HF 760 - HF 761 series - Harrier Filters

HF 760 - HF 761 series - Harrier Filters

HF 760 - HF 761 series - Harrier Filters

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE IMPORTANCE OF AN EFFICIENT FILTRATIONThe main cause of anomalies in hydraulic systems has tobe attributed to the presence of contaminants in the fluid.The nature of the contaminant may be: gaseous, namelyair mixed with the fluid; fluid, in most cases it is water thathas penetrated the fluid; solid, therefore particles of variousorigins and dimensions.The customers who operate equipment are always focusedon obtaining the best possible performance, lowerenergy consumptions and greater respect for the environment.These characteristics can be attained by using top qualitycomponents in the hydraulic system for generatingand regulating the fluid power, which are however rathersensitive to the presence of contaminants in the fluid.Starting from these requirements, we understand howimportant and fundamental it is to prevent the presenceof air and water from mixing in the fluid tank by using dedicatedsolutions.It is also crucial to limit the presence of solid particles inthe hydraulic circuit through a suitable filtering system,which is indispensable to maintain the project requirementsof the system over time and to keep running costslow.The correct choice of a filter and its optimum position inthe hydraulic system requires the same care and experienceneeded to choose all the other components.The use of filters with larger filtering surfaces reduces, atequal flow rates, the superficial contaminant load andtherefore the filter's life is extended proportionally.To maintain the maximum efficiency of the system, the filtersmust have a clogging indicator showing the differentialpressure on the filtering cartridge and to immediatelypoint out when the cartridge needs replacing in order toprevent the by-pass valve from opening.The following factors should be analysed when choosing the ideal filter: The filtration degree required to protect the most sensitive component from contamination The points of the circuit in which the filters have to be installed The working pressure of the system The maximum flow rate and the type of fluid to be filtered The duty cycle The retention efficiency of the filtering cartridge The contaminant accumulation capacity of the filtering cartridge The working ambient temperatureEach filter used generates a pressure drop that increases continuously as time goes by. This pressure drop representsan efficiency index of the filter itself.When the hydraulic system is about to be assembled, all the components must be perfectly clean and the fluid has to beadded through a device complete with a filter.During the test phase, it is advisable to run some work cycles at low pressure in order to create the best possible conditionsfor all the components.

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>TECHNICAL CHARACTERISTICSThe filters of the <strong>HF</strong> <strong>760</strong> and <strong>HF</strong> <strong>761</strong> <strong>series</strong> are connectedto the pressure line of the circuit and protect thesystem’s components against contaminant particles.The standard filters are supplied with by-pass valve calibratedat 87 psi (6 bar).<strong>HF</strong> <strong>761</strong> serie differs from the <strong>HF</strong> <strong>760</strong> one because adoptsHE K-86 elements.For applications which need maximum protection of thesystem, such as servo drives or proportional controls, thefilters are equipped with highly resistant filtering elements(versions “HC”) and do not have a by-pass valve. Flow up to 120 US gpm (450 l/min) Maximum working pressure 6090 psi (420 bar) High efficiency multilayer system Flanged ports SAE 3000 e SAE 6000MATERIALSHeadBowlSealsEnd capInner tubeFilter mediaSpheroidal cast ironGS 450-10 UNI ISO 1083Extruded steelBuna - VitonZinc plated steelZinc plated steelInorganic micro-fibre glassFLUID COMPATIBILITYConforming to ISO 2943 (Norm ISO 6743/4)Oil mineral (1)HH - HL - HM - HR - HV - HGWater emulsion (1)<strong>HF</strong>AE - <strong>HF</strong>ASWater glycol (1)<strong>HF</strong>CSyntetic fluid (2)HS - <strong>HF</strong>DR - <strong>HF</strong>DU - <strong>HF</strong>DS(1) With Buna seals(2) With Viton sealsFLOWFlow max.120 US gpm (450 l/min)OPERATING TEMPERATUREWith Buna seals-22 195 °F (-30 90 °C)With Viton seals-4 230 °F (-20 110 °C)ENDURANCE STRENGTHSize 20 and 30Size 40DEGREE OF FILTRATIONMulti-pass test conforming to ISO 16889 (regulation in force)Contaminant ISO MTD - final p 87psi(6bar)CodeDegree offiltration1.000.000 cycle0 6090 psi (0 420 bar)1.000.000 cycle0 4060 psi (0 280 bar)Ratioß x(c)Percentage ofefficiencyFG003 5 m ß 5(c) 200 99,5 %FG006 7 m ß 7(c) 200 99,5 %FG010 10 m ß 10(c) 200 99,5 %FG025 21 m ß 21(c) 200 99,5 %03/01.2010PRESSUREWorking pressureTesting pressureBurst pressureElement collapse pressurerating (conforming to ISO 2941)BY-PASS VALVE6090 psi (420 bar)8700 psi (600 bar)18275 psi (1260 bar)290 psi (20 bar) (version LC)3045 psi (210 bar) (version HC)Multi-pass test conforming to ISO 4572 (previous regulation)Contaminant ACFTD - final p 87psi(6bar)CodeDegree offiltrationRatioß xPercentage ofefficiencyFG003 3 m ß 3 200 99,5 %FG006 6 m ß 6 200 99,5 %FG010 10 m ß 10 200 99,5 %FG025 25 m ß 25 200 99,5 %By-pass setting87 psi (6 bar)INDICATORS (3)Visual differential indicatorVisual electrical differential indicatorVisual electrical differential indicator with thermostat(3) Characteristics and dimension pag. 14ICAT011-002 002 1

