Land Transportation T - Pneumatic Tools Online

Land Transportation T - Pneumatic Tools Online

Land Transportation T - Pneumatic Tools Online

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Land</strong><strong>Transportation</strong><strong>Tools</strong>The Ultimate Power <strong>Tools</strong>

The UltimatePower <strong>Tools</strong>www.cp.com

Table of ContentsCP INTRODUCTIONYour Global Supplier, Your Local Support.................................................................................................................2-3ASSEMBLY TOOLSAssembly <strong>Tools</strong> Selection Guide...............................................................................................................................4-5BATTERY TOOLSSSB Battery Screwdriver ..........................................................................................................................................6-7PLUG & TIGHTENCVIP - Plug & Tighten...............................................................................................................................................8-9Data Transfer Unit ......................................................................................................................................................10CVIP - Angle Head & In-line <strong>Tools</strong> .............................................................................................................................11Accessories ................................................................................................................................................................11CURRENT CONTROL PRODUCTSCVIC Range - Mastering Assembly ......................................................................................................................12-13Torque Range - CVIC <strong>Tools</strong> .......................................................................................................................................14CVIC <strong>Tools</strong>.......................................................................................................................................................... 15-21CVIC Accessories ......................................................................................................................................................22CVIP/C2000 Software ................................................................................................................................................23Technical Features - CVIC Range .............................................................................................................................24Controllers - CVIC Range ..........................................................................................................................................25CS TRANSDUCER CONTROL PRODUCTSCS Range / Electric Transducerized <strong>Tools</strong> ...................................................................................................................26-27SD25 Electric Screwdrivers and CS2700 Controllers ...................................................................................................28-33Torque Range - SD25 Screwdrivers ..........................................................................................................................29SD 25 Electric Screwdrivers - CS ..............................................................................................................................29SD25 Accessories - CS .......................................................................................................................................29-30Visual Supervisor Software - for all CS Products ......................................................................................................31Technical Features - CS2700 Range - CS.................................................................................................................32CS2700 Controllers and Cables ................................................................................................................................3346/66 Series Electric Nutunners and CS4746/4700 Controllers ...................................................................................34-46Torque Range - 46/66 Series Nutrunners ..................................................................................................................3446/66 Series Nutrunners .......................................................................................................................................35-3946/66 Series Accessories......................................................................................................................................40-43Technical Features - CS4746/CS4700 Range - CS...................................................................................................44CS4746 and CS4700 Controllers - CS ......................................................................................................................45CS4746 and CS4700 Controllers - Power Cords and Cables...................................................................................46177/277 Series Electric Nutrunners and CS7000 Controllers.......................................................................................47-49Torque Range - 177/277 Series Nutrunners ..............................................................................................................47177/277 Series Electric Nutrunners - CS ..................................................................................................................47Technical Features - CS7000 Range .........................................................................................................................48CS7000 Controllers ..................................................................................................................................................49CS Networks .........................................................................................................................................................50-51CVI TRANSDUCER CONTROL PRODUCTSCVI II Range/Electric Transducerized <strong>Tools</strong>..................................................................................................................52-53Torque Range - ER and EM <strong>Tools</strong> - CVI II.................................................................................................................54Electric Nutrunners - CVI II Range .......................................................................................................................55-63CVI II Accessories.................................................................................................................................................64-65CVI PC2000 Software ................................................................................................................................................66CVI-net Software........................................................................................................................................................67Technical Features - CVI II Range.............................................................................................................................68Controllers - CVI II ....................................................................................................................................................69CVI II Networks .....................................................................................................................................................70-71TORQUE MEASUREMENT SYSTEMSQuality Assurance .....................................................................................................................................................72Torque and Angle Measuring Units.......................................................................................................................73-75Rotary Transducers - 2500 Series .............................................................................................................................76Digital Rotary Transducers - DRT Series...................................................................................................................77Electronic Hand Torque Wrenches - 1500 Series......................................................................................................78Stationary Transducers - ST4000 Series ...................................................................................................................79Measurement Accessories and Cables......................................................................................................................79CUSTOMIZED SOLUTIONSCustomized Solutions and Services .....................................................................................................................80-81Tubenut and Crowfoot <strong>Tools</strong> ......................................................................................................................................82Other Special <strong>Tools</strong> ....................................................................................................................................................83Bench Stands and Articulated Arms .....................................................................................................................84-85TIGHTENING SERVICESComplete Assembly Solutions ..............................................................................................................................86-87Exceptional Service....................................................................................................................................................88PAGE1

Your global supplier,your local supportAMERICASARGENTINABRAZILCANADACOLOMBIAECUADORMEXICOURUGUAYUSAVENEZUELACP Owned Sales CompaniesDistributorsProduction SitesHemel Hempstead UKNantes FRANCENovi, MI USARock Hill, SC USAQianshao, CHINAMORE than 1000 employees2

ASIA, PACIFICAUSTRALIACHINAHONG KONGINDIAINDONESIAJAPANKOREAMALAYSIANEW ZEALANDPAKISTANPHILIPPINESSINGAPOREEUROPE, MIDDLE EAST, AFRICA, RUSSIAAUSTRIA GERMANY NORWAY TURKEYBAHRAIN GREECE OMAN UKBENELUX IBERIA QATAR UNITED ARAB EMIRATESCYPRUS ICELAND ROMANIADENMARK IRAN RUSSIAE,EUROPE ISRAEL SAUDI ARABIAEGYPT ITALY SOUTH AFRICAEIRE JORDAN SWEDENFINLAND KUWAIT SWITZERLANDFRANCE MALTA SYRIA3

Assembly <strong>Tools</strong> Selection GuideController (if used)CVIP - Plug &TightenSSB Series EAP/EDPCompatible <strong>Tools</strong> Battery SeriesScrewdrivers NutrunnersTorque RangeCVIC SeriesEC/MC Series CurrentControl <strong>Tools</strong>CS2700 SeriesSD25 Series ElectricScrewdrivers1.5 - 12 Nm 3 - 65 Nm 0.2 - 1,350 Nm 1.1 - 5.6 Nm1.1 - 8.8 ft-lb 2.2 - 47.9 ft-lb 0.1 - 995 ft-lb 0.8 - 4.1 ft-lbPages 6-7 8-11 12-25 28-33Product AttributesNo controller required ✔ ✔In-line push to start tools ✔ ✔In-line lever start tools ✔ ✔ ✔Pistol grip (no cable)✔Pistol grip (top cable)✔Pistol grip (standard cable) ✔ ✔Angle wrench ✔ ✔ ✔Fixtured spindles ✔ ✔90 degree Fixtured spindles ✔Standard Crowfoot rangeStandard tubenut rangeStandard offset outputHall Effect <strong>Tools</strong>Resolver tools ✔ ✔✔Mechanical clutch control✔Current control✔Transducer control ✔ ✔CVIP PocketPC SoftwareVisual Supervisor SoftwareCVIPC 2000 SoftwareCVI-NET✔✔✔✔Fieldbus options ✔ ✔Ethernet options ✔ ✔ ✔Multi-channel options ✔ ✔4

CS4746 Series CS4700 Series CS7000 Series CVI II Series46 Series Electric 66 Series Electric 177 &277 SeriesNutrunners Nutrunners Electric NutrunnersER Series NutrunnersEM Series Spindles2 - 18 Nm 20 - 220 Nm 150 - 3,000 Nm 0.35 - 480 Nm 0.5 - 1900 Nm1.4 - 13.2 ft-lb 14.7 - 162 ft-lb 110 - 2,213 ft-lb 0.26 - 354 ft-lb 0.37 - 1400 ft-lb26-27, 31, 34-46, 50-51 26-27, 31, 34-46, 50-51 47-49 52-60, 64, 66-71 52-53, 61-63, 65-71✔ ✔ ✔✔✔ ✔ ✔✔ ✔ ✔✔ ✔ ✔ ✔✔ ✔ ✔ ✔✔✔✔✔✔ ✔ ✔✔✔✔ ✔ ✔✔ ✔ ✔ ✔ ✔✔ ✔ ✔✔✔✔✔✔ ✔ ✔ ✔ ✔✔ ✔ ✔ ✔ ✔✔ ✔ ✔ ✔ ✔5

SSB Battery Screwdriver1.5 to 12 Nm (1.1 to 8.8 ft. lb) - 360 and 750 rpmThe SSB range has been developed to meet the needs for a high quality cordless screwdriverspecifically for the industrial user.High rundown speeds: >700rpm = reduced process timeExcellent torque accuracy assures joint integrity and qualityExtreme durability of components: >200,000 tightening operationsmeans high duty cycles and productivity as well as lower operating costs2.6Ah / 12volt NiMh battery packs can give up to 800 assemblyoperations per chargeT handle shape with 2 position battery clipErgonomic design features for improved operator comfort and outputOptical and audible OK torque indicators and low voltage warning lightSound level

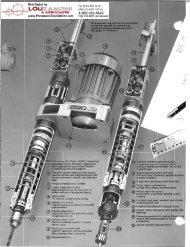

CVIP - Plug & TightenThe Assembly Revolution - Ultimate Precision,Control and ErgonomicsUnbeatable AssemblyQuality• Integrated digital transducer givesaccurate fastening (up to 3% at 6 Sigma)• Tested to ISO 5393• Easy to read LED displayTorque or Torque & Angleassembly strategy3at 6Simple Operation - Plug in anduse in seconds• Plugs into standard 230V/110V• Auto program with self-learning mode• Tamper proof torque programming, eitherdirectly on tool or from pocket PCAUTO setupin secondsShock resistant,composite handleOptional 2 hand start for tubenutapplications, or lower lever positionfor in-line toolsCrowfoot or Tubenut optionsImproveddurabilityof angle headGear boxPatenteddigital torquetransducerBrushlessmotorResolver motorangle controlAdvanced Communicationand Control• Interface via bluetooth pocket PC (Windows Mobile2003)• Program, view results, calibrateAdvanced control & integrationFlexible Assembly - Adapt to allapplications• Modular, changeable outputs• Torque capacity up to 50 ft lbs (65Nm)• 2nd lever start optional for tubenut applicationsA solution for all applications8

Change Your Expectation of Assembly <strong>Tools</strong>• Faster assembly cycle• Significantly longer tool life• Maintenance free brushless motor• Gearbox durability tested to well over 2 million cycles• Energy consumption is significantly less than traditional toolswww.plugandtighten.comwww.plugandtighten.comGround FaultCircuit Interrupter(GFCI)Tool has lowest life cycle cost availableDisplay andkeypadSoft grip handle12 LEDs andbuzzer indicateOK/NOKHighly durable, safetytestedcable and connectorBuilt-in servo driveErgonomic• Low weight, low noise, low torque reaction• Excellent weight distribution, easy to read display• Safety compliant under INTERNATIONAL STANDARD IEC 60745Proven comfort designed with operator input9

Data Transfer UnitThe DTU is a reporting box and tool power supply.There are 2 models of the DTU:• DTU Basic with I/O only• DTU Advanced with I/O and communication to PC or PLC. 10,000 result memory.Connections: I/ORS232EthernetFieldbus (option)MODEL PART DIMENSIONSNUMBER WIDTH HEIGHT DEPTHmm in. mm in. mm in.DTU Basic 615 936 045 0 90 3.5 250 9.8 190 7.5DTU Advanced 615 936 046 0 90 3.5 250 9.8 190 7.5Power supply cableincluding: Power cable + plugPLUG DESCRIPTION PART NO.A European 8.2ft (2.5m) 615 917 201 0B UK 8.2ft (2.5m) 615 917 202 0C US 8.2ft (2.5m) 615 917 203 0A B CACCESSORIESPART NO.• Probibus kit 615 929 021 0• Devicenet kit 615 929 022 0• Modbus+ kit 615 929 023 0• Tool cable 110V 16.4ft (5m) 615 917 485 0• Tool cable 110V 32.8ft (10m) 615 917 486 0• Tool cable 110V 49.2ft (15m) 615 917 487 0• Tool cable 230V 16.4ft (5m) 615 917 480 0• Tool cable 230V 32.8ft (10m) 615 917 481 0• Tool cable 230V 49.2ft (15m) 615 917 482 0• Extension tool cable 32.8ft (10m) 615 917 483 0• Extension tool cable 65.6ft (20m) 615 917 484 010

