4 - Kuwait Oil Company

4 - Kuwait Oil Company

4 - Kuwait Oil Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

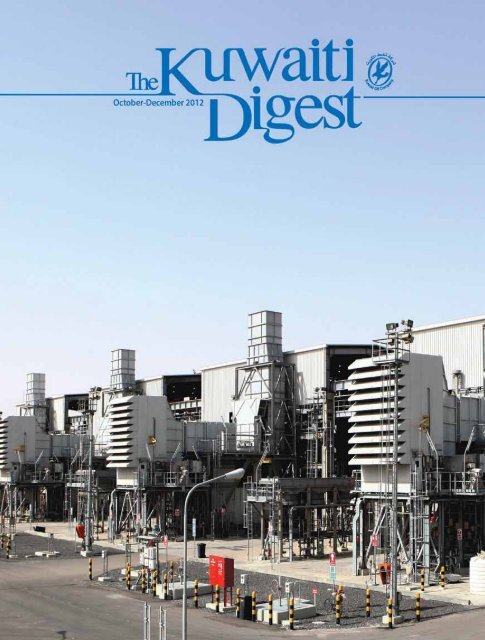

October - December 2012The <strong>Kuwait</strong>i Digest isa quarterly magazinepublished by the <strong>Kuwait</strong><strong>Oil</strong> <strong>Company</strong> (K.S.C.)since 1973.The <strong>Kuwait</strong>i Digestinvites newspaper,magazine and tradejournal editors to reprintor otherwise make useof articles or illustrationsappearing in this issue.Material should becredited and a copymailed to the <strong>Kuwait</strong> <strong>Oil</strong><strong>Company</strong>.Produced byAl-Nazaer Printing PressPublishing & Distributing Co. w.l.l.Tel: 24744741 - Fax: 24716993Editor-in-ChiefKhaled Madhi Al-KhameesDeputy Editor-in-ChiefAbdul Khaleq Al-AliCorrespondence concerningThe <strong>Kuwait</strong>i Digest should be addressed to:Editor-in-Chief, <strong>Kuwait</strong> <strong>Oil</strong> <strong>Company</strong> (K.S.C.)Information TeamP.O. Box 9758Ahmadi 61008, <strong>Kuwait</strong>Telephone: 965-2398-2747Facsimile: 965-2398-1076E-mail: kocinfo@kockw.comor visit the KOC homepage athttp://www.kockw.com8West <strong>Kuwait</strong> Asset ActionPlan: An Overview

ContentsLetter from the Editor 2Esam Al-Houti Returns Safely to <strong>Kuwait</strong> 3KOC Commissions BS-160 4West <strong>Kuwait</strong> Asset Action Plan: An Overview 8Enterprise Architecture at KOC 12Enterprise Content Management Business Value 16The Benefit of Variable Speed Drives for KOC Operations 204KOC CommissionsBS-160Significance of Safety Instrumented System 23Caring for the Community 28C&MD Visits Ahmadi Hospital 31<strong>Oil</strong> Origins: The Biotic Vs. Abiotic Theories 32<strong>Kuwait</strong>’s Water Future 34Hi-Tech 38Heavy <strong>Oil</strong>: KOC’s Next Great Challenge 40KOC Purchases 14 New Tugboats 42C&MD Visits31 34Ahmadi Hospital<strong>Kuwait</strong>’s Water FutureUnderstanding Asthma 44The Quran: An Introduction to Islam’s Holy Book 46KOC & General Fire Service DirectorateHold Fire Awareness Campaign 48KOC Purchases 14 New42 Tugboats

Esam Al-Houti Returns Safely to <strong>Kuwait</strong>KOC Manager Freed After Lebanon Hostage OrdealEsam Al-Houti (3rd from right) is pictured with senior KOC officialsEsam Al-Houti, Manager MajorProjects I, was greeted to ahero’s welcome recently at theKOC Guest House to celebratehis safe release after beingkidnapped on a recent trip toLebanon. Senior KOC officials,including C&MD Sami Al-Rushaid,DMDs and Managers werepresent to welcome Al-Houti andcongratulate him on his safe returnto <strong>Kuwait</strong>.Al-Houti’s ordeal began whenhe was kidnapped in Lebanon’sBekaa Valley while exiting his carin front of his apartment. As heexited his vehicle, six armed menattacked him, and after a struggle,they managed to blindfold himand restrain him and succeededin abducting him away in theircar. Throughout the durationof his kidnapping, Al-Houtimaintained that his captors kepthim blindfolded at an undisclosedlocation. His kidnappersdemanded $2 million in ransommoney; however, after intensepressure from both the Lebanesegovernment and abroad, Al-Houtiwas released safely without payingany ransom.During the welcoming ceremonywhich took place at the GuestHouse, Al-Houti appeared in goodhealth and in high spirits. In astatement he made to the <strong>Kuwait</strong>iDigest, Al-Houti recounted theentirety of his ordeal and saidthat he was very happy to see theoverwhelming support that hereceived from the <strong>Kuwait</strong>i peopleupon his release. He said that hewas especially surprised to see theoutpouring of support, especiallyconsidering the fact that he wasnot even certain if anyone knewabout his exact whereaboutsduring the ordeal, seeing as howhe was cut off from the outsideworld while he was held hostage.After his release, however, helearned that many segments of<strong>Kuwait</strong>i society and the Lebaneseauthorities were actively workingtowards his safe release. In thatregard, Al-Houti said he was verygrateful for the swift action that<strong>Kuwait</strong>’s diplomatic forces tookin their campaign for his releaseand thanked HH the Amir, seniorgovernment officials, various<strong>Kuwait</strong>i ministries, the <strong>Kuwait</strong>iEmbassy in Lebanon, KOCofficials and employees and the<strong>Kuwait</strong>i people for the supportthey displayed both during hiskidnapping and after his release.Al-Houti with KOC C&MD Sami Al-RushaidOctober - December 2012 3

KOC Commissions BS-160Al-Sardi: Project Accomplished Within Budget and Contract ScheduleDMD Mazen Al-Sardi speaks to the audienceKOC has officially launched theBS-160 Project in a ceremonyattended by the Minister of<strong>Oil</strong> Hani Hussein, the ItalianAmbassador to <strong>Kuwait</strong> and anumber of dignitaries and senioroil officials.On the occasion, KOC C&MDSami Al-Rushaid affirmed in aspeech delivered on his behalf bythe Deputy Chairman and DMD(TS), Mazen Al-Sardi, that thisproject, which has been underconstruction for the past threeyears, has been completed withinbudget and on time in accordancewith the contract schedule.“The booster station utilizes thehighest standards of state-of-thearttechnology that is availabletoday and is a major step forwardtowards achieving the overall<strong>Kuwait</strong> Development StrategicPlan,” the DMD pointed out.He continued, “In doing so, thefacility also sets new standards forenvironmental stewardship withsubstantially reduced emissionsto the atmosphere over previousgeneration equipment and withgreater efficiency while conservingvaluable natural gas and helpingto protect the environment.”Al-Sardi affirmed that thecompletion is a tribute to the hardwork and efforts of the more than2,500 people who comprised theworkforce and made the projectpossible.The DMD expressed profoundgratitude to all those involved inthe massive project, particularlythe KOC Management, theMajor Projects Group, theGas Management Group, themain contractor, Saipem, itssubcontractors and the ProjectManagement <strong>Company</strong> (PMC) andWorleyParsons. He then describedthe safety record of this Project asexceptional. More than 14 millionman-hours were worked without aLost Time injury.“A comprehensive safety programput in place made sure that theworkers went home safe, whichis a primary responsibility of allparties,” Al-Sardi pointed out,adding, “The commissioning ofthis facility means that there isan increased natural gas handlingcapacity from the <strong>Oil</strong> GatheringCenters of South East <strong>Kuwait</strong>which improves oil productionhandling reliability, operationalflexibility and efficiency.”The DMD explained that lessefficient equipment can alsonow be taken out of service forupgrading while still maintainingthe gas handling capability andoil production, which will leadto less flaring of gas and betterprotection of the atmosphere.“The installation incorporatesequipment sourced from all overthe world to attain the highestlevels of advanced technicalcontent,” he elaborated.Al-Sardi informed the gatheringthat more than 20% of the4October - December 2012