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>SIZING – PRESSURE DROPThe total pressure drop of the filter is calculated by summing the pressure drop value in the housing to the one filteringelement.Total p p in housing + p in elementIn filters of <strong>series</strong> <strong>HF</strong> <strong>760</strong> and <strong>HF</strong> <strong>761</strong> in normal working conditions, the total p must not be more than 11 psi (0,75 bar)whereas, for use in harsh conditions, it must be within 14.5 22 psi (1 1,5 bar).To establish the values of pressure drop involved, the following pages provide some diagrams with curves referred tothe use of mineral oils SAE 10 with kinematic viscosity of 120 SSU (30 cSt) and density of 7.29 lb/gal (0,856 kg/dm 3 ).Calculation exampleFilter <strong>HF</strong><strong>760</strong>-20.106-AS-FG010-LC-B60-GD-B-DD-GFlow rate= 12 US gpm (45 l/min)Kinematic viscosity: 120 SSU (30 cSt)Oil density : 7.29 lb/gal (0,856 kg/dm 3 )Filtering degree: 10 mData obtained from the diagrams:p in housing = 2.00 psi (0,14 bar) (page 4)p in element = 7,25 psi (0,50 bar) (page 5)Total p = 2.00 + 7.25 = 9.25 psi (0,64 bar) (p is lower than maximum value admitted – therefore sizing is correct)..If oil with different kinematic viscosity and different density is used, the values obtained from the diagrams will be re-calculatedconsidering the following indications:1) The pressure drop of the housing is proportional with the oil density, therefore for oil with density different to 7.29lb/gal (0,856 kg/dm 3 ) the value of the p in the head-bowl will be:p in housing =Orp in housing =p of diagram (psi) • Oil density ( lb/gal)7.29 (lb/gal)p of diagram (bar) • Oil density ( kg/dm 3 )0,856 (kg/dm 3 )[psi][bar]2) The pressure drop of the element is proportional with the oil density and kinematic viscosity, therefore for oil with densitydifferent to 7.29 lb/gal (0,856 kg/dm 3 ) and kinematic viscosity different to 120 SSU (30 cSt) the value of p in the elementwill be:p element = p of diagram (psi) •Orp element = p of diagram (bar) •Oil density (lb/gal) Oil viscosity (SSU)•7.29 (lb/gal) 120 (SSU)Oil density (kg/dm 3 ) Oil viscosity (cSt)•0,856 (kg/dm 3 ) 30 (cSt)Now you sum the values of the pressure drop of the housing to the value of the pressure drop of the filtering element, alwaysmaking sure the total p does not exceed the pressure limit of 11 psi (0,75 bar).[psi][bar]03/01.20102 002 ICAT011-002

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>PRESSURE DROP CURVES THROUGH THE BY-PASS VALVESThe pressure drop values are directly proportional withthe specific weight of the fluid and do not affect the establishmentof the total pressure drop of the complete filter.The curves are obtained in the following conditions:Mineral oil type SAE 10Kinematic viscosity 120 SSU (30 cSt)Density 7.29 lb/gal (0,856 kg/dm 3 ).25(362.5)<strong>HF</strong> <strong>760</strong>-2025(362.5)<strong>HF</strong> <strong>760</strong>-30 / <strong>HF</strong> <strong>761</strong>-3020(290.0)20(290.0)15(217.5)15(217.5)10(145.0)10(145.0)5(72.5)5(72.5)00 20(5.3)40(10.6)60(15.9)80(21.1)100(26.4)00 20(5.3)40(10.6)60(15.9)80(21.1)100(26.4)120(31.7)140(37.0)<strong>HF</strong> <strong>760</strong>-40 / <strong>HF</strong> <strong>761</strong>-4025(362.5)20(290.0)15(217.5)03/01.201010(145.0)5(73.5)00 100(26.4)200(52.8)300(79.3)400(105.7)ICAT011-002 002 3

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>PRESSURE DROP CURVES THROUGH THE HOUSINGThe curves are obtained in the following conditions:Mineral oil type SAE 10Kinematic viscosity 120 SSU (30 cSt)Density 7.29 lb/gal (0,856 kg/dm 3 ).(1) G 1/2(2) G 3/4(3)G1(4) G 1 1/4(5) G 1 1/2<strong>HF</strong> <strong>760</strong>-20 <strong>HF</strong> <strong>760</strong>-30 / <strong>HF</strong> <strong>761</strong>-300,8(11.60)(1)(2)0,8(11.60)0,6(8.70)0,6(8.70)(2)0,4(5.80)0,4(5.80)(3)0,2(2.90)0,2(2.90)00 20(5.3)40(10.6)60(15.9)80(21.1)100(26.4)120(31.7)140(37.0)160(42.3)00 20(5.3)40 60 80 100 120 140 160 180 200(10.6) (15.9) (21.1) (26.4) (31.7) (37.0) (42.3) (47.6) (52.8)<strong>HF</strong> <strong>760</strong>-40 / <strong>HF</strong> <strong>761</strong>-400,8(11.60)(3)(4)(5)0,6(8.70)0,4(5.80)0,2(2.90)03/01.201000 120(31.7)240(63.4)360(95.1)480(126.8)600(158.5)4 002 ICAT011-002