CVIP - Angle Head & In-line <strong>Tools</strong>2.2 to 47.9 ft.lb. (3 to 65 Nm)MODEL PART MODEL PART OUTPUT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER NUMBER DRIVE RANGE SPEED Lin. type Nm ft.lb. mm in. kg lb230V ModelsTorque Torque + Angle rpm 230VRight angle toolsEAP1.5-15-T-2 615 165 312 0 EAP1.5-15-TA-2 615 165 323 0 3/8 square drive 3-15 2.2-11.0 1020 534.5 21.0 1.85 4.1EAP1.5-20-T-2 615 165 313 0 EAP1.5-20-TA-2 615 165 324 0 3/8 square drive 5-20 3.7-14.7 800 534.5 21.0 1.85 4.1EAP1.5-26-T-2 615 165 314 0 EAP1.5-26-TA-2 615 165 325 0 3/8 square drive 7-26 5.2-19.2 510 534.5 21.0 1.85 4.1EAP2-20-T-2 615 165 315 0 EAP2-20-TA-2 615 165 326 0 3/8 square drive 5-20 3.7-14.7 1320 559.5 22.0 2.0 4.4EAP2-30-T-2 615 165 316 0 EAP2-30-TA-2 615 165 327 0 3/8 square drive 7-30 5.2-22.1 1020 559.5 22.0 2.0 4.4EAP2-40-T-2 615 165 317 0 EAP2-40-TA-2 615 165 328 0 3/8 square drive 10-40 7.4-29.5 800 570.0 22.4 2.1 4.6EAP2-65-T-2 615 165 318 0 EAP2-65-TA-2 615 165 329 0 3/8 square drive 15-65 11-47.9 510 581.5 22.9 2.2 4.8In-line toolsEDP1.5-15-T-2 615 165 319 0 EDP1.5-15-TA-2 615 165 330 0 1/4 hex F 3-15 2.2-11.0 1010 491.5 19.3 1.7 3.7EDP2-24-T-2 615 165 320 0 EDP2-24-TA-2 615 165 331 0 1/4 hex F 5-24 3.7-17.7 1390 516.5 20.3 1.8 3.9EDP2-33-T-2 615 165 321 0 EDP2-33-TA-2 615 165 332 0 3/8 square drive 7-33 5.2-24.3 1010 508.5 20.0 1.85 4.1EDP2-43-T-2 615 165 322 0 EDP2-43-TA-2 615 165 333 0 3/8 square drive 8-43 5.9-31.7 780 508.5 20.0 1.85 4.1110V ModelsTorque Torque + Angle rpm 110VMODEL ØA ØB Hmm in. mm in. mm in.EAP1.5-15-. 28 1.10 27 1.06 45.5 1.79EAP1.5-20-. 28 1.10 27 1.06 45.5 1.79EAP1.5-26-. 28 1.10 27 1.06 45.5 1.79EAP2-20-. 28 1.10 27 1.06 45.5 1.79EAP2-30-. 28 1.10 27 1.06 45.5 1.79EAP2-40-. 35 1.38 27 1.06 51.5 2.03EAP2-65-. 40 1.57 30.5 1.20 57.5 2.26Right angle toolsEAP1.5-15-T-1 615 165 334 0 EAP1.5-15-TA-1 615 165 345 0 3/8 square drive 3-15 2.2-11.0 690 534.5 21.0 1.85 4.1EAP1.5-20-T-1 615 165 335 0 EAP1.5-20-TA-1 615 165 346 0 3/8 square drive 5-20 3.7-14.7 540 534.5 21.0 1.85 4.1EAP1.5-26-T-1 615 165 336 0 EAP1.5-26-TA-1 615 165 347 0 3/8 square drive 7-26 5.2-19.2 340 534.5 21.0 1.85 4.1EAP2-20-T-1 615 165 337 0 EAP2-20-TA-1 615 165 348 0 3/8 square drive 5-20 3.7-14.7 890 559.5 22.0 2.0 4.4EAP2-30-T-1 615 165 338 0 EAP2-30-TA-1 615 165 349 0 3/8 square drive 7-30 5.2-22.1 690 559.5 22.0 2.0 4.4EAP2-40-T-1 615 165 339 0 EAP2-40-TA-1 615 165 350 0 3/8 square drive 10-40 7.4-29.5 540 570.0 22.4 2.1 4.6EAP2-65-T-1 615 165 340 0 EAP2-65-TA-1 615 165 351 0 3/8 square drive 15-65 11-47.9 340 581.5 22.9 2.2 4.8In-line toolsEDP1.5-15-T-1 615 165 341 0 EDP1.5-15-TA-1 615 165 352 0 1/4 hex F 3-15 2.2-11.0 680 491.5 19.3 1.7 3.7EDP2-24-T-1 615 165 342 0 EDP2-24-TA-1 615 165 353 0 1/4 hex F 5-24 3.7-17.7 940 516.5 20.3 1.8 3.9EDP2-33-T-1 615 165 343 0 EDP2-33-TA-1 615 165 354 0 3/8 square drive 7-33 5.2-24.3 680 508.5 20.0 1.85 4.1EDP2-43-T-1 615 165 344 0 EDP2-43-TA-1 615 165 355 0 3/8 square drive 8-43 5.9-31.7 525 508.5 20.0 1.85 4.11246357ACCESSORIESITEMPART NO.1 Mounting plate with telescopic spindle 615 396 547 02 2nd lever start option 615 396 553 03 Reaction handle 615 396 554 04 Horizontal Bail, included with the tools 615 396 562 05 Horizontal Bail, swivel 615 396 529 06 Vertical Bail 4670037 Reaction bar ring, included with the EDP tools 615 396 551 5• Plastic protective cover EAP. -15 to 30 615 573 064 0• Plastic protective cover EAP.-40 615 573 065 0• Plastic protective cover EAP.-65 615 573 066 0• Power cable EU 230V 5m (16.4ft.) 615 917 470 0• Power cable EU 230V 5m (16.4ft.) with GFI 615 917 476 0• Power cable UK 230V 5m (16.4ft.) 615 917 472 0• Power cable UK 230V 5m (16.4ft.) with GFI 615 917 478 0• Power cable US 230V 5m (16.4ft.) with GFI 615 917 477 0• Power cable US 110V 5m (16.4ft.) with GFI 615 917 479 0• CVIPocket software (Windows mobile 2003) 615 927 558 011

CVIC RangeThe CVIC system offersimproved control, joint integrityand many more advantages overconventional tools.EasySetupThe EB (Electric Brushless) tools are accuratelycontrolled to rundown and error proof bymonitoring the power consumption andangle rotation.The CVIC range can be setup fast - allparameters are auto-programmed as soon asthe controller is switched on (all tool have a built in ID).3 Programming options:• Quick Pprogramming: enter only the target torque and max angle. TheCVIC will optimize all other parameters to tighten to torque and monitorangle.• Learning: simply enter the target torque, make between 3 and 5tightenings and the CVIC will “learn” the joint rate and setup all parameters togive optimum performance.• Standard Programming: Each parameter can be modified as the applicationrequires.2 Software versions are available in the CVIC range:Version L: allows you to tighten at a programmed torque after self-learning ofthe joint and allows you to detect incorrect tightenings.Version H: all the functions of the L plus on-controller memory with 7 cycles,each with up to 20 different phases.Search sequence - Rundown - Final tighten - Action on Not OK - last 100results stored.Reliability &Quality of tighteningReduce Costof maintenanceThe quality of each tightening is checked with an OK or Not OK reportshown by LEDs on the tool, on the CVIC display and with an output onthe I/O connector.The control of the assembly station by the CVIC eliminates the riskof delivering non conforming parts, (missed screws, re-tightening,etc.).To ensure traceability of the fastening process results caneither be reviewed on the controller - H version stores last100 results - or sent to a database for storage.The CVIC systems have been extensively fordurability and exceeded all standards. TheEB (brushless) motor is maintenancefree.Reading of the tool featuresTool rotating testReading of input/output12

Mastering AssemblyMULTICVIC - Flexible multi-spindle systemControl system 1 to 32 channels- The MODCVIC is the rack version of the CVIC. It has noscreen or keyboard. It is programmed by the CVIS/CVIPC2000 software.2 software versions L and H are available, with all the functionsof the CVIC controller. The H version can be connected to a PCnetwork to make programming easier.- The MULTICVIC consists of MODCVIC modules and aCPUCVI which is the interface between a PLC and themodules. The CPUCVI centralises the control functions andthe results while monitoring the MODCVIC.- The flexibility of the MULTICVIC can be further increased byoperating the available 26 input and 32 output connections ofthe CPUCVI module through an ISaGRAF process controlapplication integrated in this module.ISaGRAFI/OCPUCVICVIPC2000 softwareThis common software of all CP EB controllers can program and collect results of CVICrange. It is possible to connect up to 32 controllers through a PC network (H version).Socket trayThe socket tray allows you to automatically select a tightening cycle by picking theappropriate socket.Bar code reader- it selects a tightening cycle- the bar code number is saved with the tightening results.Connectionof peripheralIntegral tool memory, which contains the torque tuning and tighteningparameters, makes this a ready-to-use ‘plug and play’ tool.Long lifetime gearboxAdapter forgeared offsethead (crowfoot)Tool connection offers high resistance to torsion and reaction.OperatorComfortOptimised anglehead for extremelylong life because ofspecial treatmentof angle pinions.Designed with Ergosense in mind:- Very low sound level, less than 70 dBA.- Ergo stop function and comfort grip maximizesoperator comfort.13

Torque RangePerformances of Portable electric nutrunners - series ECL, ECP, ECA and ECDIn-line & Angle headROTATIONALSPEED rpmECL1 2000ECL3 2000ECL5 2000ECL8 2000ECL11 1500ECLA11 1500Torque Nm 0 0.5 1 1.5 2 5 10 20 30Pistol gripROTATIONALSPEED rpmECP3L 2000ECP5L 2000ECP10L 1540ECP20L 790ECP20S 1540ECP30S 1070ECP40S 680ECP3LT 2000ECP5LT 2000ECP10LT 1540ECP20LT 790Torque Nm 0 0.5 1 1.5 2 5 10 20 30 40Angle headROTATIONALSPEED rpmECA15 1140ECA20 1480ECA30 1140ECA40 900ECA60 570ECA70 690ECA90 550ECA115 380ECA125 360ECA150 300ECA200 220Torque Nm 0 5 10 15 20 30 50 100 150 200In-lineROTATIONALSPEED rpmECD5 2065ECD20 1560ECD30 1100ECD50 1030ECD70 650ECD120 400Torque Nm 0 5 10 15 20 30 50 100 150 200Performances of Fixtured electric spindles - series MC and MCLIn-lineROTATIONALSPEED rpmMC35-10 2067MC35-20 2067MC38-10 1287MC38-20 1092MC51-10 650MC51-20 403MC60-10 923MC60-20 507MC60-30 299MC80-10 286MC80-20 195MC80-30 130MC80-40 91MC106-10 52MC106-20 39Torque Nm 0 10 20 50 100 150 200 300 400 600 800 1000 1200 1400AngleROTATIONALSPEED rpmMCL38-20 1092MCL51-20 403MCL60-20 481MCL60-30 312MCL80-40 91Torque Nm 0 10 20 50 100 150 200 300 400 60014

