Overload Protection Devices English

Overload Protection Devices English

Overload Protection Devices English

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

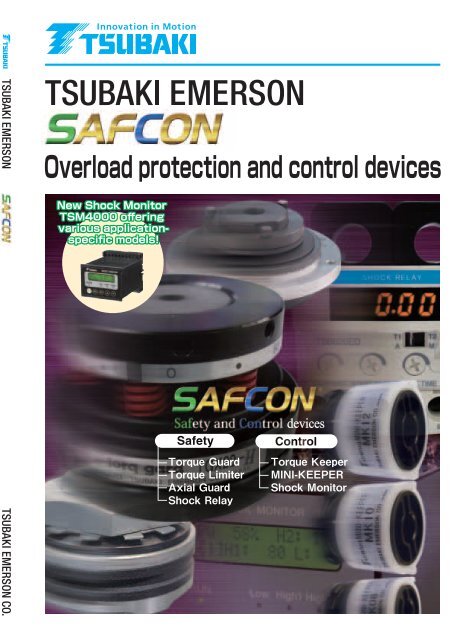

devices

devices6

Unit mmModel No.1 MaximumSet torque range MaximumRoughFSpring color bore A B C D ENm{kfm}r/minboreP.C.DdiameterdiameterG H ITGB08-L 0.29 1.47 {0.030.15}YellowTGB08-M 0.78 2.16 {0.080.22} 1200 Blue 5 8 39 6.5 5 20 40 34 26 33 TGB08-H 1.17 2.94 {0.120.3} OrangeTGB12-L 0.68 2.94 {0.070.3}YellowTGB12-M 1.96 4.9 { 0.20.5} 1000 Blue 6 12 47 8 6 23.5 48 40 32 40 TGB12-H 2.94 5.88 { 0.30.6}OrangeTGB16-L 1.47 4.9 {0.150.5}YellowTGB16-M 2.94 7.84 { 0.30.8} 900 Blue 7 16 56 8.5 8 27.7 58 50 39 48 TGB16-H 5.8811.76 { 0.61.2}OrangeTGB20-H 9.8 44 { 1.04.5} 700 Orange 8 20 47 7.5 5.7 25 90 78 62 82 54TGB30-L 20 54 { 2.05.5}Yellow500TGB30-H 54 167 { 5.517}Orange12 30 60 9.5 7 33 113 100 82 106 75TGB50-L 69 147 { 7.015}YellowTGB50-M 137 412 { 14 42} 300 Blue 22 50 81 14.5 8.5 44.8 160 142 122 150 116.7TGB50-H 196 539 { 2055}OrangeModel No. J K L M NO screw P screw Q screwSnap Massdiameter diameter diameterInertia moment GD 2S T W X ring k10 -2 km 2 10 -2 kfm 2pitch length lengthsize Y 2 2 2TGB08-LTGB08-MTGB08-HTGB12-LTGB12-MTGB12-HTGB16-LTGB16-MTGB16-HTGB20-H29.53545481520253230M 3M 4M 4M 53334M151M201M251.5M321.5M3 4M4 6M5 6M5 6M4 820.91.01.21.852320.140.240.440.90.00250.00650.01800.0580.0100.0260.0720.23TGB30-LTGB30-H65 45 42.5 M 6 6 M451.5 M5 6 M410 2 2 6 2.5 45 2.0 0.20 0.79TGB50-LTGB50-MTGB50-H98 75 70 M 8 6 M752 M510 M414 3 2.7 8 3.5 75 5.9 1.21 4.84 17

UnitmmModel No.1 MaximumSet torque range MaximumRoughE FSpring color bore A B C DNm{kf-m}r/minboreh7 P.C.DdiameterdiameterG H ITGB 70-H 2941080 { 30110} 160 Orange 32 70 110 14.5 12 68.5 220 200 170 205 166TGB 90-L 4411320 { 45135}Yellow120TGB 90-H 9313140 { 95320}Orange42 90 157 25 22 88.6 295 265 236 290 213TGB110-L 6861960 { 70200}Yellow100TGB110-H 15705100 {160520}Orange52 110 195 30 25 105 355 325 287 345 278TGB130-L 11763038 {120310}Yellow80TGB130-H 26507154 {270730}Orange60 130 230 35 27 130 400 360 319 390 316O screw P screw Q screwModel No. J K L M N diameterdiameterdiameterS Tpitch length lengthMass Inertia moment GD 2k 10 -2 km 2 10 -2 kfm 22 2 2TGB 70-H 157 110 106 M10 6 M110 2 M 5 10 M10 28 3 3.3 110 17.0 6.3 25.2TGB 90-LTGB 90-HTGB110-LTGB110-HTGB130-LTGB130-HU screwdiameterlength203 130 124 M12 8 M130 2 M10 20 M16 35 5.5 5.4 M8 16 130 37.5 33.8 135266 160 155 M16 6 M160 3 M12 20 M16 45 7 6 M10 20 160 69.6 91 364304 190 184 M16 8 M190 3 M16 30 M 20 60 7 6.6 M12 24 190 102 167 668 TGB 50 - H -40 J-25Snapringsize YTGB 50 - H18

Set torque rangeModel No.Nm{kf-m}TGB08-LC 0.291.47 {0.030.15}Maximumr/minSpring colorYellowTGB08-MC 0.782.16 {0.080.22} 1200 BlueTGB08-HC 1.172.94 {0.120.3} OrangeTGB12-LC 0.682.94 {0.070.3}TGB12-MC 1.964.9 { 0.20.5}TGB12-HC 2.945.88 { 0.30.6}TGB16-LC 1.474.9 {0.150.5}TGB16-MC 2.947.84 { 0.30.8}TGB16-HC5.8811.76 { 0.61.2}A B C D E F G H I5 8 15 80 20.6 39 19 44.5 24 331000 Blue 6 12 20 88 19.9 47 23.5 53.6 32 40900 Blue 7 16 25 112 27 56 28.3 64.3 38 48TGB20-HC 9.8 44 { 1.04.5} 700 Orange 8 20 12.5 42 76 25 47 25 32.6 7.4 117.4 63 82TGB30-LC 2054 { 2.05.5}TGB30-HC 54167 { 5.517}TGB50-LC 69147 { 7.015}TGB50-MC 137412 { 1442}TGB50-HC 196539 { 2055}TGB08-LCTGB08-MCTGB08-HCTGB12-LCTGB12-MCTGB12-HCTGB16-LCTGB16-MCTGB16-HCYellow500 12 30 18 48 93 28 60 33 40.5 9.7 146.7 73 106OrangeYellow300 Blue 22 50 18 55 126 40 81 44.8 51.0 11.6 200.3 83 150Couplingmodel No.or sprocketMassInertia moment GDk210 -2 km 2 10 -2 kfm 22 2 229.5 15 M3123 M151 7.2 13.2 0.9 L075A 0.235 0.0050 0.02037 20 M4163 M201 7.9 13.2 1 L090A 0.38 0.0123 0.04947 25 M4203 M251.5 10.2 18.8 1.2 L100A 0.673 0.0324 0.129TGB20-HC 54 48 30 M5124 M321.5 M4 8 M5 6 4 2 1.8 5 2 RS40-26 2.5 0.313 1.25TGB30-LCTGB30-HCTGB50-LCTGB50-MCTGB50-HCYellowOrangeYellowOrangeOrangeTorque Guard CouplingRough bore Maximum bore Rough bore Maximum borediameter1 diameter diameter1 diameterO screw P screw Q screwMNNo.Model No. J K Ldiameter diameter diameterR S T W Xof pieces pitch length length75 65 42.5 M6166 M451.5 M410 M5 6 5 2 2 6 2.5 RS50-26 4.8 0.948 3.79116.7 98 70 M8206 M752 M414 M510 5 3 2.7 8 3.5 RS60-30 12.2 4.43 17.7Unitmm 19

UnitmmModel No.Set torque range MaximumTorque Guard CouplingSpring colorNm{kf-m}r/minRough bore Maximum bore Rough bore Maximum borediameter diameter diameter diameterA B C D E F G H ITGB 70-HC 2941080 { 30110} 160 Orange 32 70 28 75 165 45 110 68.5 64.8 15.3 283.2 107 205TGB 90-LC 4411320 { 45135}Yellow120TGB 90-HC 9313140 { 95320}Orange42 90 33 103 242 80 157 88.6 78.5 18.2 394.4 147 290TGB110-LC 6861960 { 70200}Yellow100TGB110-HC 15705100 {160520}Orange52 110 38 113 303 100 195 105 99.2 21.9 473.4 157 345TGB130-LC 11803038 {120310}Yellow80TGB130-HC 26507154 {270730}Orange60 130 53 145 365 120 230 130 127.3 29.1 534.2 197 390O screw P screw Q screwModel No. J K LMNNo. diameter diameter diameterR S Tof pieces pitch length lengthTGB 70-HC 166 157 106 M10256 M1102 M1028 M 510 10 3 3.3 RS80-32 32.0 22.43 89.7TGB 90-LCTGB 90-HCTGB110-LCTGB110-HCTGB130-LCTGB130-HCU screwdiameterlengthMassInertia moment GDSprocket k210 -2 km 2 10 -2 kfm 21 1 1213 203 124 M12358 M1302 M1635 M1020 5 5.5 5.4 M 816 RS100-36 71.1 117.32 469.29278 266 155 M16456 M1603 M1645 M1220 8 7 6 M1020 RS120-36 130.5 314.15 1256.61316 304 184 M16508 M1903 M2060 M1630 15 7 6.6 M1224 RS160-30 202.3 632.66 2530.63 TGB 50 - L C - T35 JC45 E -10TGB 50 - M C20

UnitmmModel No.Set torque rangeNm{kf-m}Maximumr/minSprocketspecificationsSpring colorRoughborediameterMaximumborediameterA B C D EFP.C.DG H ITGB20-H- 9.844 { 1.04.5} 700TGB30-L- 2054 { 2.05.5}TGB30-H- 54167 { 5.517}500TGB50-L- 69147 { 7.015}TGB50-M- 137412 { 1442} 300TGB50-H- 196539 { 2055}TGB70-H- 2941080{ 30110} 160RS40-22T96 89.24Orange 8 20 47 5.9 7.2 25RS40-27T 116 109.462 82 54RS60-19T Yellow126 115.7412 30 60 4.8 11.6 33RS60-24T Orange156 145.9582 106 75RS80-20T Yellow176 162.37Blue 22 50 81 8.42 14.5 44.8122 150 116.7RS80-25TOrange216 202.66RS100-22TOrange 32 70 110 8.9 17.5 68.5 240 223.10RS100-26T281 263.40170 205 166O screw P screw Q screwModel No. J K L diameter diameter diameter S T W Xpitch length lengthTGB20-H- 48 32 30 M 32 1.5 M5 6 M 4 8 2 1.8TGB30-L-TGB30-H-TGB50-L-TGB50-M-TGB50-H-TGB70-H-65 45 42.5 M 45 1.5 M5 6 M 4 10 2 298 75 70 M 75 2 M5 10 M 4 14 3 2.7157110106M110 2M5 10M10 2833.35 2 326 2.5 458 3.5Snapringsize Y75110MasskInertia moment10 -2 km 2 GD 210 -2 kfm 20.94 0.255 0.0641.15 0.486 0.1212.21 1.06 0.2642.78 2.07 0.5176.35 6.10 1.527.66 10.7 2.6817.8 29.47.3519.9 42.5 10.6 TGB 50 - H - 08025 - 50 J - 30 21Model No. Sprocket specifications Indication of Model No.TGB20RS40-22T04022RS40-27T04027TGB30RS60-19T06019RS60-24T06024TGB50RS80-20T08020RS80-25T08025TGB70RS100-22T10022RS100-26T10026

Torque Guard TGBUnitmmFinished bore dimensionsTorque Guard Model No. Torque Guard Coupling Model No.Torque Guard side Coupling side (Torque Guard Coupling only)TGB20 TGB20-C9,10,11,12,14,15,16,17,18,19,2014,15,16,17,18,19,20,22,24,25,28,29,30,32,33,35,36,38,40,42TGB30TGB30-C14,15,16,17,18,19,20,22,24,25,28,29,3020,22,24,25,28,29,30,32,33,35,36,38,40,42,43,45,46,48TGB50TGB50-C24,25,28,29,30,32,33,35,36,38,40,42,43,45,46,48,5020,22,24,25,28,29,30,32,33,35,36,38,40,42,43,45,46,48,50,52,55TGB70TGB70-C35,36,38,40,42,43,45,46,48,50,52,55,56,57,60,63,65,7030,32,33,35,36,38,40,42,43,45,46,48,50,52,55,56,57,60,63,65,70,71,75Delivery timeEx.-Japan 4 weeks by seaTGB30 - H - 30JTGB50 - MC - T40JC50 JTorque GuardModel No.Torque Guard TGBTorque GuardCoupling ModelNo.Torque Guard SideSet screwSet screw positionL1 Coupling Side(Torque Guard Coupling only)Set screwSet screw positionL2TGB20 TGB20-C 2-M404 4 2-M404 08TGB30 TGB30-C 2-M505 5 2-M505 10TGB50 TGB50-C 2-M606 6 2-M606 12TGB70 TGB70-C 2-M812 6 2-M812 15 Bore diameterChamfer dimensions25 and below C0.550 and below C1.051 and above C1.522

