Download - Visqueen Building Products

Download - Visqueen Building Products

Download - Visqueen Building Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

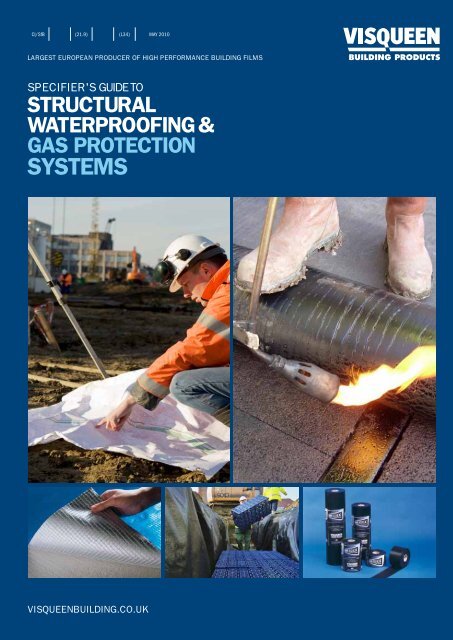

THE VISQUEEN Specifier's GUIDEThe <strong>Visqueen</strong> Specifier's Guide is theperfect introduction to <strong>Visqueen</strong>'scomprehensive support service.The guide provides an overview of ourcomplete range and details installationinstructions for all our products. It isdesigned to be closely used inassociation with our websitevisqueenbuilding.co.ukELECTRONIC NBS SPECIFICATIONSTo assist with preparing specifications,<strong>Visqueen</strong>’s products are available inNBS format. These can be downloadedfrom our website or emailed to you uponrequest.INTERACTIVE WEBSITEvisqueenbuilding.co.uk provides detailedproduct and technical information. Thesite contains downloadable informationincluding product technical datasheetsand standard details from our extensivelibrary covering typical DPC, tankingand gas protection applications.CAD SUPPORT SERVICEOur computer aided design departmentwill assist in the design of PreformedUnits to ensure 100% protection atcomplex three dimensional damp proofand gas proof detailing.TECHNICAL SITE SUPPORT SERVICE<strong>Visqueen</strong>’s national team of TechnicalSupport Managers provide comprehensivebackup to specifiers and end userswhich includes assistance with productselection, system design and on siteinstallation training. The service is freeand is provided by support personnelwith extensive experience in theconstruction industry.CPD TRAINING SEMINARSTo encourage the widespread use ofgood practice, <strong>Visqueen</strong> offers a rangeof Continuing Professional DevelopmentSeminars for specifiers such asProtection of <strong>Building</strong>s on GasContaminated Land. During these onehour approved seminars, presentersprovide key learning and criticalup-to-date information for those involvedin new-build construction orrefurbishment.COMPLETERANGECOMPLETESERVICEfii c ati o ntC e rLi mB R Eit e d4CUSTOMER SERVICEtfii c ati o nC e rLi m

Above: <strong>Visqueen</strong> CPD Seminar on gas contaminatedland including new guidanceWWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 5

IMAGE ILLUSTRATES HIGH IMPACT STRENGTH OF VISQUEEN ZEDEX DPC

08 <strong>Visqueen</strong> Zedex CPT DPC12 <strong>Visqueen</strong> Zedex High Bond DPC14 <strong>Visqueen</strong> Preformed Unit16 <strong>Visqueen</strong> Zedex Housing Grade DPC18 <strong>Visqueen</strong> Polyethylene DPC20 <strong>Visqueen</strong> GX Hydrocarbon DPC21 <strong>Visqueen</strong> Gas Resistant DPCDAMPPROOFcourses<strong>Visqueen</strong> Zedex High Performance DPC is thinner than traditional damp proofcourses without compromising performance. This helps reduce material usage,manufacturing energy and lowers transportation miles.

DAMP PROOF COURSES<strong>Visqueen</strong> Zedex CPT DAMP PROOF COURSE——Excellent peformance under high compressive loads.——Out performs all other high performance flexible DPC and cavity tray systems.——Contains no hazardous pitch or PVC plasticizers making it safe and clean to handle.——System components for all applications including standard and bespoke Preformedcavity tray (cloak) units.——Low permeability to Radon and Carbon Dioxide gas.DESCRIPTION<strong>Visqueen</strong> Zedex CPT High PerformanceDamp Proof Course (DPC) and cavitytray system is manufactured from copolymerthermoplastic (CPT) providingall the characteristics necessary for itto perform effectively for the lifetime ofthe building in which it is incorporated.<strong>Visqueen</strong> Zedex CPT DPC providessuperior strength, tear resistance andflexibility and is compatible with all other<strong>Visqueen</strong> damp proofing, gas proofingand tanking protection systems.APPLICATION<strong>Visqueen</strong> Zedex CPT DPC is suitablefor use as a DPC in all types of buildingconstruction and can be used in vertical,horizontal, stepped and cavity trayapplications.On siteHigh tear and puncture resistantcharacteristics help avoid the failurescaused by damage during installation,such as clearing mortar droppings out ofthe cavity, general manhandling on siteand during transport. Independent testingshows the tear strength of <strong>Visqueen</strong>Zedex CPT DPC to be many times that oftraditional pitch polymer DPCs.Aesthetics<strong>Visqueen</strong> Zedex CPT DPC is alsoavailable in a range of colours tomatch the mortar or outer leaf. Themost popular colours are white andsandstone. Our technical departmentwill be happy to assist you with productspecifications.mortar adhesion<strong>Visqueen</strong> <strong>Building</strong> <strong>Products</strong>commissioned Ceram <strong>Building</strong>Technology to test <strong>Visqueen</strong> ZedexCPT DPC under BSI’s DD86 Part 11983 for flexural bond strength andshear strength. These independenttests show that <strong>Visqueen</strong> Zedex CPTDPC has excellent mortar adhesioncharacteristics. With DPCs being usedextensively outside the original groundlevel applications, understanding theeffect of a damp proof course onwall strength becomes increasinglyimportant.Compatibility<strong>Visqueen</strong> Zedex CPT DPC avoids therisks of any incompatibility betweenthe damp proof course and other dampor waterproofing materials. It can beused with a wide range of productssuch as silicon mastics without causingdiscolouration, and bituminous liquidDPMs. Such compatibility is essential toensure a continuous waterproof barrierfor the lifetime of the building.Clean and safe to handle, the materialsused in <strong>Visqueen</strong> Zedex CPT DPC arechemically stable and inert, free of bothsolvents and aggressive chemicals.<strong>Visqueen</strong> Zedex CPT DPC is also cleanand safe to use, requiring no specialconditions for storage, transportation,handling, usage or recycling.——Fully recyclable.——Strong and flexible.——Robust and puncture resistant.——High tear strength.——Excellent workability in winterconditions.importantFull technical informationis available atwww.visqueenbuilding.co.uk/dpc8

P14P87REQUIRED COMPONENTSAvailable as a download fromvisqueenbuilding.co.uk/DPC<strong>Visqueen</strong> Zedex jointing system<strong>Visqueen</strong> HP TANKING PRIMER<strong>Visqueen</strong> Zedex Preformed Cavity Tray Units<strong>Visqueen</strong> Zedex FIXING STRIPs/pinsSPECIFICATION SUPPORTThe following items are availableto View Online or TO <strong>Download</strong> fromVISQUEENBUILDING.CO.UK/DPCCPDH&SCPD H&S NBSTECHNICAL DATASHEETSTYPICAL INSTALLATION CAD DETAILSHEALTH & SAFETY DATAH&SH&S NBSMANUFACTUREDIN THE UKINSTALLATIONGuidelinesInstallation must follow normal goodpractice as per BS 5628 3:2005 andmust be in accordance with BS 8215revised edition.——<strong>Visqueen</strong> Zedex High Bond DPCmust extend through the fullthickness of the wall leaf, includingpointing, applied rendering or othermaterials.——It is to be laid on a wet, even bed ofmortar and perforations in adjacentcourses of block work must becompletely filled with mortar.——All lap joints in <strong>Visqueen</strong> Zedex HighBond DPC must have a minimum100mm overlap.——<strong>Visqueen</strong> Zedex High Bond DPC siteformed cloaks must be used at stopends and all corners or changes inlevel of cavity trays must not bedamaged by cavity cleaning afterinstallation.——A sharp knife is necessary to cutthe material.——Work can be carried out underall weather conditions normal tothe construction of the wall and<strong>Visqueen</strong> Zedex High Bond DPCmaintains sufficient flexibility to beinstalled at low temperatures.Full technical datasheets, including hotbonding installation, are availablefrom our websitewww.visqueenbuilding.co.uk/dpcTECHNICAL DATATypical PropertiesTensile Strength(BS EN12311-1)675N/50mmElongation Control (BS EN12311-1) 34%Water Vapour Permeability (BS 3177)0.06g/m 2 /dayNail Tear (BS EN 12310-1)156NMethane Gas Permeability0.06 ml/m 2 /dayTransverse 17.4Accelerated WeatheringTensile Strength(BS EN12311-1)675N/50mmElongation Control (BS EN12311-1) 34%Roll DimensionsNominal Thickness3mmNominal Weight 3.8kg/m 2Roll Length8mAvailable Widths450mm, 600mm, 1mWWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 13