Electric Nutrunners - CVIC RangeTorque range from 0.2 to 11 Nm (ECL..)(0.15 to 8.1 ft.lb) in 3 modelsAdjustableLeverNo maintenance Brushless electric motorProgrammable speed from 30 to 2000 rpmSmooth start accelerationErgostop function to reduce torque reactionLow shock loading into componentLow noise level

Pistol Grip Electric Nutrunners - CVICECP3L - ECP5L - ECP10L - ECP20L - ECP20S - ECP30S - ECP40S1 to 40 Nm (0.7 to 29.5 ft.lb) - 680 to 2000 rpmECP30SECP3L - ECP5L ECP10L - ECP20LECP20SECP40SAccessories: see page 22MODEL PART OUTPUT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. kg lb.ECP3L 615 165 199 0 1/4-in hex F 1.0-3 0.7-2.2 2000 2000 196 7.7 1.0 2.2ECP5L 615 165 200 0 1/4-in hex F 1.7-5 1.3-3.7 2000 1515 196 7.7 1.0 2.2ECP10L 615 165 201 0 1/4-in hex F 3.0-10 2.2-7.4 1540 1000 196 7.7 1.1 2.4ECP20L 615 165 202 0 1/4-in hex F 7.0-20 4.9-14.8 790 515 196 7.7 1.1 2.4ECP20S 615 165 203 0 1/4-in hex F 7.0-20 4.9-14.8 1540 1000 221 8.7 1.2 2.6ECP30S 615 165 204 0 3/8-in square 10.0-30 7.4-22.1 1070 700 217 8.5 1.2 2.6ECP40S 615 165 262 0 3/8-in square 10.0-40 7.4-29.5 680 442 274 10.7 1.7 3.7Pistol Grip Electric Nutrunners - CVICECP3LT - ECP5LT - ECP10LT - ECP20LT1 to 20 Nm (0.7 to 14.8 ft.lb) - 790 to 2000 rpmAccessories: see page 22MODEL PART OUTPUT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. kg lb.ECP3LT 615 165 231 0 1/4-in hex F 1.0-3 0.7-2.2 2000 2000 196 7.7 1.0 2.2ECP5LT 615 165 232 0 1/4-in hex F 1.7-5 1.3-3.7 2000 1960 196 7.7 1.0 2.2ECP10LT 615 165 233 0 1/4-in hex F 3.0-10 2.2-7.4 1540 1000 196 7.7 1.1 2.4ECP20LT 615 165 234 0 1/4-in hex F 7.0-20 5.2-14.8 790 510 196 7.7 1.1 2.416

Angle Head Electric Nutrunners - CVICECA15 - ECA20 - ECA30 - ECA40 - ECA605 to 60 Nm (3.7 to 44.2 ft.lb) - 570 to 1480 rpmMODEL H Ø1 Ø2mm in. mm in. mm in.ECA15 45.5 1.8 28 1.1 27.0 1.06ECA20 - ECA30 45.5 1.8 28 1.1 27.0 1.06ECA40 51.5 2.0 35 1.4 27.0 1.06ECA60 57.5 2.3 40 1.6 30.5 1.20ECA15Quick change chuckP.N 615 396 262 0Accessories: see page 22MODEL PART SQUARE TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. kg lb.ECA15 615 165 192 0 3/8-in 5-15 3.7-11.0 1140 855 406 16.0 1.3 2.9ECA20 615 165 100 0 3/8-in 7-20 5.2-14.7 1480 1110 431 16.9 1.7 3.7ECA30 615 165 101 0 3/8-in 10-30 7.4-22.1 1140 855 431 16.9 1.7 3.7ECA40 615 165 102 0 3/8-in 13-40 9.6-29.5 900 675 441 17.4 1.8 4.0ECA60 615 165 103 0 3/8-in 20-60 14.7-44.2 570 427 453 17.8 1.9 4.2Angle Head Electric Nutrunners - CVICECA70 - ECA90 - ECA115 - ECA125 - ECA150 - ECA20023 to 200 Nm (16.9 to 147.5 ft.lb) - 220 to 690 rpmECA70 - ECA90 - ECA115 - ECA125 - ECA150ECA200MODEL H Ø1mm in. mm in.ECA70- ECA90 - ECA115 66 2.6 45 1.77ECA125 - ECA150 69 2.7 50 1.97Accessories: see page 22MODEL PART SQUARE TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. kg lb.ECA70 615 165 104 0 1/2-in 23-70 16.9-51.6 690 517 538 21.2 3.3 7.3ECA90 615 165 105 0 1/2-in 30-90 22.1-66.4 550 412 538 21.2 3.3 7.3ECA115 615 165 106 0 1/2-in 39-115 28.7-84.8 380 285 538 21.2 3.3 7.3ECA125 615 165 188 0 1/2-in 40-125 29.5-92.2 360 270 541 21.3 3.6 7.9ECA150 615 165 189 0 1/2-in 50-150 36.8-110.6 300 225 541 21.3 3.6 7.9ECA200 615 165 190 0 3/4-in 70-200 51.6-147.5 220 165 591 23.3 3.8 8.417

In-line Electric Nutrunners - CVICECD5 - ECD20 - ECD302 to 30 Nm (1.3 to 22 ft.lb) - 1100 to 2065 rpmECD30ECD5ECD20MODEL PART OUTPUT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. kg lb.ECD5 615 165 068 0 1/4-in hex F 2-6 1.5-4.4 2065 1548 346 13.6 1.0 2.4ECD20 615 165 093 0 1/4-in hex F 7-20 5.2-14.7 1560 1170 388 15.3 1.5 3.3ECD30 615 165 094 0 3/8-in square 10-30 7.4-22 1100 825 380 15.0 1.5 3.3In-line Electric Nutrunners - CVICECD50 - ECD70 - ECD12016 to 120 Nm (11.8 to 88.5 ft.lb) - 400 to 1030 rpmAccessories: see page 22MODELDmm in.ECD50 12.0 0.47ECD70- ECD120 16.5 0.65Accessories: see page 22MODEL PART SQUARE TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. kg lb.ECD50 615 165 095 0 3/8-in square 16-50 11.8-36.8 1030 772 456 17.9 2.6 5.7ECD70 615 165 096 0 1/2-in square 23-70 16.9-51.6 650 487 461 18.1 2.6 5.7ECD120 615 165 097 0 1/2-in square 40-120 29.5-88.5 400 300 488 19.2 3.1 6.818

Fixtured Electric Spindles - CVICMC35-10 - MC35-20 - MC38-10 -MC38-202.5 to 45 Nm (1.8 to 33.2 ft.lb) - 1092 to 2067 rpmMODELØ1mmin.MC35-10 35 1.38MC35-20 35 1.38MC38-10 - MC38-20 38 1.50Accessories: see page 22MODEL PART SQUARE TORQUE ROTATIONAL TELESCOPIC MIN. CENTRE LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT DISTANCE Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. mm in. mm in. kg lb.MC35-10 615 165 107 0 3/8-in 2.5-8 1.8-5.9 2067 1344 50 1.97 43.2 1.7 276 10.9 1.7 3.7MC35-20 615 165 108 0 3/8-in 5.0-15 3.7-11 2067 1344 50 1.97 43.2 1.7 301 11.8 2.0 4.4MC38-10 615 165 109 0 3/8-in 10.0-30 7.4-22.1 1287 837 50 1.97 43.2 1.7 347 13.7 2.0 4.4MC38-20 615 165 110 0 3/8-in 15.0-45 11.0-33.2 1092 710 50 1.97 43.2 1.7 347 13.7 2.0 4.4Fixtured Electric Spindles - CVICMC51-10 - MC51-20 - MC60-10 - MC60-20 - MC60-3025 to 190 Nm (18.4 to 140 ft.lb) - 299 to 923 rpmMODEL Ø1 Ø2 Dmm in. mm in. mm in.MC51-10 - MC51-20 51 2.01 43 1.70 113.0 4.45MC60-10 60 2.36 60 2.36 113.0 4.45MC60-20 - MC60-30 60 2.36 60 2.36 121.5 4.78Accessories: see page 22MODEL PART SQUARE TORQUE ROTATIONAL TELESCOPIC MIN. CENTRE LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT DISTANCE Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. mm in. mm in. kg lb.MC51-10 615 165 111 0 1/2-in 25-70 18.4-51.6 650 423 50 1.97 51.2 2.0 366 14.4 2.9 6.4MC51-20 615 165 112 0 1/2-in 45-135 33.2-99.5 403 262 50 1.97 51.2 2.0 393 15.4 3.5 7.7MC60-10 615 165 113 0 1/2-in 30-60 22.1-44.2 923 600 50 1.97 60.2 2.4 417 16.4 4.8 10.6MC60-20 615 165 114 0 3/4-in 60-110 44.2-81.1 507 330 50 1.97 60.2 2.4 417 16.4 4.8 10.6MC60-30 615 165 115 0 3/4-in 80-190 59.0-140 299 195 50 1.97 60.2 2.4 453 17.8 5.2 11.519

Fixtured Electric Spindles - CVICMC80-10 - MC80-20 - MC80-30 - MC80-40 - MC106-10 - MC106-20100 to 1350 Nm (73.7 to 995 ft.lb) - 39 to 286 rpmMODEL Ø1 Dmm in. mm in.MC80-10 - MC80-20 80 3.15 140 5.51MC80-30 - MC80-40 80 3.15 148 5.82MC106-10 - MC106-20 106 4.17 148 5.82Accessories: see page 22MODEL PART SQUARE TORQUE ROTATIONAL TELESCOPIC MIN. CENTRE LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT DISTANCE Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. mm in. mm in. kg lb.MC80-10 615 165 116 0 3/4-in 100-195 73.7-144 286 186 60 2.36 80.2 3.2 480 18.9 9.8 21.6MC80-20 615 165 117 0 3/4-in 150-300 110.5-221 195 127 60 2.36 80.2 3.2 480 18.9 9.8 21.6MC80-30 615 165 118 0 1-in 220-420 162.1-309 130 85 60 2.36 80.2 3.2 480 18.9 9.8 21.6MC80-40 615 165 119 0 1-in 270-600 199.0-442 91 59 60 2.36 80.2 3.2 480 18.9 9.8 21.6MC106-10 615 165 120 0 1-in 500-1100 368.5-811 52 34 60 2.36 106.2 4.2 556 21.9 15.0 33.1MC106-20 615 165 121 0 1-in 600-1350 442.2-995 39 25 60 2.36 106.2 4.2 556 21.9 15.0 33.1Fixtured Electric Spindles - CVICMCL38-2015 - 45 Nm (11 - 33.2 ft.lb) - 1092 rpmR9Accessories: see page 22MODEL PART SQUARE TORQUE ROTATIONAL TELESCOPIC MIN. CENTRE LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT DISTANCE Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. mm in. mm in. kg lb.MCL38-20 615 165 124 0 3/8-in 15-45 11-33.2 1092 710 50 1.97 43.2 1.7 140.5 5.53 3.0 6.620