Service factorOperating conditions1.25 1.50 23

Model No.TGB08TGB08-CTGB12TGB12-CBore diameter(d)6 and above8 and below7 and aboveless than1010 and aboveless than1212Bore length(L, mm)20 mm20 mm30 mmTotal lengthCounterborediameter(D)1115N/ATGB16TGB16-C8 and aboveless than1010 and aboveless than1212 and above16 and below20 mm30 mmTotal length15N/A 25

Unit: mmModel No. Spigot diameter Model No. Spigot diameterTGB08-L,M,H 40h8 TGB50-L,M,H 160h7TGB12-L,M,H 48h8 TGB70-H 220h7TGB16-L,M,H 58h8 TGB90-L,H 295h7TGB20-H 90h7 TGB110-L,H 355h7TGB30-L,H 113h7 TGB130-L,H 400h7 Unit: mmModel No. Bolt screw length Model No. Bolt screw lengthTGB08-L,M,H 4 TGB50-L,M,H 9 11TGB12-L,M,H 5 TGB70-H 13 15TGB16-L,M,H 7 TGB90-L,H 23 25TGB20-H 6 7 TGB110-L,H 26 28TGB30-L,H 8 10 TGB130-L,H 28 30 Series nameATGB08-L,M,H 34TGB12-L,M,H 40TGB16-L,M,H 50TGB20-HTGB30-L,HTGB50-L,M,HTGB70-HTGB90-L,HTGB110-L,HTGB130-L,H78100142200265325Drive member finishing dimensionsB C3 3.43 4.53 4.54 5.56 6.66 9.06 118 13.56 17.5D E F40H748H758H790H7113H7160H7220H7295H8355H828 333 341 364 384 4124 5172 5240 5292 5360 8 17.5 400H8 325 5 Unit: mmNominal screw diameter 3 4 5 6 8 10 12 16 Bolt bore diameter 3.4 4.5 5.5 6.6 9 11 13.5 17.526

SprocketModel No.TGB sizeTGB08-L,M,HRS25 RS35 RS41 RS40 RS50 RS60 RS80 RS100 RS120 RS140 RS16024171414121310TGB12-L,M,H28201616131311TGB16-L,M,H322318181514TGB20-H48342626221915131311TGB30-L,H604132322622181513TGB50-L,M,H574345433530242017TGB70-H5860584847403231262422TGB90-L,H62524033282522TGB110-L,H74624839332926TGB130-L,H83705343373224 Exxon MobilShowa Shell Japan-Energy Idemitsu Nippon Oil Corporation Cosmo OilMobilux EP2AlvaniaEP Grease 2Rizonics EP 2DaphnyEponex GreaseEP 2Epinoc Grease AP(N)2Cosmo Dynamax EPGrease 2 Hexagon socket head screw Tightening torque Nm{kfcm}M53.8 {38.7}M816 {163} 27

AC typeDC typeModel no. TGS8 TGS8DPower Rating AC24 240V DC12 24Vsupplyvoltage Range to be used AC20 264V50/60Hz DC10 30VCurrent consumption Less than 1.7mA (at AC200V) Less than 13mAControl output (opening and closing capacity) 5 100mA Max. 200mAIndicator lampOperation indicatorAmbient operating temperature-25 +70°C (does not freeze)Ambient operating humidity35 95%RHOutput formNC ( When not detecting the sensor plate,output opening and closing state is displayed)Operation mode Open collectorInsulation resistance More than 50M (at DC50V megger) In between the energized part and the caseMassApprox. 45g (with 2m code)Residual voltage Refer to characteristic dataLess than 2.0V(load current 200mA/code length 2m) 28

TGB08-L,M,H 19.2 1.2TGB12-L,M,H 22.7 1.2TGB16-L,M,H 27.5 1.2Unit: mmAmount of sensorplate movement0.91.01.2 Unit: mmAmount of sensorplate movementTGB20-H 1.8 3.3 1.8TGB30-L,H 2.0 3.5 2.0TGB50-L,M,H 2.7 4.2 2.7 Unit: mmAmount of sensorplate movementTGB70-H 3.3 4.8 3.3TGB90-L,H 5.6 6.8 5.4TGB110-L,H 6.2 7.4 6.0TGB130-L,H 6.8 8.0 6.6 30

TGX20H15J5.0TGX50MCT352C5029.532

Torque GuardModel No.Set torque rangeNmkfmMax.r/minCoil springcolornumberTGX10-LTGX10-M1.7 6.4 0.17 0.655.4 15 0.55 1.5 1400Yellow3Red3TGX10-H 11 29 1.1 3.0 Red6TGX20-L 6.5 24 0.66 2.4Yellow6TGX20-M 13 34 1.3 3.5 1100 Red3TGX20-H 25 68 2.6 6.9 Red6TGX35-L 23 68 2.3 6.9Red5TGX35-M 43 98 4.4 10 800 Green5TGX35-H 87 1968.9 20 Green10TGX50-L 45 1184.6 12Red5TGX50-M 90 1969.2 20 600 Green5TGX50-H 176 39218 40 Green10TGX70-L 127 36313 37Red8TGX70-M 265 51027 52 480 Green8TGX70-H 392 78440 80 Green12RoughborediamterMax.borediameterABC amount ofmovementduring tripDEFmin. pointpositionGh7HPCDUnitmm7 15 53 22 1.4 7.5 6.6 +0.3 62 54 428.5 25 64 35 1.6 10 13.4 +0.7 86 74 6012 35 68 37.5 2.0 11 11.6 0.5 107 88 7018 55 92 54.8 2.6 15 19.5 0.3 148 130 10523 70 98 61 3.5 15 19.2 1.0 185 164 135ITorque GuardModel No.Kdiameter xpitchLdiameter xpitchM N O PQ screwdiamterlengthRSMasskInertia moment10 2 km 2 GD 210 2 kfm 2TGX10-LTGX10-M 0M25 x 1.5 0M30 x 1.5 056 058 161.8 4 M 46 5 10 0.75 0.0293 00.117TGX10-HTGX20-LTGX20-M 0M40 x 1.5 0M40 x 1.5 070 073 186.0 6 M 58 5 10 01.67 0.1340 00.535TGX20-HTGX35-LTGX35-M 0M50 x 1.5 0M55 x 1.5 088 091 107.0 6 M 67 6 10 02.51 0.3330 01.330TGX35-HTGX50-LTGX50-M 0M80 x 1.5 0M80 x 1.5 123 129 148.0 6 M 813 9 17 07.03 1.8300 07.320TGX50-HTGX70-LTGX70-M 0M100 x 2.0 0M100 x 2.0 148 153 185.0 6 M1013 10 18 11.40 4.8800 19.500TGX70-H 33

Torque GuardModel No.Set torque rangeNmkfmMax. r/minCoil springcolornumberTGX10-LCTGX10-MC1.5 5.40.15 0.554.6 130.47 1.3 700Yellow3Red3TGX10-HC 9.3 250.95 2.6 Red6TGX20-LC 5.2 190.53 1.9 Yellow6TGX20-MC 9.8 271.0 2.8 550 Red3TGX20-HC 21 552.1 5.6 Red6TGX35-LC 19 571.9 5.8Red5TGX35-MC 36 843.7 8.6 400 Green5TGX35-HC 74 1677.5 17 Green10TGX50-LC 40 984.1 10Red5TGX50-MC 81 1768.3 18 300 Green5TGX50-HC 167 34317 35 Green10TGX70-LC 118 32312 33Red8TGX70-MC 235 46124 47 240 Green8TGX70-HC 353 69636 71 Green12Rough borediameterTorque Guard Rough boreMax. bore diameter diameterCouplingMax. bore diameterA B CD min.pointpositionEPCDUnitmmFPCD G H7 15 7 19 69 24 1.3 0.3 62 42 33 258.5 25 8.5 35 84 24 1.6 0.3 89 66 55 3512 35 12 50 88 24 1.9 0.5 113 83 70 3518 55 18 60 114 34 2.4 0.9 158 112 92 4523 70 23 80 124 36 3.3 0.6 200 145 116 50Torque GuardModel No.IJKdiamter pitchL M N OP screwdiameter lengthQ screwdiameter lengthTGX10-LCTGX10-MC 2 42 M 301.5 56 74 74 M 418 M 410 5 10 01.07 0.0555 00.222 0.6 0.1 0.5TGX10-HCTGX20-LCTGX20-MC 3 46 M 401.5 70 98 98 M 520 M 512 5 10 02.38 0.2310 00.924 0.6 0.1 0.5TGX20-HCTGX35-LCTGX35-MC 3 50 M 551.5 88 125 125 M 625 M 615 6 10 03.92 0.6630 02.650 0.6 0.1 0.5TGX35-HCTGX50-LCTGX50-MC 4 65 M 801.5 123 128 174 174 M 832 M 820 9 17 10.90 3.3500 13.400 0.6 0.1 0.6TGX50-HCTGX70-LCTGX70-MC 4 70 M1002.0 148 152 218 218 M1022 M1038 10 18 16.30 8.9300 35.700 0.6 0.1 0.7TGX70-HC RS Allowable AllowableGD 2Mass Inertia momentangular misalignmentdeg.parallel10 2 kfm 2k 10 2 km 2 misalignmentAllowableshaft directiondisplacement34

Torque Guard TGXBore dimensionsUnit: mmTorque Guard Model No. Torque Gard Coupling Model No.Torque Guard Side Coupling side (Torque Guard Coupling only)TGX10 TGX10-C(10),(11),12,14,15 10,11,12,14,15,16,17,18,19TGX20 TGX20-C(14),(15),(16),(17),18,19,20,22,24,2510,11,12,14,15,16,17,18,19,20,22,24,25,28,29,30,32,33,35TGX35TGX35-C(14),(15),(16),(17),18,19,20,22,24,25,28,29,30,32,33,3514,15,16,17,18,19,20,22,24,25,28,29,30,32,33,35,36,38,40,42,43,45,46,48,50TGX50TGX50-C20,22,24,25,28,29,30,32,33,35,36,38,40,42,43,45,46,48,50,52,5520,22,24,25,28,29,30,32,33,35,36,38,40,42,43,45,46,48,50,52,55,56,57,60TGX70TGX70-C25,28,29,30,32,33,35,36,38,40,42,43,45,46,48,50,52,55,56,57,60,63,65,7025,28,29,30,32,33,35,36,38,40,42,43,45,46,48,50,52,55,56,57,60,63,65,70,71,75,80DeliveryEX.-Japan 4 weeks by seaTGX20 - H - 15JTGX50 - MC - T35JC50JTorque GuardModel No.Torque Guard TGXTorque GuardCouplingModel No.BorediameterTorque Guard sideSet screwSet screwpositionL1Coupling side(Torque Guard Coupling only)BorediameterSet screwSet screwpositionL2TGX10 TGX10-C 15 and below 2-M44 21.0 19 and below 2-M44 08TGX20TGX20-C23 and below2-M5524,25 2-M4420.5 35 and below 2-M55 12TGX35 TGX35-C 35 and below 2-M66 20.5 50 and below 2-M66 11TGX50 TGX50-C 55 and below 2-M66 24.5 60 and below 2-M66 13TGX70 TGX70-C 70 and below 2-M66 25.0 80 and below 2-M66 15 Bore diameterChamfer dimensions25 and below C0.550 and below C1.051 and above C1.535

IL ItK IS GD2 L GD 2 tKTS K GD TLTt Tp SFTt2 s 1 KK Is Service factorOperating conditions1.25 In the case of normal start up/stop, intermittent operation1.50 In the case of a heavy shock load or forward-reverse driving GD 2 s IL GD 2 L It GD 2 t Ts Tt TL TP S.F. 36

Unit: mmModel No. dimensions TGX10-C 2 TGX20-C 3 TGX35-C 3 TGX50-CTGX70-C44Model No. Unit: mmExxon Mobil Showa Shell Japan-Energy Idemitsu Nippon Oil Corporation Cosmo OilDimensionsModel No.Allowable angularmisalignment deg.Allowable parallelmisalignmentA x screw diameter B x screw diameter C x screw diameter a b cTGX10 21 M5 and below 30 TGX20 20.5M5 40 TGX35 20.5M6 55 TGX50 24.5M6 80 TGX70 26 M6 100 TGX10-C 8M 4 and below 21 M5 and below 33 30TGX20-C 12M 8 and below 20.5M5 55 40TGX35-C 11M10 and below 20.5M6 70 55TGX50-C 13M10 and below 24.5M6 92 80TGX70-C 15M10 and below 25.2M6 116 100Unit: mmAllowable axialmisalignmentTGX10-C 0.6 0.1 0.5TGX20-C 0.6 0.1 0.5TGX35-C 0.6 0.1 0.5TGX50-C 0.6 0.1 0.6TGX70-C 0.6 0.1 0.7Mobilux EP2AlvaniaEP Grease 2Rizonics EP 2Daphny EponexGrease EP 2Model No. Outside diameter Hub end face run-outTGX10-C 53 0.092TGX20-C 75 0.131TGX35-C 98 0.171TGX50-C 138 0.241TGX70-C 177 0.309EpinocGrease AP(N)2CosmoDynamax EP Grease 2DimensionsModel No.TGX10TGX20TGX35TGX50TGX70S29.928.329.535.634.5t1.21.21.21.21.2Unit: mmAmount ofplatemovement1.41.62.02.63.5DimensionsS tModel No.TGX10-C 36.5 2.12.8TGX20-CTGX35-CTGX50-CTGX70-C4559831052.43.12.73.43.23.94.14.8Unit: mmAmount ofplatemovement1.31.61.92.43.337