DAMP PROOF COURSES<strong>Visqueen</strong> Preformed cavity tray UNITsPREFORMEDUNIT——Manufactured in the UK from specially formulated, flexible co-polymer material.——Designed to simplify the damp proofing of complex cavity tray junctions.——Speeds up cavity tray installation and eliminates leakage paths.——Ensures compliance with industry recommendations and standards.——Built-in and surface fixed units available.——Free on-site service for design of project specific Preformed units.MANUFACTUREDIN THE UKIntroductionBritish Standard 5628: Part 3 codeof practice for the use of masonry(materials and components, designand workmanship) offers guidance andrecommendations on the damp proofingof structures. It recognises that thepenetration of water into the fabric of abuilding has serious consequences forthe health of the occupants and for thelong term serviceability of the structure.The numerous bridges of the cavitywall commonly require damp proofingprotection in the form of a cavity trayand where a flexible damp proof coursematerial is used, the British Standardrecognises that many common detailscannot be satisfactorily formed on siteand that preformed units should bespecified for these complex junctions.DescriptionAn integral part of the <strong>Visqueen</strong> ZedexDamp Proofing System is the range of<strong>Visqueen</strong> Preformed Cavity Tray Units.The units simplify cavity tray detailingat columns, corners, windposts, changeof levels, etc, and so greatly reduce thetime required on site to install a cavitytray at these complex junctions.<strong>Visqueen</strong> Preformed Cavity TrayUnits are factory manufactured fromspecially formulated, tough, co-polymermaterial, which is sufficiently flexibleto accommodate normal constructiontolerances. The units can be producedfor any width of cavity and in formatssuitable to be either built-in or surfacefixed to the inner leaf.Application<strong>Visqueen</strong> Preformed Cavity Tray Units aregenerally installed prior to the main runof <strong>Visqueen</strong> Zedex DPC Cavity Tray. The<strong>Visqueen</strong> Zedex DPC Cavity Tray shouldoverlap the Preformed Unit by minimum100mm, the lap being bonded with<strong>Visqueen</strong> Zedex DPC Jointing Tape.When surface fixing, the Preformed Unitshould be bonded and then mechanicallyfixed to the inner leaf using the sametaping/fixing system as the <strong>Visqueen</strong>Zedex DPC Cavity Tray.In accordance with industryrecommendations and guidance,<strong>Visqueen</strong> Zedex DPC Joint SupportBoards should be positioned beneathunsupported laps in order to providesupport for the initial formation of thebonded lap and its long term integrity.FIXING PINS FOR Masonry (SF-01)KEY: 1) <strong>Visqueen</strong> Zedex CPT DPC (preformed cloaksto suit). 2) <strong>Visqueen</strong> Fixing Strip (25x2mm, pre-drilledwith 8mm Ø holes). 3) <strong>Visqueen</strong> Zedex 100mmJointing Tape on primed, flush inner skin.4) Weepholes at 900mm centres (min 2no. peropening). 5) <strong>Visqueen</strong> HP Tanking Primer.FIXING PINS FOR INSULATION (SF-02)KEY: 1) <strong>Visqueen</strong> Zedex CPT DPC (preformedcloaks to suit). 2) <strong>Visqueen</strong> Fixing Strip (25x2mm,pre-drilled with 8mm Ø holes) <strong>Visqueen</strong> Fixing Pins at150mm centres. 3) <strong>Visqueen</strong> Zedex 100mm JointingTape. 4) Weepholes at 900mm centres (min 2 no. peropening). 5) Metal frame construction by specialist.6) Rigid insulation board. 7) <strong>Visqueen</strong> No.2 Fixings.14

PREFORMEDUNITDesign support<strong>Visqueen</strong> Technical Support Managershave specialist knowledge and experiencein designing and producing isometricdrawings of the complex shapes requiredto allow continuity of cavity trays inbuildings. The incorporation of these unitsinto the cavity tray system ensures thatcommon leakage paths are sealed,thereby eliminating both potential dampproblems and the resulting costly remedialworks on site.The design support service is available freeof charge to both specifiers and end-users.The following table lists some typicalapplications for <strong>Visqueen</strong> Preformed CavityTray Units. Please contact yourlocal <strong>Visqueen</strong> Technical Support Managerfor assistance in the design of projectspecific units.TECHNICAL DATAPreformed Unit Built-in Surface fixedLintel stop end PFU-100 PFU-100Stop end PFU-101 PFU-102Jambs PFU-104 PFU-104Change of level PFU-107 PFU-108Internal/ external corner PFU-109 PFU-110Windpost PFU-125 PFU-125Column PFU-128 PFU-130External corner column PFU-129 PFU-131Arched window PFU-145 PFU-145surface fixed & Built-in applicationsPFU-108(LH)PFU-110PFU-108(RH)PFU-110IMPORTANTDuring installation DPC mustoverlap Preformed Unit by 100mmand be fully sealed with <strong>Visqueen</strong>Zedex DPC Jointing Tape.PFU-101(LH)PFU-100PFU-109PFU-101(RH)PFU-100PFU-128DPC to be fully lapped andsealed during installationprocess.WWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 15

DAMP PROOF COURSES<strong>Visqueen</strong> Zedex HOUSING GRADE DPC——Suitable for housing constructions up to three storeys.——Out performs all other housing grade flexible DPCs.——Contains no hazardous pitch or PVC plasticizers making it safe and clean to handle.——A superior alternative to British Standard DPCs.——Strong, puncture resistant with excellent workability in winter conditions.——British Board of Agrément (BBA) approved.DESCRIPTION<strong>Visqueen</strong> Zedex Housing Grade DPC isbased on the same polymer technologyas <strong>Visqueen</strong> Zedex CPT DPC. It isdesigned to provide housebuilderswith a robust, higher performing andcost effective alternative to traditionalBritish Standard DPCs.<strong>Visqueen</strong> Zedex Housing Grade DPC isstrong and flexible remaining workablethroughout the seasons. It can be usedwith a wide range of products suchas silicon mastics without causingdiscolouration, and bituminous liquidDPMs. Such compatibility is essential toensure a continuous waterproof barrierfor the lifetime of the building.APPLICATION<strong>Visqueen</strong> Zedex Housing Grade DPC issuitable for use as a DPC in domesticand residential construction in vertical,stepped and horizontal applications.The DPC may be used in conjunctionwith beam and block flooring and ifused as a cavity tray, the DPC shouldbe fully supported along its lengthi.e. supported by the lintel. For otherapplications use <strong>Visqueen</strong> Zedex CPTDPC. Installed in accordance with ourinstructions,<strong>Visqueen</strong> Zedex HousingGrade DPC provides an effective barrieragainst the passage of moisture.Standard detail - typical ground bearing slab edge detail (SW-30)KEY:1) <strong>Visqueen</strong> Housing Grade DPC.2) <strong>Visqueen</strong> Ecomembrane 500µm.3) <strong>Visqueen</strong> Lap Tape.4) <strong>Visqueen</strong> Jointing Tape (50mm x 10m)5) Smooth Sand Blinding Layer.All laps must be fully sealed.16

CPDBBAP14BRITISHBOARD OFAGREMENTASSESSMENT OF PRODUCTS FOR CONSTRUCTIONCERTIFICATE No. 94/3059P87REQUIRED COMPONENTSAvailable as a download fromvisqueenbuilding.co.uk/DPC<strong>Visqueen</strong> Zedex jointing system<strong>Visqueen</strong> HP TANKING PRIMER<strong>Visqueen</strong> Zedex Preformed Cavity Tray Units<strong>Visqueen</strong> Zedex FIXING STRIPs/pinsSPECIFICATION SUPPORTThe following items are availableto View Online or TO <strong>Download</strong> fromVISQUEENBUILDING.CO.UK/DPCCPDH&SCPD H&S NBSTECHNICAL DATASHEETSTYPICAL INSTALLATION CAD DETAILSHEALTH & SAFETY DATAAgrément CertificateH&SCPDNBSH&SBBA BRITISHBOARD OFAGREMENTASSESSMENT OF PRODUCTS FOR CONSTRUCTIONCERTIFICATE No. 94/3059MANUFACTUREDIN THE UKH&S NBSINSTALLATIONInstallation must be in accordancewith BS5628-3:2005, BS8000-3:2001,BS8215:1991, BRE Digest 380 DampProof Course and the procedures set outin BBA 94/3059 Detail Sheet 3.Co-polymer thermoplastic is now widelyrecognised for its ease of use on site,due to its flexibility even in cold weatherconditions.Installation Steps——The DPC must extend through thefull thickness of the wall, includingpointing, applied rendering or otherfacing materials.——The DPC must be laid on an even bedof wet mortar, and perforations inadjacent courses of brickwork mustbe completely filled with mortar.——The DPC must not be damaged bycavity cleaning after installation.——All laps in the DPC must be aminimum of 100mm and sealedusing <strong>Visqueen</strong> Zedex DPC JointingTape. For further information refer tothe BBA Certificate (94/3059).STORAGE AND HANDLINGThe materials used in <strong>Visqueen</strong> ZedexHousing Grade DPC are chemically stableand inert and are free of both solventsand aggressive chemicals. The DPC isalso clean and safe to use and containsno volatiles to 'leach' out. Due to itsrobust nature, the DPC requires nospecial conditions for storage, transport,handling, usage and recycling.TECHNICAL DATATensile Strength BS 2782:320A 20.4 N/mm 2Elongation at Break BS 2782:320A 515%Tear Strength BS 2782 360B 135N/mm 2Water Vapour Permeability BS 3177 25OC/75% RH0.3g/m 2 /dayRoll DimensionsNominal Thickness 600µmNominal Weight 0.6kg/m 2Roll Length20mAvailable Widths100mm to 1400mmWWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 17

DAMP PROOF COURSES<strong>Visqueen</strong> POLYETHYLENE DPC——Conforms to the requirements of BS 6515.——Cost effective damp proof course for domestic construction.——Embossed to assist mortar adhesion.——Proven performance over many years.——Manufactured from highest quality reprocessed materials.——Safe and clean to handle.DESCRIPTION<strong>Visqueen</strong> Polyethylene DPC is designedto prevent the passage of moisturein brick and block work from externalsources. <strong>Visqueen</strong> Polyethylene DPCis manufactured from high qualityreprocessed materials to provide acost effective and durable domesticgrade DPC.APPLICATION<strong>Visqueen</strong> Polyethylene DPC is suitable foruse in vertical and horizontal applicationsthroughout two storey domesticconstructions. <strong>Visqueen</strong> PolyethyleneDPC is produced to stringent performancestandards and includes a pronouncedemboss to improve mortar adhesion.(Note: in minimal stress applications<strong>Visqueen</strong> Zedex High Bond DPC shouldbe used.) <strong>Visqueen</strong> PolyethyleneDPC has good cold weather flexibilityproperties, remaining workable at lowtemperatures. <strong>Visqueen</strong> Polyethylene DPCis manufactured to the requirements ofBS 6515.IMPORTANTBS6515 states Polyethylene DPCis not suitable for water movementdownwards eg. above lintels in cavitywalls. Please use <strong>Visqueen</strong> ZedexCPT DPC or <strong>Visqueen</strong> High Bond DPCfor this application.18