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>PRESSURE DROP CURVES THROUGH THE ELEMENT K85-20The curves are obtained in the following conditions:Mineral oil type SAE 10Kinematic viscosity 120 SSU (30 cSt)Density 7.29 lb/gal (0,856 kg/dm 3 ).(1) HE K85-20.080(2) HE K85-20.106(3) HE K85-20.203FG003FG0063,0(43.50)(1)(2)(3)3,0(43.50)(1)(2)2,5(36.25)2,5(36.25)2,0(29.00)2,0(29.00)(3)1,5(21.75)1,5(21.75)1,0(14.50)1,0(14.50)0,5(7.25)0,5(7.25)00 20(5.3)40(10.6)60(15.9)80(21.1)100(26.4)120(31.7)140(37.0)160(42.3)00 20(5.3)40(10.6)60(15.9)80(21.1)100(26.4)120(31.7)140(37.0)160(42.3)FG010FG0253,0(43.50)(1)(2)3,0(43.50)(1)(2)2,5(36.25)2,5(36.25)2,0(29.00)2,0(29.00)03/01.20101,5(21.75)1,0(14.50)(3)1,5(21.75)1,0(14.50)(3)0,5(7.25)0,5(7.25)00 20(5.3)40(10.6)60(15.9)80(21.1)100(26.4)120(31.7)140(37.0)160(42.3)00 20(5.3)40(10.6)60(15.9)80(21.1)100(26.4)120(31.7)140(37.0)160(42.3)ICAT011-002 002 5

(3)(3)<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>PRESSURE DROP CURVES THROUGH THE ELEMENT HE K85-30 / HE K86-30The curves are obtained in the following conditions:Mineral oil type SAE 10Kinematic viscosity 120 SSU (30 cSt)Density 7.29 lb/gal (0,856 kg/dm 3 ).(1) HE K86-30.087(2) HE K85-30.115 / HE K86-30.116(3) HE K85-30.223 / HE K86-30.209FG003FG0063,0(43.50)(1)(2)3,0(43.50)(1)(2)2,5(36.25)2,5(36.25)2,0(29.00)2,0(29.00)1,5(21.75)1,5(21.75)1,0(14.50)1,0(14.50)0,5(7.25)0,5(7.25)00 20 40 60 80 100 120 140 160 180 200(5.3) (10.6) (15.9) (21.1) (26.4) (31.7) (37.0) (42.3) (47.6) (52.8)00 20 40 60 80 100 120 140 160 180 200(5.3) (10.6) (15.9) (21.1) (26.4) (31.7) (37.0) (42.3) (47.6) (52.8)FG010FG0253,0(43.50)(1)(2)3,0(43.50)(1)2,5(36.25)2,5(36.25)2,0(29.00)2,0(29.00)(2)1,5(21.75)1,0(14.50)(3)1,5(21.75)1,0(14.50)03/01.20100,5(7.25)0,5(7.25)(3)00 20 40 60 80 100 120 140 160 180 200(5.3) (10.6) (15.9) (21.1) (26.4) (31.7) (37.0) (42.3) (47.6) (52.8)00 20 40 60 80 100 120 140 160 180 200(5.3) (10.6) (15.9) (21.1) (26.4) (31.7) (37.0) (42.3) (47.6) (52.8)6 002 ICAT011-002

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>PRESSURE DROP CURVES THROUGH THE ELEMENT HE K85-40 / HE K86-40The curves are obtained in the following conditions:Mineral oil type SAE 10Kinematic viscosity 120 SSU (30 cSt)Density 7.29 lb/gal (0,856 kg/dm 3 ).FG003(1) HE K85-40.102 / HE K86-40.115(2) HE K85-40.132(3) HE K86-40.210(4) HE K85-40.227(5) HE K86-40.329(6) HE K85-40.372 / HE K86-40.428(7) HE K85-40.517FG0063,0(43.50)(1)(2)(3)(4)3,0(43.50)(1)(2)(3)2,5(36.25)2,5(36.25)(4)2,0(29.00)(5)2,0(29.00)1,5(21.75)1,5(21.75)(5)1,0(14.50)(6)1,0(14.50)(6)0,5(7.25)(7)0,5(7.25)(7)00 120(31.7)240(63.4)360(95.1)480(126.8)600(158.5)00 120(31.7)240(63.4)360(95.1)480(126.8)600(158.5)FG010FG0253,0(43.50)(1)(2)3,0(43.50)(1)(2)2,5(36.25)(3)2,5(36.25)2,0(29.00)2,0(29.00)03/01.20101,5(21.75)1,0(14.50)(4)(5)1,5(21.75)1,0(14.50)(3)(4)0,5(7.25)00 120(31.7)240(63.4)360(95.1)480(126.8)(6)(7)600(158.5)0,5(7.25)00 120(31.7)240(63.4)360(95.1)480(126.8)(5)(6)(7)600(158.5)ICAT011-002 002 7