Fixtured Electric Spindles - CVICMCL51-20 - MCL60-20 - MCL60-3045 to 190 Nm (33.2 to 140 ft.lb) - 312 to 481 rpmMODEL Ø1 Ø2 D Emm in. mm in. mm in. mm in.MCL51-20 51 2.01 43 1.69 113 4.45 412.5 16.2MCL60-20 60 2.36 60 2.36 121 4.76 448.5 17.7MCL60-30 60 2.36 60 2.36 121 4.76 448.5 17.7Accessories: see page 22MODEL PART SQUARE TORQUE ROTATIONAL TELESCOPIC MIN. CENTRE LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT DISTANCE Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. mm in. mm in. kg lb.MCL51-20 615 165 125 0 1/2-in 45-135 33.2-99.5 403 262 50 1.97 51.2 2.0 166 6.5 4 8.8MCL60-20 615 165 126 0 3/4-in 60-110 44.2-81.1 481 313 50 1.97 60.2 2.4 178 7.0 6 13.2MCL60-30 615 165 127 0 3/4-in 80-190 58.9-140 312 203 50 1.97 60.2 2.4 178 7.0 6 13.2Fixtured Electric Spindles - CVICMCL80-40270 - 600 Nm (199 - 442 ft.lb) - 91 rpmAccessories: see page 22MODEL PART SQUARE TORQUE ROTATIONAL TELESCOPIC MIN. CENTRE LENGTH WEIGHTNUMBER DRIVE RANGE SPEED AT DISTANCE Lin. Nm ft.lb rpm/230 V rpm/110 V mm in. mm in. mm in. kg lb.MCL80-40 615 165 128 0 1-in 270-600 199-442 91 59 60 2.4 80.2 3.2 241 9.49 11 24.221

Accessories1234567ECL / ECP / ECA / ECDACCESSORIES INCLUDEDITEMPART NO.• Side handle for ECP / ECL8 467033• Fixed suspension bail for ECP.LT 467003• Stationary suspension bail for ECA15/20/30/40/60 / ECD 615 571 056 0• Stationary suspension bail for ECA90/115/125/150/200 615 571 050 0• Square drive ball 3 /8" for ECA15/20/30/40/60 615 770 028 0• Reaction bar for ECD20/30 615 396 191 0• Reaction bar for ECD50/70/120 615 595 259 0• Long trigger lever for ECD5 615 396 192 0OPTIONAL ACCESSORIESITEMMC / MCLPART NO.• Rotary right angle tool connector for ECP 615 396 300 0• Suspension bail for ECP.L 615 396 121 0• Suspension bail on a swivel for ECA20/30/40/60 / ECD5/20/30 615 396 228 0• Suspension bail on a swivel for ECA70/90/115/125/150/200 / ECD50/70/120 615 396 229 0• Top cable length 4m for ECP.LT 615 917 420 0• Reaction bar ring for ECA60 615 396 226 0• Reaction bar ring for ECA70/90/115/125/150 615 396 227 0• Reaction bar ring for ECA200 615 396 230 0• Long trigger lever for ECA / ECD 615 396 192 0• Ball for ECA15/20/30/40 615 770 028 0Spring Loaded Shafts and Bearings Support for ECL1 Bit Adaptor 1037822 Spring Loaded Shaft 25mm (1") stroke, 3 /8" Sq Drive 1083423 Shaft Support and Nose Mount 108412Nose Mounts for ECL4 Nose Mount 108392Offset Head and Spring Loaded Shaft for ECL5 Offset Head, Offset 30mm (1.18") 3849936 Spring Loaded Shaft 25mm (1") stroke, 3 /8" Sq Drive 108352Screwdriver Bit Adaptor for ECL7 3 /8" Square to 1 /4" Hex Power Adaptor 108322Cable for ECP / ECA / ECDCable length: 3m 5m 10m 15m 20m 25m 30m• Nutrunnerscable 615 917 461 0 615 917 462 0 615 917 464 0 615 917 465 0• Extension cable 615 917 222 0 615 917 224 0 615 917 225 0 615 917 226 0 615 917 227 0 615 917 228 0Socket Tray• Socket tray (sockets not supplied) 615 936 005 0Cable length: 1m 5m 10m 15m• Cable for socket tray 615 917 241 0 615 917 242 0 615 917 244 0 615 917 245 0Reporting Box• Reporting Box 615 936 001 0OPTIONAL ACCESSORIESPART NO.• Motor/In-line connector assembly kit for MC35-10 to MC51-20 / MCL38-20/MCL51-20 615 396 198 0• Motor/In-line connector assembly kit for MC60-10 to MC106-20 / MCL60-20/30/MCL80-40 615 396 199 0Transducer-holder from MC tool• 3/8-in square drive MC35/MC38 615 396 426 0• 1/2-in square drive MC51/MC60.10 615 396 427 0• 3/4-in square drive MC60.20/MC60.30 615 396 428 0• 3/4-in square drive MC80.10/MC80.20 615 396 429 0• 1-in square drive MC80.30/40/MC106 615 396 430 0Cable for MC & MCL toolsMODCVICCable length: 5m 10m 15m 20m 25m 30m• Motor cable 615 917 232 0 615 917 234 0 615 917 235 0 615 917 236 0 615 917 237 0 615 917 238 0• Motor extension cable 615 917 222 0 615 917 224 0 615 917 225 0 615 917 226 0 615 917 227 0 615 917 228 022

CVIP2000 SoftwareProgram Parameters and Monitor DataCVI PC2000 software (Windows compatible) is auser friendly tool able to program tightening cycles,collect and display results and curves from alltightening controllers in real time.The Advanced network version allows the connection of up to 32controllers in RS422 mode and many more through an Ethernet link.Real time control mode• Display all stations connected• Display and save results• Display tightening reports• Print results after each tightening or from date to dateProgramming mode• General parameters of controllers: peripherals, fieldbuses, Ethernet,• Tightening cycles, up to 250• Electric brushless tool features• Downloading of all parameters to stationsDisplaying of all stations programmedAccess to main functions with soft keyFriendly InterfaceStatistical analysis mode• Standards: ISO, CNOMO, NF• Display and print:HistogramsSPCControl charts, mean, range, standard deviationMaintenance mode• Access to tool counters, partial number of cycles and total numberof cycles performed by the tool• Test mode to check torque transducer, angle encoder, brushless motor, etc…• Complete backup/restore of StationsCycles and phases programming modeEasy ControlComplete Statistical PackageFrom torque control up to yield point strategyMODELPARTNUMBERCVIS/CVIC PC2000 1 install 615 927 521 0CVIS/CVIC PC2000 5 install 615 927 534 0CVIS/CVIC PC2000 25 install 615 927 536 0MODELPARTNUMBERCVI PC2000 standard 1 install 615 927 522 0CVI PC2000 standard 5 install 615 927 526 0CVI PC2000 standard 25 install 615 927 537 0MODELPARTNUMBERCVI PC2000 advance 1 install 615 927 523 0CVI PC2000 advance 5 install 615 927 535 0CVI PC2000 advance 25 install 615 927 538 023

Technical FeaturesCVIC RangeMAIN FUNCTIONSVERSIONSLHSTANDARD ADVANCEDQuick cycle with self-learning of the joint ✔ ✔Number of cycles in the controller 0 15Number of cycle in the tool 1 1Number of phases 3 20Batch count (99 OK reports) ✔ ✔TIGHTENING RESULTSTorque + Angle + Date + Time + Report 100TYPES OF PHASES IN A CYCLESearch Sequence✔Run Down ✔ ✔Torque controlled final speed phase ✔ ✔Angle-controlled final speed phase✔Angle-controlled run reverse✔Restart cycle in case of defect✔Prevailing torque monitoring✔STRATEGIESTorque control and angle monitoring ✔ ✔Angle control and torque monitoring✔DISPLAY AND PROGRAMMINGDisplayLCD display ✔ ✔Keyboard8 buttons keyboard ✔ ✔ReportsLEDs 6 6PC Software WindowsCVIPC2000 *: program cycles, collect, display and save results, run statistics ✔ ✔Connection ‘point to point’Connection through a network (32 controllers)✔*All CVIPC2000 versions are compatible with CVICsMAINTENANCEAccess to all tool parameters (tool memory) ✔ ✔Autotest of the complete system ✔ ✔Spindle rotation test ✔ ✔Input/Output selection ✔ ✔Date of the last maintenance operation ✔ ✔Total and partial cycle counters ✔ ✔PERIPHERALSInput/Output 2/4 8/8PC point-to-point connection (RS232) ✔ ✔PC network connection (RS422)✔Bar code reader connection to select a cycle number (RS232)✔MODELCONTROLLER for low torque tools CVIC L-2 CVIC H-2MODULE for low torque tools MODCVIC L-2 MODCVIC H-2CONTROLLER for the other tools CVIC L-4 CVIC H-4MODULE for the other tools MODCVIC L-4 MODCVIC H-4MAINS SUPPLYSingle -phase 110/230 Volts ✔ ✔24

ControllersCVIC - MODCVICABPIC MODEL PART TOOLS CONSUMPTION MAINS DIMENSIONS WEIGHTREF NUMBER (current) SUPPLY WIDTH HEIGHT115V 230V 50/60 hertz mm in. mm in. mm in. kg lb.CVIC CONTROLLERA CVIC L-2 615 932 608 0 ECD5/ECL-ECPL/MC35.10/ECA15 4A 2A Single-phase 260 10.2 270 10.6 170 6.7 5 11.0A CVIC H-2 615 932 610 0 ECD5/ECL-ECPL/MC35.10/ECA15 4A 2A 100 to 250 V 260 10.2 270 10.6 170 6.7 5 11.0A CVIC L-4 615 932 609 0 Other tools 8A 4A Single-phase 260 10.2 270 10.6 170 6.7 5 11.0A CVIC H-4 615 932 611 0 Other tools 8A 4A 100 to 250 V 260 10.2 270 10.6 170 6.7 5 11.0MODCVIC MODULEB MODCVIC L-2 615 932 612 0 ECD5/ECP3 to 20L/ECL/MC35-10 4A 2A Single-phase 100 3.94 320 12.6 270 10.6 4 8.8B MODCVIC H-2 615 932 602 0 ECD5/ECP3 to 20L/ECL/MC35-10 4A 2A or 100 3.94 320 12.6 270 10.6 4 8.8B MODCVIC L-4 615 932 613 0 Other tools 8A 4A three-phase 100 3.94 320 12.6 270 10.6 4 8.8B MODCVIC H-4 615 932 604 0 Other tools 8A 4A 100 to 250 V 100 3.94 320 12.6 270 10.6 4 8.8START-UP KIT to be ordered with the controllerIncluding: Plug + Literature + ConnectorPLUG LITERATURE PART NO.A French 615 928 040 0C English 615 928 041 0A English 615 928 046 0B English 615 928 049 0A German 615 928 042 0A Spanish 615 928 043 0D Italian 615 928 044 0A Dutch 615 928 048 0A Swedish 615 928 045 0OPTIONAL ACCESSORIESPART NO.• CVICPC NETWORK 2000 software 615 927 523 0• PC cable Length 2m (78.7") 615 917 047 0• Printer cable Length 2m (78.7") 615 917 011 0• CVIS/CVICPC2000 1 Installation 615 927 521 0• CVIS/CVICPC2000 5 Installations 615 927 534 0• CVIS/CVICPC2000 25 Installations 615 927 536 0A B C D25

CS RangeControllersFlexibilityBasic andAdvanced Models• Basic models have small scrollingdisplays.• Advanced models give full information and have largebright screen designed to reduces eye strain.FlexibleUp to 32 parameter sets, 16 sequences per channel. Easy setupof all applications, from simple rundowns to complex sequences.InstantCommunicationProcessManagementStructured Logical ProgrammingApplications can be programmed from the controller keypad, using theVisual Supervisor (VS) program, or via a PLC.VS Software• VS is detachable when a laptop PC loaded with the VS program is connected toa CS controller. VS on a laptop PC is portable so it can be used to program manyCS controllers.• VS can also be embedded (permanently installed) in the built-in computers of large,multi-spindle CS controllers.• Setup is automatic. User simply enters the IP address into the controller and VS.Communication begins as soon as the tool is attached and the system is powered on.• “Drag and drop” makes programming of parameter sets and sequences easy. VSdisplays fastening rundown results, graphs, statistics, an event log, and diagnosticsinformation for communications, tool and I/O.Process ManagementMulti-spindle CS controllers can be designed for as many as 32 spindles in an RS-485network, and for as many as 99 spindles using Ethernet connections.CS controller network options: Ethernet, DeviceNet, Modbus TCP/Ethernet IP,Profibus DPV1, PFCS/Terminal Server, etc.TraceabilityGraphsQuality AssuranceController memory ensures traceability via recall of tightening results: final torque,final angle, torque rate, date, time, bar code, tightening curves and more.Up to 2,000 readings (torque, angle, date, time, report).Curves: 1 OK curve and 1 not OK curve per channel per rundown.StatisticsVS automatically calculates statistics for torque, angle, or torque and angleresults.• Results are displayed on CS controllers with keypad/display, or onthe laptop screen when VS is attached to the basic CS controller• Statistic include StDev, Cpk, CR, 6 Sigma, Mean, Low,High, Range• Printing of full statistics reportModularityFrom the simplest to themost advanced applications26