CPDREQUIRED COMPONENTSAvailable as a download fromvisqueenbuilding.co.uk/DPC<strong>Visqueen</strong> Zedex jointing systemSPECIFICATION SUPPORTThe following items are availableto View Online or TO <strong>Download</strong> fromVISQUEENBUILDING.CO.UK/DPCCPDH&STECHNICAL DATASHEETSHEALTH & SAFETY DATAH&S NBSH&SH&S NBSINSTALLATIONInstallation should be in accordancewith Code of Practice CP102:1973 asamended. Normal good practice anddamp proof course detailing shouldbe followed as described in BS 5628:Part 3. Work may be carried out in allweathers normal to the constructionof walls.JointingAll laps and joints in discontinuouslengths of DPC should be fully lapped byat least 100mm and fully sealed using<strong>Visqueen</strong> Zedex DPC Jointing Tape.STORAGE AND HANDLING<strong>Visqueen</strong> Polyethylene DPC is classifiednon-hazardous, and is chemically inert.The product requires no special storageconditions, although measures should bemade to keep it clean and dry.TECHNICAL DATATensile Strength BS2782 (320A) Long: 20.3N/mm 2 Trans: 11.2N/mm 2Elongation BS2782 (320A) Long: 301% Trans: 274%Tear Strength MOAT 27:5:4.1Long: 169N Trans: 145NWater Vapour Permeability0.28g/m 2 /dayDimensional DetailsLength (m) 30Available Widths100mm – 1200mmWWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 19

DAMP PROOF COURSES<strong>Visqueen</strong> GX HYDROCARBON DPC——Suitable for use on hydrocarbon contaminated sites.——High puncture and tear resistance.——Excellent chemical resistance.P36REQUIRED COMPONENTSAvailable as a download fromvisqueenbuilding.co.uk/dpc<strong>Visqueen</strong> Gx geomembrane<strong>Visqueen</strong> Gx Jointing SystemDESCRIPTION<strong>Visqueen</strong> GX DPC is a blend of ethyleneco-polymers suitable for use onbrownfield sites that require protectionfrom dangerous contaminants such ashydrocarbons and methane, togetherwith excellent damp proofing properties.GX DPC is available in 30m lengths andin two widths, 645mm or 970mm.APPLICATION<strong>Visqueen</strong> GX DPC has a proven trackrecord as a barrier membrane ongas contaminated and hydrocarboncontaminated brownfield sites. <strong>Visqueen</strong>GX DPC combines high strength withflexibility.SPECIFICATION SUPPORTThe following items are availableto View Online or TO <strong>Download</strong> fromVISQUEENBUILDING.CO.UK/dpcCPDH&SCPD H&S NBSH&SH&S NBSTECHNICAL DATASHEETSTYPICAL INSTALLATION CAD DETAILSHEALTH & SAFETY DATAINSTALLATIONAll joints in lengths of DPC must bea minimum of 100mm lapped andsealed with <strong>Visqueen</strong> GX Jointing Tape.<strong>Visqueen</strong> GX DPC should be installed inaccordance with BS 8215: 1991,BS 8000: Part 3, 2001 and BS 5628:Part 3: 2005. <strong>Visqueen</strong> GX DPC must bebedded on both sides with fresh mortarTECHNICAL DATAand must project through the full width ofthe wall, including any externally appliedrendering and project 5mm beyond thefinished external face.STORAGE AND HANDLING<strong>Visqueen</strong> GX DPC is classified as nonhazardouswhen used in accordance withthe relevant British Standards.The product is chemically inert and is notaffected by acids and alkalis that may bepresent in the sub-soils.Thickness (ASTM D5199)1.15mmDensity (ASTM D792) >1000 kg/m 3Puncture Resistance (FTMS 101C Method 2031)1340NTear Resistance (ASTM D751 Method B)289NBreak Strength/Reinforcement (ASTM D751 Method A) 1000NLow Temperature Flexibility (ASTM D2136) - 40°CHydrostatic Resistance (ASTM D751 Method A)PassWater Absorption (ASTM D471)

DAMP PROOF COURSES<strong>Visqueen</strong> Gas Resistant DPCGR DPC——Integral aluminium foil for resistance to methane, radon,CO 2and low levels of hydrocarbon vapours.——Easy to apply using traditional methods.——Use as part of an integral Gas Protection System.——Independently assessed.DESCRIPTION<strong>Visqueen</strong> Gas Resistant (GR) DampProof Course is a flexible polyethyleneDPC with an aluminium foil designedto prevent the transmission of carbondioxide, radon, methane and low levelhydrocarbon vapours. This is in additionto the product's usage as a damp proofcourse. Resistance to harmful gases isachieved by an integral aluminium film.Good Practice TipTo avoid slip or shear planes it is notrecommended to take membranesthrough the wall. In order to provide acontinuous barrier across the cavity<strong>Visqueen</strong> Gas Resistant DPC shouldbe sealed to the membrane, takenthrough the blockwork, up the wall andincorporated below the damp proofcourse on the cavity tray outer leaf.APPLICATION<strong>Visqueen</strong> Gas Resistant (GR) DPCshould be used on any site where carbondioxide, radon, methane or low levelhydrocarbon vapours are a problem.Methane can occur on any constructionon any site previously used for landfill.Such conditions can exist on household,commercial and industrial sites. <strong>Visqueen</strong>Gas Resistant (GR) DPC has excellentphysical characteristics and good coldflexibility performance. It is suitable forvertical, horizontal, stepped and cavitytray applications.IMPORTANTWhere the DPC may be indirect contact with hydrocarboncontamination the use of <strong>Visqueen</strong>GX DPC must be considered.P31P60CPD H&S NBSH&SH&S NBSREQUIRED COMPONENTSAvailable as a download fromvisqueenbuilding.co.uk/dpc<strong>Visqueen</strong> Top Hat Units<strong>Visqueen</strong> detailing strip<strong>Visqueen</strong> Gas BarrierJointing System<strong>Visqueen</strong> Gas membranes<strong>Visqueen</strong> Gas ResistantSelf Adhesive DPMSPECIFICATION SUPPORTThe following items are availableto View Online or TO <strong>Download</strong> fromVISQUEENBUILDING.CO.UK/dpcCPDH&STECHNICAL DATASHEETSTYPICAL INSTALLATION CAD DETAILSHEALTH & SAFETY DATAINSTALLATION<strong>Visqueen</strong> Gas Resistant (GR) DPCshould be installed in accordancewith BS 8215:1991, BS 8000: Part 3,2001 and BS 5628: Part 3, 2005. Allhorizontal DPCs must be bedded on bothsides with fresh mortar. All DPCs mustproject through the full width of the wall,including any externally applied renderingand project 5mm beyond the finishedTECHNICAL DATAexternal face. All cavities must be keptclear of mortar droppings and otherdebris. Any mortar droppings reachingthe DPCs must be removed before theyharden, avoiding the use of sharp objectsfor removal. Reference should also bemade to NHBC guidance notes and BREReport BR211.STORAGE AND HANDLING<strong>Visqueen</strong> Gas Resistant (GR) DPC isclassified as non-hazardous when usedin accordance with the relevant BritishStandards. The product is chemicallyinert and is not affected by acids andalkalis that may be present in the subsoils.Dimensional DetailsRoll Length30mAvailable Widths500mm - 1000mmWeight 0.5kg/m 2Thickness0.5mmPhysical CharacteristicsTensile Strength (BS2782:320A)Transverse 17.4N/mm 2Longitudinal 19.0N/mm 2Elongation at Break% (BS2782:320A) Longitudinal 262%Elongation at Break % Foil 58.4%Methane Gas Resistance ml/m 2 /24hr

26 <strong>Visqueen</strong> 100% Recycled Ecomembrane28 <strong>Visqueen</strong> DPM To Pifa StandardDAMPPROOFmembraneS<strong>Visqueen</strong> Ecomembrane ® is a BRE certified DPM manufactured from 100% recycledpolythene. This ensures valuable reusable material is retained in the economy andreduces waste going to landfill.

SUSTAINABILITY IN THECONSTRUCTION SECTORSustainability has become the buzzword in the construction industry. Notonly has it become the main focus ofgovernment policy in the constructionsector, but it is increasingly on clients’agendas as a result of being asked toexplain their approach to sustainabilityby investors, employees or suppliers.64ktesOF WASTE PLASTIC ISREPROCESSED IN OURUK PLANTSThe Largest PolyethyleneRecycler in Europe<strong>Visqueen</strong> <strong>Building</strong> <strong>Products</strong>, part of bpiPLC Recycled <strong>Products</strong> Division, hasan enviable reputation as the leader inthe field of polyethylene recycling. Eachyear we recycle over 64,000 tonnesof low density polyethylene across ourEnvironment Agency Accredited sites.Why Recycle?Increasing the use of recycled productshas an enormous impact on theenvironment; independent studiesshow that compared to using virginpolyethylene it is estimated that eachtonne of polyethylene bpi recycles:——Prevents the release of 1.5 tonnesof CO 2into the atmosphere.——Cuts sulphur dioxide emissionsby 33%.——Cuts nitrous oxide emissionsby 50%.——Saves 1.8 tonnes of crude oil.——Reduces water usage by 90%.——Reduces energy use by two thirds.*SUSTAINABILITYIN THECONSTRUCTIONSECTOR*www.wasteonline.org.uk**DEFRA.24