Minister of <strong>Oil</strong> Hani Hussein (L) and Al-Sardi, Hussein and DMD Planning & Gas Menahi Al-Anzithat cooperation and team workwere the main factors behind theproject’s accomplishment.At the conclusion of the ceremony,plaques were presented to thosewho contributed to the success ofthis vital project for the State of<strong>Kuwait</strong>.An Overview of BS-160:• Construction on BS-160 beganon Nov. 15th, 2008.• BS-160 consists of two trains.Each train has Low Pressure (LP)and High Pressure (HP) units.This facility also has the controlflexibility of changing the flowroute from Train-I to Train-IIand vice versa. The boosteroverall design capacity is 500MMSCFD.• BS-160 offers Gas Operation(S&EK) a greater capacitycontrol over the gas compressionamount. The integration of thisnew constructed facility withBooster Stations 140 & 150provides significant flexibilitywhich will reduce gas flaringtremendously.This project provides manyfactors that will play a key role inachieving the KOC 2030 strategy,such as:• Satisfying customer needs whichinclude increased demands ofoperating capacity and technicalcapability.• The optimization of productionand utilization of associatedgas.• Maximizing the production andutilization of non-associatedgas.• Provide support to the energyrequirements for the State of<strong>Kuwait</strong>.• Environment-friendly impact byreducing gas flaring.• Offer many opportunities forrecruitment.The project takes concernsregarding the environment intoconsideration. BS-160 turbinesare of the latest technology andhave significantly reduced CO2emissions. In addition, FlaringSystems have environmentfriendlyimpacts. This facility hasmet the <strong>Company</strong> EnvironmentProtection values.The contribution of this projectto <strong>Kuwait</strong> can be viewed in manyways:• Reducing gas flaring not onlyprotects the environment butalso saves money in terms ofgas production cost as well asenvironmental protection costs.• Maximizing the production linewill grow the economy.• Provides solutions to thedemand of energy requirements.Factors that distinguish this projectfrom similar projects include:• The first new booster in S&EKarea for 35 years.• The booster station is designedto handle sour gas. (BS-140 &BS-150 require upgrades)• The gas turbines use aeroderivativedesigns whichimprove overall Booster Stationavailability. (i.e. Quick to repair)• The compression units are of thelatest design which means thatpower efficiency is significantlyimproved. (i.e. Fuel Gas used toprovide gas compression poweris significantly reduced)October - December 2012 7

West <strong>Kuwait</strong> Asset Action Plan: An OverviewSubmitted by: Rima Al-Awadhi, Team Leader Planning (WK)Planning is generally a processwhich involves the determinationof future courses of action. It isa dynamic process which is veryessential for every organizationto achieve their ultimate goals.Planning bridges the gap from“where we are” to “where we wantto go,” and it makes it possiblefor certain outcomes to occurthat would not otherwise come tofruition if there was no planninginvolved.In other words, planning in anorganization can be definedas the process of creating andmaintaining a plan. It is a processof thinking about the activitiesrequired to accomplish a desiredtask or reaching the organizationalgoal. In short, choosing adestination, evaluating alternativeroutes, and deciding the specificcourse of the plan are the majorsteps involved in the process ofplanning.The importance of planning is thatit provides directions, reduces therisks of uncertainty, overlap andwasteful activities while facilitatingdecision-making and establishingstandards of control.The benefits of planning are that itincreases an organization's abilityto adapt to future eventualities,helps crystallize objectives, ensuresrelatedness among decisions,helps the company remain morecompetitive in its industry,reduces unnecessary pressuresof immediacy, reduces mistakesand oversights, ensures a moreproductive use of the organization'sresources and makes control ofcertain operations and tasks easier.Bad planning, on the otherRima Al-AwadhiTeam Leader Planning (WK)hand, can ultimately result inbusiness frustration or, at thevery least, prevent the businessfrom operating at its full capacity.The plan, however, provides avital paradigm against which theperformance can be rated andrestricts managers from makingbad decisions.The Action Plan includesthe following main steps:What is an Action Plan?An Action Plan is a process thathelps to focus ideas and decidewhat steps need to be taken toachieve particular goals. It is astatement of what to achieve over agiven period of time.An Action Plan also involvesidentifying the objectives, settingobjectives which are achievableand measurable, prioritizing thetasks effectively, and identifyingthe steps needed to achievegoals and meet deadlines whiletaking contingency plans intoconsideration.An effective Action Plan shouldgive a concrete timetable and set ofclearly defined steps to help reachobjectives rather than aimlesslywondering what to do next.8October - December 2012

At KOC, the Asset Action Planis always derived from BusinessGuidelines and aligned with KPC-KOC strategic objectives.The very purpose of the AssetAction Plan is to formulate thedirections, projects, technologies,important initiatives, the quality& quantity of skills required,supports required from thesister directorates, identifyingthe external & internal risks andactivities required to deliver thecore business and to achieve thecorporate objectives.WK Asset Action Plan:our long-term objectives outlinedin the KOC 2030 Strategy. Thesedirections are provided throughestablishing performance targetsand guiding principles for planningpurposes. Planning Group releasesthe BGs and Asset Action Plantemplate in October each year.• Establishment of Core Team inWK DirectorateThe Core Team is responsible forthe preparation of AAP and iscomprised of members from thePlanning (WK) Team, all teams in2030Strategyprepare the best plan to fulfillthe Assets Goals & Objectivestaking into consideration thenew challenges in gas flaring,sustaining production targets, watermanagement, sub-surface potential,reservoir management, major &other projects delivery, skilledmanpower, etc.• Development of the PlanDocumentThe Planning (WK) is assigned todevelop the different sections ofthe Plan document – as detailedbelow - and assure compliancewith guidelines and procedures.Generally this milestone iscompleted by the month of Januaryof the next year, and during thatperiod several interim reviews aretaking place with stakeholders.BusinessGuideline• Finalization of the AAPand presentation to WKManagementThe final step prior to submissionof the AAP document to PlanningGroup per the due date is toreview the whole Plan documentand present its outcomes to West<strong>Kuwait</strong> Management for their finalendorsement.Capex/OpexAllocationAssetActionPlanProjectsinitiationthrough PGS5 Year PlanMain Sections of the AAPdocument:1. DMD’s MessageAAP Preparation Guideline- Chronological Order:• Release of KOC BusinessGuideline/AAP TemplateThe most critical purpose of theBusiness Guideline is to provideKOC Assets and Groups with ahigh-level direction of where and,to some extent, how we want tomove our company forward in thenext several years with an eye onBalancedScorecardWKD and support groups in KOCsuch as Drilling, Well Surveillance,Major Projects, R&T, etc. Thispractice eases the communicationsbetween Planning (WK) Teamand other groups in additionto expediting the availability ofinformation for timely submissionof the Plan. The Core Team shallThe Vision and Mission of WKD.Identifying key goals from nowuntil 2030 that should be achievedby WK groups to support the KOC2030 Strategy.2. Historical PerformanceIllustration of current year keyperformance measures comparedto last year’s (Production, wellsdrilled, reserves, Capex/Opex,workover jobs). This is in additionto indicating successes of eachGroup and major accomplishmentsof previous years.October - December 2012 9

1. KOC Business GuidelinesBusiness Guideline details that arerelated to West <strong>Kuwait</strong> Directoratefor Metric, Core Business andStrategic Functions & Enablers.2. Strategic Initiatives• Core Business InitiativesList of category-wise initiativesunder core business for eachGroup with description.• Strategic Functions & EnablersInitiativesList of category-wise initiativesunder Strategic Functions &Enablers for each Group withdescription.3. High Level ImplementationPlan• Action Plan ImplementationRoad MapAction Plan Roadmap for eachinitiative under each strategicfunction for each Group inthe given template for theDevelopment and improvement ofthe WK operations program.• Delivery Road Map (ProductionProfile)The annual average WKproduction capacity up to 2030for Base/Planned/ Potential andPossible cases.• Water & Gas ManagementThe annual average WK gasproduction capacity up to 2030and flaring chart with mainhighlights. In addition to theannual average, WK WaterProduction and injection up to2030.• Financial OutlookCapex and Opex requirementsup to year 2030 along with majorhighlights.• Manpower OutlookManpower forecast of all WKteams up to 2030.• Technology Road MapList of technologies needed tosupport the activities and projects,stating Business Impact Vs.Ability.4. Progression Template andResources RequiredSummary of the main elementsof AAP, i.e. production forecastup to 2030 compared to resourcesrequired wells to be drilled,ESPs by field, surface facilitiesavailability and utilities.5. Risks and IssuesRisk Matrix indicating (ImpactVs. Probability) is generatedwhich shows list of associatedrisks identified by WK teams andsupport groups that may hinderthe delivery of targeted objectives.6. Economic AssessmentsEconomic assumptions as per thelatest KPC Corporate Guidelinesare being used to developeconomic results for Planned,Potential and Possible productionscenarios.7. Conclusions and WayForwardAs a result of the said exercise,summary of main outcomes andpotential issues is given alongwith recommendations for WayForward.Other Appendices of AAP:Appendix I: Production Profile• Crude <strong>Oil</strong> ProductionForecast - 20 Year by GC& Field and also by cases(Planned+Potential+Possible)• Crude <strong>Oil</strong>, Water and GasProduction Composite Forecast10October - December 2012