Acceptable/Unacceptable (OK/NOK) SignalsThe quality of each tightening is displayed on all tools:Green (OK) and Red (Not OK) for the SD25 Screwdrivers.Green (OK) and user programmable red and yellow lights, factory set for torqueand angle rejects• All tools have a built-in torque transducer with leading edge strain gauge technology• Angle monitoring, digital communication between tool/controller ensure joint qualityElectric Transducerized <strong>Tools</strong>Tightening QualityTightening Strategies to Meet the Joint SpecificationAll CS controllers perform continuous process monitoring. Tthe following control andmonitoring strategies are available:ControlMonitoring• Torque only• Torque and angle• Yield• Torque only• Torque and angle• Yield• Prevailing torque• Self-tap• Re-hitErgonomic, User-Friendly• SD25 Screwdrivers weigh just 1 lb. (0.4 kg).• Nutrunners have programmable green, yellow and red LEDs with a handle displaythat shows tightening result and programable scrolling message.• 46 and 66 Series tools are high speed to minimizeoperator reaction.No Need to Re-Calibrate ControllersCS controllers automatically recognize the intelligent tool that’s attached.Controllers need NO calibrationMaintenanceGear greasing is the only maintenance required. Digital display in the tool handleshows when maintenance is needed.IntelligenceIntelligence is built into every tool providing:• Model number• Display• Build date• Auxiliary pushbutton• Serial number• Cycle count• Torque parameters • Locked rotor count• Speed parameters • Overtemperature count• Calibration data• Preventive maintenance counter• Angle count/revolution• Last calibration• Last repairErgonomicsOperator comfortProductivityProcess<strong>Tools</strong>Large range of tools(1-3,000 Nm)Low maintenanceCost SavingsAutomatic self diagnosiswith user-friendly messagesReduction of assemblyinspection proceduresChoose This For This Torque Tool DesignController Tool RangeCS2700 SD25 Series 1 - 5.6 Nm • IntelligentScrewdrivers• Hall effect sensor (when speed andCS4746 46 Series 5 - 15 Nm operator comfort matter)Nutrunners • VS Software compatibleCS4700 66 Series 2 - 226 NmNutrunnersWorkstation or Multi SD25, 1 - 226 NmMulti CS5000 Multi 46/66 SeriesspindlesCS7000 177 /277 Series 150 - • IntelligentMulti CS7000 Nutrunners 3,000 Nm • Resolver (when precision matters)• VS Software compatible27

Torque RangePerformances of electric screwdrivers - series SD25Electric Screwdrivers - CSSD25 ScrewdriverROTATIONALSPEED rpmSD25I010 1700SD25I020 1100SD25I035 800SD25I050 500Torque Nm 0 0.5 1.0 1.5 2 5 10 20 30LMODEL PART OUTPUT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED Lin. type in.lb in.oz kgf.cm Nm rpm mm in. kg lb.SD25I010LAQ2 615 004 098 2 1/4 quick release chuck 10 160 11.5 1.1 1700 238.7 9.4 .41 .9SD25I020LAQ2 615 004 098 3 1/4 quick release chuck 20 320 23.0 2.3 1100 238.7 9.4 .41 .9SD25I035LAQ2 615 004 098 4 1/4 quick release chuck 35 560 40.3 3.9 800 238.7 9.4 .41 .9SD25I050LAQ2 615 004 098 5 1/4 quick release chuck 50 800 57.6 5.6 500 238.7 9.4 .41 .9SD25I010BAQ2 615 004 012 1 1/4 quick release chuck 10 160 11.5 1.1 1700 238.7 9.4 .41 .9SD25I020BAQ2 615 004 012 4 1/4 quick release chuck 20 320 23.0 2.3 1100 238.7 9.4 .41 .9SD25I035BAQ2 615 004 012 7 1/4 quick release chuck 35 560 40.3 3.9 800 238.7 9.4 .41 .9SD25I050BAQ2 615 004 012 9 1/4 quick release chuck 50 800 57.6 5.6 500 238.7 9.4 .41 .9SD25I010MAQ2 615 004 012 2 1/4 quick release chuck 10 160 11.5 1.1 1700 238.7 9.4 .41 .9SD25I020MAQ2 615 004 012 5 1/4 quick release chuck 20 320 23.0 2.3 1100 238.7 9.4 .41 .9SD25I035MAQ2 615 004 012 8 1/4 quick release chuck 35 560 40.3 3.9 800 238.7 9.4 .41 .9SD25I050MAQ2 615 004 013 0 1/4 quick release chuck 50 800 57.6 5.6 500 238.7 9.4 .41 .9KEY TO THE SD25 SCREWDRIVER 8-DIGIT PREFIXExample: SD25I010SD 25 I 010Screwdriver Series Type: In-line Capacity: in.lbAND THE SUFFIX:SUFFIX: L, B, or M A Q2Applications• White goods/appliances• Electronics• Automotive dashboards, electronics,headlights, headliners• Light assembly where error-proofing is essentialTRIGGER LEVERBOTH TRIGGER AND PUSH-TO-STARTMOUNTEDALUMINUM HEAD1/4-IN QUICK RELEASE CHUCKAccessories: see page 30SD25OPTIONAL ACCESSORIESITEM MODEL NUMBER PART NO.Foam grip for In-line SD25 Screwdriver 31-80-39445 615 005 147 2Foam grip for In-line SD25 Screwdriver, no cutout 31-80-39445P 615 005 147 3Pistol grip attachment for In-line SD25 Screwdriver 49-SD-10111 615 004 090 7Suspension bail (all SD25 Screwdrivers) 49-SD-10112 615 004 090 8Mounting plate, double flange (for fixtured mounting) 49-SD-10121 615 005 309 5Mounting plate, single flange (for close fixtured mounting) 49-SD-10125 615 005 309 629

AccessoriesSD25 Tool-to-Controller Cables, CEREQUIRED ACCESSORIES to be ordered with controllerLENGTHWEIGHTWITH STRAIGHT CONNECTORS m ft. kg lb. MODEL NUMBER PART NUMBERScrewdriver to Controller Cable 1.5 5 .23 .5 299230-81050C 615 004 110 2Screwdriver to Controller Cable 3.0 10 .45 1.0 299230-81100C 615 004 070 6Screwdriver to Controller Cable 4.6 15 .68 1.5 299230-81150C 615 004 070 9Screwdriver to Controller Cable 6.1 20 .90 2.0 299230-81200C 615 004 071 2Screwdriver to Controller Cable 7.6 25 1.13 2.5 299230-81250C 615 004 0714Screwdriver to Controller Cable 9.1 30 1.36 3.0 299230-81300C 615 004 110 3Screwdriver to Controller Cable 10.7 35 1.58 3.5 299230-81350C 615 004 098 6Screwdriver to Controller Cable 12.2 40 1.81 4.0 299230-81400C 615 004 098 7Screwdriver to Controller Cable 13.7 45 2.04 4.5 299230-81450C 615 004 098 8Screwdriver to Controller Cable 15.2 50 2.26 5.0 299230-81500C 615 004 098 9SD25 Tool-to-Controller Cables, CEOPTIONAL ACCESSORIESLENGTHWEIGHTWITH HEAVY DUTY CONNECTORS m ft. kg lb. MODEL NUMBER PART NUMBERScrewdriver to Controller Cable 1.5 5 .23 .5 299230-81050CH 615 004 110 4Screwdriver to Controller Cable 3.0 10 .45 1.0 299230-81100CH 615 004 110 5Screwdriver to Controller Cable 4.6 15 .68 1.5 299230-81150CH 615 004 110 6Screwdriver to Controller Cable 6.1 20 .90 2.0 299230-81200CH 615 004 110 7Screwdriver to Controller Cable 7.6 25 1.13 2.5 299230-81250CH 615 004 110 8Screwdriver to Controller Cable 9.1 30 1.36 3.0 299230-81300CH 615 004 110 9Screwdriver to Controller Cable 10.7 35 1.58 3.5 299230-81350CH 615 004 111 0Screwdriver to Controller Cable 12.2 40 1.81 4.0 299230-81400CH 615 004 111 1Screwdriver to Controller Cable 13.7 45 2.04 4.5 299230-81450CH 615 004 111 2Screwdriver to Controller Cable 15.2 50 2.26 5.0 299230-81500CH 615 004 111 3LENGTHWEIGHTWITH RIGHT ANGLE CONNECTORS m ft. kg lb. MODEL NUMBER PART NUMBERScrewdriver to Controller Cable 1.5 5 .23 .5 299230-81050CR 615 004 092 2Screwdriver to Controller Cable 3.0 10 .45 1.0 299230-81100CR 615 004 070 7Screwdriver to Controller Cable 4.6 15 .68 1.5 299230-81150CR 615 004 071 0Screwdriver to Controller Cable 6.1 20 .90 2.0 299230-81200CR 615 004 099 3Screwdriver to Controller Cable 7.6 25 1.13 2.5 299230-81250CR 615 004 099 4Screwdriver to Controller Cable 9.1 30 1.36 3.0 299230-81300CR 615 004 071 7Screwdriver to Controller Cable 10.7 35 1.58 3.5 299230-81350CR 615 004 099 5Screwdriver to Controller Cable 12.2 40 1.81 4.0 299230-81400CR 615 004 099 6Screwdriver to Controller Cable 13.7 45 2.04 4.5 299230-81450CR 615 004 099 7Screwdriver to Controller Cable 15.2 50 2.26 5.0 299230-81500CR 615 004 099 8LENGTHWEIGHTEXTENSION CABLES m ft. kg lb. MODEL NUMBER PART NUMBERScrewdriver to Controller Cable 6.1 20 .90 2.0 299230-81200CE 615 004 111 4Screwdriver to Controller Cable 9.1 30 1.36 3.0 299230-81300CE 615 004 111 5Screwdriver to Controller Cable 15.2 50 2.26 5.0 299230-81500CE 615 004 111 6Screwdriver to Controller Cable 23.1 70 3.17 7.0 299230-81700CE 615 004 111 730