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>FLOWFilter type<strong>HF</strong> <strong>760</strong>-20.080<strong>HF</strong> <strong>760</strong>-20.106<strong>HF</strong> <strong>760</strong>-20.203<strong>HF</strong> <strong>761</strong>-30.087<strong>HF</strong> <strong>760</strong>-30.115<strong>HF</strong> <strong>761</strong>-30.116<strong>HF</strong> <strong>760</strong>-30.223<strong>HF</strong> <strong>761</strong>-30.209<strong>HF</strong> <strong>760</strong>-40.102<strong>HF</strong> <strong>761</strong>-40.115<strong>HF</strong> <strong>760</strong>-40.132<strong>HF</strong> <strong>761</strong>-40.210<strong>HF</strong> <strong>760</strong>-40.227<strong>HF</strong> <strong>761</strong>-40.329<strong>HF</strong> <strong>760</strong>-40.372<strong>HF</strong> <strong>761</strong>-40.428<strong>HF</strong> <strong>760</strong>-40.517GAS(BSPP)NPTPorts IN/OUTSAE J514bG 1/2 1/2 NPT 3/4-16 UNF-2BG 3/4 3/4 NPT 1 1/16-12 UN-2BG 1/2 1/2 NPT 3/4-16 UNF-2BG 3/4 3/4 NPT 1 1/16-12 UN-2BG 1/2 1/2 NPT 3/4-16 UNF-2BG 3/4 3/4 NPT 1 1/16-12 UN-2BSAE J518bNom. sizeG 3/4 3/4 NPT 1 1/16-12 UN-2B 3/4G 1 1 NPT 1 5/16-12 UN-2B 1G 3/4 3/4 NPT 1 1/16-12 UN-2B 3/4G 1 1 NPT 1 5/16-12 UN-2B 1G 3/4 3/4 NPT 1 1/16-12 UN-2B 3/4G 1 1 NPT 1 5/16-12 UN-2B 1G 1 1 NPT 1 5/16-12 UN-2BG11/4 11/4NPT 15/8-12UN-2B 11/4G11/2 11/2NPT 17/8-12UN-2B 11/2G 1 1 NPT 1 5/16-12 UN-2BG11/4 11/4NPT 15/8-12UN-2B 11/4G11/2 11/2NPT 17/8-12UN-2B 11/2G 1 1 NPT 1 5/16-12 UN-2BG11/4 11/4NPT 15/8-12UN-2B 11/4G11/2 11/2NPT 17/8-12UN-2B 11/2G 1 1 NPT 1 5/16-12 UN-2BG11/4 11/4NPT 15/8-12UN-2B 11/4G11/2 11/2NPT 17/8-12UN-2B 11/2G 1 1 NPT 1 5/16-12 UN-2BG11/4 11/4NPT 15/8-12UN-2B 11/4G11/2 11/2NPT 17/8-12UN-2B 11/2G 1 1 NPT 1 5/16-12 UN-2BG11/4 11/4NPT 15/8-12UN-2B 11/4G11/2 11/2NPT 17/8-12UN-2B 11/2G 1 1 NPT 1 5/16-12 UN-2BG11/4 11/4NPT 15/8-12UN-2B 11/4G11/2 11/2NPT 17/8-12UN-2B 11/2Degree of filtrationFG003 FG006 FG010 FG0256.6(25)6.6(25)9.2(35)9.2(35)15.9(60)17.2(65)11.9(45)11.9(45)15.9(60)15.9(60)27.7(105)29.1(110)29.1(110)30.4(115)31.7(120)37.0(140)38.3(145)39.6(150)47.6(180)51.5(195)52.8(200)55.5(210)62.1(235)63.4(240)63.4(240)71.3(270)74.0(280)71.3(270)83.2(315)87.2(330)77.9(295)95.1(360)101.7(385)Flowp= 11 psi (0.75 bar)US gpm(l/min)7.9 9.2(30) (35)7.9 9.2(30) (35)10.6 13.2(40) (50)10.6 13.2(40) (50)17.2 19.8(65) (75)18.5 21.1(70) (80)13.2 15.9(50) (60)13.2 15.9(50) (60)17.2 21.1(65) (80)18.5 22.5(70) (85)31.7 35.7(120) (135)33.0 38.3(125) (145)33.0 39.6(125) (150)34.3 42.3(130) (160)35.7 43.6(135) (165)42.3 48.9(160) (185)43.6 52.8(165) (200)44.9 54.2(170) (205)52.8 59.4(200) (225)56.8 66.0(215) (250)58.1 68.7(220) (260)60.8 67.4(230) (255)67.4 76.6(255) (290)70.0 80.6(265) (305)67.4 72.6(255) (275)76.6 85.9(290) (325)80.6 89.8(305) (340)74.0 77.9(280) (295)88.5 95.1(335) (360)93.8 101.7(355) (385)79.3 81.9(300) (310)99.1 103.0(375) (390)105.7 112.3(400) (425)11.9(45)11.9(45)15.9(60)15.9(60)22.5(85)25.1(95)19.8(75)21.1(80)26.4(100)27.7(105)40.9(155)44.9(170)48.9(185)51.5(195)52.8(200)56.8(215)63.4(240)64.7(245)67.4(255)77.9(295)80.6(305)74.0(280)87.2(330)92.5(350)77.9(295)95.1(360)100.4(380)81.9(310)101.7(385)111.0(420)84.5(320)108.3(410)118.9(450)03/01.20108 002 ICAT011-002

