Vinnolit E 67 ST

Vinnolit E 67 ST

Vinnolit E 67 ST

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

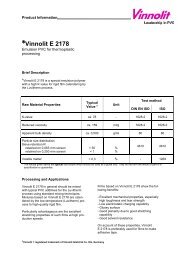

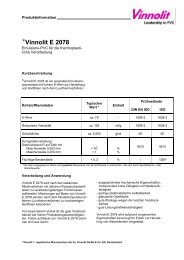

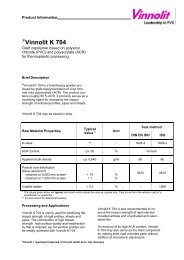

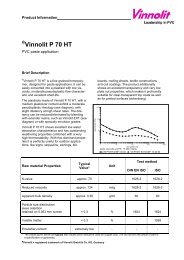

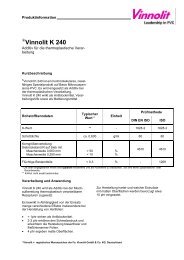

Product Information® <strong>Vinnolit</strong> E <strong>67</strong> <strong>ST</strong>PVC for paste applicationBrief Description® <strong>Vinnolit</strong> E <strong>67</strong> <strong>ST</strong> is a very fine-particle, pastemakingemulsion homopolymer, giving mediumviscosity plastisols with a good shelf life.Plastisols made with <strong>Vinnolit</strong> E <strong>67</strong> <strong>ST</strong> have aslightly pseudoplastic rheology (see diagram).<strong>Vinnolit</strong> E <strong>67</strong> <strong>ST</strong> exhibits excellent foamingcharacteristics in chemically blown foams,particularly for screen printing and hotembossing for wall covering manufacturing.paste viscosity [Pas]10001001011 10 100 1000 10000shear gradient [s -1 ]paste viscosity at 23°C, 1h after mixingVN E<strong>67</strong><strong>ST</strong>:DINP 100:60Raw material PropertiesTypicalValue*UnitDIN EN ISOTest methodISOK-value approx. <strong>67</strong> - 1628-2 1628-2Reduced viscosity approx. 112 ml/g 1628-2 1628-2Apparent bulk densitiy approx. 0.39 g/ml 60 60Particle size distribution:sieve retentionretained on 0.063 mm screen < 0.35 % 1624 1624Volatile matter < 0.5 % - 1269Emulsifier content medium - - -* The values given above are typical test results which should be used as a guide only. The do not form the whole or part ofa specification or guarantee. <strong>Vinnolit</strong> = registered trademark of <strong>Vinnolit</strong> GmbH & Co. KG, Germany

Product InformationProcessing and ApplicationPlastisols based on <strong>Vinnolit</strong> E <strong>67</strong> <strong>ST</strong> can beapplied by all commonly used coating techniques.<strong>Vinnolit</strong> E <strong>67</strong> <strong>ST</strong> is recommended for the productionof foamed wallcoverings havingsmooth or structured surfaces.The product has the following properties:- outstanding foaming characteristics; lowdensity foams with fine cell structure, evenat very high filler content- medium viscosity at low shear rates withslightly pseudoplastic flow behaviour- very fine particle size- foams with good whiteness- good foam inhibition (eg with benzotriazole)- low gelling temperature- good paste deaeratibility- the product is compatible within a widerange of processing variables, with no tendencyto overfoamingPackaging, Delivery and StorageThe product is supplied in 25-kg bags.<strong>Vinnolit</strong> E <strong>67</strong> <strong>ST</strong> should be stored dry andaway from direct or indirect sources of heat.Please consult the safety data sheet for informationabout the safety precautions necessaryfor transport, storage, blending and processing.General InformationFurther processing information and recommendationscan be obtained from our TechnicalService department or our local representatives.The data and recommendations contained in this product informationrepresent the current state of our knowledge and serve as a guide onlyto our products and their potential applications. Therefore, no warrantyof specific properties of the products mentioned here in nor of theirsuitability or fitness for a particular purpose is implied.The information given in this leaflet should be checked by preliminarytrials because of conditions during processing over which we have nocontrol, especially where other companies' raw materials are also used.Patent or other proprietary rights of third parties must be observed. Thequality of our products is warranted under the terms of our GeneralConditions of Sale.Ismaning, January 2010<strong>Vinnolit</strong> GmbH & Co. KGCarl-Zeiss-Ring 25D-85737 IsmaningTel.: +49 89 9 61 03-0Fax: +49 89 9 61 03-103www.vinnolit.com