Innovation and Investmentin RecyclingWith our unrivalled experience andexpertise, we are uniquely positioned tomanage all plastic waste requirements.Through investment in our recyclingoperations we can reprocess varyingtypes of plastic materials, from industrialwaste to heavily contaminated agriculturalwaste to even old wheelie bins. We turnthis waste plastic into building films andour recycled plastic street furniture range.Carbon FootprintMost UK waste polythene is actuallyshipped overseas for sorting andreprocessing. In marked contrast, allof our recycling actually takes place inthe UK. This ensures the green benefitsof recycling in the first place aren'toffset by remanufactured products withunacceptable 'product miles'.70% **of the plastic that can berecycled in the UK is actuallyexported overseas.SUSTAINABLE PRODUCT DEVELOPMENTFrom concept to disposal, we arecreating new products that reduce ouroverall environmental impact.<strong>Visqueen</strong> Zedex High PerformanceDPC is thinner than traditional dampproof courses without compromisingperformance. This helps reduce materialusage, manufacturing energy and cuttingtransportation miles.<strong>Visqueen</strong> Ecomembrane is a BREcertified DPM manufactured from100% recycled polythene. This ensuresvaluable reusable material is retained inthe economy and reduces waste goingto landfill.virgin productreprocessfeedstock100% recycled membranePost-use waste explainedPost-use: "Materials collected from outside the individual manufacturing industry after it has been used for its primarypurpose. This can include material from agricultural use, commercial, industrial, retailing, distribution and domesticoutlets, but in all cases the material will have been used for the purpose for which it was manufactured."(British Polythene Industries 1994)WWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 25

DAMP PROOF MEMBRANE<strong>Visqueen</strong> ECOMEMBRANE ®——Independently accredited by BRE Certification Ltd, Certification No.112/04.——Manufactured from 100% post-use polyethylene, diverting more waste from landfill.——High tear resistance helps reduce damage during installation.——Does not compromise on traditional DPM performance.——Comprehensive range to satisfy most site conditions.Description<strong>Visqueen</strong> EcoMembrane ® DPM is ablown film of extruded low-densitypolyethylene for use as a Type “A” dampproof membrane as defined by BS EN13967: 2004. It is manufactured from100% post-use waste, is black in colourand available in 250μm, 300μm and500μm thicknesses. EcoMembrane ®has been independently accredited byBRE Certification Ltd (Certificate No.112/04).Applications and use<strong>Visqueen</strong> EcoMembrane ® DPM issuitable for use in concrete floors, inaccordance with clause 11 of CP 102:1973, where there may be capillaryrise of moisture but not where it maybe subject to hydrostatic pressure. Insuch a circumstance, <strong>Visqueen</strong> TankingMembranes should be used.Where there is a risk that the groundmay be waterlogged, sub-soil drainage inaccordance with CP 102 and BS 8102should be provided.The effectiveness of EcoMembrane ® willbe reduced if it is exposed to sunlighteither during storage or when in use.Under normal operating conditions,<strong>Visqueen</strong> EcoMembrane ® DPM can beused in conjunction with underfloorheating, although follow the advice of<strong>Visqueen</strong>’s Technical Support Service.As indicated in paragraph 4.8 of <strong>Building</strong>Regulations Approved Document C, jointsin the membrane are sealed using the<strong>Visqueen</strong> DPM Jointing System.INSTALLATIONInstallation guideLines<strong>Visqueen</strong> EcoMembrane ® DPM mustbe installed in accordance with BRECertificate No.112/04 and thefollowing guidelines.Preparation for layingthe membraneEven though <strong>Visqueen</strong> EcoMembrane ®has a high puncture resistance to normalfoot and site traffic, care should be takento avoid accidental damage on site.Similarly, where the base is uneven, ablinding of soft sand of a thickness thatwill cover all sharp projections should beused to avoid damage to the membranewhen it is being installed, and when theconcrete or screed is being laid.Jointing the EcoMembrane ®Adjacent sheets of the membrane shouldbe overlapped by at least 150mm andbonded using <strong>Visqueen</strong> Double SidedJointing Tape. The joint should then besealed using 100mm wide <strong>Visqueen</strong> GirthTape. The membrane should be clean anddry at the time of jointing.26FOR MAINTAINING CONTINUITY,PUNCTURES AND SERVICE PIPEPENETRATIONS, PLEASE SEE OURINSTALLATION SECTION P83.Covering<strong>Visqueen</strong> EcoMembrane ® should becovered by a protective layer (such as<strong>Visqueen</strong> Protection Boards) as soon aspossible after installation.The membrane should be sufficientlyloosely laid against upstands to ensurethat the membrane is not stretched ordisplaced when applying the screed orconcrete. A minimum thickness of 50mmscreed is recommended.When reinforced concrete is to belaid over the membrane, the wirereinforcements or spacers mustbe prevented from contacting themembrane. It is recommended that themembrane be covered with <strong>Visqueen</strong>Protection Board or 50mm screed priorto placing the reinforcements.When underfloor heating is to beinstalled, <strong>Visqueen</strong> recommend that thebarrier is positioned between the blindedhardcore and the insulation to protectthe installation from moisture and toavoid any risk of overheatingthe membrane.

P8REQUIRED COMPONENTSAvailable as a download fromvisqueenbuilding.co.uk/dpM<strong>Visqueen</strong> top hat units<strong>Visqueen</strong> DPM Jointing System<strong>Visqueen</strong> Zedex CPT DPCSPECIFICATION SUPPORTThe following items are availableto View Online or TO <strong>Download</strong> fromVISQUEENBUILDING.CO.UK/dpmCPDH&SCPD H&S NBSTECHNICAL DATASHEETSTYPICAL INSTALLATION CAD DETAILSHEALTH & SAFETY DATABRE Certificatefii c ati o nH&SCPDtC e rB R ELi miNBSH&SH&S NBSt e dCertificate No.112/04fii c ati o ntTECHNICAL DATAC e rB R Et e dLi miDimension PropertiesThickness (µm) 250 300 500Roll Width (m) 4 4 4Roll Length (m) 25 25 12.5Colour Black Black BlackFULL TECHNICAL INFORMATIONIS AVAILABLE ATWWW.VISQUEENBUILDING.CO.UK/DPMPHYSICAL CHARACTERISTICSNominal Thickness of sheets (µm)Property Test Description 250µm 300µm 500µmResistance to Tearing(Nail shank) in Machine DirectionResistance to Tearing(Nail shank) in Cross DirectionMax Tensile Stress in MachineDirectionElongationMax Tensile Stress inCross DirectionElongationBS EN12310 -1 165 N 205 N 310 NBS EN170 N 215 N 315 N12310 -1BS EN19.4 N/mm 2 24.9 N/mm 2 18.5 N/mm 212311 -2 370%390%370%BS EN23.2 N/mm 2 23.7 N/mm 2 19.9 N/mm 212311 -1 430%430%380%Standard detail -jointing detail (JD-01)Standard detail -typical ground bearing slab edge detail (SW-30)KEY:1) <strong>Visqueen</strong> Zedex CPT DPC.2) <strong>Visqueen</strong> Ecomembrane 500mu.3) <strong>Visqueen</strong> Lap Tape.4) <strong>Visqueen</strong> Jointing Tape (50mm x 10m).5) Smooth Sand Blinding Layer.Ensure laps are a minimum of150mm and fully sealed.KEY:1) <strong>Visqueen</strong> Ecomembrane - Laid on smooth slab or blinding.2) <strong>Visqueen</strong> 100mm x 33m Girth Tape.3) <strong>Visqueen</strong> 50mm x 10m Jointing Tape.4) <strong>Visqueen</strong> Protection Board.Ensure laps are a minimum of150mm and fully sealed.WWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 27

DAMP PROOF MEMBRANE<strong>Visqueen</strong> DPM TO PIFA STANDARD——Conforms to PIFA standard 6/83A:1995.——High puncture resistance.——Proven performance over many years.——Withstands rough site handling.——Comprehensive range to satisfy most site conditions.——Manufactured from the highest quality reprocessed materials.Description<strong>Visqueen</strong> Damp Proof Membranes are ahigh quality range of polyethylene dampproof membranes, available in blue orblack and produced to PIFA Standard6/83A:1995. Manufactured from highquality reprocessed low densitypolyethylene (LDPE) <strong>Visqueen</strong> DampProof Membranes have successfullyprevented moisture penetration fromfloors for many years. A strict selectiveraw material policy ensures aconsistently high quality DPM. <strong>Visqueen</strong>DPMs comply with the relevant <strong>Building</strong>Regulations and should be used inconjunction with the <strong>Visqueen</strong> JointingSystem to ensure complete integrityof joints.To maintain compatibility between dampproofing components and avoid issuessuch as polymer plasticizer migration,<strong>Visqueen</strong> strongly recommend the use of<strong>Visqueen</strong> DPCs.ApplicationThe extensive range of <strong>Visqueen</strong> DampProof Membranes means that they aresuitable for use in floors in most siteconditions, not subject to hydrostaticpressure. If hydrostatic pressure existsuse <strong>Visqueen</strong> Tanking Membranes.For jointing adjacent sheets of <strong>Visqueen</strong>DPM, DPM to DPC and DPC to DPC,<strong>Visqueen</strong> Jointing System should be used.To complete the system <strong>Visqueen</strong>strongly advise the use of the followingcomponents when installing themembrane;——<strong>Visqueen</strong> Double SidedJointing Tape.——<strong>Visqueen</strong> Girth Jointing Tape.——<strong>Visqueen</strong> Top Hat Units.IMPORTANTBased on BRE and CIRIA guidelines,<strong>Visqueen</strong> <strong>Building</strong> <strong>Products</strong>recommend the use of special gasprotection membranes (rather thantraditional polythene DPMs) assuitable protection against groundgases. On brownfield sites or wherethere is ground contamination pleaseseek further advice from <strong>Visqueen</strong><strong>Building</strong> <strong>Products</strong> as use of specialist<strong>Visqueen</strong> Gas Protection maybe necessary.TECHNICAL DATAThickness (μm)250 300 500Nominal Weight (g/m²) 232 279 465Roll Length (m) 25 25 12.5Roll Width (m) 4 4 4Water Vapour Transmission (g/m2/day) max 1 0.8 0.5Tensile Strength BS2782:320A 90N/25mm (min), 14.4MPa (min)Elongation at Break BS2782:320A*(56 days @ 80OC)Tear Resistance MOAT 27.5.4.1unaged 500% (min)aged* 250% (min)10N (min) 40N/mm(min)108N/25mm (min),14.4 MPa (min)unaged 500% (min)aged* 250% (min)12N (min) 40N/mm(min)Impact Strength Body (f50,g) 500 600 1000180N/25mm (min),14.4 MPa (min)unaged 500% (min)aged* 250% (min)20N (min) 40N/mm(min)28