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong><strong>HF</strong><strong>760</strong>-20 DIMENSIONSIndicator portB60B6NBy-passBy-pass andno return valveB00 B0N B0R03/01.2010Filter type<strong>HF</strong> <strong>760</strong>-20.080<strong>HF</strong> <strong>760</strong>-20.106<strong>HF</strong> <strong>760</strong>-20.203Weight A B (Ports) (1) C (2)kg(lbs)5,3(11.69)5,7(12.57)7,2(15.87)Without by-passmm(in)Availability208(8.1889) GAS (BSPP)234(9.2126)NPT331SAE J514b(13.0315)Without by-passwith no return valveWithout by-passwith reverse flowM8(1) Ports dimensions: see pages 15 18(2) The respective threads 5/16-18 UNC-2B are available.On request, mounting holes can have special threads and different locations between center lines.ICAT011-003 002 9

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong><strong>HF</strong> <strong>760</strong>-30 - <strong>HF</strong> <strong>761</strong>-30 DIMENSIONSIndicator portB60B6NBy-passBy-pass andno return valveB00 B0N B0RFilter type<strong>HF</strong> <strong>761</strong>-30.087<strong>HF</strong> <strong>760</strong>-30.115 <strong>HF</strong> <strong>761</strong>-30.116<strong>HF</strong> <strong>760</strong>-30.223 <strong>HF</strong> <strong>761</strong>-30.209Weight A B (ports) (1) C (2)kg(lbs)7,6(16.75)8,2(18.08)10(22.05)Without by-passmm(in)215(8.4646)250(9.8425)358(14.0945)Without by-passwith no return valveAvailabilityGAS (BSPP)NPTSAE J514bSAE J518Without by-passwith reverse flowM10(2)03/01.2010(1) Ports dimensions: see pages 15 18(2) The respective threads 3/8-16 UNC-2B are available.On request, mounting holes can have special threads and different locations between center lines.10 002 ICAT011-003

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong><strong>HF</strong> <strong>760</strong>-40 - <strong>HF</strong> <strong>761</strong>-40 DIMENSIONSIndicator portB60B6NBy-passBy-pass andno return valveB00 B0N B0RWithout by-passWithout by-passwith no return valveWithout by-passwith reverse flow03/01.2010Filter type<strong>HF</strong> <strong>760</strong>-40.102 <strong>HF</strong> <strong>761</strong>-40.115<strong>HF</strong> <strong>760</strong>-40.132<strong>HF</strong> <strong>760</strong>-40.227 <strong>HF</strong> <strong>761</strong>-40.210<strong>HF</strong> <strong>760</strong>-40.372 <strong>HF</strong> <strong>761</strong>-40.329<strong>HF</strong> <strong>760</strong>-40.517 <strong>HF</strong> <strong>761</strong>-40.428(1) Ports dimensions: see pages 15 18Weight A B ((ports) (1) C (2)kg(lbs)14,3(31.53)15,2(33.51)18(39.68)22(48.50)28,5(62.83)mm(in)274(10.7874)304(11.9685)399(15.7087)544(21.4173)689(27.1260)AvailabilityGAS (BSPP)NPTSAE J514bSAE J518M12(2)(2) The respective threads 1/2-13 UNC-2B are available.On request, mounting holes can have special threads and different locations between center lines.ICAT011-003 002 11

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>ELEMENTS DIMENSIONS FOR <strong>HF</strong> <strong>760</strong>Filtering elements with p - collapse pressure of 3046 psi (210 bar) are also available (please consult our technicaldepartment).Technical data for (MS) version elements are available on request.Element typeHE K85-20.080HE K85-20.106HE K85-20.203HE K85-30.115HE K85-30.223HE K85-40.102HE K85-40.132HE K85-40.227HE K85-40.372HE K85-40.517ØA ØB Cmm(in)25,5(1.0039)27,5(1.0827)40,5(1.5945)mm(in)46,5(1.8307)54,5(2.1457)78(3.0709)mm(in)87(3.4252)113(4.4488)210(8.2677)122(4.8031)230(9.0551)110(4.3307)140(5.5118)235(9.2520)380(14.9606)525(20.6693)Filteringsurface (AS)cm 2(in 2 )415(64.3251)560(86.8002)1103(170.9653)908(140.7403)1808(280.2405)1757(272.3355)2306(357.4307)4045(626.9762)6700(1038.5020)9350(1449.2528)Dirt holding capacity (ISO MTD)p = 72.5 psi (5 bar)FG003 FG006 FG010 FG025grgrgrgr(lbs) (lbs) (lbs) (lbs)2,3 3,0 3,3 4,8(0.0051) (0.0066) (0.0073) (0.0106)3,1 4,0 4,5 6,5(0.0069) (0.0089) (0.0099) (0.0143)6,2 7,9 8,8 12,8(0.0136) (0.0175) (0.0195) (0.0282)5,1 6,5 7,3 10,5(0.0112) (0.0144) (0.0160) (0.0232)10,1 13,0 14,5 21,0(0.0223) (0.0287) (0.0319) (0.0462)9,8 12,7 14,1 20,4(0.0217) (0.0279) (0.0310) (0.0449)12,9 16,6 18,4 26,7(0.0285) (0.0366) (0.0407) (0.0590)22,7 29,1 32,4 46,9(0.0499) (0.0642) (0.0713) (0.1034)37,5 48,2 53,6 77,7(0.0827) (0.1064) (0.1182) (0.1713)52,4 67,3 74,8 108,5(0.1154) (0.1484) (0.1649) (0.2391)03/01.201012 002 ICAT011-003

