Technoply Data - Install

Technoply Data - Install

Technoply Data - Install

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

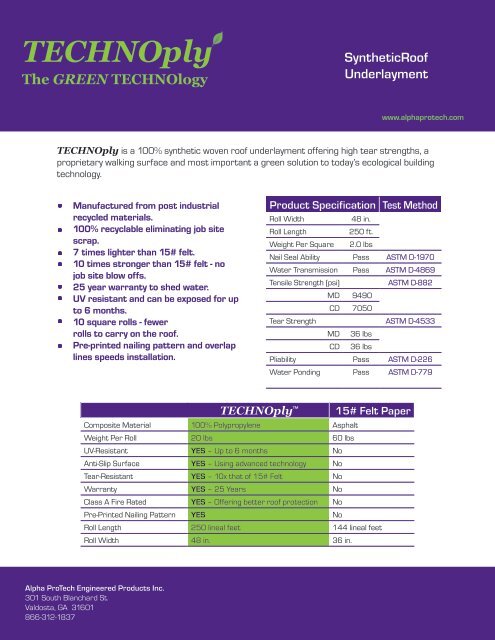

TECHNOplyThe GREEN TECHNOlogySyntheticRoofUnderlaymentwww.alphaprotech.comTECHNOply is a 100% synthetic woven roof underlayment offering high tear strengths, aproprietary walking surface and most important a green solution to today’s ecological buildingtechnology.Manufactured from post industrialrecycled materials.100% recyclable eliminating job sitescrap.7 times lighter than 15# felt.10 times stronger than 15# felt - nojob site blow offs.25 year warranty to shed water.UV resistant and can be exposed for upto 6 months.10 square rolls - fewerrolls to carry on the roof.Pre-printed nailing pattern and overlaplines speeds installation.Product Specification Test MethodRoll Width48 in.Roll Length250 ft.Weight Roll Per Width Square 2.0 lbs48 in.Nail Seal Roll Ability Length Pass250 ft. ASTM D-1970Water Weight Transmission Per SquarePass2.8 lbs ASTM D-4869Tensile Nail Strength Seal Ability (psi) PassASTM ASTM D-882 D-1970Water TransmissionMD 9490Pass ASTM D-4869Tensile StrengthCD 7050ASTM D-828Tear StrengthMD 96 lbsASTM D-4533MDCD36 lbs116 lbsTear StrengthCD 36 lbsASTM D-4533PliabilityWater PondingMDPass58 lbsASTM D-226CDPass77 lbsASTM D-779Pliability Pass ASTM D-226Water Ponding Pass ASTM D-779Product Specification Test MethodTECHNOply TECHNOply 15# 30# Felt PaperComposite MaterialComposite Material100% Polypropylene100% PolypropyleneAsphaltAsphaltWeight Per RollWeight Per Roll20 lbs20 lbs60 lbs60 lbsUV-ResistantUV-ResistantYES – Up to 6 monthsYES Up to monthsNoNoAnti-Slip SurfaceAnti-Slip SurfaceYES – Using advanced technologyYES Using advanced technologyNoNoTear-ResistantTear-ResistantYES – 10x that of 15# FeltYES 20x that of 30# FeltNoNoWarrantyWarrantyYES – 25 YearsYES 25 YearsNoNoClass A Fire RatedClass Fire RatedYES – Offering better roof protectionYES Offering better roof protectionNoNoPre-Printed Nailing PatternPre-Printed Nailing PatternYESYESNoNoRoll LengthRoll Length250 lineal feet250 lineal feet144 lineal feet72 lineal feetRoll WidthRoll Width48 in.48 in.36 in.36 in.Alpha ProTech Engineered Products Inc.301 South Blanchard St.Valdosta, GA 31601866-312-1837

TECHNOplyThe GREEN TECHNOlogySyntheticRoofUnderlaymentwww.alphaprotech.com1. Please insure the roof deck is clean, smooth, and dry prior to beginning installation.2. TECHNOply is laid out horizontally (parallel) to the eave with the printed side up, with 3” (76mm) horizontal laps and 6” (152 mm) vertical laps. On roof slopes less than 3:12,Product Specification Test MethodTECHNOply should be lapped at 24” (61 cm) or to center line as printed, over theRoll Width48 in.underlying course.Roll Length250 ft.Weight Roll Per Width Square 2.0 lbs48 in.3. TECHNOply should be attached to the roof using plastic cap roofing nails or staples having aNail Seal Roll Ability Length Pass250 ft. ASTM D-19701 (25mm) diameter plastic cap. Spacing should be at 6” (15 cm) on center at both horizontalWater Weight Transmission Per SquarePass2.8 lbsand vertical caps for normal wind zones or high wind zones and coastal areas. InASTMall casesD-4869fastenat 12” (30 cm) from end laps of the roll in the field of the roof. The pre-printed nail patternTensile Nail Strength Seal Ability (psi) PassASTM ASTM D-882 D-1970Water TransmissionMD 9490Pass ASTM D-4869spacing described above applies to normal as well as high wind conditions.Tensile StrengthCD 7050ASTM D-8284. Tear StrengthMD 96 lbsThe use of staples, 3/8” head diameter EG smooth shank roofing nails or 12 guage ASTM corrosionD-4533resistant ring shank nail having a 1” diameter cap or ting tag MDto attachCD36 lbs116TECHNOplylbs ispermitted only when the final roof covering is to be installed Tear Strength immediately CD 36 afterward. lbsASTM PneumaticD-4533staple guns are not recommended. PliabilityMDPass58 lbsASTM D-226Water PondingCDPass77 lbsASTM D-7795. Where seams and joints require the use of sealant or Pliability adhesives, use a high Pass quality, low ASTM D-226solvent, asbestos free, plastic roofing cement meeting Water ASTM Ponding D-4586 Type Pass 1, Federal ASTM Spec D-779SS-153 Type 1 and consult manufacturer’s installation instructions.Product Specification Test MethodTECHNOply TECHNOply 30# Felt PaperComposite Material 100% Polypropylene Asphalt6. Depending Composite Material on roof pitch and 100% surface Polypropylene conditions, it is recommended Asphalt that roof jacks,Weight Per Roll 20 lbs 60 lbstoe-boards Weight Per Roll or a storage platform 20 lbsbe secured to support roofing materials 60 lbs placed on roof.UV-Resistant YES – Up to 6 months NoUV-Resistant YES Up to months No7.Anti-Slip Surface YES – Using advanced technology NoTECHNOply Anti-Slip Surface is not designed YES for indefinite Using advanced outdoor technology exposure, and it Nois recommended thatinstallation Tear-Resistant YES – 10x that of 30# FeltTear-Resistant of the final roof covering YES 20x take that place of 30# within Felt 6 months. NoNoWarrantyWarrantyYES – 25 YearsYES 25 YearsNoNo8. As Class A Fire Rated YES – Offering better roof protection NoClass with Fire any Rated roofing product, YES always Offering be careful better to roof observe protection safe roofing No codes and practicesas Pre-Printed Nailing Pattern YES NoPre-Printed by OSHA Nailing Regulation PatternStandard YES – 29CFR and Fall Protection Systems No Criteria andPractices Roll LengthRoll Length– 1926.502. 250 lineal feet250 lineal feet72 lineal feet72 lineal feetRoll WidthRoll Width48 in.48 in.36 in.36 in.LIT EPB 024 01/12Alpha ProTech Engineered Products Inc.301 South Blanchard St.Valdosta, GA 31601866-312-1837