Visual SupervisorOne program for all CS controllers and intelligent tighteningVisual Supervisor (VS) is the user-friendly Windows ® -based software program that simplifies setup andtroubleshooting of these intelligent tightening system controllers:• CS2700• CS4700• CS4746• CS5000• Workstation• CS7000Such systems can have:• One intelligent electric brushless tightening tool and a single-channel controller• Assorted intelligent electric nutrunners operated by one or more single or multi-channel controllers in anetwork (with as many as 32 spindles total, 99 with Ethernet).VS can exchange tightening rundown results and real time fastening cycle status with industry buses such as:• DeviceNet• Modbus TCP/Ethernet IP• Profibus DPV1VS makes it easy to set up, collect and manage your tightening torque strategy.• Enter parameter values• Assign soft I/O using the drag and drop method• Create sequences and steps• Read bar codes off parts• View, collect, graph, print and store fastening rundown data on a hard drive or network database• Troubleshoot errors quickly• Adapt to wireless communicationVS lets you choose the torque strategy that is right for your application, whether it calls for hand-held tools orfixtured spindles.VS automatically collects data for local drive storage. Data can be saved to any third-party database programfor network storage, retrieval and sharing.VS Program user interface screens include:• Readings – For a single tool the VS readings screen displays a large box showing the torque, angle (indegrees) and the parameter set of the last cycle. The box is green when the fastening is accepted, or redwhen rejected. If multiple tools are monitored, VS displays a status line for each.• Setup – utilizes Windows ® tabs and drag and drop features for easy setup of tightening system inputs,outputs, and parameter sets for each tool that is attached.• Diagnostics – provides I/O, transducer and communications information for troubleshooting.• Graphs – automatically saves accepted and rejected fastening cycle waveforms as graphs, updatesgraphs between cycles, and displays/prints multiple graphs.• Event Log – provides a running list of the date, time, spindle name, address and description, user andstation of all tightening performed.Detachable and Embedded Versions of VS• VS loaded on a laptop PC running WindowsXP ® or 2000 is connected via RS-232 port to asingle-channel CS controller. The portable VSprogram may be taken from one CS controller toanother, therefore it is detachable.• VS is permanently installed (embedded) on thebuilt-in industrial computer of multi-spindle CScontrollers (for up to 32 channels) operating onWindows NT ® . VS is also embedded on theCS5000 Workstation which controls multi-spindle46/66 Series nutrunner systems.MODEL PART DESCRIPTIONNUMBER464000SVSSFTWR* 615 004 139 9 Visual Supervisor (VS) Program, Version X.XX, CDR* X’s indicate version. Number changes for each release31

Technical FeaturesCS2700 RangeMAIN FUNCTIONSCS2700VERSIONSControl Strategies (Use any of these with any/all of the Monitoring Strategies)Torque only ✔ ✔Torque and angle ✔ ✔Yield ✔ ✔Monitoring StrategiesTorque only ✔ ✔Torque and angle ✔ ✔Yield ✔ ✔Prevailing torque ✔ ✔Self-tap ✔ ✔Re-hit ✔ ✔CS5000Number of channels 1 2–32Number of parameter sets 1–32 1–32Number of sequences (phases) 16 total 16Number of steps (cycles) 32/sequence 32/sequenceBatch count 99 99Real time statistics – 6 Sigma, CR, Cpk, St Dev, Pop, Mean, Low, High, Range ✔ ✔Bar code reading ✔ ✔Synchronization of spindles ✔ ✔TIGHTENING RESULTSTorque + Angle + Date + Time + Report Up to 2,000/controller Up to 2,000/controllerNumber of curves 1 accept, 1 reject 1 accept, 1 reject/spindleTIGHTENING STRATEGIESEXTERNAL CONNECTIVITYInput 8 8Output 8 8RS232 programming port✔Serial printer/barcode scanner port (dual function) ✔ ✔High speed RS485 port (SDLC) ✔ ✔ADVANCED OPTIONSEthernet or SDLC or RF ✔ ✔Fieldbus: DeviceNet, Modbus TCP/Ethernet IP, Profibus DPV1 ✔ ✔Plant Floor Communication System (PFCS) ✔ ✔MAINTENANCEAccess to all tools parameters for setup ✔ ✔Access to all I/O for troubleshooting ✔ ✔Serial/Diagnostics port✔PROGRAMMINGFull keypad + large LCD screen + function keys✔Laptop PC laded with VS software ✔ ✔Keyboard or touch screen monitor✔Visual Supervisor (VS) software ✔ ✔Supply Voltage 120V✔Supply Voltage 230V ✔ ✔Supply Voltage 480V with step down transformer✔CS5000 ControllersModel Part Number Description Dimensions (W x H x D) Weight485000-36269 615 004 070 3 CS5000 Workstation, Industrial PC with built-in monitor, 52.1 x 54.6* x 41.9** cm 35.22 kgkeypad/mouse, SDLC 20.5 x 21.5* x 16.5** in 77.66 lb*Height includes mounting flanges**Depth includes handlesMulti-spindle CS5000 Controllers can be customized for your particular application.32

CS2700 ControllersTotal tightening functionality is packaged in a space-saving enclosure.Slim new CS2700 Controllers are designed for use with the SD25 Series transducerizedelectric screwdrivers (1 to 50 in.-lb).Controller configurations include:1 Basic + with parameter set selection dial; no keypad, small scrolling display2 Advanced with keypad/display user interface, EthernetEach model comes with RS-485 connection for daisy-chaining to other controllers.Limited programming can be performed via the keypad/display on the Advanced model.Both models may be programmed using the Visual Supervisor (VS) program. VS is loadedonto a laptop PC that connects to the controller via RS-232 port.Data that the controller collects about the selected fastening strategy and results can bestored to internal memory, off-line, a network database, or communicated viaprogrammable logic controller (PLC) for sharing with in-plant workstations.Field bus option kits for all models are available.Each configuration is available in 120V or 230V. Tool control module is 7A. Designed tomeet automotive OEM tightening, size and CE, CSA requirements. Enclosure measures17.4 x 45.9 x 33.3 cm / 6.85 x 18.07 x 13.12 in (width x height x depth). Approximateweight is 13.6 kg / 30 lb.1 2CS2700 CONTROLLERMODEL PART NUMBER PSET KEYPAD USED TCM AMPS, COMM FIELD INPUT CABLE SAFETYDIAL DISPLAY WITH COLOR BUS* VOLTS CONNECTOR STD.C2700AP1V112 615 004 108 2 1 No SD25 7A - White — None 120 Screwdriver CE, CSAC2700A01K112051 615 004 108 5 0 Yes SD25 7A - White Ethernet None 120 Screwdriver CE, CSAC2700AP1V212 615 004 108 3 1 No SD25 7A - Blue — None 230 Screwdriver CE, CSAC2700A01K212051 615 004 090 9 0 Yes SD25 7A - Blue Ethernet None 230 Screwdriver CE, CSA• Additional models are available. Consult your CP sales representative.OPTION KITS MODEL CP PART NUMBERCS2700/4746/4700 Ethernet Option (for Basic+ models only) 1 244700KETHN051 615 004 138 7CS2700/4746/4700 Devicenet Option 2 244700KDNET054 615 004 138 8CS2700/4746/4700 Profibus DPV1 Option 2 244700KPBUS058 615 004 138 9CS2700/4746/4700 Modbus TCP/Ethernet IP Option 2 244700KMTCP05A 615 004 139 0CS2700/4746/4700 PFCS/Terminal Server Option 2 244700KPFCSB51 615 004 139 11Ethernet is already installed on Advanced controllers with keypad/display so this option is not required.2When this option is selected, the Ethernet option 1 must also be ordered.Contact your CP Representative for more information.ABCS2700 Power CableREQUIRED ACCESSORIES to be ordered with controllerLENGTHPLUG DESCRIPTION m ft. MODEL NO. PART NO.A China CS2700/4700/4746 Controller power cord, 230V 2.5 8 244100-42222 615 004 092 3B England CS2700/4700/4746 Controller power cord, 230V 2.5 8 244100-40105 615 004 085 5C Europe CS2700/4700/4746 Controller power cord, 230V 2.5 8 244100-40106 615 004 085 6D USA/North America CS2700/4700/4746 Controller power cord, 230V 2.5 8 244100-40107 615 004 085 7D USA/North America CS2700/4700/4746 Controller power cord, 120V 2.5 8 244100-40526 615 004 092 1CDCS2700 Controller CablesOPTIONAL ACCESSORIESLENGTHWEIGHTITEM m ft. kg lb. MODEL NO. PART NO.Controller to printer/PC programming kit 1.8 6 .23 .5 244000-35087 615 004 092 3Serial cable for data transfer, laptop VS toCS2700 controller 6.1 20 .23 .5 41-41-0109FN 615 005 258 1Controllers for fixtured multiple screwdriver applications may be customized to your requirements. Contact your sales representative.33

Torque RangePerformances of electric nutrunners - series 46 and 66ROTATIONAL46 Series Pistol Grip (Handheld and Fixtured) SPEED rpmT046P005 1630T046P010 1050T046P015 670Torque Nm 0 0.5 1.0 1.5 2 5 10 20 30ROTATIONAL66 Series Pistol Grip (Handheld and Fixtured) SPEED rpmT066P020 2290T066P030 1485T066P035 1177T066P045 937T066P060 630T066P075 424Torque Nm 0 5 10 15 20 50 100 150 200ROTATIONAL46 Series Angle Head (Handheld and Fixtured) SPEED rpmT046A015 680T046A019 540T046A024 430Torque Nm 0 0.5 1.0 1.5 2 5 10 20 30ROTATIONAL66 Series Angle Head (Handheld and Fixtured) SPEED rpmT066A026 1526T066A041 990T066A050 765T066A065 610T066A100 280T066A126 235T066A156 200T066A186 160T066A226 1540Torque Nm 0 5 10 15 20 50 100 150 200ROTATIONAL46 Series In-line (Handheld and Fixtured) SPEED rpmT046I005 1630T046I010 1050T046I015 670Torque Nm 0 0.5 1.0 1.5 2 5 10 20 30ROTATIONAL66 Series In-line (Handheld and Fixtured) SPEED rpmT066I020 2290T066I030 1485T066I035 1177T066I045 937T066I060 630T066I075 424T066I100 345T066I150 208T066I170Torque Nm 0 5 10 15 20 50 100 150 200Torque Information atYour Fingertips!Close up of display and four-way positioningAll CP Techmotive 46 and 66 Series nutrunners contain the following components in thetool handle, providing the operator with information at hand:• Programmable multipurpose pushbutton that can be used for CycleComplete, multiple parameter set selection, data send (transmission), etc.• Forward/reverse button• Green, yellow and red indicator/status lights• 4-place alphanumeric digital display that can be positioned four waysto accommodate vertical and left-hand use of the tool to show• Torque and angle values• OK and other status information• 15-character scrolling messages• Identification of the selected parameter set34