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>ELEMENTS DIMENSIONS FOR <strong>HF</strong> <strong>761</strong>Filtering elements with p - collapse pressure of 3046 psi (210 bar) are also available (please consult our technicaldepartment).Technical data for (MS) version elements are available on request.03/01.2010Element typeHE K86-30.087HE K86-30.116HE K86-30.209HE K86-40.115HE K86-40.210HE K86-40.329HE K86-40.428ØA ØB Cmm(in)24.5(0.9645)43,2(1.7008)mm(in)53(2.0866)78(3.0709)mm(in)87(3.4252)116(4.5669)209(8.2283)115(4.5276)210(8.2677)329(12.9528)428(16.8504)Filteringsurface (AS)cm 2(in 2 )667(103.3852)923(143.0653)1719(266.4455)1685(261.1755)3167(490.8860)5023(778.5665)6568(1018.0420)Dirt holding capacity (ISO MTD)p = 72.5 psi (5 bar)FG003 FG006 FG010 FG025grgrgrgr(lbs) (lbs) (lbs) (lbs)3,7 4,8 5,3 7,7(0.0082) (0.0106) (0.0118) (0.0171)5,2 6,6 7,4 10,7(0.0114) (0.0147) (0.0163) (0.0236)9,6 12,4 13,8 19,9(0.0212) (0.0273) (0.0303) (0.0440)9,4 12,1 13,5 19,5(0.0208) (0.0267) (0.0297) (0.0431)17,7 22,8 25,3 36,7(0.0391) (0.0503) (0.0559) (0.0810)28,1 36,2 40,2 58,3(0.0620) (0.0797) (0.0886) (0.1285)36,8 47,3 52,5 76,2(0.0811) (0.1043) (0.1158) (0.1680)ICAT011-003 002 13

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>INDICATORSVISUAL DIFFERENTIALCode: HVISUAL ELECTRICAL DIFFERENTIAL WITHTHERMOSTATCode: W231N.C.N.O.Differential pressure setting116 psi (8 bar) without by-pass72.5 psi (5 bar) with by-passT=30°CVISUAL ELECTRICAL DIFFERENTIALCode: U116 psi (8 bar) without by-passDifferential pressure setting72.5 psi (5 bar) with by-pass250 VACMax. working voltage30 VCC5 A (resistivity)Max. working current5 A (inductive)Protection class IP 65Min. function temperature 86 °F (30 °C)231N.C.N.O.116 psi (8 bar) without by-passDifferential pressure setting72.5 psi (5 bar) with by-pass250 VACMax. working voltage30 VCC5 A (resistivity)Max. working current5 A (inductive)Protection class IP 6503/01.201014 002 ICAT011-003

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>PORTS IN/OUTPORTS TYPENominal Gas NPT SAE Split SSM Split SSSFilter type sizeBSPP ODT (3000 PSI) (6000 PSI) (3000 PSI) (6000 PSI)<strong>HF</strong> <strong>760</strong>-20<strong>HF</strong> <strong>760</strong>-30<strong>HF</strong> <strong>761</strong>-30<strong>HF</strong> <strong>760</strong>-40<strong>HF</strong> <strong>761</strong>-401/2" GD ND OB 3/4" GE NE OD 3/4" GE NE OD MB QB SB VB1" GF NF OF MC QC SC VC1" GF NF OF MC QC SC VC1" 1/4 GG NG OG MD QD SD VD1" 1/2 GH NH OH ME QE SE VEGAS STRAIGHT THREAD PORTSBSPPBritish standard pipe parallel (55°) conforms to UNI - ISO 22803/01.2010CODENominalsizeGD 1/2" G 1/2GE 3/4" G 3/4GF 1" G 1GG 1" 1/4 G 1 1/4GH 1" 1/2 G 1 1/2A Bmm(in)19,0(0.7480)24,5(0.9646)30,5(1.2008)39,5(1.5551)45,5(1.7913)Cmm(in)16,0(0.6299)18,0(0.7087)20,0(0.7874)22,0(0.8661)24,0(0.9449)Nm(lbf in)50 +2,5(443 465)90 +5(797 841)130 +10(1151 1239)170 +10(1505 1593)210 +15(1859 1991)ICAT011-003 002 15

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>PORTS IN/OUTNPT STRAIGHT THREAD PORTSNPTNPT thread (60°) conforms to ANSI - ASME B1-20CODENominalsizeND 1/2" 1/2 NPTNE 3/4" 3/4 NPTNF 1" 1 NPTNG 1" 1/4 1 1/4 NPTNH 1" 1/2 1 1/2 NPTA Bmm(in)18,0(0.7087)23,5(0.9252)29,5(1.1614)38,5(1.5157)44,0(1.7323)Cmm(in)13,5(0.5315)14,0(0.5512)17,5(0.6890)18,0(0.7087)18,5(0.7283)Nm(lbf in)45 +2,5(398 420)75 +5(664 708)120 +10(1062 1151)250 +20(2213 2390)350 +20(3098 3275)SAE STRAIGHT THREAD PORTS J514ODTAmerican straight thread UNC-UNF 60° conforms to ANSI B 1.1CODENominalsizeOB 1/2" 3/4" - 16 UNF - 2BOD 3/4" 1 1/16" - 12 UN - 2BOF 1" 1 5/16" - 12 UN - 2BOG 1" 1/4 1 5/8" - 12 UN - 2BOH 1" 1/2 1 7/8" - 12 UN - 2BA Bmm(in)17,3(0.6811)24,7(0.9724)31,0(1.2205)39,0(1.5354)45,3(1.7835)Cmm(in)15,0(0.5906)20,0(0.7874)20,0(0.7874)20,0(0.7874)20,0(0.7874)Nm(lbf in)45 +2,5(398 420)120 +10(1062 1151)170 +10(1505 1593)200 +10(1770 1859)270 +15(2390 2522)03/01.201016 002 ICAT011-003