P8REQUIRED COMPONENTSAvailable as a download fromvisqueenbuilding.co.uk/dpM<strong>Visqueen</strong> top hat units<strong>Visqueen</strong> DPM Jointing System<strong>Visqueen</strong> Zedex CPT DPCSPECIFICATION SUPPORTThe following items are availableto View Online or TO <strong>Download</strong> fromVISQUEENBUILDING.CO.UK/dpmCPDH&STECHNICAL DATASHEETSTYPICAL INSTALLATION CAD DETAILSHEALTH & SAFETY DATACPD H&S NBSH&SH&S NBSINSTALLATIONWhen used in accordance with the PIFACertificate and the relevant clausesof CP 102: 1973 in concrete floorsnot subject to hydrostatic pressure,<strong>Visqueen</strong> Damp Proof Membranes forman effective barrier to the passage ofmoisture from the ground. The DPMmust be continuous with the DPC in thesurrounding walls.The membrane should be installed ona compacted sand blinding layer orsmooth concrete float finish. The DPMmust be covered by a screed or otherprotective layer as soon as possibleafter installation. Care should be takento ensure that the membrane is notstretched or displaced when placing theconcrete or screed over the membrane.Sufficient allowance should be madeto avoid bridging (i.e. creating areasof unsupported membrane) duringscreeding operations at internal angles.JOINTING PROCEDURES——Always ensure that the membrane isclean, dust free and dry at the timeof jointing.——Adjacent sheets must be overlappedby a minimum of 150mm.——Bond together using <strong>Visqueen</strong>Double Sided Jointing Tape.——The joint should then be sealedusing <strong>Visqueen</strong> Single SidedGirth Tape.Where the sheets have been perforatedthey should be patched with sheetsof identical thickness lapped at least150mm beyond the limits of thepuncture and bonded with <strong>Visqueen</strong>Double Sided Jointing Tape and sealedwith <strong>Visqueen</strong> Single Sided GirthJointing Tape.IMPORTANTFor more information on jointingplease see our installationsection P83.ALSO CONSIDER<strong>Visqueen</strong> ecomembraneFor further details see P26.<strong>Visqueen</strong> GX Pre AppliedmembraneFor further details see P64.<strong>Visqueen</strong> highperformance dpm<strong>Visqueen</strong> High Performance DPMis manufactured from co-polymerthermoplastics giving superiorstrength and tear resistance. Fulldetails available on request or visitvisqueenbuilding.co.uk/dpm<strong>Visqueen</strong> BBA DPM<strong>Visqueen</strong> <strong>Building</strong> <strong>Products</strong>also produce a DPM with BBAAccreditation, certificate number94/3009. Further details areavailable upon request or visitvisqueenbuilding.co.uk/dpmWWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 29

32 Introduction to Gas Protection36 <strong>Visqueen</strong> GX Geomembrane System38 <strong>Visqueen</strong> Gas Barrier System42 <strong>Visqueen</strong> Low Permeability Gas Membrane44 <strong>Visqueen</strong> CO 2Gas Membrane46 <strong>Visqueen</strong> Radon Membrane49 <strong>Visqueen</strong> Radon Sump50 <strong>Visqueen</strong> Gas Venting System53 <strong>Visqueen</strong> Gas Venting Matground GASPROTECTION<strong>Visqueen</strong>’s Gas Membranes and Venting Systems allow construction to build on gascontaminated land such as disused petrol stations and post industrial sites. This ensuresreclamation of land and eases political pressure of building on green fields.

What gases andcontaminants are involved?HydrocarbonsHydrocarbons can be highly toxic and arederivative of the petrol chemical industry.Hydrocarbons are prevalent in areas such asdisused petrol stations and post industrial sites,most hydrocarbons are carcinogenic.MethaneAn odourless flammable gas that is explosivewhen released to the atmosphere at levels aslow as 5% and exposed to a source of ignition.Methane is formed wherever there is below-grounddegradation of organic substances e.g. landfillsites, sewage treatment areas, mining localitiesand peat bogs.Carbon dioxideCarbon Dioxide is a colourless gas that in highconcentrations can result in asphyxiation.The gas is formed by the oxidation of carboncompounds such as in landfill sites. When carbondioxide levels reach concentrations of 3%,symptoms of headaches and shortness of breathwill occur, becoming severe at 5%, with loss ofconsciousness at 10%. It’s fatal at 22%.RadonRadon is a naturally occurring radioactive gasthat is odourless and colourless. It is formedwhere uranium and radium are present. Itmigrates into any building that is built overthe source. If it accumulates in a building atunacceptably high concentrations it will increasethe risk of lung cancer.32

Protectionof <strong>Building</strong>son GasContaminatedlandIdentifying the RiskWhen identifying risk from contaminatedland up-to-date published guidancerelating to the risk assessment shouldbe used. Detailed historical mapping isthe principal starting point for any sitespecific environmental assessment.The historical maps provide a powerfulinsight into past activity and help identifyany historically contaminated land andprevious uses of the land e.g. disusedfilling station. The Health ProtectionAgency (HPA) produce a map whichshows the estimated percentage ofhomes above the radon Action Level, alevel set by the Health Protection Agencyat 200 becquerels per cubic metre.The provision of gas protectionmeasures should include measurementof borehole flow rates. This will helpidentify ground conditions, potentialsource(s) of gas, migration pathwaysand general potential. The level ofrisk may then be assessed and anappropriate gas protection systemdesigned. Account should be taken ofthe sensitivity of the proposed end use.Regulation and GuidanceThe assessment of risk from contaminated ground is a requirement ofPlanning Policy Statement PPS23 and <strong>Building</strong> Regulations ApprovedDocument C. The assessment needs to be carried out to supportany proposed development whether or not the development is near arecognised gas emission source i.e. landfill. If the development is atrisk from contamination then the developer’s consultant must submita risk assessment to the local planning authority. The risk assessmentmust include information about the source(s) of contamination, the keyproperties of the contamination and the proposed remediation strategiesto deal with any contamination. Where a proposed development is within250m of a landfill the Environment Agency Policy (2003c) on developmentwithin 250m landfill should be used. The policy states the proposals shouldinclude detailed risk management actions to deal with any risks. Failing todeal with the risks the LPA will refuse the application.Useful ReferencesThe <strong>Building</strong> Regulations Approved Document Part C 2004, CP 102: 1973Code of practice for the protection of buildings against water fromthe ground.BS 8102: 1990 Code of practice for the protection of structures againstwater from the ground.BS 8215: 1991 Code of practice for the design and installation of dampproof courses in masonry construction.BS 8000: Part 4:1989 Workmanship on <strong>Building</strong> Sites. Code of practice forwaterproofing.<strong>Building</strong> Research Establishment BRE 414 "Protective measures forhousing on gas contaminated land".CIRIA C665 Ground Gas Handbook 2009.<strong>Building</strong> Research Establishment BRE 211 "Radon Guidance onProtective Measures".CIRIA C682 The VOCs Handbook 2009.GASPROTECTIONWWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 33

The Complete Solution– <strong>Visqueen</strong>’s GasProtection SystemProtection of buildingsand occupiersThe main methods of protecting buildingsfrom gas ingress are the provision of arobust floor slab and gas resistant barrieracross the floor slab combined with anunderfloor passive venting system.At <strong>Visqueen</strong> we offer a comprehensiverange of gas barriers (a traditionaldamp proof membrane is NOT suitablefor protection on gas contaminatedland) and ventilation systems to protectagainst all the aforementioned gasesand contaminants. When installed inaccordance with the relevant codesof practice, <strong>Visqueen</strong>’s Gas Systemsare essential components to provide aprotective barrier to gas ingress. Also,all <strong>Visqueen</strong> gas barrier products act asdamp proof membranes.Gas BarriersThe impermeable gas membrane providesa barrier to gas ingress and should becontinuous beneath the full ground floorplan of the building. <strong>Visqueen</strong> offers fullprotection against the ingress of harmfulmethane, radon, CO 2and hydrocarbongases. Used in conjunction with <strong>Visqueen</strong>Gas Resistant DPCs, Gas BarrierJointing Systems and Gas Resistant SelfAdhesive Membrane, these systems offersuperior protection.To ease specification issues,<strong>Visqueen</strong> has produced a productselector that responds to the variousand complex design challenges on gascontaminated lands.gas Product selector<strong>Visqueen</strong> ProductGases involvedRadon CO 2Methane Hydrocarbons Page RefGX Geomembrane 36Gas Barrier 38Low Permeable Gas Membrane * 42CO 244Radon 46*Low Levels34