Appendix II: 72 MonthsProduction Forecast and ShutdownPlanAppendix III: Wells DrillingRequirements and Well InventoryAppendix IV: Workover/Surveillance & RiglessAppendix V: Capital Projects• Recent re-phasing of all WKDcapital projects listed in KOCBudget Book, taking intoconsideration the current statusfor project’s implementation andlink with other activities in thefields.Appendix VI: Facility ProjectTiming• List the key facility projectsand provide the status. Theseprojects are considered keymajor events to deliver the 2030Strategy.• The status is updated by PL(WK)Appendix VII: Detailed EconomicAppraisal• Using PEEP application andlatest KPC guidelines, economicassessment is carried out for theWK Development Plan basedon the different scenarios andin comparison with last yearindicators.Appendix VIII: 2030 PowerStrategy charts for WK Directorate• 2030 Power Strategyrequirements are coordinatedand finalized by PL (WK).Appendix IX: 2030 WKD PowerPlan• An update of electrical powerrequirements for WK facilitiesand wells categorized by WKproduction fields, Export andMarine business.ConclusionThe primary objective of theKOC Action Plan is to help the<strong>Company</strong> concentrate its effortson areas that require the mostattention in order to allow fordecisions to be made that willturn particular goals into reality.The Action Plan also seeks toidentify and set a range of KOCobjectives that are achievableand measurable and presentthem in a platform that KOCofficials can easily understand andbenefit from. When Action Planinformation is compiled, it allowsfor the effective prioritizationof tasks while also providingchannels for KOC to identifysteps needed to achieve goals andmeet deadlines. The end result isthat KOC will be better adaptedto anticipate future occurrences.This, in turn, will reduce the totalnumber of mistakes and oversightsthat may occur in day-to-dayoperations. As a result, KOCwill be more competitive in itsfield by remaining able to use itsresources to be more productiveand efficient throughout all areasof operation.October - December 2012 11

Enterprise Architecture at KOCSubmitted by: Mohammad Haji Al-Sarraf, Business Systems Leader, Information Technology PlanningFigure 1: A Bird’s Eye View of EnterpriseArchitectureBusiness ArchitectureMohammad Haji Al-SarrafBusiness Systems Leader, InformationTechnology PlanningWhat is Enterprise Architecture?Enterprise Architecture (EA) is a guide to anorganization’s fitness. It is the dynamic processof managing the enterprise IT change through aplanned transformation. The transformation planprovides the process of translating business vision andstrategy into effective enterprise change by creating,communicating and improving the key requirements,principles and models that describe the enterprise'sfuture state and enable its evolution. The scope ofEA includes the people, processes, information andtechnology of the enterprise, and their relationshipsto one another and to the external environment.Enterprise architects compose holistic solutions thataddress the business challenges of the enterprise andsupport the governance needed to implement them.Enterprise architects use the EA process to discoverthe target state that the organization wishes to investin and then helps the organization understand itsprogress toward the desired state.The foundation principle of ‘Aligning IT withBusiness’ for any EA program involves aligningBusiness Architecture with the other threeArchitectural components. There are four buildingblocks for any Enterprise Architecture initiative,namely:1. Business Architecture2. Information Architecture3. Application Architecture4. Technology ArchitectureApplicationArchitectureInformationArchitectureTechnologyArchitectureBusiness ArchitectureBusiness Architecture defines the structure of theenterprise in terms of its governance structure and keybusiness processes. In defining the structure of theenterprise, business architecture considers customers,finances, and the ever-changing market to alignstrategic goals and objectives with decisions regardingproducts and services, partners and suppliers,organization, capabilities, and key initiatives.Information ArchitectureInformation Architecture describes the conceptual,logical and physical view of the corporate data assetstructures of an organization along with the datamanagement resources.Solution ArchitectureSolution Architecture describes the components andelements required to deliver a solution, how theyfit together, and the core technologies required.Therefore, Solution Architecture provides a blueprintof the Application systems deployed enterprise-wideand their interaction and relationship with the corebusiness processes of the organization.Technology ArchitectureTechnology Architecture describes the infrastructurethat supports the deployment of core, mission-criticalapplications.What are the drivers for the EnterpriseArchitecture (EA) Project?Let us understand this through the ‘Chain’ metaphor asdescribed in Figures 2, 3 and 4 shown below.12October - December 2012

Figure 3: Comparison of any company without Enterprise Architecture to an openended chainEnterprise Architecture is in the unique position of addressing these “open” links by creatinga quality feedback loop at every step of the way. Using Enterprise Architecture, BusinessArchitecture, and Solution Architecture, the chain becomes stronger, more flexible, and lessexpensive to own. KOC is currently developing its own customized architecture framework to suitFigure 4: An organization view with Enterprise Architecture14October - December 2012

its needs based on TOGAF (The Open GroupArchitecture Framework) version 9.0. Thecustomized framework is based upon suiting ourorganizational needs of Business and IT.There are innumerable benefits that KOC willobtain as a result of leveraging the usage of theEnterprise Architecture Program. Some of thesalient benefits include:• Capturing facts about KOC’s mission, functions,and business foundation in an understandablemanner to promote better planning anddecision making• Aligning IT with business by enabling the useof Technology to drive the facilitation of KOC’sbusiness drivers and help improve consistency,accuracy, timeliness, integrity, quality,availability, access, and sharing of informationacross the enterprise• Achieve economies of scale by providingmechanisms for sharing services across KOCthereby reducing or removing complexity andduplication of efforts• Improve communication among the businessorganizations and IT organizations within theenterprise through a standardized vocabulary• Provide architectural views that helpcommunicate the complexity of large systemsand facilitate management of extensive,complex environments• Focus on the strategic use of emergingtechnologies to better manage the enterprise’sinformation and consistently insert thosetechnologies into the enterprise• Support the processes for assessment ofbenefits, impacts, and capital investmentmeasurements and supporting analyses ofalternatives, risks, and tradeoffs• Highlight opportunities for building greaterquality and flexibility into KOC’s coreapplications without increasing cost• Expedite integration of legacy, migration, andnew systemsAny Enterprise Architecture initiative’s successdepends upon the co-operation and supportof the Executive Sponsorship, Business Usercommunity and ease of use usability of theprogram in everyday function. In addition toworking closely with all the six teams at CITGwe are currently are working with the StrategicPlanning Team from the Planning Group.We are also trying to interface with theInformation Solutions Team from the Research& Technology (R&T) Group. In addition,individuals can also begin to see the ROIfor this project through both the qualitativeand quantitative benefits of the of the EAimplementation.In Stage 2 we will be focusing on the “quickwins” or tactical initiatives that will fetch us animmediate return on investment for this projectand in Stage 3 we will be focusing on strategicinitiatives that will bring value to KOC in thelong run.Improved time to execute, standardized businessprocesses, formal governance and a steeringcommittee to monitor and improve the projectexecution times and incorporating industry bestpractices into KOCs daily functions are someof the benefits one will notice within the firstyear of the project. As the EA program maturesby leveraging technology and plugging-in withother groups at KOC, the benefits realized bythe EA program will be immense.Enterprise Architecture is one of the mostsophisticated IT initiatives that many largecorporations have implemented with great careand caution owing to its complexity due to theinvolvement of people, processes and varioustechnologies under one umbrella.The success of any Enterprise Architectureinitiative depends upon the support andcooperation of the company’s executiveleadership. It also requires strong capabilityof the execution team and support of all thesecondary contributors involved in the project.Upon successful implementation and ongoingmaintenance of any EA program, the benefitswill naturally outweigh the implementationcomplexities, and provide a more organizedand easily manageable platform to serve KOCbusiness needs that help contribute to the<strong>Company</strong> and State of <strong>Kuwait</strong>.October - December 2012 15