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>PORTS IN/OUTSAE FLANGED PORTS J518 - Standard pressure <strong>series</strong> 3000 PSISSMMetric thread ISO 60° conforms to ISO/R 262CODENominalsizeMB 3/4MC 1MD 11/4ME 11/2 A B C Dmm(in)19,1(0.7520)25,4(1.0000)31,8(1.2520)38,1(1.5000)mm(in)47,6(1.8740)52,4(2.0630)58,7(2.3110)69,8(2.7480)mm(in)22,2(0.8740)26,2(1.0315)30,2(1.1890)35,7(1.4055)ThreadDepth mm (in)M1015,0 (0.5906)M1015,0 (0.5906)M1015,0 (0.5906)M1218,0 (0.7087)Nm(lbf in)30 +2,5(266 288)40 +2,5(354 376)50 +2,5(443 465)65 +5(575 620)SAE FLANGED PORTS J518 - Standard pressure <strong>series</strong> 6000 PSISSMMetric thread ISO 60° conforms to ISO/R 26203/01.2010CODENominalsizeQB 3/4QC 1QD 11/4QE 11/2 A B C Dmm(in)19,1(0.7520)25,4(1.0000)31,8(1.2520)38,1(1.5000)mm(in)50,8(2.0000)57,2(2.2520)66,7(2.6260)79,4(3.1260)mm(in)23,8(0.9370)27,8(1.0945)31,7(1.2480)36,5(1.4370)ThreadDepth mm (in)M1015,0 (0.5906)M1216,0 (0.6299)M1418,0 (0.7087)M1622,0 (0.8661)Nm(lbf in)40 +2,5(354 376)60 +5(531 575)90 +5(797 841)160 +10(1416 1505)ICAT011-003 002 17

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>PORTS IN/OUTSAE FLANGED PORTS J518 - Standard pressure <strong>series</strong> 3000 PSISSSAmerican straight threads UNC-UNF 60° conforms to ANSI B 1.1CODENominalsizeSB 3/4SC 1SD 11/4SE 11/2 A B C Dmm(in)19,1(0.7520)25,4(1.0000)31,8(1.2520)38,1(1.5000)mm(in)47,6(1.8740)52,4(2.0630)58,7(2.3110)69,8(2.7480)mm(in)22,2(0.8740)26,2(1.0315)30,2(1.1890)35,7(1.4055)ThreadDepth mm (in)3/8-16 UNC-2B15,0 (0.5906)3/8-16 UNC-2B15,0 (0.5906)7/16-14 UNC-2B15,0 (0.5906)1/2-13 UNC-2B18,0 (0.7087)Nm(lbf in)30 +2,5(266 288)40 +2,5(354 376)50 +2,5(443 465)65 +5(575 620)SAE FLANGED PORTS J518 - Standard pressure <strong>series</strong> 6000 PSISSSAmerican straight threads UNC-UNF 60° conforms to ANSI B 1.1CODENominalsizeVB 3/4VC 1VD 11/4VE 11/2 A B C Dmm(in)19,1(0.7520)25,4(1.0000)31,8(1.2520)38,1(1.5000)mm(in)50,8(2.0000)57,2(2.2520)66,7(2.6260)79,4(3.1260)mm(in)23,8(0.9370)27,8(1.0945)31,7(1.2480)36,5(1.4370)ThreadDepth mm (in)3/8-16 UNC-2B15,0 (0.5906)7/16-14 UNC-2B16,0 (0.6299)1/2-13 UNC-2B18,0 (0.7087)5/8-11 UNC-2B22,0 (0.8661)Nm(lbf in)40 +2,5(354 376)60 +5(531 575)90 +5(797 841)160 +10(1416 1505)03/01.201018 002 ICAT011-003

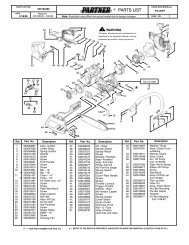

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>ASSEMBLY AND REPLACING ELEMENT INSTRUCTIONSASSEMBLYOnce you have checked the integrity of the filter inside its package,proceed as follows:ABCDEFSecure the filter to the attachment device via the threadedholes in the head (pos.6).Take the protection caps off the oil inlet and outlet.Connect the circuit pipes to the filter, checking the flow direction,which is pointed out by the arrow on the head(pos.6).If the clogging indicator (pos.9 - 10 - 11) is immediately mountedin the filter, take the protection cap off and screw theindicator in the dedicated seat and tighten to a tighteningtorque of 266 lbf in (30 Nm). If the indicator is electric, completethe required connections.Start the circuit for a few minutes.Make sure there are no leaks.REPLACING ELEMENTOnce the working hours limit indicated in the maintenance instructionsof the system is reached, or when the clogging indicatorspoint out the limit pressure drop created inside the filter, thecartridge must be replaced, remembering that this procedure involvesthe drainage of hydraulic oil and therefore you need toprepare suitable containers to collect the oil.Proceed as follows:ABCDEFGHIStop the system in “Machine stopped” status.Secure any shut-off valves on the hydraulic circuit.Unscrew the filter container (pos.1).Remove the clogged filtering cartridge (pos.5), makingsure no residual particles have settled on the bowl bottom(pos.1).Make sure the O-ring (pos.2 - 4) and the anti-extrusion ring(pos.3) are not damaged, otherwise replace them and consequentlyposition the new ones correctly.Insert the new filtering cartridge, lubricating the sealingO-ring beforehand.Screw the container tight (pos.1) making sure the threadingis screwed correctly. Tighten to a tightening torque asindicated on pages 9,10,11.Start the machine for a few minutes.Make sure there are no leaks.03/01.2010Pos. Description1 Filter bowl2 External O-Ring3 Anti-extrusion ring4 Sealing O-Ring5 Filtering element6 Filter head7 By-pass valve8 Sealing cap9 Visual differential indicator10 Visual electrical differential indicator11 Visual electrical differential indicatorwith thermostatWhen ordering spare parts, always specify the referencenumber, the filter code and quantity.Example: Spare part pos. 4 - HHP02050 - Qty 2ICAT011-004 002 19