46 Series Pistol Grip Electric Nutrunners - CS5 to 15 Nm (3.7 to 11.1 ft.lb)Used with a CS4746 or CS5000 ControllerA suspension bail (A046BS-P37694/615 004 074 6) and analuminum reaction bar and nut kit (A066SIL2R/615 004 138 5)are included.66 Series Pistol Grip Electric Nutrunners - CS**Change the detent from pin to ball by substituting a B for the P inthe Model No.Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgfm rpm mm in. kg lb.T046P005SSP2 615 004 022 7 1/4 square drive Pin 5 3.7 0.5 1630 216 8.5 1.6 3.6T046P005SSP3 615 004 022 8 3/8 square drive Pin 5 3.7 0.5 1630 216 8.5 1.6 3.6T046P005SSQ04 615 004 022 9 1/4 hex socket Quick chuck 5 3.7 0.5 1630 216 8.5 1.7 3.8T046P005SSQ07 615 004 096 8 7/16 hex socket Quick chuck 5 3.7 0.5 1630 274 10.8 1.7 3.8T046P010SSP2 615 004 023 0 1/4 square drive Pin 10 7.4 1.0 1050 269 10.6 1.6 3.6T046P010SSP3 615 004 023 1 3/8 square drive Pin 10 7.4 1.0 1050 274 10.8 1.7 3.8T046P010SSQ04 615 004 023 2 1/4 hex socket Quick chuck 10 7.4 1.0 1050 274 10.8 1.7 3.8T046P010SSQ07 615 004 096 9 7/16 hex socket Quick chuck 10 7.4 1.0 1050 269 10.6 1.6 3.6T046P015SSP3 615 004 023 5 3/8 square drive Pin 15 11.1 1.5 670 274 10.8 1.7 3.8T046P015SSQ07 615 004 097 0 7/16 hex socket Quick chuck 15 11.1 1.5 670 274 10.8 1.7 3.820 to 75 Nm (14.7 to 55.3 ft.lb)Used with a CS4700 or CS5000 ControllerA suspension bail (A046BS-P37694/615 004 074 6) isincluded with all models.For 20-45 Nm models, an aluminum reaction bar and nut kit(A066SIL2R/615 004 138 5) is included.For 60-75 Nm models, a long steel reaction bar and nut kit(A066SIL3R/615 004 083 4) is included.Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgfm rpm mm in. kg lb.T066P020SSP2 615 004 097 1 1/4 square drive Pin 20 14.7 2.0 2290 269 10.6 1.6 3.6T066P020SSP3 615 004 034 1 3/8 square drive Pin 20 14.7 2.0 2290 269 10.6 1.6 3.6T066P020SSQ04 615 004 034 2 1/4 hex socket Quick chuck 20 14.7 2.0 2290 274 10.8 1.7 3.8T066P020SSQ07 615 004 097 2 7/16 hex socket Quick chuck 20 14.7 2.0 2290 274 10.8 1.7 3.8T066P030SSP3 615 004 044 4 3/8 square drive Pin 30 22.1 3.1 1485 269 10.6 1.6 3.6T066P030SSQ04 615 004 097 3 1/4 hex socket Quick chuck 30 22.1 3.1 1485 274 10.8 1.7 3.8T066P030SSQ07 615 004 097 4 7/16 hex socket Quick chuck 30 22.1 3.1 1485 274 10.8 1.7 3.8T066P035SSP3 615 004 034 6 3/8 square drive Pin 35 25.8 3.6 1177 269 10.6 1.6 3.6T066P035SSQ04 615 004 097 5 1/4 hex socket Quick chuck 35 25.8 3.6 1177 274 10.8 1.7 3.8T046P035SSQ07 615 004 097 6 7/16 hex socket Quick chuck 35 25.8 3.6 1177 274 10.8 1.7 3.8T066P045SSP3 615 004 034 8 3/8 square drive Pin 45 33.2 4.6 937 269 10.6 1.6 3.6T066P045SSQ04 615 004 097 7 1/4 hex socket Quick chuck 45 33.2 4.6 937 274 10.8 1.7 3.8T066P045SSQ07 615 004 097 8 7/16 hex socket Quick chuck 45 33.2 4.6 937 274 10.8 1.7 3.8T066P060SSP4 615 004 035 0 1/2 square drive Pin 60 44.3 6.1 630 302 11.9 1.8 3.9T066P075SSP4 615 004 035 1 1/2 square drive Pin 75 55.3 7.6 424 302 11.9 1.8 3.935

46 Series Angle Head Electric Nutrunners - CS15 to 24 Nm (11.1 to 17.7 ft.lb)Used with a CS4746 or CS5000 ControllerA mounting plate kit (A066SRAP/615 004 083 5)is available for all models.No reaction bar is used.Short lever kit (483066-S/615 005 285 0)is standard.Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgfm rpm mm in. kg lb.T046A015SHP2 615 004 092 7 1/4 square drive Pin 15 11.1 1.5 680 353 13.9 1.5 3.3T046A015SHP3 615 004 022 3 3/8 square drive Pin 15 11.1 1.5 680 353 13.9 1.5 3.3T046A019SHP2 615 004 092 8 1/4 square drive Pin 19 14.0 1.9 540 353 13.9 1.5 3.3T046A019SHP3 615 004 022 5 3/8 square drive Pin 19 14.0 1.9 540 353 13.9 1.5 3.3T046A024SHP2 615 004 092 9 1/4 square drive Pin 24 17.7 2.4 430 353 13.9 1.5 3.3T046A024SHP3 615 004 022 6 3/8 square drive Pin 24 17.7 2.4 430 353 13.9 1.5 3.366 Series Angle Head Electric Nutrunners - CS26 to 226 Nm (19.2 to 166 ft.lb)Used with a CS4700 or CS5000 ControllerA mounting plate kit (A066SRAP/615 004 083 5)is available for all models.No reaction bar is used.Short lever kit (483066-S/615 005 285 0)is standard.Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgfm rpm mm in. kg lb.T066A026SHP2 615 004 093 0 1/4 square drive Pin 26 19.2 2.7 1526 383 15.1 1.8 4.0T066A026SHP3 615 004 024 6 3/8 square drive Pin 26 19.2 2.7 1526 383 15.1 1.8 4.0T066A041SHP3 615 004 026 7 3/8 square drive Pin 41 30.2 4.2 990 409 16.1 1.9 4.1T066A041SHP4 615 004 093 1 1/2 square drive Pin 41 30.2 4.2 990 409 16.1 1.9 4.1T066A050SHP3 615 004 027 6 3/8 square drive Pin 50 36.9 5.1 765 409 16.1 1.9 4.1T066A050SHP4 615 004 027 7 1/2 square drive Pin 50 36.9 5.1 765 409 16.1 1.9 4.1T066A065SHP3 615 004 028 8 3/8 square drive Pin 65 47.9 6.6 610 427 16.8 2.1 4.6T066A065SHP4 615 004 028 9 1/2 square drive Pin 65 47.9 6.6 610 427 16.8 2.1 4.6T066A100SHP4 615 004 093 2 1/2 square drive Pin 100 73.7 10.2 280 517 20.2 2.2 7.4T066A126SHP4 615 004 031 5 1/2 square drive Pin 126 92.9 12.8 235 543 21.3 4.0 8.9T066A156SHP4 615 004 031 6 1/2 square drive Pin 156 115.1 15.9 200 543 21.3 4.0 8.9T066A156SHP6 615 004 093 3 3/4 square drive Pin 156 115.1 15.9 200 543 21.3 4.0 8.9T066A186SHP6 615 004 093 4 3/4 square drive Pin 186 137.1 18.9 160 543 21.3 4.0 8.9T066A226SHP6 615 004 033 5 3/4 square drive Pin 226 166.6 23.0 154 543 21.3 4.0 8.9**Change the detent from pin to ball by substituting a B for the P in the Model No.36

46 Series In-line Electric Nutrunners - CSUsed with a CS4746 or CS5000 ControllerAn aluminum reaction bar and nut kit (A066SIL2R/615 004 138 5) isincluded.Short lever kit (483066-S/615 005 285 0)is standard.5 to 15 Nm (3.7 to 11.1 ft.lb)Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgfm rpm mm in. kg lb.T046I005SSP2 615 004 044 8 1/4 square drive Pin 5 3.7 0.5 1630 320 12.6 1.2 2.6T046I005SSP3 615 004 044 9 3/8 square drive Pin 5 3.7 0.5 1630 320 12.6 1.2 2.6T046I005SSQ04 615 004 045 0 1/4 hex socket Quick chuck 5 3.7 0.5 1630 320 12.6 1.2 2.6T046I005SSQ07 615 004 094 6 7/16 hex socket Quick chuck 5 3.7 0.5 1630 320 12.6 1.2 2.6T046I010SSP2 615 004 046 0 1/4 square drive Pin 10 7.4 1.0 1050 320 12.6 1.2 2.6T046I010SSP3 615 004 046 1 3/8 square drive Pin 10 7.4 1.0 1050 320 12.6 1.2 2.6T046I010SSQ04 615 004 046 2 1/4 hex socket Quick chuck 10 7.4 1.0 1050 320 12.6 1.2 2.6T046I010SSQ07 615 004 094 7 7/16 hex socket Quick chuck 10 7.4 1.0 1050 320 12.6 1.2 2.6T046I015SSP2 615 004 047 4 1/4 square drive Pin 15 11.1 1.5 670 320 12.6 1.2 2.6T046I015SSP3 615 004 047 5 3/8 square drive Pin 15 11.1 1.5 670 320 12.6 1.2 2.6T046I015SSQ04 615 004 047 7 1/4 hex socket Quick chuck 15 11.1 1.5 670 320 12.6 1.2 2.6T046I015SSQ07 615 004 094 8 7/16 hex socket Quick chuck 15 11.1 1.5 670 320 12.6 1.2 2.6Used with a CS4700 or CS5000 ControllerFor the 20-45 models, an aluminum reaction bar and nut kit(A066SIL2R/615 004 138 5) is included.For the 60-170 Nm models, a long steel reaction bar and nut kit(A066SIL3R/615 004 083 4) is included.Short lever kit (483066-S/615 005 285 0)is standard.66 Series In-line Electric Nutrunners - CS20 to 170 Nm (14.7 to 125 ft.lb)**Change the detent from pin to ball or thru-hole by substituting a B or a Tfor the P in the Model No.Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgfm rpm mm in. kg lb.T066I020SSP3 615 004 049 1 3/8 square drive Pin 20 14.7 2.0 2290 376 14.8 1.7 3.7T066I020SSQ04 615 004 094 9 1/4 hex socket Quick chuck 20 14.7 2.0 2290 376 14.8 1.7 3.7T066I020SSQ07 615 004 095 0 7/16 hex socket Quick chuck 20 14.7 2.0 2290 376 14.8 1.7 3.7T066I030SSP3 615 004 050 0 3/8 square drive Pin 30 22.1 3.1 1485 376 14.8 1.7 3.7T066I030SSQ04 615 004 095 1 1/4 hex socket Quick chuck 30 22.1 3.1 1485 376 14.8 1.7 3.7T066I030SSQ07 615 004 095 2 7/16 hex socket Quick chuck 30 22.1 3.1 1485 376 14.8 1.7 3.7T066I035SSP3 615 004 050 4 3/8 square drive Pin 35 25.8 3.6 1177 376 14.8 1.7 3.7T066I035SSQ04 615 004 095 3 1/4 hex socket Quick chuck 35 25.8 3.6 1177 376 14.8 1.7 3.7T066I035SSQ07 615 004 095 4 7/16 hex socket Quick chuck 35 25.8 3.6 1177 376 14.8 1.7 3.7T066I045SSP3 615 004 051 5 3/8 square drive Pin 45 33.2 4.6 937 376 14.8 1.7 3.7T066I045SSQ04 615 004 095 5 1/4 hex socket Quick chuck 45 33.2 4.6 937 376 14.8 1.7 3.7T066I045SSQ07 615 004 051 8 7/16 hex socket Quick chuck 45 33.2 4.6 937 376 14.8 1.7 3.7T066I060SSP4 615 004 052 4 1/2 square drive Pin 60 44.2 6.1 630 403 15.9 2.2 4.9T066I075SSP4 615 004 053 2 1/2 square drive Pin 75 55.3 7.6 424 403 15.9 2.2 4.9T066I100SSP4 615 004 053 9 1/2 square drive Pin 100 73.8 10.2 345 403 15.9 2.2 4.9T066I150SSP4 615 004 054 7 1/2 square drive Pin 150 110.6 15.3 208 403 15.9 2.2 4.9T066I170SSP4 615 004 054 9 1/2 square drive Pin 170 125.3 17.3 208 403 15.9 2.2 4.937

