Epoxy Bonding Polyester Gelcoats Brochure - English - Scott Bader

Epoxy Bonding Polyester Gelcoats Brochure - English - Scott Bader

Epoxy Bonding Polyester Gelcoats Brochure - English - Scott Bader

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

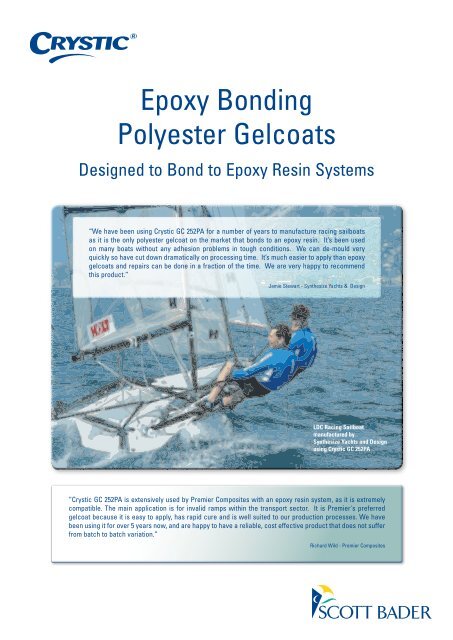

<strong>Epoxy</strong> <strong>Bonding</strong><strong>Polyester</strong> <strong>Gelcoats</strong>Designed to Bond to <strong>Epoxy</strong> Resin Systems“We have been using Crystic GC 252PA for a number of years to manufacture racing sailboatsas it is the only polyester gelcoat on the market that bonds to an epoxy resin. It’s been usedon many boats without any adhesion problems in tough conditions. We can de-mould veryquickly so have cut down dramatically on processing time. It’s much easier to apply than epoxygelcoats and repairs can be done in a fraction of the time. We are very happy to recommendthis product.”Jamie Stewart - Synthesize Yachts & DesignLDC Racing Sailboatmanufactured bySynthesize Yachts and Designusing Crystic GC 252PA“Crystic GC 252PA is extensively used by Premier Composites with an epoxy resin system, as it is extremelycompatible. The main application is for invalid ramps within the transport sector. It is Premier's preferredgelcoat because it is easy to apply, has rapid cure and is well suited to our production processes. We havebeen using it for over 5 years now, and are happy to have a reliable, cost effective product that does not sufferfrom batch to batch variation.”Richard Wild - Premier Composites

Operating PerformanceThe higher Tg demonstrated by Crystic GC 252PA means it canwithstand higher operating temperatures than the epoxy gelcoat.Note 1: GC 252PA curing schedule of 16 hours at 40 o CNote 2: <strong>Epoxy</strong> Gelcoat curing schedule of 28 days at 21 o CMechanical PerformanceTemperature oC100806040Comparison of Tg measured byPeak Tan from DMTA<strong>Epoxy</strong> GelcoatCrystic GC 252PAWhen Crystic <strong>Epoxy</strong> <strong>Bonding</strong> <strong>Gelcoats</strong> are used for the production of atypical laminate, the finished structure retains the excellent mechanicalproperties associated with epoxy systems. Values are similar acrossthe Crystic <strong>Epoxy</strong> <strong>Bonding</strong> Gelcoat range.200GelcoatBack UpDelay TimeTensile Strain to FailureFirst GCCrack %Strain To LaminateFailure %FlexuralStrength (MPa)Flexural PropertiesFlexural Modulus(MPa)GC Strain ToFailure %Crystic GC 252PA 2 hours 1.6 6.5 152 6060 2.7Crystic GC 252PA 24 hours 2.2 6.7 159 6365 2.6<strong>Epoxy</strong> 6 hours 2.0 7.1 109 5340 2.3Adhesion TestingRigorous testing for adhesion to a number of different epoxy backingsystems has been carried out. The results match a complete epoxysystem. Similar results are seen across the Crystic <strong>Epoxy</strong> <strong>Bonding</strong>Gelcoat range.GelcoatBack Up DelayTimeZ-directionStrength (MPa)Crystic GC 252PA 2 hours 19.7Crystic GC 252PA 24 hours 19.4<strong>Epoxy</strong> 6 hours 19.9Note 1: Values for Crystic GC 252PA used as an example. Other gelcoats in thisrange show similar properties.Note 2: Results based on laminates produced with liquid epoxy backing systemcured for 16 hours at 50°C.Laminate FailureResult of GC 252PA adhesion test showing that failure is internal withinthe laminateIf 251PA, 252PA, 253PA or 255PA is used as a gelcoat with polyester laminating systems, then adhesion failure is likely to occur.Similarly, if the product is “double-gelled”, then this is also likely to lead to adhesion failure. For these reasons, neither of theseprocedures is recommended.It is recommended that customers test the gelcoat before use under their own conditions of application to ensure the requiredsurface finish and adhesion is achieved.Z-Direction TestingThe Z-Direction test completed on Crystic GC 252PAshowed laminate failure, see image above. This proves that CrysticGC 252PA bonds effectively to epoxy substrates as the gelcoatadhesion to the epoxy laminate did not fail. Same laminate failuremode is achieved across the Crystic <strong>Epoxy</strong> <strong>Bonding</strong> Gelcoat range.GelcoatGelcoatGlassfibre LaminateGlassfibre LaminateLaminate FailureLaminate Failure