GAS PROTECTION SYSTEMS<strong>Visqueen</strong> HYDROCARBONPROTECTION SYSTEM——Low Permeability to Hydrocarbon substances and vapours.——High quality single layer HDPE.——Excellent puncture and tear resistance.——Complies with current codes of practice.——Also acts as a DPM.DESCRIPTION<strong>Visqueen</strong> GX Geomembrane is a highquality single layer HDPE membrane andis suitable for use as a barrier membraneon brownfield sites that require protectionfrom dangerous contaminants suchas hydrocarbons and methane. Dueto the membrane's high puncture andimpact resistance the <strong>Visqueen</strong> GXGeomembrane generally requires noprotective screed or boarding whenlaying reinforced concrete above it. The<strong>Visqueen</strong> GX is also suitable as a highperformance damp proof membrane.APPLICATION<strong>Visqueen</strong> GX Geomembrane offers a safesolution for the protection of buildings andoccupiers against all levels ofhydrocarbons, methane, carbon dioxideand radon ingress. Typically these are sitespreviously used as petrol stations,coalfields, landfill sites or arecontaminated industrial sites.Technical SupportDue to the wide variety ofhydrocarbon contaminants found, westrongly recommend the use of the<strong>Visqueen</strong> <strong>Building</strong> <strong>Products</strong> TechnicalSupport Team at an early designstage so that the most appropriatedetailing and material specificationsare adopted. A full technicaldatasheet is available onlinewww.visqueenbuiding.co.uk/gasInstallation Guidelines<strong>Visqueen</strong> GX and ancillary componentsmust be installed in accordance withthe recommendations of <strong>Building</strong>Research Establishment BRE 414“Protective measures for housing ongas contaminated land” and CIRIAC665 “Assessing risks posed byhazardous ground gases to buildings”,NHBC guidelines, Chartered Instituteof Environmental Health Ground GasHandbook and CIRIA C682 the VOCHandbook.The <strong>Visqueen</strong> GX system is suitablewhere hydrostatic pressure is present,however in this application the jointsmust be welded and not taped. Themembrane should be installed on ablinded or smooth surface allowingadequate overlap for jointing betweenthe sheets and avoiding bridging (i.e.areas of unsupported membrane).In areas where high levels ofunsupported membrane occur it isrecommended that <strong>Visqueen</strong> GX PreApplied Membrane is used. To avoidlinear expansion due to temperaturechange the membrane should NOTbe taken through any masonry wall.In order to provide a continuousbarrier across the cavity <strong>Visqueen</strong>GX DPC should be taken through theblockwork and incorporated below thedamp proof course cavity tray in theouter leaf.When a welded joint system is beingused, punctures to the membrane canonly be repaired by welding a patchof membrane with identical thicknessand lapped at least 150mm beyondthe limits of the puncture. Wherethis is not possible and the threedimensional shapes are complex itis recommended a preformed unitis used.To avoid high linear expansionwhen installed in hot weather,the membrane should be coveredimmediately after installation withconcrete or screed.VentilationWhen medium to high levels ofground gases are present or whenthe generation of gases still occurs,then an open void beneath theground floor should be constructed asventilation beneath the ground floorwill dilute and disperse the gases toatmosphere. Open voids are normallyrestricted to beam and block floors orother precast concrete floor systems.An alternative for providing ventilationto in situ concrete floor slabs is toinstall a <strong>Visqueen</strong> Ventilation System.See page 50 for further details.36

CPDP53P20REQUIRED COMPONENTSAVAILABLE AS A DOWNLOAD FROMVISQUEENBUILDING.CO.UK/GASVISQUEEN GX JOINTING SYSTEMVISQUEEN GEOCOMPOSITE VENTING SYSTEMVISQUEEN GX DPCSPECIFICATION SUPPORTTHE FOLLOWING ITEMS ARE AVAILABLETO VIEW ONLINE OR TO DOWNLOAD FROMVISQUEENBUILDING.CO.UK/GASCPDH&STECHNICAL DATASHEETSTYPICAL INSTALLATION CAD DETAILSHEALTH & SAFETY DATACPD H&S NBSH&SH&S NBSMANUFACTUREDIN THE UKDIMENSIONSGX GeomembraneGX GeomembraneGX Jointing SystemGX Geocomposite Venting SystemPreformed Top Hat UnitsGX DPCPreformed DPC Internal & External Corner Units1.0mm x 2.95m x 30m (88.50m 2 ) Standard Roll1.5mm x 2.95m x 25m (73.75m 2 ) Standard RollTwo part jointing system25mm & 50mm venting matsFor sealing around service pipe penetrations645mm / 970mm x 30m Roll A flexible reinforced DPCdesigned to prevent the transmission of hydrocarbon gasesthrough the cavityTo form an effective seal at cornersTECHNICAL DATA1mm1.5mmDensity (ASTM D1505) 941kg/m 3 +/- 1% 941kg/m 3 +/- 1%Thickness (BS2782-630A) +/- 5% +/- 5%Melt Flow Index (ASTM D1238)

GAS PROTECTION SYSTEMS<strong>Visqueen</strong> GAS BARRIER——Low permeability to methane, radon and carbon dioxide.——High quality multi-layer reinforced LDPE membrane withaluminium core with high levels of tear and impact resistance.——High resistance to puncture.——Complies with relevant codes of practice such as BRE and CIRIA.——Also acts as a damp proof membrane.BBA BRITISHBOARD OFAGREMENTASSESSMENT OF PRODUCTS FOR CONSTRUCTIONCERTIFICATE No. 10/4754BBA BRITISHBOARD OFAGREMENTASSESSMENT OF PRODUCTS FOR CONSTRUCTIONCERTIFICATE No. 10/4754DESCRIPTIONThe <strong>Building</strong> Regulations require thatproper precautions be taken to preventdanger to health and safety whenbuilding on contaminated land. <strong>Visqueen</strong>Gas Barrier offers a safe solution for theprotection of buildings against methane,radon and carbon dioxide, when installedin accordance with the relevant codesof practice such as BRE, CIRIA and theChartered Institute of EnvironmentalHealth Ground Gas Handbook. <strong>Visqueen</strong>Gas Barrier is a multi-layer reinforcedpolyethylene membrane with an integralaluminium foil. For ease of identificationon site <strong>Visqueen</strong> Gas Barrier is colouredblue on one side and silver on thereverse. The barrier combines strengthand performance with flexibility and easyinstallation. <strong>Visqueen</strong> Gas Barrier alsoacts as a damp proof membrane.Multi-Layer Protection<strong>Visqueen</strong> Gas Barrier utilises advancedmulti-layer lamination process tocreate an impenetrable and lastingprotection whilst retaining flexibility foreasy installation. A 0.4mm membranecomprising of five precision co-extrudedfilm layers, it is made from high qualityvirgin LDPE laminating films, asthickness tolerance is critical for theheat bonding process. The <strong>Visqueen</strong> GasBarrier provides a one piece barrier forsafety, security, flexibility and durability.Application<strong>Visqueen</strong> Gas Barrier offers a safesolution for the protection of buildingsand occupiers against methane, carbondioxide and radon ingress. Typically theseare sites previously used as coalfields,landfill or are contaminatedindustrial sites.Installation Guidelines<strong>Visqueen</strong> Gas Barrier and ancillarycomponents must be installed inaccordance with the recommendationsof <strong>Building</strong> Research EstablishmentBRE 414 “Protective measures forhousing on gas contaminated land” andCIRIA C665 “Assessing risks posed byhazardous ground gases to buildings”,NHBC guidelines, and the CharteredInstitute of Environmental Health GroundGas Handbook. The product is notintended for use where there is a riskof hydrostatic pressure. The membraneshould be installed blue side up. Themembrane should be installed on acompacted sand blinding layer or smoothconcrete float finish. In areas where highlevels of unsupported membrane occurit is recommended that <strong>Visqueen</strong> PreApplied Membrane is used. To avoid slipor shear planes and high compressiveloadings it is not recommended to takethe membrane through the wall. In orderto provide a continuous barrier acrossthe cavity <strong>Visqueen</strong> Gas Resistant DPCshould be taken through the blockworkand incorporated below the damp proofcourse cavity tray in the outer leaf.Laps can be joined together by eitherusing the <strong>Visqueen</strong> Gas Barrier jointingsystem or welded by our specialiston-site contractors.NB. In demanding site conditions use<strong>Visqueen</strong> GR Lap Tape as a highperformance alternative to <strong>Visqueen</strong>Foil Jointing Tape.IMPORTANTFor lapping, jointing and puncturerepair, please see ourInstallation section P83For more information on the <strong>Building</strong>Regulations on gas contaminatedlands see P32Jointing Detail<strong>Visqueen</strong> Gas Barrier<strong>Visqueen</strong> GR Lap TapeLDPETough polyethylene outer layerprovides absolute protectionagainst moisture ingress.<strong>Visqueen</strong> Blue LDPEAluminium FoilCentral shield layer of aluminiumprovides impenetrable gasreflectingproperties.Split Yarn HDPEAdhesive split yarn woven matrixprovides 3-D tear resistance.LDPEProtective polyethylene outerlayer confers additional tensileand tear strength properties.<strong>Visqueen</strong> DoubleSided Jointing TapeSplit Yarn HDPE<strong>Visqueen</strong> GR DPC38

GAS PROTECTION SYSTEMS<strong>Visqueen</strong> Gas Barrier Pre-Weld——65% time saving over traditional tape and roll sealing methods.——Fast track installation on site.——Reduced wastage through off-site fabrication.——<strong>Visqueen</strong>'s pre-welding technology ensures high Integrity to gas membrane joints.Recent building techniques have seena tendency towards the use of offsitefabrication in many sectors ofthe building process. It seems logicaltherefore, that <strong>Visqueen</strong> <strong>Building</strong><strong>Products</strong> should, in recognising thistrend, provide an economical and timesaving solution to the needs of themodern developer who requires a provengas barrier system.With increasing numbers of housing andindustrial developments taking placeon gas contaminated sites, developersmust ensure that a high integrity gasprotection membrane is installed, yetcontinue to operate under the timerelated pressures of today’s fast trackbuilding programmes.Welding technology for joiningmembranes is well established but haspreviously only been available whenspecialist on-site contractors have beenused. It is widely recognised that joiningsheets of membranes on site is oftenthe most vulnerable element in theinstallation of a gas protection system.By working closely with the designerin early project stages, <strong>Visqueen</strong> canproduce a complete gas protectionpackage that is delivered direct to sitewhen required.The use of pre-welded sheets means thatthe designer can now have increasedlevels of confidence as all joints areconstructed in factory conditionsand have been rigorously tested forairtightness before reaching site.Additionally, as there are fewer tapedjoints to be performed on site, thegas barrier installation is less affectedby adverse weather conditions (to beeffective, taped joints must be formed indry conditions).<strong>Visqueen</strong> Gas Barrier is pre-welded inthe factory to the exact dimensions ofthe footprint to the building and can bedispatched with the correct quantities ofancillary components as required to forma high integrity gas barrier system.Factory fabrication helps reduce wastageon site and <strong>Visqueen</strong>’s factory weldedjoints ensure that a high integrity airtightbarrier is always achieved. The reducedtime for on-site jointing ensures thatfor each footprint the installation timeis significantly reduced. Each footprintcan be identified by a unique reference,thereby, ensuring that on-site ordering isstraightforward.Technical Properties - <strong>Visqueen</strong> Pre-Weld Gas Barrier JoinTensile Strength MOAT 27 1983 5.5.2Resistance to Water PressureM.O.A.T 27 983 5.1.4Resistance to 6m head of water pressure35.3 daN/50mmPass, No leaksWWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 41