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>HOW TO ORDER A COMPLETE FILTER1 2 3 4 5 6 7 8 9<strong>HF</strong><strong>760</strong><strong>HF</strong><strong>761</strong>20.080 - AS - FG010 - LC - B60 - GD - B - DD - G1 Filter type CODESee table frompag. 9 to pag. 11<strong>HF</strong>76.2 Filtering surface CODEStandardMultilayerASMS3 Degree of filtration CODE3 m] Micro-fibre glass FG0036 [m] Micro-fibre glass FG00610 m] Micro-fibre glass FG01025 [m] Micro-fibre glass FG0254 p collapse pressure CODE290 [psi] (20 [bar]) LC3046 [psi] (210 [bar]) HC5 Valves CODEBy-pass Setting 87 [psi] (6 [bar])By-pass Setting 87 [psi] (6 [bar]) andno return valveWithoutWithout by-pass, with no return valveWithout by-pass, with reverse flowB60B6NB00B0NB0R6 Ports IN/OUT CODEThreads GAS (BSPP)G1/2 GDG3/4 GEG1GFG11/4 GGG11/2 GHThreads NPT1/2 ND3/4 NE1 NF11/4 NG11/2 NHThreads SAE ODT1/2 OB3/4 OD1 OF11/4 OG11/2 OH6 Ports IN/OUT CODEFlanged SAE (SSM) - 3000 PSI3/4" MB1" MC1" 1/4 MD1" 1/2 MEFlanged SAE (SSM) - 6000 PSI3/4" QB1" QC1" 1/4 QD1" 1/2 QEFlanged SAE (SSS) - 3000 PSI3/4" SB1" SC1" 1/4 SD1" 1/2 SEFlanged SAE (SSS) - 6000 PSI3/4" VB1" VC1" 1/4 VD1" 1/2 VE7 Seals CODEBunaViton8 Indicator ports CODEArrangedArranged with plugStandardOn requestBVXADD9 Indicators CODEWithoutVisual differential indicatorVisual electrical differential indicatorVisual electrical differential indicator withthermostatGHUW03/01.201020 002 ICAT011-005

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>HOW TO ORDER A REPLACEMENT ELEMENTHE K85HE K861 2 3 4 520.080 - AS - FG010 - LC - B1 Element type CODESee table pag. 12HE K85..See table pag. 13HE K86..4 p collapse pressure CODE290 [psi] (20 [bar]) LC3046 [psi] (210 [bar]) HC2 Filtering surface CODEStandardASMultilayerMS5 Seals CODEBunaBVitonV3 Degree of filtration CODE3 m] Micro-fibre glass FG0036 [m] Micro-fibre glass FG00610 m] Micro-fibre glass FG01025 [m] Micro-fibre glass FG025StandardOn request03/01.2010ICAT011-005 002 21

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>NOTES:03/01.201022 002 ICAT011-005

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>NOTES:03/01.2010ICAT011-005 002 23

<strong>HF</strong> <strong>760</strong> - <strong>HF</strong> <strong>761</strong>NOTES:03/01.201024 002 ICAT011-005

Building &constructionAgricultureTruckMarketMaterialHandlingIndustrialFull range of filtersfor all hydraulic circuits

Suction filters<strong>HF</strong> 410<strong>HF</strong> 412Tank mountedreturn line filters<strong>HF</strong> 502<strong>HF</strong> 547<strong>HF</strong> 554<strong>HF</strong> 570<strong>HF</strong> 575In line filters Spin-On<strong>HF</strong> 620<strong>HF</strong> 625<strong>HF</strong> 650In line medium and highpressure filters<strong>HF</strong> 690<strong>HF</strong> 705<strong>HF</strong> 725<strong>HF</strong> 735<strong>HF</strong> 745<strong>HF</strong> <strong>760</strong><strong>HF</strong> <strong>761</strong>AccessoriesFiller breathersAir filtersLevel and temperature gaugesPressure gaugesPressure/vacuum gaugesClogging indicators<strong>HF</strong> <strong>760</strong> 03 T A Edition: 03/01.2010 Replaces: <strong>HF</strong> <strong>760</strong> 02 TAIKRON S.r.l.Via Prampolini, 2 - 43044 Lemignano di Collecchio - Parma - ItalyTel.: + 39 0521 304911 - Fax: + 39 0521 304900IP VideoconferencingE-mail: info@ikron.itwww.ikron.it