Enterprise Content Management Business ValueSubmitted by: Safa Al-Nashmi, TPL Specialist I (Inf. Technology), Corporate Information Technology GroupOver the years, the CorporateInformation Technology Group(CITG) at KOC has madesignificant investments in astrong IT portfolio of innovativeand world-class informationtechnology solutions andservices that help achieve greaterefficiency and productivity whichaid the <strong>Company</strong>’s strategicbusiness objectives. In thecurrent competitive environment,the need for better managementof all the organizationalresources, especially IT, requirescomprehensive assessmentof their contribution to theorganization performance. Whilesome projects will truly generatea fiscal return on investment,others will only generategoodwill, or in other words,better service and improvedcustomer satisfaction. Whetherthe value added is fiscal orimproved service is somethingthat the <strong>Company</strong> shouldrecognize at the onset.Some of the questions thatshould be asked before makingany investment into a possibleIT project include: What valuedoes the project bring to the<strong>Company</strong>? Should the projectbe undertaken if the cost tocreate, implement and maintainis greater than the value/savingsreturned to the <strong>Company</strong>? Is theproject true to the objectivesand overall strategy of theorganization? Does the serviceobtained from the projectsupport the organizationalSafa Al-NashmiTPL Specialist I (Inf. Technology), CorporateInformation Technology Groupmission? How can we use thisproject to reduce costs andincrease effectiveness?Looking for a way to answerthese important questionsand be effective in deliveringresponsible IT solutions andservices to KOC users, aconceptual framework has beenestablished by CITG in orderto judge the business valueoutcomes of enterprise (IT)projects. It has been developedby synthesizing the extantliterature on IT business value,IT services and process design.The framework provides a setof financial measurements andseries of tools for evaluating ITproducts, services, and supportso as to ascertain their businessbenefits. This frameworkboosts CITG ability to measureIT initiatives and facilitatesdecisions on investment thatbring the most value to theorganization.The custom-made frameworkwas used as a part of theCITG basic decision-makingprocess to evaluate one of itsmost critical initiatives calledEnterprise Content Management(ECM). The result of applyingthis framework to the ECMprogram highlights the expectedbusiness value and expectedtechnical value, associated,where possible, with realfinancial benefits, in addition tothe Return on Investment (ROI),financial benefits and cost savingof the ECM initiative. Theseresults could be used by theorganization and managementto understand and “judge” thevalue of the ECM program andwhether or not it is needed forimproving the organization’sperformance.What is ECM?Enterprise Content Management(ECM) as defined by the ECMassociation AIIM (Associationfor Information and ImageManagement) as “The strategies,methods and tools usedto capture, manage, store,preserve and deliver contentand documents related toorganizational processes.”Looking at KOC Group processesand activities, ECM can bedescribed as the bond that linksthe contents of the businessprocesses across the organizationwith the necessary controls andsecurity.16October - December 2012

Figure 1: ECM Strategy at KOCToday, the idea of managing KOC Groups’ business processes andcontent is not enough. Managing the complete lifecycle of content,from creation to disposal, and managing the complexity of thedata and information which results from isolated applications areunderstood as the two main challenges that the <strong>Company</strong> shouldlook at in order to achieve its strategic objectives.ECM Business Case and BVA ApproachThe preliminary step in this exercise was to identify a suitablebusiness case for further investigation. Among many candidate cases,the “Burgan Development Drilling Wells Process” was the mostapplicable case for its direct relation to KOC core business.Figure 2: High-levelflowchart of BurganDevelopment DrillingWells Business ProcessThe diagram illustrates a "birds-eyeview" of the process and portraysthe major stages to identify anddrill the necessary number offuture wells required to meet the<strong>Company</strong>’s strategic productiontarget, including conductingstudies, identifying appropriatewell locations and drilling andconnecting the wells to therespective GC.To achieve more accurate andcredible results, CITG had tolook at business value from thecustomer’s viewpoint. Therefore,in-depth inquiries into the BurganDevelopment Drilling WellsProcess had to be conductedby an internal task force teamwhich was formed to achieve thisobjective. Key members of theteam included, in addition to ECMBVA domain experts from IBM,selected members from CITG andbusiness owners from differentareas, represented by TL FieldDevelopment (SK), TL GeneralProjects, TL Production Operations(EK) and TL HSE (S&EK). Theywere all very committed andsupportive and have contributedimmensely towards successfullyachieving the objectives of thisexercise.Several meetings, interviews,workshops and conference callswere held in order to obtain asmuch information as possible andgain a deeper understanding of thepotential business value that willbe realized from the ECM program.Activities included:• Fully comprehending theinformation intensive businesschallenges across the BurganDevelopment Drilling WellsProcess (the current state businessproblems, the drivers for changeand goals and benefits of FutureState environment).October - December 2012 17

• Identifying requirements andmaking recommendations forimprovements and alignment ofIT and business, specifically forthe Burgan Development DrillingWells Process in relation toEnterprise Content Management.• Providing a financial businesscase for the Enterprise ContentManagement program byextrapolating the BurganDevelopment Drilling WellsProcess benefits to the enterprise.1. Information BusinessChallengesDuring the interviews, someinformation challenges associatedwith the process, people andsystem dimensions were identified.The manual process of managingthe content and sharing andcommunicating information resultedin unexpected delays, re-work, anddistrusted information.Normally, non-value time existsin any discipline during thecommunication and integrationof various business functionsand applications throughout theenterprise. In any business process,there is time where people arebeing contacted in some way toplay a critical part in running/executing a process for a givenrequest by following rules andusing systems. The aim was tounderstand how this time is beingused today and whether it can beaccelerated through automation,optimization or elimination of timewasted, to return non-value addedtime back to the <strong>Company</strong> bygetting the right documents to theright people at the right time.Figure 3 summarizes the information challenges observed during the study in relation to ECM:Process People System• Manual processes takingsubstantially longer than theirdesired completion• 4-5 months of re-work due toinaccuracy• Communication (Time spentsharing information)• Delays in providing welllocations and GC destination(Information is not timely)• Cultural change issues• Minimal systems integration• Different sources of updatedinformation• Complexity in managing andsharing data due to largeamounts of physical storage• No version control ofdocuments• Information retention policydefaults to “forever”• Lack of automation ofstandards and governanceFigure 3: Information Challenges2. Defining RequirementsThe next stage of this exercisewas the definition of what therequirements are and how theycan be satisfied. These can besummarized into four main pointsas follows:Reduce process latency andincrease process adherence by:• Automating all business processesincluding HSE processes throughdifferent applications andplatforms• Combining information,processes, and people to providea 360-degree view of informationand achieve optimized outcomes• Enhancing and automatingthe <strong>Company</strong>’s informationmanagement processes toefficiently manage informationthroughout its entire lifecycle,from creation to disposal• Enabling defensible disposalof content whose retentionperiod has expired for a bettermanagement of risk andstreamline regulatory complianceImprove Knowledge WorkerProductivity by:• Reducing rework (such asrecreating content not found,version control issues, andsearching but not findingdocuments)• Improving the Content Analyticsand Enterprise Search capabilities• Reducing or eliminatingunproductive tasks such as filingand organizing documents,managing document approvals,and managing document routing• Enabling systems integration• Enabling Version Control• Sharing business information andmaking it available for reuse• Delivering Trusted Informationthat improves fact-based businessdecisionsReduce Expense by:• Decreasing expenditures onpaper-based expenses (Reducepaper storage and distributioncosts)• Minimizing wasted time onrework18October - December 2012

• Applying standards andgovernance like retention polices• Managing critical business emails,archiving based on the businessvalue of the content or legalobligations and making themactive and accessible wheneverand wherever needed• Optimizing storage capacity bycreating and enforcing an effectiveretention policy to enable disposalof expired content or content thathas no legal or business valueIncrease production capacity bydecreasing the time to get wells intoproduction by:• Getting the right documents to theright people at the right time3. Define the Business Value andAssessment ResultsThe financial analysis was donebased on the following key metricsand assumptions:• The estimated budgetary cost: KD5 million• Contract duration: 5 years• Number of knowledge workers(using ECM system): 5,000 users• Average monthly wage perknowledge worker: KD 1,200• Average documents generated peryear: 4 million• ECM solutions benefits begin: 9months after kickoff date• Adoption business benefit curveduring the project period (startingfrom deployment): 7% for Y1, 15%for Y2, 15% for Y3, 15% for Y4and 15% for Y5 adoption, whichis the assumption of the yearlybusiness benefit• CITG worked closely withBVA consultants to develop abusiness value ROI templatethat incorporates the associatedcalculations and helps translatethe collected data into accurateand objective business-valuemeasurements. This template usesROI analysis, which includes, inaddition to traditional cost andbenefit summaries, soft benefitssuch as employee productivityand time savings.The calculated benefits include:• Reduce paper storage anddistribution costs with ContentManagement• Increase knowledge workerproductivity with CaseManagement• – Increase knowledgeworker productivity with ContentManagement• – Reduce storage costs withInformation Lifecycle Governance• – Increase productioncapacity by decreasing the time toget wells into productionFigure 5: Savings by year for a 5 year contractROIRisk Adjusted ROINPV SavingsPayback Period (includingdeployment period)2.51%1.78KD 5,394,76613 monthsThe <strong>Company</strong> will achieve 2.51% as ROI returnon investment which is the ratio of the net gainfrom the ECM program within 5 years based onthe above assumptions. The 13 month PaybackPeriod is the time needed to recoup the cost ofthe ECM investment.ConclusionThe study was conducted including some of theECM components solutions and shows that ECMwill be promising to the objectives and overallstrategy of the organization by reducing costsand increasing effectiveness and productivity.October - December 2012 19

