN{kf} kN{kf} kN{kf} k/mRivetingCotter pinNote: 1. Maximum allowable load when using a one-pitch offset link (OL) is 65% of the above.2. Number of links per unit = 1603.043.564.114.695.285.906.547.217.918.589.3310.110.811.612.513.314.114.916.718.520.423.428.534.02.182.552.943.353.784.224.695.165.656.166.687.217.768.288.889.4810.110.711.913.314.616.720.424.3Drawing Scale 1/2.41.661.942.242.552.873.223.563.924.304.695.085.485.906.336.777.217.688.139.1010.111.112.7001.311.541.782.022.282.552.833.113.413.724.034.354.695.025.365.726.086.4500001.071.261.451.661.872.092.312.552.793.043.3000000000.901.051.221.390000000Note: 1. KW rating when using a one-pitch offset link (OL) is 80% of the above.2. Please consult TSUBAKI prior to use of kW ratings in the colored area of the table.Multi-strandfactorNumber of chain strandsDouble strandTriple strandQuadruple strandMulti-strand factor Number of chain strands Multi-strand factor1.7 Quintuple strand 3.92.5 Sextuple strand 4.63.3 LubricationmethodABCManual lubrication or drip lubricationOil bath or slinger disc lubricationForced pump lubricationDetailsonPg. 16133