N23S1.551.8538101213141516171819202224252830323536384042454850555660636570PL010013EPL012015EPL013016EPL014018EPL015019EPL016020EPL017021EPL018022EPL019024EPL020025EPL022026EPL024028EPL025030EPL028032EPL030035EPL032036EPL035040EPL036042EPL038044EPL040045EPL042048EPL045052EPL048055EPL050057EPL055062EPL056064EPL060068EPL063071EPL065073EPL070079E10.81.1015.71.6010.81.1015.71.6018.61.9030.43.1035.33.6039.24.0043.14.4046.14.7041.24.2044.14.5010.81.1015.71.6018.61.9030.43.1035.33.6039.24.0043.14.4046.14.7041.24.2044.14.5035.33.6040.24.1045.14.6051.05.2056.85.8062.76.4075.57.7090.29.2035.33.6040.24.1045.14.6051.05.2056.85.8062.76.4075.57.7090.29.2091.19.3011111.311511.712412.712713.062.76.4075.57.7090.29.2098.010.012312.514114.416016.321722.122923.425626.131231.834435.136637.339840.641942.862.76.4075.57.7090.29.2098.010.012312.514114.416016.321722.122923.425626.131231.834435.136637.339840.641942.898.010.012312.514114.416016.321722.122923.425626.131231.834435.149050.053054.155756.862463.759060.264465.768569.971172.672473.949050.053054.155756.862463.759060.264465.768569.971172.672473.998.010.012312.514114.416016.321722.122923.425626.131231.834435.1TGX10 TGX20 TGX35 TGX50 TGX70Power LockModel No.Model No. of Touque GuardBore diameterAdjustablenut sideFixednut sideAdjustablenut sideFixednut sideAdjustablenut sideFixednut sideAdjustablenut sideFixednut sideAdjustablenut sideFixednut side101213141516171819202224252830323536384042454850555660636570PL010013EPL012015EPL013016EPL014018EPL015019EPL016020EPL017021EPL018022EPL019024EPL020025EPL022026EPL024028EPL025030EPL028032EPL030035EPL032036EPL035040EPL036042EPL038044EPL040045EPL042048EPL045052EPL048055EPL050057EPL055062EPL056064EPL060068EPL063071EPL065073EPL070079E2.940.303.140.321.960.202.060.212.160.223.530.363.920.404.020.414.020.414.020.414.020.411.960.202.060.212.160.223.530.363.920.404.020.414.020.414.020.414.020.414.020.41 4.020.412.940.303.040.313.140.323.230.333.630.373.720.383.720.383.920.404.020.414.020.414.020.414.020.414.020.415.490.565.590.575.590.576.270.646.470.667.060.727.350.759.110.939.510.979.901.0111.71.1912.31.2613.71.4013.71.4013.71.405.490.565.590.575.590.576.270.646.470.667.060.727.350.759.110.939.510.979.901.0111.71.1912.31.2613.71.4013.71.4013.71.407.640.787.940.819.310.959.801.0013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.405.000.515.190.535.590.575.880.607.250.747.640.787.940.819.310.959.801.0013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.405.000.515.190.535.590.575.880.607.250.745.000.515.100.525.190.535.390.556.170.636.370.656.270.646.660.68TGX10 TGX20 TGX35 TGX50 TGX70Power LockModel No.Model No. of Touque GuardBore diameterAdjustablenut sideFixednut sideAdjustablenut sideFixednut sideAdjustablenut sideFixednut sideAdjustablenut sideFixednut sideAdjustablenut sideFixednut side

39Unit: mm TGX10-FTGX20-FTGX35-FTGX50-FTGX70-F3040558110114.924.839.856.878.710.110.115.120.225.2566776661010111212171722324769894688104.54.54.56.66.60.0370.0800.160.530.870.0430.1500.5984.24010.830.1730.6002.3916.9643.33M414M414M414M622M622M48M48M48M612M612468810A D E F H JBCPressure flangeModel No.Rough boremeasurements1Masskg2 GD 2kgfm 2Pressure bolt sizethe numberTap side screweffective depthInertiamomentkgm 2GPCD 101213141516171819202224252830323536384042454850555660636570PL010013EPL012015EPL013016EPL014018EPL015019EPL016020EPL017021EPL018022EPL019024EPL020025EPL022026EPL024028EPL025030EPL028032EPL030035EPL032036EPL035040EPL036042EPL038044EPL040045EPL042048EPL045052EPL048055EPL050057EPL055062EPL056064EPL060068EPL063071EPL065073EPL070079E10.81.1015.71.6010.81.1015.71.6018.61.9030.43.1035.33.6039.24.0043.14.4046.14.7041.24.2044.14.5010.81.1015.71.6018.61.9030.43.1035.33.6039.24.0043.14.4046.14.7041.24.2044.14.5035.33.6040.24.1045.14.6051.05.2056.85.8062.76.4075.57.7090.29.2091.19.3011111.311511.712412.712713.010.81.1015.71.6035.33.6040.24.1045.14.6051.05.2056.85.8062.76.4075.57.7090.29.2091.19.3011111.311511.712412.712713.062.76.4075.57.7090.29.2098.010.012312.514114.416016.321722.122923.425626.131231.834435.136637.339840.641942.862.76.4075.57.7090.29.2098.010.012312.514114.416016.321722.122923.425626.131231.834435.136637.339840.641942.898.010.012312.514114.416016.321722.122923.425626.131231.834435.149050.053054.155756.862463.759060.264465.768569.971172.672473.949050.053054.155756.862463.759060.264465.768569.971172.672473.998.010.012312.514114.416016.321722.122923.425626.131231.834435.1TGX10-C TGX20-C TGX35-C TGX50-C TGX70-CPower LockModel No.Model No. of Touque GuardBore diameterTorque GuardsideCouplingsideTorque GuardsideCouplingsideTorque GuardsideCouplingsideTorque GuardsideCouplingsideTorque GuardsideCouplingside101213141516171819202224252830323536384042454850555660636570PL010013EPL012015EPL013016EPL014018EPL015019EPL016020EPL017021EPL018022EPL019024EPL020025EPL022026EPL024028EPL025030EPL028032EPL030035EPL032036EPL035040EPL036042EPL038044EPL040045EPL042048EPL045052EPL048055EPL050057EPL055062EPL056064EPL060068EPL063071EPL065073EPL070079E2.940.303.140.322.940.303.140.321.960.202.060.212.160.223.530.363.920.404.020.414.020.414.020.414.020.411.960.202.060.212.160.223.530.363.920.404.020.414.020.414.020.414.020.412.940.303.040.313.140.323.230.333.630.373.720.383.720.383.920.404.020.414.020.414.020.414.020.414.020.412.940.303.040.313.140.323.230.333.630.373.720.383.720.383.920.404.020.414.020.414.020.414.020.414.020.415.490.565.590.575.590.576.270.646.470.667.060.727.350.759.110.939.510.979.901.0111.71.1912.31.2613.71.4013.71.4013.71.405.490.565.590.575.590.576.270.646.470.667.060.727.350.759.110.939.510.979.901.0111.71.1912.31.2613.71.4013.71.4013.71.407.640.787.940.819.310.959.801.0013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.405.000.515.190.535.590.575.880.607.250.747.640.787.940.819.310.959.801.0013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.4013.71.405.000.515.190.535.590.575.880.607.250.74TGX10-C TGX20-C TGX35-C TGX50-C TGX70-CPower LockModel No.Model No. of Touque GuardBore diameterTorque GuardsideCouplingsideTorque GuardsideCouplingsideTorque GuardsideCouplingsideTorque GuardsideCouplingsideTorque GuardsideCouplingside

40 Unit: mm101213141516171819202224252830323536384042454850555660636570Power LockModel No.Borediameter(mm)TGX10CFTGX20CFTGX35CFTGX50CFTGX70CFPL010013EPL012015EPL013016EPL014018EPL015019EPL016020EPL017021EPL018022EPL019024EPL020025EPL022026EPL024028EPL025030EPL028032EPL030035EPL032036EPL035040EPL036042EPL038044EPL040045EPL042048EPL045052EPL048055EPL050057EPL055062EPL056064EPL060068EPL063071EPL065073EPL070079E12.914.910.112.112.914.915.917.918.919.920.921.923.824.810.112.113.114.115.116.117.118.119.220.218.919.920.921.923.824.825.827.829.831.834.835.839.818.919.920.921.923.824.825.827.829.831.834.835.839.841.843.844.847.851.854.856.829.831.834.835.839.841.843.844.847.851.854.856.861.863.867.870.872.878.715.116.117.118.119.220.222.224.225.228.230.232.235.215.116.117.118.119.220.222.224.225.228.230.232.235.236.238.240.242.245.248.250.225.228.230.232.235.236.238.240.242.245.248.250.255.256.260.263.265.270.30do 0.10.10di0do 0.10.10di0do 0.10.10di0do 0.10.10di0do 0.10.10di

qwer tyuio!0!1!2!3!4!5!6!7!8!9@0@1@2 42

Set torque range Max. rpmModel No.Nmkfm r/minBorerangeStock bore diameterH7Semi-standard bore diameterH7Inertia moment10 2 km 2 GD 210 2 kfm 2MasskTGM3 1.5 3.70.15 0.38 600 10 14 14 10, 120.0425 0.17 0.6TGM6 2.5 6.40.26 0.65 600 10 14 14 10, 120.0425 0.17 0.6TGM20 6.4 200.65 2.0 500 14 20 20 14, 16, 180.168 0.67 1.1TGM60 20 692.0 7.0 300 20 30 30 20, 22, 25, 280.938 3.75 2.5TGM200 68 2256.9 23 200 28 50 50 30, 35, 40, 454.03 16.1 5.4TGM400 225 45123 46 150 38 60 6040.0 160 17.2TGM800 451 90246 92 150 38 60 6040.0 160 17.2 Model No. A B C D E F GHh7SI J K L M P Q R 1 R 2H7U W X Y ZTGM3 60 57 2 48 3 80 22 30 50 3 40 8 5 M4 40 4 6 14 16.3 5 4 M 4 8TGM6 60 57 2 48 3 80 22 30 50 3 40 8 5 M4 40 4 6 14 16.3 5 4 M 4 8TGM20 70 66 3 57 3 100 30 40 60 4 50 10 6 M4 50 4 7 20 22.8 6 4 M 5 10TGM60 89 81 3 68 5 133 47.6 60 86 7 73 14 12 M5 76 6 12 30 33.3 8 6 M 6 13TGM200 110 100 3 85 5 178 69.9 82 133 14 114 20 12 M6 105 7 14 50 53.8 14 6 M10 19TGM400 157 147 9 131 5 273 88.9 114 190 17 165 28 17 M8 124 7 16 60 64.4 18 8 M12 28TGM800 157 147 9 131 5 273 88.9 114 190 17 165 28 17 M8 124 7 16 60 64.4 18 8 M12 28 43Model No.Weak spring, torque rangeNmkfmReinforced spring, torque rangeNmkfmTGM3(C) 0.59 1.50.06 0.15 TGM6(C) 6.0 12.70.61 1.3TGM20(C) 3.7 120.38 1.2 7.3 230.74 2.3TGM60(C) 7.6 260.78 2.7 44 1054.5 10.7TGM200(C) 30 983.1 10 101 28910.3 29.5TGM400(C) 118 23512 24 TGM800(C) 532 106054.3 108TGM60 D30 WS 2.5

qwertTorqueGuardCouplingModel No.Set torque rangeNmkfmMax.rpm r/minStandard bore diameter Semi-standard bore diameterH7Torque Guard boreH7CouplingboreRough bore Maximum borediameter*1 diameterA B C D E F G H sprocketMasskInertiamoment10 2 kfm 2TGM3C 1.5 3.70.15 0.38600 1410,12 12.5 30 90 64.2 5.8 20 80 50 70 9 RS35-20 1.12 0.07TGM6C 2.5 6.40.26 0.65Unit : mmGD 210 2 kfm 20.28TGM20C 6.4 200.65 2.0 500 20 14,16,18 12.5 32 100 72.2 5.8 22 100 53 82 7 RS35-24 1.78 0.218TGM60C 20 692.0 7.0 300 30 20,22,25,28 12.5 42 120.6 88.2 7.4 25 133 63 117 17 RS40-26 4.15 1.21TGM200C 68 2256.9 23 200 50 30,35,40,45 18 55 163.3 111.7 11.6 40 178 83 188 26 RS60-28 11.8 6.800.874.8127.5TGM400C 225 45123 46TGM800C 451 90246 92150 60 28 75 221.9 161.6 15.3 45 273 107 251 38 RS80-28 31 50.8203 Torque GuardModel No.Finished sprocket dimensionsTGM60C D30C40J SS 10.0Min. No. of sprocket teethUnit : mmd H7 D Y RS 25 RS 35 RS 40 RS 50 RS 60 RS 80 RS100 RS120TGM3 30 40 4.5TGM6 30 40 4.5303030 24 20 30 24 20 TGM20 40 50 5.5343728 24 20 TGM60 60 73 6.6 32 26 30 26 20 TGM200 82 114 11.0 37 30 26 20 17 TGM400 114 165 14.0 TGM800 114 165 14.0 41 3541 3527 24 2027 24 2044

Service factorOperating conditions1.25 In the case of normal start up/stop, intermittent operation1.50 In the case of a heavy shock load or forward-reverse driving K I L I t I S GD2 L GD 2 tKTSK TLGD Tt 2S 1 KTp SFTtK I S GDS 2 I L GD 2 L I t GD 2 t T S T t T L T P S.F. 45