The Benefit of Variable Speed Drives for KOCOperationsSubmitted by: Ahmad Jumah Al-Qallaf, Engineer Elec. Maint., Operations Support GroupFor centuries, machinery andmotors have been the coreaspect of the industrial processwhich symbolizes growth andprogress. Semiconductors haveplayed a leading role and haverepresented the heartbeat of anevolving world that has witnessedimprovements in all aspectsof industrial life. In addition,machineries and motors have hada fair amount of time to progressand develop over the years toovercome their weaknesses andshortfalls in terms of mechanicaland electrical stress duringstartup and speed control.And thanks to semiconductors,electrical drives known asVariable Frequency/SpeedDrives have been introducedto the industrial market as anenhancement to AlternatingCurrent (AC) motors.Pilot’sObjectivesDescriptionA variable-frequency drive (VFD),also called “variable-speed drive,”is a type of adjustable-speeddrive used in electromechanicaldrive systems to control AC motorspeed and torque by varyingmotor input frequency andvoltage.Fixed-speed operated loadssubject the motor to a highstarting torque and to currentsurges that are up to eight timesthe full-load current. AC drivesinstead gradually ramp themotor up to operating speed toreduce mechanical and electricalstress, reducing maintenance andrepair costs, and extending thelife of the motor and the drivenAhmad Jumah Al-QallafEngineer Elec. Maint., OperationsSupport Groupequipment.The following are process controlbenefits that might be providedby VFDs:• Smoother operation.• Acceleration control.• Different operating speed foreach process mode.• Compensate for changingprocess variables.• Adjust the rate of production.The task of a variable speedelectrical drive is to convertthe electrical power suppliedby the mains into mechanicalpower with a minimum amountof loss. This is ensured by thelow loss control using solidstate technology in electroniccontrollers. The solid statetechnology is used to achievean optimum process to drive themotor with varying its speed.The controllers are connected toa mains supply and the electricalFigure 1 VSD System Configurationmachine as shown in Figure 1.The solid-state devices convertthe AC supply to DC supply byusing the armature voltage ofa DC motor, and therefore thespeed can be adjusted, almostwithout losses and over a widerange of speed. This helps tomaintain the desired selectedspeed, independently of the loadand operated with good dynamicresponse.Recently, technology hasimproved VFD (VariableFrequency Drive) performancethrough advances insemiconductor switching devises,drive topologies, simulation andcontrol techniques.Pulse Width Modulation - PWMPulse Width Modulation (PWM)is the method of control wherevariable voltage (AC/DC) isachieved from a fixed DC voltageusing switching devices. DCvoltage is applied for some timein the cycle and in the remainingperiod, no voltage is applied tothe load. By adjusting the dutyratio, (ratio of on period to cycletime) output voltage is adjustedbetween zero and rated voltage.Scalar ControlIn scalar control, the relationshipbetween voltage and frequencyof the AC voltage applied to themotor terminals is predeterminedby the user. This relationship issometimes marginally alteredin scalar drives to improve theperformance of the drive. Scalarcontrolled inverters can only havespeed control, and these are idealfor group/multi motor drives.At <strong>Kuwait</strong> <strong>Oil</strong> <strong>Company</strong>, variable20October - December 2012

speed drive is used widely in production, gas and export facilities to reduce power consumption as well asthe high inrush current caused by starting induction motors. Moreover, scalar control is one of the betterunderstood and widely used technologies used, among other technologies, at KOC.One example of where VSD is being used includes compressors, which are used in a wide variety ofapplications. Their task is to pump and compress gases to almost any pressure level in addition to fulfillinggeneral requirements regarding efficiency; however, availability and a high power density are also decisivefactors in their operation.Saving energy can be achieved by using VSDs. The following example shows a simple application of whereVSD can save energy:• Fans and pumps are the most commonenergy saving applications.• In fixed speed mode, airflow can beregulated by using a damper.• In VSD, it’s more efficient to regulatethe speed of the motor and accordinglyairflow will be regulated.October - December 2012 21

The simulation results of the scalar control – V/F open loop drive, are shown in the followingfigures:Figure.1: Load torqueFigure 2: Load speedFigure 3: V/F ratioThe above figures show the implementation of open-loopconstant V/Hz control of an induction machine.The open-loop constant V/Hz operation is simulated forFigure 4: Variable output load speed1.2s ramping up and down the speed command (as shownin figure No. 2 in 1.5, 3.5 & 4.5 seconds) and applying stepload torques (as shown in figure No. 2 in 8 & 10 seconds).Figure No. 3 shows the change in V/F ration when changingthe speed command while maintaining a constant ration toavoid flux saturation.Figure No. 4 shows the performance of motor speed whenchanging the required speed and time required to approachthe desired speed. We can notice that there is some delay.However, this delay & performance has been improved byimplementing other controller technologies such as Field-Oriented Control (FOC) and Direct Torque Control (DTC).At <strong>Kuwait</strong> <strong>Oil</strong> <strong>Company</strong>, variable speed drives will continueto be used widely in production, gas and export facilitiesto reduce power consumption and create better efficiencyand control over operations. In addition, as technologiesimprove, the <strong>Company</strong> will play a major role in adoptingnew and improved methods to help better create a moreefficient and productive environment.22October - December 2012

Significance of Safety Instrumented SystemSubmitted by: Shemej Kumar Kattikolath, Engineer I Design, Design Team, Engineering Groupreduced to an acceptable level. Therefore all risks should be dealt withon the ALARP basis, i.e. the target is to ensure that risk is reduced toAs Low As Reasonably Practicable (ALARP).Shemej Kumar KattikolathEngineer I Design, Design Team, EngineeringGroupSafety and protection of theprocess plants are one of thehighly concerned areas of theplant management and insurancecompanies. Human safety, assetsafety and reputation of theorganization are main areas ofconcerns. Most of the plants aredesigned with inherent processsafety and with additionalindependent protection layers.After conducting Process HazardAnalysis (PHA), Hazard andOperability Study (HAZOP) andQuantitative Risk Assessments(QRA) to find risks involved,additional protection may berequired which shall be achievedthrough Safety InstrumentedSystem (SIS). By implementingSafety Instrumented System,the reliability and availabilityof safety/protection system isensured as and when required.Risk, Safety and HazardSafety can be defined as“freedom from unacceptable risk.”Absolute safety, where risk iscompletely eliminated, can neverbe achieved; risk can only beIf the hazards are not known, the risk cannot be determined. ProcessHazard Analysis (PHA), and Hazard and Operability (HAZOP) studyare carried out to identify the risks and risk levels are quantifiedbased on the respective industry standards and legal regulations. Riskis the combination of the probability of an occurrence of harm and theseverity of that harm.Risk reduction can be considerably achieved by the process selectionand/or engineering design by:• Improving mechanical integrity of the system• Improving the Basic Process Control System (BPCS)• Providing detailed training and operational procedures• Increasing the frequency of proof testing of critical systemcomponents• Implementing safety Instrumented System (SIS)• Implementing mitigating equipmentRisk Reduction LayersRisk reduction layers or Protective layers can be classified as eitherPrevention or Mitigation layers.Protective layers such as alarm system, emergency shutdownsystems, safety relief systems, etc. are put in place to stop hazardousoccurrences and mitigation layers such as fire and gas detectionsystems, deluge systems, etc. are designed to reduce the consequencesafter hazardous events have occurred.October - December 2012 23