GAS PROTECTION SYSTEMS<strong>Visqueen</strong> LOW PERMEABILITY(LP) GAS MEMBRANELOW PERMEABILITYGAS MEMBRANE——Low permeability to carbon dioxide radon and low levels of methane.——High quality robust Co-Polymer Thermoplastic Membrane.——High resistance to puncture.——Complies with relevant codes of practice such as current BRE and CIRIA documentation.——Also acts as a damp proof membrane.MANUFACTUREDIN THE UKDESCRIPTIONThe <strong>Building</strong> Regulations require thatproper precautions be taken to preventdanger to health and safety when buildingon contaminated land. <strong>Visqueen</strong> LowPermeability Gas Membrane offers a safesolution for the protection of buildingsagainst low levels of methane and carbondioxide, when installed in accordancewith the relevant codes of practicesuch as BRE, CIRIA and the CharteredInstitute of Environmental Health GroundGas Handbook. For more informationon the <strong>Building</strong> Regulations on gascontaminated lands see P32. <strong>Visqueen</strong>Low Permeability Gas Membrane isa robust co-polymer thermoplasticmembrane; for ease of identification onsite the membrane is coloured yellow.The membrane is supplied in 4m x 12.5mroll and has a centre fold. It is flexibleand is easy to install, and is also suitablefor use as a damp proof membrane.Application<strong>Visqueen</strong> Low Permeability GasMembrane offers a safe solution for theprotection of buildings and occupiersagainst low levels of methane, carbondioxide and radon ingress. Typicallythese are sites previously used ascoalfields, landfill or are contaminatedindustrial sites.Installation<strong>Visqueen</strong> Low Permeability GasMembrane and ancillary componentsmust be installed in accordance withthe recommendations of <strong>Building</strong>Research Establishment BRE 414"Protective measures for housing on gascontaminated land", and CIRIA C665“Assessing risks posed by hazardousground gases to buildings”, NHBCguidelines and the Chartered Instituteof Environmental Health Ground GasHandbook. The product is not intendedfor use where there is the risk ofhydrostatic pressure.The membrane should be installed on acompacted sand blinding layer or smoothconcrete float finish allowing adequateoverlap for jointing between the sheetsand avoiding bridging (i.e. areas ofunsupported membrane). In areas wherehigh levels of unsupported membraneoccur it is recommended that <strong>Visqueen</strong>Pre Applied Membrane is used. To avoidslip or shear planes and high compressiveloadings it is not recommended to takethe membrane through the wall. In orderto provide a continuous barrier acrossthe cavity <strong>Visqueen</strong> Zedex CPT DPCshould be taken through the blockworkand incorporated below the damp proofcourse cavity tray in the outer leaf.Laps can be joined together by eitherusing the <strong>Visqueen</strong> Gas Barrier jointingsystem or welded by our specialiston-site contractors.VentilationBS8485 recommends ventilationlayers on open voids may be requiredbeneath the floor slab in order to diluteand disperse ground gases to theatmosphere. Open voids are normallyrestricted to beam and block floors orother precast concrete floor systems. Analternative for providing ventilation to insitu concrete floor slabs is to install a<strong>Visqueen</strong> Ventilation System. See page50 for further details.NB. In demanding site conditionsuse <strong>Visqueen</strong> GR Lap Tape as a highperformance alternative to <strong>Visqueen</strong>Foil Jointing Tape.IMPORTANTFor lapping, jointing andpuncture repair, please see ourInstallation section P83.A full technical datasheet isavailable onlinewww.visqueenbuilding.co.uk/gas42

CPDP53P88P8P60REQUIRED COMPONENTSAVAILABLE AS A DOWNLOAD FROMVISQUEENBUILDING.CO.UK/GAS<strong>Visqueen</strong> Gas Barrier Jointing System<strong>Visqueen</strong> detailing strip<strong>Visqueen</strong> Top Hat Units<strong>Visqueen</strong> geocomposite drainage & venting maT<strong>Visqueen</strong> heavy duty protection board<strong>Visqueen</strong> Zedex CPT DPC<strong>Visqueen</strong> Gas Resistant Self Adhesive membraneSPECIFICATION SUPPORTTHE FOLLOWING ITEMS ARE AVAILABLETO VIEW ONLINE OR TO DOWNLOAD FROMVISQUEENBUILDING.CO.UK/GASCPDH&SCPD H&S NBSH&SH&S NBSTECHNICAL DATASHEETSTYPICAL INSTALLATION CAD DETAILSHEALTH & SAFETY DATACoveringCovering<strong>Visqueen</strong> CO 2Gas Membrane should becovered by a protective layer as soon aspossible after installation. Care shouldbe taken to ensure that the membraneis not punctured, stretched or displacedwhen applying a screed or final floorcovering. A minimum thickness of 50mmscreed is recommended.When reinforced concrete is to be laidover the barrier the wire reinforcementsand spacers must be prevented fromcontacting the barrier. It is recommendedthat the barrier is covered with <strong>Visqueen</strong>Protection Boards or screed beforepositioning the reinforcement. Whenunderfloor heating is being installed,it is recommended that the barrier ispositioned between the blinded hardcoreand insulation. This will protect theinsulation from moisture and avoid anyrisk of overheating the membrane.Storage and Handling<strong>Visqueen</strong> CO 2Gas Barrier is classified asnon-hazardous when used in accordancewith the relevant Code of Practice (CP102:1973). The product is chemicallyinert and is not affected by acids andalkalis that may be present in the subsoils.The material is not recommendedfor uses where it will be exposed tolong periods of outdoor weathering asexposure to ultraviolet light will embrittlethe product. Weathering will not occurwhen the membrane is installed inaccordance with CP 102:1973. Careshould be taken to avoid accidentaldamage when handling the membrane onsite. When the weather is cold all jointingtapes should be kept in a warm and dryplace until needed. Installation is notrecommended below 5°C.TECHNICAL DATANominal Thickness (μm) 500Nominal Weight (g/m²) 465Roll Length (m) 12.5Roll Width (m) 4Carbon Dioxide Gas PermeabilityISO 27822.80 x 10 -17 m²/sec/PaWWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 45

iGAS PROTECTION SYSTEMS<strong>Visqueen</strong> RADON MEMBRANE——Independently tested for radon resistance.——BRE Certified.——High resistance to puncture.——Also acts as a damp proof membrane.——Complies with CIRIA C665.C e rtB R Efii c ati o nt e dLi miCertificate No.083/01fii c ati o nMANUFACTUREDIN THE UKtC e rLi mAssessing The Risk For Your AreaBecause the level of risk differs acrossthe country according to local geology,the risk depends on where your site issituated.The main source of guidance on the risksand solutions is BRE Report BR 211.It includes maps for determining the needfor radon protection, as well as detailedinformation on construction solutions.The maps are used as the basis fordetermining in general terms the requireddegree of radon protection (“basic” or“full”) in your area. Essentially, “basic”protection means you need to lay aground floor radon membrane and “full”protection means that, in addition, youneed to make provision for underfloordepressurisation.Your local authority <strong>Building</strong> ControlOfficer or a local Approved Inspectorshould also be able to help you determinethe broad level of risk in your area but,like the maps, they can only give a broadindication. Ultimately, if you are in anarea that is potentially at risk, there isno substitute for an assessment close toyour actual site – you may be in a pocketwhere the geology is different from theregion as a whole, allowing the requiredprotection to be downgraded from“full” to “basic”, or even making radonprotection unnecessary.Determining The Risk ForYour SiteIf you are in an area where the mapsindicate that no protection is required,there is no need to take further action.However, if the maps indicate theneed for “full” protection, it is worthconfirming this by requesting a detailedassessment from the British GeologicalSurvey (BGS), which focuses moreaccurately on your location. This mayshow that only “basic” protection isnecessary on your particular site.Construction SolutionsRadon ProtectionOnce you have determined whether youneed “basic” or “full” protection, youmust check that your preferred groundfloor construction gives you the right levelof protection. The options are as follows:Basic Radon ProtectionFor “basic” protection, you need toprovide an airtight barrier coveringthe entire ground floor of the building,linked to the damp proof course usingcavity trays which prevent radon movingthrough the wall cavity and into thebuilding.All junctions between the floor membraneand cavity trays should be sealed. Youcan achieve “basic” protection withboth ground supported and suspended(ventilated) concrete ground floorsby installing a radon-proof membranesystem. With a suspended concrete slab,the space beneath the floor is availableto ventilate radon safely away should“full” protection be required.Full Radon ProtectionFor “full” protection, you not only needto provide a radon-proof floor membrane,but also an underfloor depressurisationsystem. Depressurisation can beachieved by natural or mechanicalunderfloor ventilation through thesubfloor space, or from a radon sumpif there is no underfloor space. If youprefer to use an in situ slab in contactwith the ground, the slab should besupported on the inner leaf. The fullsystem consists of;——<strong>Visqueen</strong> Radon Jointing System,prevents radon ingress at joints,——<strong>Visqueen</strong> Top Hat Units preventsradon ingress at pipe penetrations,——<strong>Visqueen</strong> Radon Sumps, wheresubfloor depressurisation may berequired.B R EIMPORTANTFor more information on the <strong>Building</strong>Regulations on gas contaminatedlands see P32A full technical datasheetis available onlinewww.visqueenbuilding.co.uk/gasBelow: <strong>Visqueen</strong>'s RadonSystem Componentst e d46