Model No.Amount of torque variation per one (1) rotationNmkfmTotal numberof rotationsTGM3 0.280.029 8TGM6 0.480.049 8TGM20 1.020.10 13TGM60 4.900.5 10 TGM200 9.801.0 16TGM400 20.62.1 11TGM800 41.24.2 11 46

Model No.Amount of movementmmForce whenmovingNfTGM3 4 3.9400TGM6 4 3.9400TGM20 4 3.9400TGM60 6 3.9400TGM200 6 5.4550TGM400 8 5.9600TGM800 8 5.9600 47

Model No. Bolt screw-in length (mm) Bolt tightening torque Nmkfm Prepared hole diameter for installation bolt (mm)TGM3 6 7 2.0 2.90.2 0.3 4.5TGM6 6 7 2.0 2.90.2 0.3 4.5TGM20 8 9 3.9 5.90.4 0.6 5.5TGM60 9 11 6.9 110.7 1.1 6.6TGM200 15 17 34 513.5 5.2 11.0TGM400 18 25 59 896.0 9.1 14.0TGM800 18 25 59 896.0 9.1 14.0 Exxon MobilMobilux EP248

TGZ30L25J1.8 TGZ30LCT25JC35E1.850

ActuationModel No.OFF ONNkfON OFFNkfTGZ20-L 4905 0 245025TGZ20-M 8809 0 431044TGZ20-H 17618 0 862088TGZ30-L 9810 0 470048TGZ30-M 23524 1176120TGZ30-H 47048 2352240Amount ofmovementmm4.14.7ActuationModel No.OFF ONNkfON OFFNkfTGZ40-L 0 157016 0774079TGZ40-M 0 421043 2087213TGZ40-H 0 833085 4155424TGZ50-L 0 451046 2269231TGZ50-M 0902092 4518461TGZ50-H 1382141 6919706Amount ofmovementmm5.97 Model no.A B Cmin.Dmin.Emin.Fmin.G H Stroke max.deg.Shaft directionaxial forceNkgfPinMax. pin lengthdiameterTGZ20 23.5 50.5 60 70 170 230 4.5 49 3.9 22523 7 13TGZ30 24.5 59.0 70 90 210 280 4.5 60 3.9 58860 7 15TGZ40 32.5 68.5 90 100 250 340 5.0 77 3.8 1098112 8 16TGZ50 34.2 80.3 110 120 300 410 6.0 90 3.3 1852189 9.5 2051

Unit : mmCoil springTorque Guard Set torque range Max. rpmcolor XModel No. Nmkfm r/minthe numberTGZ20-L 2.4 8.30.24 0.85 Yellow X 3TGZ20-M 4.1 160.42 1.6 1800 BlueX 3TGZ20-H 8.2 310.84 3.2 BlueX 6TGZ30-L 5.9 210.6 2.1Yellow X 4TGZ30-M 20 522.0 5.3 1800 Red X 4TGZ30-H 39 1084.0 11 Red X 8TGZ40-L 25 932.6 9.5BlueX 5TGZ40-M 44 1274.5 13 1800 Red X 5TGZ40-H 88 2459.0 25 Red X10TGZ50-L 63 1576.4 16Red X 5TGZ50-M 127 30413 31 1800 Red X10TGZ50-H 245 45125 46 Green X10Rough Max.bore borediameter diameterA B C D E FGmin.pointpositionHI amountofmovementduringtripJKPCD8 20 74 73 1 8 6 13.5 0.8 11 4.1 96 8612 30 83.5 82 1.5 8 6 14.5 1.1 11.5 4.7 118 10617 40 101 100 1 9 8 20 1.1 14 5.9 152 13922 50 114.5 112 2.5 10 9 20.2 1.2 16 7 178 162Torque GuardModel No.Lh7M N P Q R S TUscrew diameterX lengthTGZ20-LTGZ20-M 072 35 24.5 32 057 070 088 4 M510 5 10 M510 M510 2.57 0.273 1.09TGZ20-HTGZ30-LTGZ30-M 087 45 27.5 45 075 088 108 4 M612 6 10 M510 M610 4.17 0.695 2.78TGZ30-HTGZ40-LTGZ40-M 114 65 32.5 65 103 119 141 6 M612 8 14 M810 M810 8.71 2.409.60TGZ40-HTGZ50-LTGZ50-M 133 75 37.0 75 113 138 166 6 M816 9 14 M810 M810 13.7 5.30 21.2TGZ50-H VWXscrew sizeX lengthYscrew sizeX lengthMasskGD 2Inertia moment10 2 kfm 210 2 km 252

Torque GuardModel No.Set torque rangeNmkfmMax. rpmr/minTorque GuardRoughborediameterMax.borediameterCouplingRoughborediameterMax.borediameterUnit : mmA B C D R 1 R 2 E FTGZ20-LC 2.4 8.30.24 0.85TGZ20-MC 4.1 160.42 1.6 1800 8 20 12.7 35 146 83 18.8 27.2 27 73 96TGZ20-HC 8.2 310.84 3.2TGZ30-LC 5.9 210.6 2.1TGZ30-MC 20 522.0 5.3 1800 12 30 18.0 47 180 93.5 22.6 32.5 42.9 82 118TGZ30-HC 39 1084.0 11TGZ40-LC 25 932.6 9.5TGZ40-MC 44 1274.5 13 1800 17 40 19.1 58 213 111 26.1 32.9 54 100 34.9 152TGZ40-HC 88 2459.0 25TGZ50-LC 63 1576.4 16TGZ50-MC 127 30413 31 1800 22 50 19.1 63 242 127.5 26.1 40.4 63.5 112 34.9 178TGZ50-HC 245 45125 46Torque GuardModel No.GHIJNo. of pieces-Noscrew size X screw size Xof pieces-length lengthMasskGD 210 2 km 2 m 2Inertia moment 10 2 kfModel No.of couplingusedTGZ20-LCTGZ20-MC 64.3 3-M620 4-M522 4.34 0.44 1.76 L099-H 27 0.5 0.38 0.5TGZ20-HCTGZ30-LCTGZ30-MC 84.1 6-M622 4-M622 7.77 1.22 4.86 L110-H 40 0.5 0.38 0.7TGZ30-HCTGZ40-LCTGZ40-MC 114.3 101.6 6-M625 6-M625 15.4 4.05 16.2 L190-H 54 0.5 0.38 1.0TGZ40-HCTGZ50-LCTGZ50-MC 127 107.9 6-M825 6-M825 23.2 8.63 34.5 L225-H 60 0.5 0.38 1.0TGZ50-HC KAllowableangularmisalignment(deg.)AllowableparallelmisalignmentAllowableshaft directiondisplacement53

Service factorOperating conditions1.25 In the case of normal start up/stop, intermittent operation1.50 In the case of a heavy shock load or forward-reverse driving IL ItK IS GD2 L GD 2 tK KTS TLTt Tp SFTtGD 2 s 1 K K Is GD 2 s IL GD 2 L It GD 2 t Ts Tt TL TP S.F. 54

Model No.Axial loadNkfTGZ20-L 495TGZ20-M 889TGZ20-H 17618TGZ30-L 9810TGZ30-M 23524TGZ30-H 47048TGZ40-L 15716TGZ40-M 42143TGZ40-H 83385TGZ50-L 45146TGZ50-M 90292TGZ50-H 1382141Amount ofdisplacementA mmBmm4.1 13.54.7 14.55.9 20.07.0 18.2Exxon Mobil Showa Shell Japan-EnergyIIdemitsuNippon Oil CorporationKygnusMobiluxEP2AlvaniaEP Grease 2RizonicsEP 2DaphnyEponexGrease EP 2EpinocGreaseAP(N)2CosmoDynamax EPGrease 255

measurementModelSno.TGZ20 40TGZ30 50TGZ40 66.5TGZ50 79Unit: mmAmount oft platemovement4.25.6 4.14.86.2 4.767.4 5.97.18.5 7.0measurementModelSno.TGZ20 9.5TGZ30 10.2TGZ40 15TGZ50 12.2t1.21.21.21.2Unit: mmAmount ofplatemovement4.14.75.97.0 TGZ sizeSprocket Model No.TGZ20L, M, HTGZ30L, M, HTGZ40L, M, HTGZ50L, M, HRS25 RS35 RS41 RS40 RS50 RS60 RS80 RS100 RS12051 35 2862 43 33546241483029242335 3033 2745 3541 3448 403920 16 13 131224 18 16 142330 24 19 1624 2335 26 21 143356

TL500TL200TL700TL10TL200TL20TL500-CTL200-CTL20-C57

TL3501B6.520JTL3502CT20JC40J9.0 57 58

TL200TL250TL350TL200 does not have a tap for the setscrew.TL200-1L, TL250-1L and TL350-1L have a spacer between the disk spring and lock washer. Model No.Set torque range Max.rpm Rough boreNmkfm r/min diameterTL200-ILTL200-11.0 2.00.1 0.22.9 9.80.3 1.0TL200-2 6.9 20 0.7 2.0TL250-IL 2.9 6.90.3 0.7TL250-1 6.9 27 0.7 2.81,800TL250-2 14 54 1.4 5.5TL350-IL 9.8 20 1.0 2.0TL350-1 20 74 2.0 7.6TL350-2 34 1493.5 15.2710Max. borediameter142217 25Bushlength3.86.04.56.54.56.59.5Bush outerdiameterCenter memberbore diameterDimensionsSD D H L R T t A Cmax.Adjustable nut Set screwdiameter X pitch diameterUnit : mm30 0.024 0.049 30 0.030 50 24 29 6.5 2.6 2.5 7 38 M241.0 0.241 0.010 0.045 41 0.050 65 35 48 16 4.5 3.2 9 4 50 M351.5 M5 0.649 0.025 0.065 49 0.050 89 42 62 19 4.5 3.2 16 6 63 M421.5 M6 1.2MasskTL500, TL700Model No. Set torque range Max.rpm Rough boreNmkfm r/min diameterMax. borediameterBushlengthBushCenter memberouterbore diameterdiameterD D H L R T tDimensionsAAdjustable nutdiameter X pitch 0.05TL500-1L 20 49 2.0 5.06.5TL500-1 47 210 4.8 21.4 20 4274 0.05 0.10 M8174 0 127 65 76 22 6 3.2 16 7 M651.5 M 8 3.59.5TL500-2 88 420 9.0 42.91,800TL700-1L 49 118 5.0 12 9.5TL700-1 116 56911.8 58.1 30 64 105 0.075 0.125 105 0.050 M101.25 M10 8.4178 95 98 24 8 3.2 29 8 M951.512.5TL700-2 223 108022.8 111SMaxAdjustable boltdiameter X pitchSet screwdiameterUnit : mmMassk59

TL10TL14, TL20 Model No.TL10 16TL10 24TL14 10TL14 15TL20 6TL20 12Set torque range Max.rpm Rough boreNmkfm r/min diameter392 1247 40 1301,000588 1860 60 190882 2666 90 2721960 3920200 4002450 4900250 5004606 9310470 95050030Max. borediameter7240 10050 130Bushlength12.515.519.515.519.523.515.519.523.5Bush outerdiameterCenter memberbore diameterDimensionsSD D H L R T 1 T 2 tmax.CAdjustable nutdiameter X pitch135 0.085 0.125 135 0.070 254 100 115 23 8.5 4.0 24 19 M181.5Unit : mm183 0.07 0.12 183 0.070 356 145 150 31 13 13 4.0 29 27 M261.5 52226 0.07 0.12 226 0.070 508 185 175 36 15 18 4.0 31 36 M321.5 117Massk21Product code Model No. Product code Model No.S110701 TL200-1L S110711 TL200-1L-B3.8S110001 TL200-1 S110721 TL200-1L-B6.0S110011 TL200-2 S110101 TL200-1-B3.8S110702 TL250-1L S110102 TL200-1-B6.0S110002 TL250-1 S110103 TL200-2-B3.8S110012 TL250-2 S110104 TL200-2-B6.0S110703 TL350-1L S110712 TL250-1L-B4.5S110003 TL350-1 S110722 TL250-1L-B6.5S110013 TL350-2 S110105 TL250-1-B4.5S110106 TL250-1-B6.5S110107 TL250-2-B4.5S110108 TL250-2-B6.5S110713 TL350-1L-B4.5S110723 TL350-1L-B6.5S110724 TL350-1L-B9.5S110109 TL350-1-B4.5S110110 TL350-1-B6.5S110111 TL350-1-B9.5S110112 TL350-2-B4.5S110113 TL350-2-B6.5S110114 TL350-2-B9.5Product codeS110704S110004S110014S110705S110005S110015Model No.TL500-1LTL500-1TL500-2TL700-1LTL700-1TL700-2Product code Model No.S110714 TL500-1L-B6.5S110725 TL500-1L-B9.5S110115 TL500-1-B6.5S110116 TL500-1-B9.5S110117 TL500-2-B6.5S110118 TL500-2-B9.5S110715 TL700-1L-B9.5S110726 TL700-1L-B12.5S110119 TL700-1-B9.5S110120 TL700-1-B12.5S110121 TL700-2-B9.5S110122 TL700-2-B12.5Product codeS110006S110016S110017S110018S110019S110020Model No.TL10-16TL10-24TL14-10TL14-15TL20-6TL20-12Product code Model No.S110123 TL10-16-B12.5S110124 TL10-16-B15.5S110125 TL10-16-B19.5S110126 TL10-24-B12.5S110127 TL10-24-B15.5S110128 TL10-24-B19.5S110129 TL14-10-B15.5S110130 TL14-10-B19.5S110131 TL14-10-B23.5S110132 TL14-15-B15.5S110133 TL14-15-B19.5S110134 TL14-15-B23.5S110135 TL20-6-B15.5S110136 TL20-6-B19.5S110137 TL20-6-B23.5S110138 TL20-12-B15.5S110139 TL20-12-B19.5S110140 TL20-12-B23.560