Fig. 1: Risk reduction layersIndependent Protection Layers(IPL) is a safeguard that worksindependent of other safeguards like relief valves, BPCS,interlocks, alarms, etc. In case ofan independent protection layer,the plant operator gets adequatetime to respond to prevent ahazardous event from occurring.However it is not a good practiceto have an operator or humanintervention to achieve safetyprotection layer, as they are notreliable enough during momentsof stress and can make systematicfailures. It is more advisable touse only as a secondary meansof shutdown. Furthermore, anyIPL must be totally independentto exclude common cause andcommon design problems.The effectiveness of IPL isdescribed in terms of theprobability that it will fail toperform its required functionwhen called upon to do so(demand) and the scenariocontinuous towards hazardousconsequences despite of thepresence of IPL. This is calledProbability of Failure on Demand(PFD).Layers of ProtectionAnalysis (LOPA)Layers of Protection Analysis(LOPA) is a simplified form ofrisk assessment. LOPA typicallyuses order of magnitudecategories for initiating eventfrequency, consequence, severity,and the likelihood of failure ofindependent protection layers(IPLs) to approximate the riskof scenario. LOPA is limitedto evaluating a single causeconsequencepair as a scenario.In LOPA, the initiating eventsare always described in terms offrequency.The LOPA method quantifiesrisk and therefore reducesit subjectively. It is mostlyperformed after HAZOP andfocuses on selected high riskissues. LOPA helps to choose fromvarious alternative safeguardsto get the most economicallyjustifiable safe guard. TheLOPA analysis includes hazardscenarios described by causeand consequences. All IPLs areanalyzed for their effectivenessand the combined effects arecompared against the tolerablerisk and decide the requirementof additional risk reduction.To execute a proper LOPA,experienced facilitators, anexperienced LPOA team andupdated relevant plant documents24October - December 2012

are required. Any irrelevantassumptions or unrealistic hazardevent frequency or misjudgmentmay lead to wrong risk levels asLOPA is a tool which deals withnumbers.Safety Instrumented System(SIS)A SIS is a system comprisingsensors, logic solvers and finalcontrol element (actuators) forthe purposes of taking a processto a safe state when normalpredetermined set points areexceeded, or safe operatingconditions are violated. It ismandatory that any protectionsystem (including a SIS) be keptfunctionally separate from theBasic Process Control System(BPCS) in terms of its ability tooperate independent of the stateof the BPCS. However, these twosystems need some integrationat certain levels to have effectiveplant control and monitoring.The classical shutdown systemis being eventually replacedby a safety certified protectionsystem due to the stringentsafety regulations and insurancerequirements.Safety InstrumentedFunction (SIF)Safety Instrumented Function(SIF) consists of sensors (e.g.transmitters), final controlelement (e.g. valves) and a logicsolver with safety algorithm. Thepurpose of the SIF is to increaseprocess safety or reduce risk.SIFs are usually implemented in asafety instrumented system (SIS).Each SIF is designed to meet aspecific Safety Integrity Level(SIL), which is called the level ofreliability.A SIF with SIL-1 must at leastperform nine times out of 10,which provides a risk reductionfactor (RRF) of 10 and Probabilityof Failure on Demand (PFD) of0.1. A SIL-2 SIF must performat least 99 times out of 100 andprovides RRF as 100 and PFD as0.01. Meanwhile, a SIL-3 SIF mustperform minimum 999 times outof 1000 providing RRF as 1000and PFD as 0.001.The SIL rating of a SIF dependson various factors such asreliability analysis of all loopcomponents, demand frequency,proof test interval, diagnosticcoverage, human factors, etc.SIF protects against a singlehazard usually on demand, buta SIS implements one or moreSIFs, often multiple connectivitybetween one initiator and severalfinal elements, a final elementand several initiators etc. SomeSIF’s mitigate after the eventconsequences, like the Fireand Gas system, which reduceescalation.The design of SIF is initiallybased on achieving the requiredsafety integrity levels (SIL). Inaddition to that, the SIF designmust also consider the acceptablelevels of spurious (or nuisance)trips, which is the likelihoodthe safety function will activateunnecessarily. Nuisance trip is notyet completely controlled by anymethods in SIF design until now,however methods are available topredict the expected frequency ofnuisance tips such as meantime tofailure spurious (MTTFS), but notto determine an acceptable levelfor any particular SIF function.A practical approach is that thesafety function should not causein more nuisance trips than truetrips.Probability of Failure onDemand (PFD) and RiskReduction Factor (RRF)PFD probability of failure ondemand is the chance that aspecific safe guard will notperform its intended functionwhen required. For example,failure of a shutdown valve toclose when an abnormal processhazard arises. If that valve fails toclose on time of 100 times, thenthe PFD value is 0.01). Deviceswith smaller PFD values helpto reduce risk more than thedevices with higher PFD value.The probability of failure ondemand depends on its frequencyof testing and repair. The prooftest coverage is also a veryimportant factor in maintaining aSIL loop performance compliance.A device which is not prooftested gets larger PFD value astime increases since the failureremains uncorrected.Using the maximum failureprobability is a safe andconservative method in SILevaluation, but a more realisticmethod is to use averageprobability of failure (PFD Avg.)during the entire testing interval.The demand for a safeguard tooperate can happen any timeduring the test interval with equalprobability.Two fundamental differentways to calculate PFD Avg. are1. The unreliability approachin which an unreliabilityfunction is calculated as afunction of time intervalfor a specific mission timeusually equal to a “proof test”interval. The average of thisfunction is considered overthe entire mission time. PFDavg. is the average value of theunreliability function plottedover the testing period.2. In another approach, PFD avg.is considered as steady stateunavailability. The identicalapproximation in both casesproves that either methodunreliability averaged orunavailability averaged may beused to calculate PFD Avg.The integrity of a SIF issometimes expressed as the RiskReduction Factor (RRF).October - December 2012 25

The risk reduction factor fromeach independent layer can becombined to obtain the total riskreduction factor. Risk reductionfactor (RRF) = 1/PFD Avg.Safety Integrity Level (SIL)Safety Integrity Level (SIL) is astatistical representation of safetyavailability of a SIS at the timeof process demand. When thehazards identification and riskassessment phase concludes thata SIS is required, the level ofrisk reduction afforded by theSIS and the target SIL has to beassigned. The effectiveness of aSIS as an independent protectivelayer is described in terms of theprobability it will fail to performits required function when it iscalled upon to do so.The level of risk reduction varieswith respect to the amount ofrisk that has to be reduced andtolerable risk that has to beachieved. Once the level of riskreduction is determined, it isexpressed as safety integrity level(SIL). An adequate safety relatedsystem (SRS) can then be selectedby choosing a system that fallsunder the appropriate safetyintegrity level.The necessity of SIF is termed asdemand mode and is classifiedas Low demand mode and Highdemand or Continuous mode. Ifthe demand frequency is less thanone per year and test frequencyis greater than two times demandfrequency, then it is called lowdemand mode. If the demandfrequency is greater than oneper year and test frequency isless than two times demandfrequency, then it is consideredhigh demand mode.Target failure measures for SIF at low demand mode of operation is given in Table 1:Safety IntegrityLevelPFDavg.Risk Reduction Factor4≥ 10-5 to

AnalysisRealizationSLC analysis phase focuses onthe SIL selection process andstarts from the basic conceptualdesign of the process and safetysystem through to the releaseof the safety requirementsspecifications. This includescollecting supporting informationon process and tolerable risklevels of the organization throughPHA, HAZOP and potentialsafety instrumented functionsare identified. By LPOA, theamount of risk present withoutSIS is characterized. If the riskis within a tolerable level, SIS isnot required to be implementedand can rely on existinglayers of protections. If risk isintolerable, appropriate SIL toreduce the risk to an acceptablelevel is determined and thesame shall be documented withrelevant information as safetyspecification.SLC realization phase highlightson designing and fabricating theSIS to meet the specificationsyielded by the analysis phase.SLC operation phase starts fromstartup to decommissioningthrough the entire safety system.The highlights of this phase ismaintaining function, testingand proof testing the system toOperationensure the system is functionallysafe. The operation phaseends when the system is fullydecommissioned and taken outof service or when modified withrespect to a specific MOC whichwill start the safety lifecyclefrom beginning. The SLC can besummarized in three steps whichinclude analyzing the hazardousrisk, designing the suitablesolution and verifying that thesolution effectively solves thehazard risk.Proof TestingIn order to maintain the SIL levelof a SIS loop, proof testing isan important factor. Dangerousfailures are identified by prooftesting. For the proof testexecuted online, all the prooftesting devices shall be anintegral part of SIS loop. In mostcases, full proof testing is notpractical in a running plant. Inthis case partial stroke testing isadopted as a method to executeproof testing.Periodic proof testing shallbe carried out by well writtenprocedures and methodologies,and proof testing shall haveproper records with details suchas description of tests, dates,name of person, serial number,tag numbers, results of tests andinspection, etc.Personnel competencycertificationA major issue faced bycompanies that implement SISis the verification of personnelcompetency. Personnel whodesign, implement, maintain andoperate SIS are required to becompetent in the process they areassigned.As per IEC 61508, “All personnelinvolved in any overall E/E/PES or software safety life cycleactivity including managementactivities should have theappropriate training, technicalknowledge, experience, andqualifications relevant to thespecific duties they have toperform.” Personnel competencyis therefore now a “Normative”requirement in the IEC 61508edition 2.0. Many companies areconcerned that there has been noguidance on how this assessmentshall be carried out. There areagencies such as TUV, ISA, Exida,Risknowlogy and more whichprovide certification programs toovercome these issues.What may go wrong in SISdesign?There is a general tendency tokeep adding safeguards in thebelief that the more safeguardsadded, the safer the process.In fact it is a false concept.Eventually the more and moresafeguards that are added thatare unnecessary for the SIF,the effect shall be less focuson the safeguards that arecritical to achieve tolerablerisk. Unnecessary safeguardsalso become complex whichmay result in new unidentifiedhazard situations. Selection ofa competitive team for the SISdesign is an important criterionto achieve an optimum andeconomical design. Gatheringrelevant plant data and historyis another major factor to beconsidered during SIS design.October - December 2012 27