<strong>Scott</strong> <strong>Bader</strong>Composites EuropeHEAD OFFICE<strong>Scott</strong> <strong>Bader</strong> Company LimitedWollastonEnglandTel: +44 1933 663100Fax: +44 1933 666139email: composites@scottbader.com<strong>Scott</strong> <strong>Bader</strong> IrelandDublinIrelandTel: +353 1801 5660Fax: +353 1801 5657email: composites@scottbader.ie<strong>Scott</strong> <strong>Bader</strong>Group Companies<strong>Scott</strong> <strong>Bader</strong> IncStow, OHUSATel: +1 330 920 4410Fax: +1 330 920 4415email: info@scottbaderinc.com<strong>Scott</strong> <strong>Bader</strong> SAAmiensFranceTel: +33 3 22 66 27 66Fax: +33 3 22 66 27 80email: composites@scottbader.fr<strong>Scott</strong> <strong>Bader</strong> Scandinavia ABFalkenbergSwedenTel: +46 346 10100Fax: +46 346 59226email: composites@scottbader.se<strong>Scott</strong> <strong>Bader</strong> (Pty) LimitedHammarsdaleRepublic of South AfricaTel: +27 31 736 8500Fax: +27 31 736 8511email: composites@scottbader.co.za<strong>Scott</strong> <strong>Bader</strong> IbericaBarcelonaSpainTel: +34 93 553 1162Fax: +34 93 553 1163email: composites@scottbader.es<strong>Scott</strong> <strong>Bader</strong> Eastern EuropeLiberecCzech RepublicTel: +420 48 5228 344/5111 255Fax: +420 48 5228 345/5111 254email: composites@scottbader.cz<strong>Scott</strong> <strong>Bader</strong> Middle East LimitedJebel AliDubaiTel: +971 488 35025Fax: +971 488 35319email: info@scottbader.ae<strong>Scott</strong> <strong>Bader</strong> S.A.Zur Drehscheibe 5D - 92637 WeidenGermanyTel: +49 961 401 84474Fax: +49 961 401 84476email: composites@scottbader.de<strong>Scott</strong> <strong>Bader</strong> d.o.o.10 000 ZagrebZitnjak BBCroatiaTel: +385 1 240 6440Fax: +385 1 240 4573email: info@scottbader.hr<strong>Scott</strong> <strong>Bader</strong> Asia PacificShanghai 200042ChinaTel: +86 (21) 52987778 / +86 (21) 52988887Fax: +86 (21) 52988889email: info@scottbader.cnLeading composites innovation for over 60 yearsVisit us at:EPOXY/BONDGEL/2/12 ISSUE 1