TorqueFinished boreSprocketsMassLimiterModel No.diameter(mm)Bush lengthType F(mm) No. of teeth No. of teeth(kg)(mm)RS350TL200 11,12,14, 10 04.3 0.25 0 .00 3.8 20,21,22,23,24,25,26,27,28,30 0.3RS400 07.0 0.35 0.0 0 6.0 16,17,18,19,20,21,22,23,24,25,26 0.33TL25012,14,15,16,RS400 0. 00 07.0 0.35 6.5 22,23,24,25,26,27,28,30 21,320.851718,19,20,22RS500 07.0 0.25 0.0 0 6.5 18,19,20,21,22,23,24,25,26,27,28 170.92RS400 0. 00 07.0 0.35 6.5 26,27,28,30,32,34,35,36,38 40,42,451.55TL35018,19,20, RS500 0. 0022,24,25 07.0 0.25 6.5 22,23,24,25,26,27,28,30,32 21,34,35,361.68RS600 0. 00 10.0 0.30 9.5 18,19,20,21,22,23,24,25,26,27,28,30 1.9122,24,25,RS500 07.0 0.25 0.0 0 6.5 30,32,34,35,36,38,40,42,45 48,504.3TL50028,30,29,33,36 RS600 0. 0032,35,38, 10.0 0.30 9.5 25,26,27,28,30,32,34,35,36,38 404.740,42RS800 13.0 0.30 0.0 0 9.5 19,20,21,22,23,24,25,26,27,28,30 5.235,40,42,45, 32,33,36,RS600 10.0 0.30 0.0 0 9.5 35,36,38,40,42,45,48,50,54 10.7TL700 50,55,60, 38,43,46, RS800 13.0 0.30 0.0 0 12.5 26,27,28,30,32,34,35,36,38 11.263,64 48,52,56,57RS100 0. 00 16.5 0.30 12.5 21,22,23,24,25,26,27,28,30 12.2Delivery 1 1 1 2 TL2502040 2220J5.0 Bore diameterChamfer dimensions25 and less C0.5 50 and lessC151 and above C1.561

TL200-C TL250-C, TL350-C TL500-C, TL700-CTL10-C TL14-C TL20-CModel No.Set torque rangeNmkfmMax. rpmr/minRough bore diameterCoupling Torqueside Limiter sideMax. shaft diameterCoupling Torqueside Limiter sideSprocketDimensionsD D H L R 1 R 2 SUnit : mmTL200-1LC 1.0 2.0 0.1 0.2TL200-1C 2.9 9.8 0.3 1.0 1200 8 7 31 14 RS 40-16T 76 50 55 24 29 7.5 1.0TL200-2C 6.9 20 0.7 2.0TL250-1LC 2.9 6.9 0.3 0.7TL250-1C 6.9 27 0.7 2.8 1000 13 10 38 22 RS 40-22T 102 56 76 25 48 7.4 1.9TL250-2C 14 54 1.4 5.5TL350-1LC 9.8 20 1.0 2.0TL350-1C 20 74 2.0 7.6 800 13 17 45 25 RS 50-24T 137 72 103 37 62 9.7 4.2TL350-2C 34 149 3.5 15.2TL500-1LC 20 49 2.0 5.0TL500-1C 47 210 4.8 21.4 500 18 20 65 42 RS 60-28T 188 105 120 40 76 11.6 10TL500-2C 88 420 9.0 42.9TL700-1LC 49 118 5.0 12TL700-1C 116 56911.8 58.1 400 23 30 90 64 RS 80-28T 251 150 168 66 98 15.3 26TL700-2C 223 108022.8 111TL10-16C 392 1274 40 130TL10-24C 588 1860 60 190300 33 30 95 72 RS140-22T 355 137 189 71 115 26.2 66TL14-10C 882 2666 90 272TL14-15C 1960 3920200 400200 38 40 118 100 RS160-26T 470 167 235 80 150 30.1 140TL20-6C 2450 4900250 500TL20-12C 4606 9310470 950140 43 50 150 130 RS160-36T 631 237 300 120 175 30.1 285 Massk62

Unit : mmTorque Limiter Coupling Model No.Torque Limiter sideFinished bore dimensionsCoupling sideTL200-1LCTL200-1C10,11,12,14 10,11,12,14,15,16,17,18,19,20,22,24,25,28,29,30TL200-2CTL250-1LCTL250-1CTL250-2C12,14,15,16,17,18,19,20,2215,16,17,18,19,20,22,24,25,28,29,30,32,33,35,36,38TL350-1LCTL350-1C 18,19,20,22,24,25TL350-2C15,16,17,18,19,20,22,24,25,28,29,30,32,33,35,36,38,40,42,43,45TL500-1LCTL500-1CTL500-2CTL700-1LCTL700-1CTL700-2C22,24,25,28,29,30,32,33,35,36,38,40,4232,33,35,36,38,40,42,43,45,46,48,50,52,55,56,57,60,63,6420,22,24,25,28,29,30,32,33,35,36,38,40,42,43,45,46,48,50,52,55,56,57,60,63,64,6525,28,29,30,32,33,35,36,38,40,42,43,45,46,48,50,52,55,56,57,60,63,64,65,70,71,75,80,85,90Date of deliveryEx.-Japan 4 weeks by seaTL250 - 2C - T18JC30J - 5.0 Bore diameterChamfer dimensions25 and less C0.550 and lessC151 and above C1.563

Number ofSpecial camsRotational detection speed ranger/minNumber ofSpecial camsRotational detection speed ranger/min1 6 60 6 1.0 102 3 30 7 0.85 8.53 2 20 8 0.75 7.54 1.5 15 9 0.67 6.75 1.2 12 10 0.6 6.0 65

asdfTorque LimiterModel No.Sprocket borediameter(center memberbore diameter)Min.No.of teethMin. No. of sprocket teethRS35 RS40 RS50 RS60 RS80 RS100 RS120 RS140 RS160Bush Min.No. Bush Min.No. Bush Min.No. Bush Min.No. Bush Min.No. Bush Min.No. Bush Min.No. Bush Min.No. Bushlength of teeth length of teeth length of teeth length of teeth length of teeth length of teeth length of teeth length of teeth lengthTL200 30 0.030TL250 41 0.050 20 3.8 16 6 20 6.5 17 6.5 TL350 49 0.050TL500 74 0.050TL700 105 0.050TL10 135 0.070TL14 183 0.070TL20 226 0.070 26 4.5 21 6.5 18 9.5 15 9.5 29 6.53025 9.5 19 9.5 339.53526 12.5 21 12.5 18 12.5 29 12.53024 15.5 22 19.5 39 3315.5 15.5 29 19.5 26 23.540 35 54 15.5 46 15.5 40 19.5 35 23.560 Torque LimiterModel No.Sprocket borediameter(center memberbore diameter)Min. No. of sprocket teethRS35 RS40 RS50 RS60 RS80 RS100 RS120 RS140 RS160Min.No.Bush Min.No. Bush Min.No. Bush Min.No.Bush Min.No. Bush Min.No. Bush Min.No. Bush Min.No. Bush Min.No. Bushof No.of teeth length of teeth length of teeth length of No.of teeth length of teeth length of teeth length of teeth length of teeth length of teeth lengthTL200 30 0.030TL250 41 0.050 25 3.8 19 6.0 24 6.5 20 6.5 TL350 49 0.050TL500 74 0.050TL700 105 0.050TL10 135 0.070TL14 183 0.070TL20 226 0.070 30 4.5 24 6.5 21 9.5 17 9.5 32 6.5 2830 36 9.5 28309.5 21 9.5 239.5 12.5 20 12.5 24 31 12.5 26 15.5 23 19.5 32 41 15.5 35 15.5 30 19.5 27 23.545 56 4715.5 15.5 41 19.5 36 23.560 60 66

TGA150 67

qwertyuiTGA 65Unit : mmModel No.Trip load set rangeNkfABCh7DEH7F G H I J K L M N P S T U V X YMasskTGA65 147 637 15 65 33 23 14 10 7 22.5 5 2 40 5 5 42 11 58 16 5 7.5 M 6 7 M3 6TGA150 588 1470 60 150 38 28 18 14 10 24 6 2 43 7 8 45 19 72 21 7 8 M 8 10 M4 8TGA250 735 2450 75 250 45 34 24 18 14 28 7.5 3 50 10 15 53 22 90 24 8 9 M12 14 M5 10TGA350 980 3430100 35056 44 28 22 16 34 9 3 63 10 20 66 24 110 30 10 12 M14 15 M6 100.20.40.71.2 70

Model No. Axial direction load for reset Dimension A when resettingTGA 65 83 N{8.5 kgf} 11TGA150 196 N{20 kgf} 19TGA250 343 N{35 kgf} 22TGA350 490 N{50 kgf} 24 72

Model No. TGA65 TGA150 TGA250 TGA350A direction allowable stroke14203038B direction allowable stroke14222426 73

B C D E F G H I J K L M N P J CModel No. 0 0screw screwModel No. 0.2 0.2 0 0.2 0.2 h7h9size size 0 H7 0 0.2 TGA65 10 6 47 10 M6P1.0 M6P1.0TGA150 15 9 6Select byinstallation10 14 M8P1.25 M8P1.25TGA250 22 13 9length,14 18 M12P1.75 M12P1.75stroke, etc.TGA350 23 14 9 16 22 M14P2.0 M14P2.0TGA65 2.56 3.4 23 14 10.5 16TGA150 2.5Select byinstallation6 4.5 28 18 14.5 20TGA250 3.5length,6 5.5 34 24 18.5 24.5stroke, etc.TGA350 3.5 6 6.6 44 28 22.5 31 74

Unit : mmModel No. A Thread depthTGA65 52TGA150 54.5TGA250 584.5TGA350 63.5TGA Sensor AC typeDC typeModel No.TGA S8TGA S8DPower Rating AC24 240VDC12 24Vsupplyvoltage Possible use range AC20 264V50/60Hz DC10 30VCurrent consumption Less than 1.7mA(at AC200V) Less than 13mAControl output (open, close capacity) 5 100mA Max. 200mAIndicator lampOperation indicatorAmbient operating temperature 5 70 (no condensation)Ambient operating humidity35 95 RHOutput formNC (Output open/close condition when notdetecting sensor plate)Operation formNPNInsulation resistance More than 50MΩ (at DC500V mega) Charge portion - CaseMassApprox. 45 (with 2m cord)Residual voltage Refer to characteristic dataLess than 2.0V (Load current200mA, 2m cord length) Positioning nutLock nut ALock nut B Model No.TGA65TGA150TGA250TGA350Screw size M2M2M2M3 75

Kyodo Oil Sumitomo Lubricant Dow Corning STTGrease HD Low temp grease Molykote 44MA Grease Solvest 83276

MEMO77

787878

Shock RelayThermal RelayOperation timeShort LongProtected objectEquipmentMotor ElectricalMechanicalExisting equipmentEasy to install laterDifficult to install laterEnvironmentBuilt inside the panelNecessary environmental precautions 79

⎞⎟⎠MotorkW132907522113.70.20.1Power sourceV 200/220 400/440 200/220 400/440 200/220 400/440 200/220 400/440 200/220 400/440 200/220 400/440 200/220 400/440 200/220Operation setting levelStart time setting rangeShock time setting rangeAmpereA0.2 12.0s adjustable0.2 5.0s adjustableAmpereA0.2 10.0s adjustable0.2 5.0s adjustableThe ratio of motor-ratedcurrent value (%)0.2 20s adjustable0.2 3s adjustableAmpereA0.2 30s adjustable0.3 10s adjustableAmpereA0.2 10s adjustable0.2 5s adjustableAmpereANo0.2 30sThe ratio of motor-ratedcurrent value (%)3s (fixed)0.3 3s adjustableAmpereA1.5s (fixed)1s (fixed)Operation power source AC100 240V100 120V or AC100/110V orAC100/110V orAC100 240V AC100 240V AC200 240V1 AC90 250VCondition of output relay after activationTest functionOperation display2 Open phasereverse phasephase unbalance detectionAlarm outputDIN rail installedSelectable; self-holdingor automatic resetLED digital display200 240VSelectable; self-holdingor automatic resetLED digital displayAC200/220V 50/60HzSelf-holdingLED lightSelf-holdingLED lightAutomatic resetLED lightSelf-holdingLED lightAC200/220V 50/60HzAutomatic resetAutomatic resetDisplay meterDigital meter current value display Digital meter current value display Analog meter % display Additional specifications Special models45⎞⎟⎠Series nameModel No.CombinedwithexternalCTFeaturesConforms to UL/cUL standardsCE markingSubtropical specificationsSupport for abnormal voltageof control power supplyPanel installationStart time modificationShock time modificationAutomatic resetSC SeriesTSBSCB/S06 TSBSCB/S60Digital display,Communication functionselectable selfholding/automaticreset typeCT (current transformer)Built-in (for large capcitymotors, external CT isused together.)4Impact load detection 1A inputLower and upper limit detection 3 6 ED SeriesTSB020ED-1-2 TSB550ED-1-2Digital display,economical,selectable selfholding/automaticreset typeBuilt-in3150 SeriesTSB151152Analog display,self-holdingtypeExternal CTseparateSS SeriesTSBSS05 300Economical,self-holdingtypeBuilt-in (for large capcitymotors, external CT isused together.)3SA SeriesTSBSA05 300Economical,automatic resettypeBuilt-in (for large capcitymotors, external CT isused together.)3SU SeriesTSBSU05-2 TSBSU60-2Economical,self-holdingtypeUnder-loadDetection TypeBuilt-in 350 SeriesTSB50Economical,automatic resettypeExternal CTseparateSM SeriesTSBSM02Economical,automatic resettypeBuilt-inPlease consultTEAMPlease consultTEAM 81