Caring for the CommunityKOC’s History of Corporate Social ResponsibilityHubara Club, 1963Since its earliest days, CorporateSocial Responsibility (CSR) hasplayed a major role in <strong>Kuwait</strong> <strong>Oil</strong><strong>Company</strong>’s day-to-day activities.Stretching as far back as the1930s, when the <strong>Company</strong> wasstill run by a mostly Britishworkforce, employees wereprovided with housing, healthcare and food. Of course,these earliest accommodationsand services were very basic;however, over time, KOC wenton to build one of the strongestsupport structures that directlybenefited not only employees,but residents throughout <strong>Kuwait</strong>as a whole.Happiness and HealthDuring the 1940s, the first majorsteps were taken to createa vibrant community withinAhmadi that would turn thesmall desert town into a selfsustaininghub where KOCemployees could live comfortablyand enjoy various activitiesfor entertainment after workhours. It was around this timethat major construction beganwhich saw the building of morehomes, swimming pools, playingfields and parks, a golf courseand a number of different clubsfor entertainment, such as the<strong>Kuwait</strong> Little Theater, which isone of the oldest theaters in theregion.Ensuring the health and safetyof its employees has also beena longstanding tradition of KOC.Before 1960, most employeesreceived their medical care atthe medical center in Magwa,which was used as the <strong>Company</strong>hospital until Ahmadi Hospitalwas built. Today, the hospitalprovides a range of medicalservices to not only KOCemployees and their families, butall oil sector employees.The EnvironmentPart of KOC’s CSR initiative isto do everything in its power28October - December 2012

to ensure the <strong>Company</strong>’s oiloperations have as little negativeimpact as possible on thecountry’s environment. Examplesof these initiatives include thewater re-injection program,where polluted and unusablewater resulting from productionis re-injected into the reservoirinstead of being dumped onthe soil on the surface inevaporation pits.KOC’s extremely successful effortto reduce gas flaring must alsobe mentioned, as this campaignhas resulted in positive resultsthanks to the cooperationthat exists among employeesthroughout KOC. Recently, KOChas been able to reduce gasflaring from 17% to 1.75%, andin many cases, that figure iseven lower, with some extremelysuccessful cases attaining figuresof less than 1% flaring. Theenvironmental and economicramifications of this extremelysignificant achievement willleave a positive impact on<strong>Kuwait</strong> for years to come.Ahmadi is considered by manyto be one of <strong>Kuwait</strong>’s greenerareas, and this is definitely notthe result of chance or accident.KOC has spent decades plantingand maintaining the many treesthat line Ahmadi’s streets andboulevards, and this practicehas turned out to be a verygood investment. Many studiesindicate a greener environmentleads to happier people, andhappy people are generallymore satisfied and productiveat their jobs, which leads to anarrangement that is mutuallybeneficial to the <strong>Company</strong> andits employees.The One Million Trees Projectwas also an undertaking thatwitnessed the <strong>Company</strong> makeefforts to beautify <strong>Kuwait</strong>KOC Hospital, 1964by planting trees throughoutthe country. In addition,concerns about the impact ofoil production on the locallandscape resulted in KOCinitiating two projects. Theseincluded Spirit of the Desertand the <strong>Kuwait</strong> Oasis, whosegoal was to bring areas of thedesert back to their naturalstate. Both projects involvedthe transformation of pollutedUnity Club Library, 1966land into green areas that areavailable for use by companyemployees. In addition to beingleisure areas, the parks arealso sanctuaries for local andmigrating wildlife. In addition,the <strong>Company</strong>’s concern forthe environment affected itsdecision to work with the <strong>Kuwait</strong>Environment Protection Agencyto review and improve locallegislation pertaining to theOctober - December 2012 29

An instructor gives a lesson in English, 1965environment and the actions ofthe petroleum industry.KOC is active in and financiallysupports local projects that aimto improve the environment,such as the formation of theMarine Colony, the cleaningof local beaches, and thepreservation of sensitive natureareas such as the local islands.In fact, the Marine Colony wasa first for an oil company andis one of the largest reserves inthe Gulf. Covering an area of54,000 square meters, the reserveincludes 1,000 reef balls whichare intended to foster <strong>Kuwait</strong>’smarine life.On top of its direct efforts tomake a positive impact on theenvironment, KOC routinelyholds awareness campaigns thattouch on issues such as energyconservation, recycling, safedriving, health related issuessuch as back pain, and more.These awareness campaigns notonly target employees and theirfamilies, but extend to studentsas well. In recent years, KOChas made an active effort to holdregular awareness sessions forstudents throughout <strong>Kuwait</strong>.Education and AwardsThe continuous drive to bettertrain KOC employees andsend them abroad for highereducation is demonstrativeof the <strong>Company</strong>’s realizationthat a highly educated staff ofemployees leads to a better-runorganization. A focus on traininghas resulted in the constructionof many training centers thatprepare <strong>Kuwait</strong>i employees forlife in the oil sector. As a result,this has led KOC to acceptmore <strong>Kuwait</strong>i applicants, whichfalls in line with <strong>Kuwait</strong>izationpolicy of hiring more <strong>Kuwait</strong>is invarious positions when possible.Approximately 80% of KOCemployees today are <strong>Kuwait</strong>inationals.Health, Safety and Environmentalissues are very important toKOC, which was reflected in thecreation in 1998 of the annualChairman’s HSE Awards, whichrecognize initiatives within thecompany that focus on reducingdamage to the environment whilesafeguarding the health andsafety of employees. Receivingan HSE Award is quite an honor,and many employees and theirfamilies are now more awarethan ever of the importance ofleading initiatives that go a longway in caring for the community.Corporate Social Responsibilitywill continue to play a majorrole in the day-to-day operationsof KOC. As the <strong>Company</strong> growsand makes plans for the future,KOC’s CSR initiatives will growin turn and increase in theirscope, resulting in a communitythat can be proud of itsaccomplishments and eager to domore in the future.30October - December 2012

C&MD Visits Ahmadi HospitalA group photo of KOC officials and Ahmadi Hospital staffKOC has a long history of reaching out to employees andtheir families and providing them with the support servicesthat define the <strong>Company</strong>’s reputation as an organizationthat truly cares about the community it operates in. The<strong>Company</strong>’s senior officials realize the importance offostering a sense of community and responsibility, which isreflected in the many services and outreach programs thatKOC engages in.On the occasion of Eid Al-Fitr, Chairman and ManagingDirector Sami Al-Rushaid visited Ahmadi Hospital in orderto extend Eid greetings to patients who were receivingcare there. Many of these patients were unable to spendEid with their families because the necessary treatmentthey were receiving obligated them to remain at AhmadiHospital. Accompanying the Chairman to Ahmadi Hospitalwas DMD Administration and Finance Khaled Al-Khamees.During his visit to patients at the hospital, C&MD Al-Rushaid was met by the Assistant Chief Officer (PrimaryHealth Care Services), Dr. Aref Al-Abbasi and the Headof Support of Administrative Services, Qusai Al-Amer. Anumber of medical and nursing officials also accompaniedthe officials throughout their tour of Ahmadi Hospital,which saw the officials visiting various sections of thehospital, learning about the function of some of thefacilities there, and meeting with patients receiving care. Tocelebrate the joyous and festive occasion of Eid Al-Fitr, giftswere distributed to patients throughout the hospital.About Ahmadi Hospital:• <strong>Kuwait</strong> <strong>Oil</strong> <strong>Company</strong> offers Health Services to employeesand their families through Ahmadi Hospital.• Ahmadi Hospital was inaugurated in April of 1960 to treatKOC employees and their families. In the 1980s, theseservices were extended to all oil sector employees.• Ahmadi Hospital provides many services, medicaltreatment and other relevant support services.Among these important services are: Emergency,General Practice, Internal Medicine, General Surgery,Orthopedics, Dermatology, Obstetrics & Gynecology,Pediatrics, Ophthalmology, Ear, Nose & Throat, Dentistry,Preventive Medical Services, Radiology, Anesthesia,Intensive Care Unit, Laboratory, Physiotherapy andDietary services.• Ahmadi Hospital also offers Home Visits to older patientsand those who are bedridden. In addition, AhmadiHospital can also refer patients that need specialized careto locations abroad so that they can receive the care theyneed.October - December 2012 31