GAS PROTECTION SYSTEMSVISQUEEN RADON MEMBRANEINSTALLATION & JOINTINGInstallation<strong>Visqueen</strong> Radon Gas Membrane andancillary components must be installedin accordance with the recommendationsof <strong>Building</strong> Research EstablishmentBRE 414 "Protective measures forhousing on gas contaminated land" andCIRIA C665 “Assessing risks posed byhazardous ground gases to buildings”,NHBC guidelines and the CharteredInstitute of Environmental Health GroundGas Handbook. The product is notintended for use where there is the riskof hydrostatic pressure.The membrane should be installed ona compacted sand blinding layer orsmooth concrete float finish allowingadequate overlap for jointing betweenthe sheets and avoiding bridging (i.e.areas of unsupported membrane). Inareas where high levels of unsupportedmembrane occur it is recommendedthat <strong>Visqueen</strong> Pre Applied Membraneis used. To avoid slip or shear planesand high compressive loadings it is notrecommended to take the membranethrough the wall. In order to provide acontinuous barrier across the cavity<strong>Visqueen</strong> Zedex CPT DPC should betaken through the blockwork andincorporated below the damp proofcourse cavity tray in the outer leaf.Laps can be joined together by eitherusing the <strong>Visqueen</strong> Gas Barrier JointingSystem or welded by our specialist onsitecontractors.If the membrane is punctured orperforated then a patch of material withidentical thickness should be lappedat least 150mm beyond the limits ofthe puncture and bonded with <strong>Visqueen</strong>Double Sided Jointing Tape and sealedwith <strong>Visqueen</strong> Single Sided Girth Tape.Alternatively a patch can be formedusing <strong>Visqueen</strong> Detailing Strip and lappedat least 150mm beyond the limits of thepuncture. External and internal cornersshould be round and reinforced with<strong>Visqueen</strong> Detailing Strip. Where this isnot possible and the three dimensionalshapes are complex it is recommendeda preformed unit is used.Covering<strong>Visqueen</strong> Radon Membrane should becovered by a protective layer as soon aspossible after installation. Care should betaken to ensure that the membrane is notpunctured, stretched or displaced whenapplying a screed or final floor covering.A minimum thickness of 50mm screed isrecommended. When reinforced concreteis to be laid over the barrier the wirereinforcements and spacers must beprevented from contacting the barrier.It is recommended that the barrieris covered with <strong>Visqueen</strong> ProtectionBoards or screed before positioningthe reinforcement. When underfloorheating is being installed, it isrecommended that the barrier ispositioned between the blinded hardcoreand insulation. This will protect theinsulation from moisture and avoid anyrisk of overheating the membrane.Storage and Handling<strong>Visqueen</strong> Radon Gas Barrier is classifiedas non-hazardous when used inaccordance with the relevant Code ofPractice (CP 102:1973). The product ischemically inert and is not affected byacids and alkalis that may be presentin the sub-soils. The material is notrecommended for uses where it willbe exposed to long periods of outdoorweathering as exposure to ultravioletlight will embrittle the product.Weathering will not occur when themembrane is installed in accordance withCP 102:1973. Care should be taken toavoid accidental damage when handlingthe membrane on site. When the weatheris cold all jointing tapes should be keptin a warm and dry place until needed.Installation is not recommendedbelow 5°C.sealing method around universal column penetration(SLAB JUNCTIONS ONLY) (rad - 19)IMPORTANTFor lapping, jointing and puncturerepair, please see ourInstallation section P83.A full technical datasheet isavailable onlinewww.visqueenbuilding.co.uk/gas48

GAS PROTECTION SYSTEMS<strong>Visqueen</strong> RADON SUMPSUMPHow to install a proprietary radon sump and exhaust pipe at the external wall123Excavate a pit for the sump, ensuringthat, for maximum depressurisation,any fill used beneath the slab does notcontain excessive fines.4Remove the blanking piece from theproprietary sump and connect a 110mmdiameter PVC-U pipe to one outlet of thesump.5Extend the pipe horizontally so that itpasses through the external wall. Ensurethat all joints and couplings are airtight.6Backfill using a clean permeable materialwithout excessive fines.<strong>Visqueen</strong> Radon SumpColourLengthWidthHeightMaterial CompositionTerminate the pipe just above groundlevel, and cap it. It will then be ready forextension to form a vent if necessary.Various Colours: White, Black, or Green430mm430mm220mmPolyethyleneSumps For Use With Full ProtectionWhere subfloor depressurisation is required, a <strong>Visqueen</strong> Radon Sump should beused. This is a prefabricated plastic sump, to which pipework is connected, withthe joints fully sealed using the <strong>Visqueen</strong> Radon Membrane Jointing System.A venting pipe should be connected to the sump, pass through the external walland brought out above ground level about 100mm from the face of the externalwall. The pipe is then capped until such time as a fan is installed.Position the capped section of pipe sothat it is about 100mm from the face ofthe external wall. This will allow space toaccommodate a fan if necessary. Provide aplate on the wall to indicate the presenceof the radon exhaust pipe.IMPORTANTA sump is only installed as a fallbackmeasure and does not provide anyradon removal until a fan is installedor, if the sump is located centrally,the pipe is connected to a passivestack system. Typically sumps areinstalled at one unit per dwelling orevery 15m radius.WWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 49

visqueen Gasventing systemBackgroundThe hazards of ground gases must betaken into account when designing andconstructing new developments.Ground gas can be drawn into a buildingby the pressure difference that existsbetween the inside and outside of thebuilding (warm indoor air is less densethan cold outdoor air). Ground gasescan enter buildings through:——Gaps around service pipes.——Construction joints.——Wall cavities.——Cracks in walls and ground slabs.Having entered buildings, ground gasmay accumulate in confined spacessuch as:——Subfloor voids / voids created bysettlement beneath floor slabs.——Cupboards.——Drains and soakaways.Methods of ProtectionCurrent UK construction practice adoptsthe concept of multiple gas protectionmeasures to form a gas control system,typically, protection measures increase innumber and robustness as the potentialrisk increases.The main methods of protecting buildingsfrom gas ingress are the provision ofa robust floor slab and gas resistantbarrier across the floor slab which maybe combined with an underfloor passiveventing system.In most buildings passive gas protectivemeasures are constructed either ator just below the ground floor level.The protection consists of a number ofindividual elements, which combine toform an integrated gas protection system.The most commonly used components ina passive gas protection system are:——Ground floor construction.——Gas resistant membrane/Gas DPC.——Open void or GeocompositesVentformers with associatedpipework and perimeter vents.——Sealed service entries.Passive VentingIn a passive venting system gas risesto the underside of the building and isdiluted to safe concentrations belowthe slab by the introduction of fresh airthrough predetermined inlets and outletswhich typically provide 2000mm 2 permetre run of perimeter wall. The ventsare placed on opposite sides of thebuilding which allows sufficient air toenter the void below the building andthe diluted gas is then released out toatmosphere at safe concentration.The required air changes per hour to theunderside of the building are calculatedto ensure that the gas emanating fromthe ground is safely diluted.<strong>Visqueen</strong> Geocomposite Venting Matsare available in both 25mm and 50mmthicknesses and both have beenthoroughly tested as per the DETRPartners In Technology Research Report(Passive Venting of Soil Gases Beneath<strong>Building</strong>s 1997).50

<strong>Visqueen</strong> Geocomposite Venting Matscan be laid in a blanket under the entirefloor area on more heavily gassing sitesor alternatively can be laid in strips atpredetermined centres to suit the gasregime on site.It is however important to note thatwhere <strong>Visqueen</strong> Geocomposite VentingMat is laid in strips that a gas collectionpipe running perpendicular to the ventsmust be provided. Furthermore it isimportant to recognise that the strips ofventing mat alone will not be adequate interms of providing the venting capacityrequired unless they are laid in a 150mmthick layer of course granular materiale.g 4/20 that must extend under theentire footprint of the building.Laying strips of geocomposite in MOTtype 1 is a common mistake and bothDETR Partners In Technology ResearchReport (Passive Venting of Soil GasesBeneath <strong>Building</strong>s 1997) and CharteredInstitute of Environmental Health “Thelocal authority guide to ground gas”stipulate that it is not acceptable tolay perforated pipes or geocompositesventing strips in low permeabilitysubstrates.Both documents also state that whereventing mat or pipes are laid in stripsthey must be interleaved to avoid shortcircuiting.On more heavily gassing sites it may benecessary to provide a full blanket ofeither <strong>Visqueen</strong> 25mm or 50mm VentingMat in order to facilitate the required airflow under the building.Table 28 of the DETR Partners InTechnology Research Report (PassiveVenting of Soil Gases Beneath <strong>Building</strong>s1997) gives performance data onthe performance of venting mat onbuildings up to 30m widths based on thecharacteristic situation of the site.On wider buildings that fall outside of thescope of Table 28 of the DETR report,<strong>Visqueen</strong> can provide calculations toprove that the gas emanating from theground will be kept below the requiredtarget concentrations for the site.The introduction of high level ventswith rotating cowls can further enhancethe performance of the <strong>Visqueen</strong>Geocomposite Venting Mat which meansthat it can be used to safely dilute gaseson problematic sites without the need forenvironmentally unfriendly electric fans.The Chartered Institute of EnvironmentalHealth report “The local authorityguide to ground gas” recommends thatactive systems that extract or positivelypressurise subfloor voids should only beused when passive measures have beenproven to be unsuitable.At <strong>Visqueen</strong> <strong>Building</strong> <strong>Products</strong> we havea range of gas membranes and ventinglayers with accessories for selection andspecification for different constructiontypes and gas regimes.The products and systems have beenspecifically developed to reduce therisk of harm to building occupants.Please contact our technical servicesdepartment for further information.WWW.VISQUEENBUILDING.CO.UK | 0845 302 4758 51