Special modelsImpact load detection1A inputUpper-lower limit detectionAdditional specificationsSubtropical specificationsSupport for abnormal voltage of control power supplyOutline of specificationsSeparately from the usual overload, abnormally large current is instantly detected andoutputted. Impact load settings can be set from 30%-300%. Impact load shock time is within0.05s. Other functions and outline dimensions conform to product standards.When the secondary side of CT is 1A, it can input directly to the Shock Relay.(It's not necessary to consider motor capacity.)Other specifications and outline dimensions conform to product standards.Detects both overload and under-loads; however, because there is 1 output relay,it cannot distinguish between upper and lower limits.Outline of specificationsCan be used when ambient humidity is 90% RH and below. Other specifications conform to standard products.Power source voltage: AC230V, AC240V, AC115V, AC120V (please contact us for more information on other voltages)Special unit modelTSB151MTSB152MOrder symbolPanel installation It can be mounted on the control panel surface and operated.The integral multiple can be extended for a maximum of 60 seconds.PStart time modification The front panel scale becomes an integral multiple (x2, x3 •••).Other specifications conform to standard products.T1The integral multiple can be extended for a maximum of 60 seconds.Shock time modification The front panel scale becomes an integral multiple (x2, x3 •••).Other specifications conform to standard products.T2Automatic reset For the 150 Series only, the self-holding output relay can be changed to automatic reset. HTSB152CTSB151WTSB152WSV82

TSBSCS06 TSBSCD TSBSCC0530TSBSCS34 TSBSCD TSBSCC0530TSBSCS60 TSBSCD TSBSCC0530TSBSCB06TSBSCB34TSBSCB60Motor<strong>Protection</strong> functionOutput relayModel No.All-in-one type TSBSCB06 TSBSCB34 TSBSCB60Panel type TSBSCS06 TSBSCS34 TSBSCS604t 0.1kW 200V class2t 0.2, 0.4kW 1.5, 2.2kW Number of wires pass 1t 0.75kW 3.7, 5.5kW 7.5, 11kWthrough the CT hole 4t 0.2kW 400V class2t 0.4, 0.75kW 2.2, 3.7, 5.5kW 1t 1.5kW 7.5, 11kW 15, 18.5, 22kWFrequency of detect current20 200HzMaximum voltage of motor circuitAC690V 50/60HzOperational power source100 240VAC±10%, 50/60HzOvercurrentsettingNumber of wires passthrough the CT hole4t 0.15 1.60A (0.01A) ( ): Increment2t 0.30 3.20A (0.02A) 3.00 17.0A (0.1A) 1t 0.60 6.40A (0.04A) 6.00 34.0A (0.2A) 10.00 60.0A (0.4A)0 12.0s (0.2s and larger: Increment 0.1s)0.2 5.0s (Increment 0.1s)±5% (In case of commercial power source)Start timeShock timeAccuracyCurrent detection accuracyTime detection accuracy ±5%Under currentTrip at 0.2 5s (OFF: No action)Lock when starting upSet at 2 8 times of overcurrent setting value (OFF: No action) Trip after Start time + 0.2s when starting up.Lock when operating Set at 1.5 8 times of overcurrent setting value (OFF: No action), trip at 0.2 5s.Phase-reversalTrip within 0.15s, (OFF: No action)Phase lossTrip at 0.5 5s (OFF: No action)Imbalance Trip at 1 10s (OFF: No action) when setting at 10 50%Alarm Output when A, F and H are set (OFF: No action)Running hourTrip when 10 9990hr is set (OFF: No action)Fail-safeActivated when setting ON (Conducting normally: Excited, Trip: Non-excited)Rated load3A,250VAC cos 1Minimum allowable load *1DC24V, 4mALifeActivation 100,000times at rated loadContact arrangementOC:1c,AL/UC/TO:1aResetSelf-holdingE-r: Manual release or reset of power source, H-r: Only manual releaseAuto-resetA-r: Auto-reset and set the return time at 0.2s 20minAnalog outputAnalog output 4 ~20mA DC Output (OFF: No action) Allowable load resistance: 100 and belowCommunication outputRS485/ModbusInsulation resistance (Between housing-circuit)DC500V 10MDielectric strength Between housing-circuit2000VAC 60Hz 1min.voltageBetween relay contacts1000VAC 60Hz 1min.PlaceIndoor, no water splashAmbient temperature 20 60 °CAmbient humidity30 85%RH (No dew condensation)Altitude2000m and belowAtmosphereNo corrosive gas, oil-mist or dustVibration5.9m/s 2 and belowPower consumption7VA and belowApprox. mass0.3kg and belowUse environment*1: In case inputting the output relay contact to programmable controller (PLC) directly, input through the relay for minute current, because contact failure may happendue to minute current.83

4 4 1 23 1 3 21234 5 Terminal symbol Function ExplanationA1, A2Operationalpower sourceConnect AC100 to 240V, commercial powersource95 Common terminal Terminal 96, 98, 08 common96b contact: Normal-close, Overcurrent-open(In case FS:OFF)OC output98a contact: Normal-open, Overcurrent-close(In case FS:OFF)08 AL/TO/UL outputAlarm output/Running hour output/UndercurrentoutputAnalog output Output analog current DC4 to 20mAV-, D1, D0, STerminal forcommunicationConnect when using communication function.84

85 TSBSCB06TSBSCS06TSBSCC05TSBSCDTSB3CTC100

Item Operation button Operation instruction1. Selection of parameter UP/DN Select the setting parameter by pushing the UP/DN buttons.2. Preparation for setting SET The setting value begins blinking when the SET button is pushed after selecting a parameter.3. Selection of setting UP/DN Push the UP/DN buttons until the desired setting value is shown.4. Register of setting5. Initial indicationSETESCPress the SET button after selecting the setting value, the blinking value indication returns to normaland the setting value is registered.Push the ESC button to return to the initial indication after completing the settings. In the case that no buttonis pushed, returns to initial indication automatically after 50 seconds.No.MenuInitial ValueParameterSetting ValueExplanation of function0 All parameter settings are possible.1 Parameter lock1To lock parameter settings, input "1" for every parameter set.To unlock the setting, input "1", then "0". Whencompleted.is displayed, the setting is2Selection ofphase No.3Ph1PhMonitoring 3 phase motorMonitoring single phase motor.dEOperates with definite time characteristic.3OperationcurvethInOperates with inverse time characteristic and is cumulative as in the case of thermalcharacteristic.(Refer to Thermal characteristic chart on page 90.)Operates with inverse time characteristic. (Refer to Inverse characteristic chart on page90.)4 CT rationo Setting for disabling the upper limit detection.Setting the number of motor wires that pass through the CT (1t: 1time, 2t: 2 times, 4t: 41t,2t,4t times)Type 34; only 1t and 2t, Type 60; only 1t100,200,300 Select when using External CT (Type 06 only)5 Fail Safe6Reverse phasedetectionoFFonoFFonNormal mode When a trip occurs, the relay turns ON (95-96: Open, 95-98: Closed).Fail safe mode After the power is turned on, the relay turns ON (95-96: Open, 95-98: Closed);and when a trip occurs, the relay turns OFF (95-96: Closed, 95-98: Open).* This setting becomes effective after a power reset.Set to "on" when detecting phase-reversal.Set the current value for overcurrent. For type 34 and 60, the current value cannot be setover 32A for inverse characteristics "th" and "In" . 06 type 34 type 60 typeCT RatioSetting range Increments Setting range Increments Setting range Increments7Over currentthresholdSee the right1t 0.60 6.40 0.04 6.00 34.0 0.2 10.0 60.0 0.42t 0.30 3.20 0.02 3.00 17.0 0.14t 0.15 1.60 0.01100 12.0 128 1200 24.0 256 1300 36.0 384 187

No. Menu8 Start timeParameterInitial Value Setting Value00.2 12.0sExplanation of functionWhen setting the inverse characteristic "In", be aware that it operates in Coldcharacteristic from the starting of the motor until the current becomes lower than OCsetting, and then operates in Hot characteristic after that.The relay does not output within the time setting, so as to not operate when the motorstarts. When inverse characteristic "In" is set, it operates in Hot characteristic after Starttime.0.2 5.0s Set continuous overloading time of the overcurrent setting.9Over currentShock time1 30Select the operation characteristic when inverse characteristic "th", "In" are set. (Refer toThermal and inverse characteristic charts)1011Under currentthresholdUnder currentShock timeoFFSee the rightSet current value when detecting undercurrent.This cannot be set higher than the overcurrent value. Relay output for undercurrent is asfollows:Alarm ALo is set to "except uc": outputs at OC terminalAlarm ALo is set to "uc": outputs at AL/UC/TO terminals0.2 5.0s Set continuous under-loading time of under-current setting.12 Phase lossoFFonSet to "on" in the case that phase loss is detected.13Phase losstime0.5 5sSet operation time in the case that phase loss is detected.When phase loss detection is set to oFF, it does not display.1415ImbalancethresholdImbalancedurationoFF10 50%1 10sSet to 10~50% in case imbalance is detected.Imbalance ratio (%) = (Max.Current-Min.Current) ×100Max.CurrentSet operation time in the case that an imbalance is detected. When imbalance detectionis set to oFF, this does not display.16 Stall threshold17 Jam thresholdoFF2 8 timesoFF1.5 8 timesSet the ratio against overcurrent setting in the case of detecting the lock when starting.Setting range; Sc setting value ×OC 250A. This parameter is not displayed when thestart time is set to 0s.Set the ratio against overcurrent setting in the case of detecting the lock when running.Setting range; JA setting value ×OC 250A.18 Jam fault duration 0.2 5sSet the operating time in the case of detecting the lock when running. When lock JA is setto oFF, it does not display.19Analog OutputrangeSee the rightSet the current value as analog current output scale for 20mA output. Refer to page 87Current setting chart for setting range.oFFSet when disabling analog current output.noSet when disabling alarm output.AFSet when enabling alarm output. Refer to the table on page 89.20 AlertHtoucoFF50 100%Set to trigger an output when the running hour is set.Set in the case of detecting under-load.Set the ratio against the OC current when alarm outputting.88

No.MenuParameterInitial Value SettingValueExplanation of functionE-rSelf-holding after trip, back in when power is reset or ESC button is pushed.21 ResetH-rA-rSelf-holding after trip, back in when ESC button is pushed.Automatic reset after tripping.0.2s 20min Set automatic reset time22 Reset limitation23Total runninghouroFF There is no limit to the number of resets1 5times Set the number of reset operations (within 30 minutes).Display total running hours24 Running hour Display operational time since inputting running hours setting time.25Running hoursettingoFF10 99990hrTo output the running hours, set the number of hours. The running hours will be countedfrom the point when the input is completed.1 247 Set the communication address26CommunicationsettingSee the rightodd, Evn, nonSet the communication speed 1.2, 2.4, 4.8, 9.6, 19.2, 38.4kbpsSet the parityoFF, 1 999sSet the waiting time until an error is displayed when there is communication trouble.27 Test modeIn the case that the set button is pushed when this is displayed, after 3 sec.+ Shock Time, is shown and relay is output.ALo selectionOperational modeWhen motor startsNormal operationWhen exceeding alarmsetting valueWhen tripsOperational outputFlicker output1s1time/s2time/sHold output1sTrip function Indication Contents of trip SolutionOver currentAfter the preset Start time period, the current exceeds the upper setting value andcontinues to flow longer than the preset Shock time. Trip current is 3.6A.Check the abnormality of machinePhase loss Trip due to phase loss of R(L1) phase Check the abnormality of machinePhase reversalStall (Lock whenstarting)Jam (Lock whenoperating)ImbalanceUnder currentLimitation of thenumber of autoresetTrip due to phase reversalWhen the motor starts, the current exceeds Sc setting value and continues toflow longer than the preset Start time.When motor is operating, the current exceeds Ja setting value and continuesto flow longer than Jt setting time.Current of each phase becomes imbalanced larger than the Ub setting value,and continues to remain imbalanced longer than the Ubt setting time.After the preset Start time period, the current under-runs the lower settingvalue and continues to fl ow longer than the preset Shock time. Trip current is1.6A.Number of auto-resets after trip exceeds the setting value within 30 minutes.Check phase sequence with phasesequence meterCheck the abnormality of machineCheck the abnormality of machineCheck the power source, motor andmotor wiringCheck the abnormality of machineCheck the abnormality of machine89

100001000100101253015201051100001000100101302520151051302520151051HotCold0.11 2 3 4 5 6 7 8 9100.11 2 3 4 5 6 7 8 9 10Note 1) Set the parameter “CT ratio” based on the number of motor wires that pass through the CT.2) In case that the motor kW exceeds the above table, use external CT. 90

ItemTransmittance StandardsMax. transmittance distanceTransmittance systemTransmittance speedContentRS-4851200m (Depends on transmittance speed)Half-duplex system Protocol: modbus1.2k to 38.4kbps1) Prepare a signal converter to use the monitoring software (PCON) of TSBSC.2) Use twist cables and connect as follows. Terminal Signal RS485 TerminalV- GND GNDD1 Data (B) Tx+D0 Data (A) Tx-S Shield Shield91