<strong>Oil</strong> Origins: The Biotic Vs. Abiotic TheoriesThe origin of oil has been thesubject of an extended debatesince its founding in the mid-19th century. Some professionalsbelieve that oil is primordial – thatit dates back to Earth’s origin –and thus was made through aninorganic process. This thesis ischaracterized as the abiotic (alsocalled abiogenic or inorganic)theory. Others argue that oil wasproduced from the decay of livingorganisms (primarily oceanicplankton) that proliferated millionsof years ago during relatively briefperiods of global warming andwere subsequently buried underocean sediment in fortuitouscircumstances. This view describesthe biotic view of oil.During the latter half of the 20thcentury, largely due to advancesin geophysics and geochemistry,the vast majority of scientistshave lined up on the side of thebiotic theory. A small group ofscientists, mostly Russians and asmall minority of Western scientists(notably Cornell Universityphysicist Thomas Gold), werecommitted to the abiotic theory.Gold’s research work argued thathydrocarbons existed at the timeof our solar system’s formationand that they are known to beabundant on other planets (Jupiter,Saturn, Uranus, and some of theirmoons) where no life is presumedto have existed in the past.Implications of Biotic <strong>Oil</strong>Theory<strong>Oil</strong> companies have used thebiotic theory as the practical basisfor their successful explorationefforts over the past few decades.If there are vast untapped deeppools of hydrocarbons refillingthe reservoirs that oil producersdrill into, operational experiencessuggest that appears to make littledifference to actual production.The industry’s tens of thousandsof oil and gas fields around theworld are observed to depleteand refilling (which is indeed veryrarely observed) is not occurring ata commercially significant scale.Implications of Abiotic <strong>Oil</strong>TheoryThe abiotic theory suggests thatthere are virtually limitless poolsof liquid primordial hydrocarbonsat great depths in the Earth.These pools slowly replenish thereservoirs that conventional oildrillers tap. The abiotic theoristssuggest that conventional drillers,constrained by an incorrect theory,ignore many sites where deep,primordial pools of oil accumulate;if only they would drill in the rightplaces, they would discover muchmore oil than they are findingnow. However, thus far tests of thisclaim have proven inconclusive.Possible Evidence ofAbiotic <strong>Oil</strong>Abiotic theorists often point outevidence of fields refilling assupport of the theory. The mostfrequently quoted example isEugene Island, located on the tipof a mostly submerged mountainthat lies approximately 80 milesoff of the coast of Louisiana. Asignificant reservoir of crude oilwas discovered nearby in thelate ’60s. By 1970 the Eugene330 platform was producingabout 5,000 barrels a day ofhigh-quality crude oil. By thelate 1980s, the Eugene 330′sproduction had slipped to lessthan 4,000 barrels per day andwas generally considered to bedeclining. In 1990, oil productionsuddenly soared back to 15,000barrels a day, and the reserveswhich had been estimated at 60million barrels in the 1970s, wererecalculated at 400 million barrels.Most interestingly, the measuredgeological age of the new oil wassignificantly different than the oilpumped in the 1970s. Analysis ofseismic recordings has revealed thepresence of a “deep fault” at thebase of the Eugene Island reservoirwhich was gushing up a river of oilfrom some deeper and previouslyunknown source.The Abiotic Theory:Within the mantle, carbon mayexist as hydrocarbons - chieflymethane - and as elementalcarbon, carbon dioxide,and carbonates. The abiotichypothesis is that the full suite ofhydrocarbons found in petroleumcan be generated in the mantleby abiogenic processes, and thesehydrocarbons can migrate outof the mantle into the crust untilthey escape to the surface or aretrapped by impermeable strata,forming petroleum reservoirs.Abiogenic theories reject thesupposition that certain moleculesfound within petroleum, knownas biomarkers, are indicative ofthe biological origin of petroleum.They contend that these moleculesmostly come from microbesfeeding on petroleum in its upwardmigration through the crust,that some of them are found inmeteorites, which have presumablynever contacted living material,and that some can be generatedabiogenically by plausible reactionsin petroleum.The presence of methane onSaturn's moon Titan and in theatmospheres of Jupiter, Saturn,Uranus and Neptune is cited as32October - December 2012

evidence of the formation ofhydrocarbons without biology(Terrestrial natural gas is composedprimarily of methane). Somecomets contain massive amounts ofan organic material almost identicalto high grade oil shale (kerogen),the equivalent of cubic kilometersof such mixed with other material;for instance, correspondinghydrocarbons were detected duringa probe fly-by through the tail ofComet Halley in 1986.The Biotic Theory:Most petroleum geologists preferthe theory that attributes oilorigination to vast quantities ofdead marine plankton or plantmaterial that sank into the mud ofshallow seas. Under the resultinganaerobic conditions, organiccompounds remained in a reducedstate where anaerobic bacteriaconverted the lipids (fats, oils andwaxes) into a waxy substancecalled kerogen.As the source rock was burieddeeper, overburden pressureraised temperatures into the oilwindow, between 80 and 180°C.Most of the organic compoundsdegraded into the straight-chainhydrocarbons that comprise mostof petroleum. This process is calledthe generation kitchen. Once crudeoil formed, it became very fluidand migrated upward through therock strata. This process is calledoil expulsion. Eventually it waseither trapped in an oil reservoir oroil escaped to the surface and wasbiodegraded by soil bacteria.<strong>Oil</strong> buried deeper entered the "gaswindow" of more than 160 °C andwas converted into natural gas bythermal cracking. Thus, this theorypredicts that only unassociatedgas—not oil—will be foundbelow a certain depth. At greaterdepths, even natural gas would bepyrolyzed.Tectonic structures do not necessarily correlate with oil deposits.Abiogenic Hydrocarbons Forming in the MantleThis image illustrates the theory of abiogenic formation of hydrocarbons in theupper mantle. These hydrocarbons then can migrate upward into the crust,and become trapped under impermeable minerals.This visual demonstrates the theory of biotic oil formation.October - December 2012 33

wells pumped water with a salinitylevel higher than 7,500 ppm in1989, reaching 75 percent and85 percent in the years 1997 and2002 respectively. In Abdali, thesefigures were estimated at 55, 75and 90 percent respectively.During an interview at his officein Shuwaikh, Dr. Kotwickimaintained that “<strong>Kuwait</strong>’s naturalrecharge is only 160 million cubicmeters per year. However, weproduce 610 million cubic metersof freshwater per year, whichis almost four times more thanthe natural recharge.” This hugedisparity in the amount of water<strong>Kuwait</strong> consumes compared towhat is naturally available isreliant on <strong>Kuwait</strong>’s efforts at waterproduction, which relies heavilyon seawater desalination. Withoutseawater desalination, it would beimpossible for <strong>Kuwait</strong> to providethe amount of freshwater that isreadily available to its population.Desalination in <strong>Kuwait</strong><strong>Kuwait</strong>’s first desalination plant wasestablished at Ahmadi Port in 1951with a very modest productioncapacity. Over the years, <strong>Kuwait</strong>’sproduction capacity greatlyincreased as new technologiesdeveloped and new plants werebuilt. According to Dr. Kotwicki,the desalination of water in <strong>Kuwait</strong>will continue indefinitely because<strong>Kuwait</strong> simply has no other choicebut to desalinate water becauseof the country’s lack of freshwaterresources.While the Ministry of Electricityand Water does provide anexcellent service in its ability tocontinuously supply <strong>Kuwait</strong> withfreshwater, there are concernssurrounding the feasibility ofthe economic costs associatedwith providing an abundance ofdesalinated water to the generalpopulation. One of the majorconcerns, says Dr. Kotwicki, dealswith the cost of the governmentsubsidizing water in <strong>Kuwait</strong>, whichby comparison to the rest of theworld, is exceptionally discounted.“Water subsidies in <strong>Kuwait</strong>account for 2.5% of gross domesticproduct, or 6% of the nation’s oilrevenue,” said Dr. Kotwicki. “Thisis expected to increase in 2025 to25%, and in 2050, 100% of grossdomestic product will go towardthe production of water andelectricity.”To get an idea of just how much<strong>Kuwait</strong>’s water needs havegrown and are currently growing,consider the following: FreshwaterOctober - December 2012 35