46 Series Fixtured Angle Head Electric Spindles - CS15 to 24 Nm (11.1 to 17.7 ft.lb)Used with a CS4746 or CS5000 ControllerA mounting plate kit (A066SRAP/615 004 083 5) is includedfor all models.No reaction bar is used.Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgfm rpm mm in. kg lb.T046A015MHP2 615 004 093 5 1/4 square drive Pin 15 11.1 1.5 680 353 13.9 1.4 3.1T046A015MHP3 615 004 022 1 3/8 square drive Pin 15 11.1 1.5 680 353 13.9 1.4 3.1T046A019MHP2 615 004 093 6 1/4 square drive Pin 19 14.0 1.9 540 353 13.9 1.4 3.1T046A019MHP3 615 004 022 4 3/8 square drive Pin 19 14.0 1.9 540 353 13.9 1.4 3.1T046A024MHP2 615 004 093 7 1/4 square drive Pin 24 17.7 2.4 430 353 13.9 1.4 3.1T046A024MHP3 615 004 093 8 3/8 square drive Pin 24 17.7 2.4 430 353 13.9 1.4 3.166 Series Fixtured Angle Head Electric Spindles - CS26 to 65 Nm (19.2 to 166 ft.lb)Used with a CS4700 or CS5000 ControllerFor 26-65 Nm models, a mounting plate kit(A066SRAP/615 004 083 5) is included.For 126-226 Nm models, a hevay duty mounting plate kit(A066SRAPH/615 004 104 2) is included.No reaction bar is used on 66 Series Angle Head nutrunners.Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgfm rpm mm in. kg lb.T066A026MHP2 615 004 093 9 1/4 square drive Pin 26 19.2 2.7 1526 383 15.1 1.7 3.9T066A026MHP3 615 004 094 0 3/8 square drive Pin 26 19.2 2.7 1526 383 15.1 1.7 3.9T066A041MHP3 615 004 026 4 3/8 square drive Pin 41 30.2 4.2 990 409 16.1 1.8 4.0T066A041MHP4 615 004 094 1 1/2 square drive Pin 41 30.2 4.2 990 409 16.1 1.8 4.0T066A050MHP3 615 004 027 2 3/8 square drive Pin 50 36.9 5.1 765 409 16.1 1.8 4.0T066A050MHP4 615 004 094 2 1/2 square drive Pin 50 36.9 5.1 765 409 16.1 1.8 4.0T066A065MHP3 615 004 028 5 3/8 square drive Pin 65 47.9 6.6 610 427 16.8 2.0 4.5T066A065MHP4 615 004 094 3 1/2 square drive Pin 65 47.9 6.6 610 427 16.8 2.0 4.5T066A100MHP4 615 004 103 6 1/2 square drive Pin 100 73.7 10.2 280 517 20.2 2.2 7.4T066A126MHP4 615 004 031 4 1/2 square drive Pin 126 92.9 12.8 235 543 21.3 4.0 8.9T066A156MHP4 615 004 094 4 1/2 square drive Pin 156 115.1 15.9 200 543 21.3 4.0 8.9T066A156MHP6 615 004 094 5 3/4 square drive Pin 156 115.1 15.9 200 543 21.3 4.0 8.9T066A186MHP6 615 004 032 6 3/4 square drive Pin 186 137.1 18.9 160 543 21.3 4.0 8.9T066A226MHP6 615 004 033 3 3/4 square drive Pin 226 166.6 23.0 154 543 21.3 4.0 8.9** Weight excludes mounting plate. **Change the detent from pin to ball or thru-hole by substituting a B or a Tfor the P in the Model No.38

46 Series Fixtured In-line Electric Spindles - CS5 to 15 Nm (3.7 to 11.1 ft.lb)Used with a CS4746 or CS5000 ControllerAmounting plate kit (A066SIL2P/615 004 083 2) is included.Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgrm rpm mm in. kg lb.T046I005MSP2 615 004 044 4 1/4 square drive Pin 5 3.7 0.5 1630 320 12.6 1.1 2.4T046I005MSP3 615 004 044 5 3/8 square drive Pin 5 3.7 0.5 1630 320 12.6 1.1 2.4T046I005MSQ04 615 004 044 6 1/4 hex socket Quick chuck 5 3.7 0.5 1630 320 12.6 1.1 2.4T046I005MSQ07 615 004 095 6 7/16 hex socket Quick chuck 5 3.7 0.5 1630 320 12.6 1.1 2.4T046I010MSP2 615 004 095 7 1/4 square drive Pin 10 7.4 1.0 1050 320 12.6 1.1 2.4T046I010MSP3 615 004 045 5 3/8 square drive Pin 10 7.4 1.0 1050 320 12.6 1.1 2.4T046I010MSQ04 615 004 045 7 1/4 hex socket Quick chuck 10 7.4 1.0 1050 320 12.6 1.1 2.4T046I010MSQ07 615 004 095 8 7/16 hex socket Quick chuck 10 7.4 1.0 1050 320 12.6 1.1 2.4T046I015MSP2 615 004 095 9 1/4 square drive Pin 15 11.1 1.5 670 320 12.6 1.1 2.4T046I015MSP3 615 004 047 1 3/8 square drive Pin 15 11.1 1.5 670 320 12.6 1.1 2.4T046I015MSQ04 615 004 047 2 1/4 hex socket Quick chuck 15 11.1 1.5 670 320 12.6 1.1 2.4T046I015MSQ07 615 004 096 0 7/16 hex socket Quick chuck 15 11.1 1.5 670 320 12.6 1.1 2.466 Series Fixtured In-line Electric Spindles - CS20 to 170 Nm (14.7 to 125 ft.lb)Used with a CS4700 or CS5000 ControllerFor the 20-45 models a mounting plate kit (A066SIL2P/615 004 083 2) is included.For the 60-170 Nm models a mounting plate kit (A066SIL3P/615 004 083 3) is included.Accessories: see pages 40–43MODEL PART OUTPUT DETENT TORQUE ROTATIONAL LENGTH WEIGHTNUMBER DRIVE RANGE SPEED ATin. type Nm ft.lb kgfm rpm mm in. kg lb.T066I020MSP3 615 004 048 7 3/8 square drive Pin 20 14.7 2.0 2290 376 14.8 1.6 3.6T066I020MSQ04 615 004 048 8 1/4 hex socket Quick chuck 20 14.7 2.0 2290 376 14.8 1.6 3.6T066I020MSQ07 615 004 096 1 7/16 hex socket Quick chuck 20 14.7 2.0 2290 376 14.8 1.6 3.6T066I030MSP3 615 004 049 8 3/8 square drive Pin 30 22.1 3.1 1485 376 14.8 1.6 3.6T066I030MSQ04 615 004 096 2 1/4 hex socket Quick chuck 30 22.1 3.1 1485 376 14.8 1.6 3.6T066I030MSQ07 615 004 096 3 7/16 hex socket Quick chuck 30 22.1 3.1 1485 376 14.8 1.6 3.6T066I035MSP3 615 004 050 3 3/8 square drive Pin 35 25.8 3.6 1177 376 14.8 1.6 3.6T066I035MSQ04 615 004 096 4 1/4 hex socket Quick chuck 35 25.8 3.6 1177 376 14.8 1.6 3.6T066I035MSQ07 615 004 096 5 7/16 hex socket Quick chuck 35 25.8 3.6 1177 376 14.8 1.6 3.6T066I045MSP3 615 004 051 1 3/8 square drive Pin 45 33.2 4.6 937 376 14.8 1.6 3.6T066I045MSQ04 615 004 051 3 1/4 hex socket Quick chuck 45 33.2 4.6 937 376 14.8 1.6 3.6T066I045MSQ07 615 004 096 6 7/16 hex socket Quick chuck 45 33.2 4.6 937 376 14.8 1.6 3.6T066I060MSP4 615 004 052 2 1/2 square drive Pin 60 44.2 6.1 630 403 15.9 2.1 4.8T066I075MSP4 615 004 053 0 1/2 square drive Pin 75 55.3 7.6 424 403 15.9 2.1 4.8T066I100MSP4 615 004 053 7 1/2 square drive Pin 100 73.8 10.2 345 403 15.9 2.1 4.8T066I150MSP4 615 004 054 4 1/2 square drive Pin 150 110.6 15.3 208 403 15.9 2.1 4.8T066I170MSP4 615 004 096 7 1/2 square drive Pin 170 125.3 17.3 208 403 15.9 2.2 4.9*RPM is ±10%, depending on the application.** Weight excludes mounting plate.**Change the detent from pin to ball or thru-hole by substituting a B or a Tfor the P in the Part No.Contact customer Service for availability and lead times.39

AccessoriesHow to Set the Torque Reaction BarThe Torque Reaction Bar is mechanicallysecured in place and can be adjusted easilyto different positions.A. Position the torque bar after bendingit to the desired angle.B. Brace the bar against the workopposite to the direction of spindlerotation. See the diagram.Torque ReactionOpposes SpindleRotation12453OPTIONAL ACCESSORIESMODELPARTTOOL REACTION BARS LENGTH WEIGHT NUMBER NUMBER1. Reaction Bar Kit – Aluminum for 46 and 66 Series 273 mm /10.75 in 12 kg / .26 lb A066SIL2R 615 004 138 5In-line and Pistol Grip tools – 5 to 45 Nm2. Reaction Bar – Steel, optional, for 46 and 66 Series 273 mm /10.75 in 12 kg / .26 lb 49-5803-8105 615 005 380 1In-line and Pistol Grip tools – 5 to 45 Nm3. Reaction Bar Kit – Steel, for 66 Series In-line tools, 635 mm / 25 in 1.37 kg / 3 lb A066SIL3R 615 004 083 460 to170 Nm, includes nut4. Locknut for reaction bars and mounting plates,49-40-35308 615 005 347 3— —66 Series In-line tools, 60 to 170 Nm5. Locknut for reaction bars and mounting plates, 46/6649-5803-8106 615 005 380 2— —Series In-line tools, 5 to 45 Nm67 89 10MODELPARTTOOL SUSPENSION BAILS DIMENSIONS WEIGHT NUMBER NUMBER6. Horizontal Bail for 46/66 Series 108 mm / 4.25 in long .29 kg / .64 lb A066BS 615 004 074 97. Horizontal Bail, swivel, 46/66 Series 152 mm / 6 in long .65 kg / 1.4 lb A066BSS 615 004 075 18. Horizontal Bail, heavy duty, 46/66 Series 152 mm / 6 in long .65 kg / 1.4 lb A066BS-37316 615 004 075 09. Vertical Bail for ALL 46/66 Series tools, 108 mm / 4.25 in .02 kg / .04 lb 49-70-24566 615 005 382 5except Pistol Grip models10. Bail Assembly, 46/66 Series 43.94 x 49.78 x 46.99 mm / .045 kg / .1 lb A046BS-P37694 615 004 074 6Pistol Grip tools1.73 x 1.96 x 1.85 in11161214/14A131517MODELPARTTOOL MOUNTING PLATES DIMENSIONS WEIGHT NUMBER NUMBER11. Reaction Mounting Plate Kit for 46 and 66 Series 71 x 56 x 9.7 mm/ .27 kg/.6 lb A066SIL2P 615 004 083 2In-line and Pistol Grip tools, 5 to 45 Nm, handheld 2.8 x 2.2 x .38 in12. Reaction Mounting Plate Kit for 66 Series In-line 71 x 56 x 9.7 mm / .2 kg/.5 lb A066SIL3P 615 004 083 3tools, 60 to 170 Nm, handheld or fixtured2.8 x 2.2 x .38 in13. Reaction Mounting Plate Kit, optional, for 66 76 x 51 x 11 mm / .21 kg/.46 lb 49-40-35054 615 005 344 5Series In-line tools - 60 to 170 Nm, fixtured only 3 x 2 x .43 in14. Reaction Mounting Plate for all 46 and 66 89 x 51 x 13 mm / .2 kg/.5 lb A066SRAP 615 004 083 5Series Right Angle tools, 15 to 226 Nm3.5 x 2 x .5 in14A. Reaction Mounting Plate Kit, heavy duty 101 x 54 x 19 mm / .34 kg/.75 lb A066SRAPH 615 004 104 2for 126-226 Nm 66 Series Right Angle tools.4.0 x 2.1 x .75 in15. Reaction Mounting Plate, optional, for 46 and 66 61 x 44 x 9.7 mm / .16 kg/.36 lb 49-5711-7103 615 005 378 7Series In-line and Pistol Grip tools, 5 to 45 Nm2.4 x 1.8 x .38 in16. Locknut for reaction bars and mounting plates,49-40-35308 615 005 345 5— —66 Series In-line tools, 60 to 170 Nm17. Locknut for reaction bars and mounting plates,49-5803-8106 615 005 380 2— —46 and 64/66 Series In-line tools, 4 to 45 Nm40