TSBSCB06, TSBSCB34, TSBSCB60TSBSCS06, TSBSCS34, TSBSCS60 TSBSCDTSBSCC05, TSBSCC10, TSBSCC15,TSBSCC20, TSBSCC30 TSB3CTC100, TSB3CTC200, TSB3CTC30093

TSB020ED-1TSB220ED-1TSB020ED-2TSB220ED-2TSB075ED-1TSB550ED-1TSB075ED-2TSB550ED-2ModelControl power supply voltage 100120VControl power supply voltage 200240V200V No. of wires that pass through T2Applicable class the CT hole, DIP switch 4 T1motors1 400V No. of wires that pass through T2class the CT hole, DIP switch 4 T1Frequency of motor currentMaximum motor circuit voltageOperating power supply12Motor<strong>Protection</strong> functionsAccuracy <strong>Overload</strong>Output relayInsulationWithstandvoltageWork environmentCurrent settingrange3ResetNo. of wires thatpass throughthe CT hole,DIP switchStart time 3Shock time 3Current detection accuracyTemporal accuracyLocked rotor startRated loadMinimum allowable loadLife spanContact constitutionOperationTrip reset,DIP switchBetween case and circuitBetween case and circuitRelay contact electrodesLocationAmbient temperatureAmbient humidityAltitudePower consumptionMassT2T1AMTSB020ED–1TSB075ED–1TSB220ED–1TSB550ED–1TSB020ED–2TSB075ED–2TSB220ED–2TSB550ED–20.1kW0.4kW1.5kW3.7kW0.2kW0.75kW2.2kW5.5kW0.1, 0.2kW—2.2, 3.7kW7.5kW0.4, 0.75kW1.5kW5.5kW11kW20200HzAC600V 50/60Hz100120VAC10%, 50/60Hz200240VAC10%, 50/60Hz0.201.20A1.203.20A3.0010.0A6.0026.0A(0.01A increments) (0.02A increments) (0.1A increments) (0.2A increments)0.402.40A1.805.80A4.0014.0A9.0034.0A(0.02A increments) (0.04A increments) (0.1A increments) (0.25A increments) 20.210.0s (0.2s increments)0.25.0s (0.2s increments)5% 1 digit or less (except, when combined with the inverter, 10% 1 digit or less)5% 1 digit or lessIt will trip if the set current value exceeds 200% when starting, after the set start time +0.2s has elapsed3A, 250VACcos1DC24V, 4mA100,000 times at rated load1a1bEnergization/normal operation: no excitation; at the time of trip: excitationAfter resetting to normal current value, it takes 1s to automatically resetCan be manually reset by pressing the "RESET" buttonDC500V, 10M2000VAC 60Hz: 1 minute1000VAC 60Hz: 1 minuteIndoors, where it will not get wet2050°C3085%RH (no condensation)2000m or less2.0W or less0.25kg or less94

TSB020ED196

TSB151TSB152TSBCOMTSBATFunctionModelTSB151-COMTSB152, TSBMotor200V class0.23.7kW 15.590kW400V class0.23.7kW5.590kWWork environmentAmbient temperatureRelative humidityVibrationHeightAmbient atmosphere10°C50°C4585% RH; there is no condensationLess than 5.9m/s 2Less than 1000mNo corrosive gas, dustMain unit modelTSB151TSB152Load current (current range) 4301301005mA301301005ACurrent accuracy setting10 (full-scale)Time setting rangeStart time 40.220sShock time 40.23sControl power supply voltageMax. motor circuit voltageCurrent detecting systemSelf-holdingNormal stateAC100/110V or AC200/220V 50/60Hz 10%AC600V, 50/60Hz1 phase CT systemSelf-holding availableOutput relay deenergizationOutput relayAbnormal caseContact ratingMinimum applicable load 3Output relay energization1c contact, AC250V 0.2A (inductive load cos=0.4)DC24V, 4mAOutput relay life-spanTest functionIncludedMechanical10,000,000 timesElectric100,000 timesWithstand voltageGap between circuit and housingContact gapCircuit gapAC1500V, 60Hz, 1 minute (power supply circuit and contact circuit)AC700V, 60Hz, 1 minuteAC1500V, 60Hz, 1 minute (power supply circuit and contact circuit)Mass1.0kg1.2kgConsumed power1.2VAExternal accessory CT modelTSB COMTSBATRated input current valueRated input current0.75A, 1.5A, 1.75A, 2.0A, 2.5A, 3.3A, 4.0A,100A, 120A, 150A,5.3A, 7.0A, 9.0A, 10.0A, 16.0A200A, 250A, 300ARated output current5mA5ARated load0.5VA5VAMass0.5kg0.6kgCommonExternal CT Main UnitAT 297

97 98

TSB151 - TSB152TSBAT ModelStandardImpact load detection1A input(motor capacity is not necessary to consider)Upper/lowerlimit detectionAdditional specifications151/152151M/152M152C151W152WSubtropical spec.SControl power supplyvoltage modificationVPanel mountingPStart time modification Shock time modificationT1Auto-resetT2H 99

Power supply: AC200/ 220VMotors(kW)0.20.40.751.52.23.7Motor ratedcurrent (A)1.752.54.07.010.016.0Connecting terminalMotor side Shock Relay sideK-L2K-L2K-L2K-L1K-L1K-L1 k-1k-1k-3k-1k-2k-3Power supply: AC400/ 440VMotor rated Connecting terminalcurrent (A) Motor side Shock Relay side0.751.52.03.35.39.0K-L2K-L2L1-L2L1-L2L1-L2K-L11-22-32-3k-2k-31-3 Motor ratedConnecting terminalcurrent (A)ShockMotor sideRelay side0.150.250.40.61.01.6K-L2K-L2K-L2K-L1K-L1K-L1k-1k-2k-3k-1k-2k-3 Motor(kW)5.57.511151922303745557590Power supply: AC200/ 220VMotor ratedcurrent (A)2530506075100120150170200250300CT size100AT120AT100AT120AT150AT100AT120AT150AT200AT200AT250AT300ATNumber of wiresthat pass throughthe CT hole (T)442221111111Power supply: AC400/ 440VMotor ratedcurrent (A)142025303750607585100130150CT size100AT100AT100AT120AT150AT100AT120AT150AT100AT100AT150AT150ATNumber of wiresthat pass throughthe CT hole (T)754442221111 100

TSBSS05TSBSS30TSBSS60TSBSS100TSBSS05TSB2CT100TSBSS200TSBSS05TSB2CT200TSBSS300TSBSS05TSB2CT300ItemsModel No.Load current (current setting range) 3Applicable 200V classmotor capacity 400V classAmbient temperatureAmbient humidityWorkenvironment VibrationAltitudeAmbient atmosphereUnit model No.Current setting accuracySet timeStart time 3rangeShock time 3Control power supply voltage (L1 - L2)Maximum motor circuit voltageCurrent detection systemSelf-holdingNormal stateOutput relay Abnormal case1 Contact capacityMinimum applicable load 2Reset methodOutput relay Mechanicallife-span ElectricalTest functionsCommonMain unitExternal CTWithstandvoltagePowerconsumptionBetween the circuit and caseBetween contactsBetween circuitGross massWhen AC110VWhen AC200VDIN rail mountingULcULCEExternal CT Model No.Rated primary currentRated secondary currentRated loadMassTSBSS05 TSBSS30 TSBSS60 TSBSS100 TSBSS200 TSBSS3000.55A330A560A 10100A 20200A 30300A0.10.75kW 1.55.5kW 7.511kW 1518.5kW 2237kW 4575kW0.22.2kW 3.711kW 1522kW 3045kW 5590kW 110132kW20604585%RH; no condensationLess than 5.9m/s 2Less than 2000mNo corrosive gas, dustTSBSS05 TSBSS30 TSBSS60 TSBSS05 TSBSS05 TSBSS0510% (full scale)4 0.230s5 0.210sAC100240V, 5060HzAC600V, 5060HzTwo-phase CT systemIncludes self-holdingAt start up there is a 0.5s delay, then the output relay excitesWhen it trips or the power is shut off, the output relay is not excited1c contact, AC240V 3A (in the case of a resistance load)DC10V, 10mAPress the RESET button or cut the operation power10,000,000 times100,000 timesInternal circuit and output relay operation checkAC2000V, 60Hz, 1 minute (power supply circuit and contact circuit)AC1000V, 60Hz, 1 minuteAC2000V, 60Hz, 1 minute (power supply circuit and contact circuit)0.2kg (not including external CT)2.7VA0.35W11.0VA1.2W6 Not neededTSB2CT100100ATSB2CT200200A5A5VA0.5kgTSB2CT300300A101

101 102

TSBSS05103

TSBSA05TSBSA10TSBSA30TSBSA60TSBSA100TSBSA05TSB2CT100TSBSA200TSBSA05TSB2CT200TSBSA300TSBSA05TSB2CT300FunctionModelLoad current (current setting range) 3Motor200V classcapacity 400V classAmbient temperatureAmbient humidityWorkVibrationenvironmentAltitudeAtmosphereUnit modelCurrent setting accuracyTime setting Start time 3rangeShock time 3Operation power sourceA1A2Maximum motor circuit voltageCurrent detection systemSelf-holdingNormal stateOutput relay Abnormal case1Contact capacityMinimum applicable load 2Output relay Mechanicallife spanElectricalTest functionsBetween the circuit and caseWithstandvoltage Between contactsBetween circuitsMassPower When AC110Vconsumption When AC200VDIN rail mountingExternal CT Model No.Rated primary currentRated secondary currentRated loadMassCommonMain UnitExternal CTTSBSA05 TSBSA10 TSBSA30 TSBSA60 TSBSA100 TSBSA200 TSBSA3000.55A 110A 330A 560A 10100A 20200A 30300A0.10.75kW 1.52.2kW 3.75.5kW 7.511kW 1518.5kW 2237kW 4575kW0.22.2kW 3.7kW 5.511kW 1522kW 3045kW 5590kW 110132kW20°C60°C4585%RH: no condensationLess than 5.9m/s 2Less than 2000mNo corrosive gas or dustTSBSA05 TSBSA10 TSBSA30 TSBSA60 TSBSA05 TSBSA05 TSBSA0510% (full-scale)4 0.210s5 0.25sAC100240V, 50/60HzAC600V, 50/60Hz2 phase CT systemNo self-holding (automatically returns after 1s)Output relay is not excitedOutput relay is excited0.2A AC250V cos0.4DC10V, 10mA10,000,000 times100,000 timesInternal circuit and output relay operation verificationAC2000V, 60Hz, 1 minute (power supply circuit and contact circuit)AC 1000V, 60Hz, 1 minuteAC2000V, 60Hz, 1 minute (power supply circuit and contact circuit)0.2kg (excluding external CT)2.7VA0.35W11.0VA1.2WNot neededTSB2CT100 TSB2CT200 TSB2CT300100A200A300A5A5VA0.5kg104

105

TSBSA05 Capacity(kW)AC200V class motorShock RelayModel No.No. of wires thatpass through theCT hole0.1 TSBSA05 40.2 TSBSA05 30.4 TSBSA05 20.75 TSBSA05 11.5 TSBSA10 12.2 TSBSA10 13.7 TSBSA30 15.5 TSBSA30 17.5 TSBSA60 111.0 TSBSA60 1 Capacity(kW)AC400V class motorShock RelayModel No.No. of wires thatpass through theCT hole 00.2 TSBSA05 400.4 TSBSA05 30.75 TSBSA05 201.5 TSBSA05 102.2 TSBSA05 103.7 TSBSA10 105.5 TSBSA30 107.5 TSBSA30 111.0 TSBSA30 115.0 TSBSA60 118.5 TSBSA60 122.0 TSBSA60 1106

TSBSU05-2TSBSU30-2TSBSU60-2Model No.Current setting range 1, 2TSBSU05-20.55ATSBSU30-2330ATSBSU60-2560AShock Time setting range 1Current setting accuracyControl power supply voltage (A1 – A2)Maximum motor circuit voltageCurrent detection system0.230s±10% (full scale)AC 100240V±10% 50/60HzAC 600V 50/60Hz 32 phase CT systemDisplayOutput relayWork environmentInsulation resistanceMON lampUC lampContact arrangementContact ratingRecommended amperes (in case of frequent operation)Minimum application load 4OperationSelf-holdingLifeReset methodAmbient temperatureStorage temperatureHumidityAltitudeAtmosphereVibrationBetween case and circuitNormal monitoring state: MON lamp (green) is onDetection of under current: UC lamp (red) is on1c3A AC250V cos=10.2A and below AC250V cos=0.4DC10V, 10mARelay is excited when trippingYes (refer to the diagram shown in the next page)100,000 times at contact rating loadRESET button: ON or Power source: off2060°C3070°C4585%RH; no condensation2000m and belowNo corrosive gas nor dust; Pollution degree 3 and below; in the control box5.9m/s 2 and below10M and above (DC500V megger)Between case and circuitAC2000V 60Hz 1 min.WithstandBetween contactsAC1000V 60Hz 1 min.voltageBetween circuitsAC2000V 60Hz 1 min.MaterialsCasePolycarbonate, UL94V0Cover for terminalsNylon 6DimensionsMassPower consumptionMountingMain unit (including CT)Main unit (including CT)2VA and below35mm DIN rail or attached bracketLength 62 x width 54 x height 66mm0.2kg 107

TSBSU05-2 AC 200V class 3 phase motorAC 400V class 3 phase motorCapacity(kW)ApplicableShock Relay Model No.Number of wires that passthrough the CT holeCapacity(kW)ApplicableShock Relay Model No.Number of wires that passthrough the CT hole00.1 TSBSU05-2 4 00.2 TSBSU05-2 300.2 TSBSU05-2 400.4 TSBSU05-2 200.4 TSBSU05-2 30.75 TSBSU05-2 10.75 TSBSU05-2 201.5 TSBSU30-2 301.5 TSBSU05-2 102.2 TSBSU30-2 202.2 TSBSU05-2 103.7 TSBSU30-2 103.7 TSBSU30-2 305.5 TSBSU30-2 105.5 TSBSU30-2 207.5 TSBSU60-2 107.5 TSBSU30-2 111.0 TSBSU60-2 111.0 TSBSU30-2 1 15.0 TSBSU60-2 1 18.5 TSBSU60-2 1 22.0 TSBSU60-2 1108

TSB50TSBCOMModelFunction200V classMotor400V classAmbient temperatureAmbient humidityWork environmentVibrationAltitudeAtmosphereUnit Model No.Load current (current setting range) 3Current setting accuracyStart timeTime setting rangeShock timeControl power supply voltageMaximum motor circuit voltageCurrent detecting systemSelf-holdingNormal operationOutput relayAbnormal caseContact capacityMinimum applicable load 2MechanicalOutput relay life spanElectricalTest functionsSpace between circuit and housingWithstand voltage Contact spacingCircuit spacingMassElectricity consumptionAttached External CTCommonExternal CT Main UnitRated primary currentRated secondary currentRated loadMassTSB50-COM0.23.7kW 10.23.7kW–10°C50°C4585%RH: no condensationLess than 5.9m/s 2Less than 1000mNo corrosive gas, dustTSB5050130% (100%5mA)10% (full-scale)Fixed at 3s0.33sAC100/110V or AC200/220V 50/60Hz 10%AC600V, 50/60HzSingle-phase CT systemNo self-holding (automatic return)Output relay is not excitedOutput relay is excited1s contact, AC250V 0.1A (inductive load cos=0.4)DC10V, 10mA10,000,000 times100,000 timesNot availableAC1500V, 60Hz, 1minute (power supply circuit and contact circuit)AC500V, 60Hz, 1minuteAC1500V, 60Hz, 1minute (power supply circuit and contact circuit)0.3kg (not including external CT)0.5VATSB COM0.75A, 1.5A, 1.75A, 2.0A, 2.5A, 3.3A,4.0A, 5.3A, 7.0A, 9.0A, 10.0A, 16.0A5mA0.5VA0.5kg109

TSB 50COM & COM-A Motor voltage AC200/220V Motor voltage AC400/440VMotorMotor rated Connecting terminal Motor rated Connecting terminal(kW)current (A) Motor side Shock Relay side current (A) Motor side Shock Relay side0.2 1.75 K-L 2k- 1 0.75 K-L 2 1 - 20.4 2.5 K-L 2k- 2 1.5 K-L 2 2 - 30.75 4.0 K-L 2k- 3 2.0 L 1-L 2 2 - 31.5 7.0 K-L 1k- 1 3.3 L 1-L 2k- 22.2 10.0 K-L 1k- 2 5.3 L 1-L 2k- 33.7 16.0 K-L 1k- 3 9.0 K-L 1 1 - 3 Motor ratedConnecting terminalcurrent (A) Motor side Shock Relay side0.15 K-L 2k- 10.25 K-L 2k- 20.4 K-L 2k- 30.6 K-L 1k- 11.0 K-L 1k- 21.6 K-L 1k- 3ModelAdditional specs.Subtropical specifications Control power supply voltage modification Start time modification Shock time modificationSV T1 T2TSB50 110

TSBSM02Function Model TSBSM02Three phase 200V60200WMotor capacitySingle phase 200V60200W1Single phase 100V2590WLoad current setting 30.52.0AStart time1.5s (fixed)Shock time1.0s (fixed)Current detection systemOne phase conversion type1c contact 3A AC250V cos1Contact capacityMinimum applicable load DC10V, 10mA 2Output relay OperationAutomatic resetOperation timingOutput when operatingLife span100,000 timesControl power supply voltageAC90250V50/60HzAmbient operating temperature1050°C 6.55535 657556.95 775111

112

113

113 114

115

116

Unit : mmModel No.DimensionsRough Max.Setting torque rangeWeightbore boreNmkfmdia. dia.FA B Ch7 G H I J-KAdjusting nutL N O PSet screwPCD No.-dia.dia.pitchk0.59 1.18TFK20-1L0.06 0.121.76 5.88TFK20-10.18 0.63.92 11.8TFK20-20.4 1.21.76 4.12TFK25-1L0.18 0.423.92 16.7TFK25-10.4 1.77.84 32.3TFK25-20.8 3.35.88 11.8TFK35-1L0.6 1.27101422374813.316.87884965065243570844-M64-M65638525522M241.0M351.5M5 x 8M5 x 80.560.7611.8 44.1TFK35-11.2 4.520.6 89.2TFK35-22.1 9.117 25 62 19.8 8 120 89 42 108 4-M6 7 65 6 2.5 M421.5 M6 x 12 1.5 117

Unit : mmModel No.Setting torque rangeNmkfmRoughboredia.Max.boredia.A B CDimensionsFh7 G H I J-KPCD No.-dia.LAdjusting nutdia.pitchAdjusting boltdia. X pitchSet screw11.8 29.4TFK50-1L1.2 3.028.4 125TFK50-12.9 12.852.9 252TFK50-25.4 25.729.4 70.6TFK70-1L3.0 7.269.6 341TFK70-17.1 34.8134 650TFK70-213.7 66.320304264769822.824.8121216621612717865951502004-M86-M8910M651.5M951.5M81M101.25M8 x 20M10 x 204.09.4Weightk 33TFK3528 24 19 16 1434TFK50 45 37 3124 20 183832 47 39 31TFK704840SprocketModel.NoRS35 RS40 RS50 RS60 RS80 RS100 RS12032 25 22TFK20 32 25 TFK25 35 28 23 20 16TFK35-1-25J-2.5 118

Unit : mmTorque Keeper Model No.Finished bore sizeTFK20-1LTFK20-19,10,11,12,14TFK20-2TFK25-1LTFK25-114,15,16,17,18,19,20,22TFK25-2TFK35-1LTFK35-119,20,22,24,25TFK35-2TFK50-1LTFK50-122,24,25,28,29,30,32,33,35,36,38,40,42TFK50-2TFK70-1LTFK70-132,33,35,36,38,40,42,43,45,46,48,50,52,55,56,57,60,63TFK70-2DeliveryEx.-Japan 4weeks by seaTFK35 - 1 - 25J Shaft bore diameter Chamferingsize25 and less C0.550 and lessC1Above 51 C1.5 119

120

121

as a s a s 122

i Tightening torque N·m{kgf·cm}M53.8 {38.7}M816 {163} 123

MEMO124

125

125 126

127

128

129

130

100500 131

ItemModel No.TSM300012 Basic typeTSM3000H12 Economy typeTSM3000H2Load slavedtracking typeTSM3000M1Contactdetection typeTSM3000M2Integral power typeTSM3000C1Built-in forward/reversesequencer typeAppliedmotorCapacity3 Power source voltageFrequency0.1 110kWAC200/220V, AC400/440V5 120HzControl power supply voltageAC90 250 V50/60Hz, DC90 250V Nonpolar3 Motor voltageAC250V, MAXInputCurrent sensorDC2.5VControl inputX1, X2, X3, IHX1, X2, RESX1, RESX1, X2, X3, X4, X5X1, X2, X3, X4, X5X1, X2No. of contact3c2c2c2a, 1c2a, 1c3a, 1bOutputOutputrelay lifeMechanicalElectrical10,000,000 activations100,000 activationsAnalog output relay DC2V1.5VDC0 3.0VLoadsettinglevelOutput 1Output 2Output 3High1 200 200High2 200 200Low 99 99HIGH1 5 200HIGH2 5 200HIGH1 1 99HIGH2 5 200OUT1 1 99OUT2 1 99OUT3 5 200OUT1 0 99OUT2 5 200OUT3 5 200<strong>Overload</strong> 5 200No load 5 200Start time setting rangeShock time0.1 20.0s“MIN” or 0.1 10.0s1 300ssetting rangeIn case motor power souce frequency is 50Hz and higher, shock time at “MIN” is approximately 30ms.ReponseSet by number ofmoving averageQUICK (Average no. 1 time), NORMAL (Average no. 5 times), SLOW (Average no. 20 times)4 Inhibit functionRelay self-holdingManual/auto switchingAutoinhibitSelf-hold/auto reset selectableManual/auto switchingOnly OUT3 is selectableAutoinhibitSequencer functionSwitching detection level 8 steps4 stepsNone8 stepsNoneTest functionPeak-holdfunctionRelay output testWhen the load ratio exceeds the pre-set level (or falls below it), shows the maximum value within shock time.Only when the output is set as self-hold, it is peak hold.% Power display range 200 2000 200Voltage display rangeCurrent display rangeFrequency display range0 500V0.01 999A5 120HzPower consumptionApproximate mass10VA (Inrush current 5A within 5ms)1.0kgAmbienttemperature0 50WorkReative humidity45 85% RH; there is no condensationenvironment Altitude1000m and lessAmbientatomosphereNo corrosive gas, dust SettingFunctionDisplayRelay contactoutputAC250V, 0.5A (Inductive load cos 0.4)DC30V, 0.4A (Inductive load) DC110V, 0.2A (Inductive load) Minimum load applicable DC24V, 4mA 131 132

ItemModel No.TSM400012 Basic typeTSM4000H12 Economy typeTSM4000H2Load slavedtracking typeTSM4000M1Contactdetection typeTSM4000M2Integral power typeTSM4000C1Built-in forward/reversesequencer typeAppliedmotorCapacity3 Power source voltageFrequency0.1 110kWAC200/220V, AC400/440V5 120HzControl power supply voltageAC90 250V50/60Hz, DC90 250V Nonpolar3 Motor voltageAC250V, MAXInputCurrent sensorDC2.5VControl inputX1, X2, X3, IH, RSTX1, X2, RSTX1, RSTX1, X2, X3, X4, X5X1, X2, X3, X4, X5X1, X2No. of contact3c2c2c3c3c2a, 1b, 1cOutputSettingFunctionDisplayRelay contactoutputOutputrelay lifeMechanicalElectricalAnalog output relayLoadsettinglevelStart time setting rangeShock timesetting rangeReponse4 Inhibit functionRelay self-holdingSwitching detection levelTest functionPeak-holdfunctionOutput 1Output 2Output 3% Power display rangeVoltage display rangeCurrent display rangeFrequency display rangePower consumptionApproximate massAmbienttemperatureReative humidityWorkenvironment AltitudeAmbientatomosphereHigh1 200 200High2 200 200Low 99 99AC250V, 0.5A (Inductive load cos 0.4)DC30V, 0.4A (Inductive load) DC110V, 0.2A (Inductive load) Minimum load applicable DC24V, 4mA10,000,000 activations100,000 activationsDC0 10VHIGH1 1 99 OUT1 1 99HIGH2 5 200 OUT2 1 99 OUT3 5 2000.1 20.0s“MIN” or 0.1 10.0sIn case motor power souce frequency is 50Hz and higher, shock time at “MIN” is approximately 50ms.Set by number ofmoving averageQUICK (Average no. 1 time), NORMAL (Average no. 5 times), SLOW (Average no. 20 times)Manual/auto switchingAutoinhibitSelf-hold/auto reset selectableManual/auto switchingOnly OUT3 is selectableSequencer function8 steps4 stepsNone8 stepsNoneRelay output testWhen the load ratio exceeds the pre-set level (or falls below it), shows the maximum value within shock time. 200 200HIGH1 5 200HIGH2 5 200Only when the output is set as self-hold, it is peak hold.0 2000 500V0.01 999A5 120Hz10VA (Inrush current 5A within 5ms)1.0k0 5045 85% RH; there is no condensation1000m and lessNo corrosive gas, dustOUT1 0 99OUT2 5 200OUT3 5 200<strong>Overload</strong> 5 200No load 5 2001 300s 133

134

135

136

Motor capacitykW0.10.20.40.751.52.23.75.57.5111518.522303745557590110AC 200/220V motorSensorModel No.TSM-U010TSM-U010TSM-U010TSM-U050TSM-U050TSM-U050TSM-U050TSM-U050TSM-U100TSM-U100TSM-U150TSM-U150TSM-U200TSM-M300TSM-M300TSM-M400TSM-M600TSM-M600TSM-M800TSM-M800Number of wiresthat pass throughthe CT hole63263211111111111111AC 400/440V motorSensorModel No.TSM-U010TSM-U010TSM-U010TSM-U010TSM-U050TSM-U050TSM-U050TSM-U050TSM-U050TSM-U050TSM-U100TSM-U100TSM-U100TSM-U150TSM-U150TSM-U200TSM-M300TSM-M300TSM-M400TSM-M400Number of wiresthat pass throughthe CT hole126326532111111111111 Model No.Cable length (L)TSM4-S01 (attached)1mTSM4-S033mTSM4-S055mTSM4-S1010mTSM4-S2020mTSM4-S3030m Model No.TSM4-C01TSM4-C03Cable length (L)1m3m137