Ministry of Commerce And Supplies - Enhanced Integrated ...

Ministry of Commerce And Supplies - Enhanced Integrated ...

Ministry of Commerce And Supplies - Enhanced Integrated ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

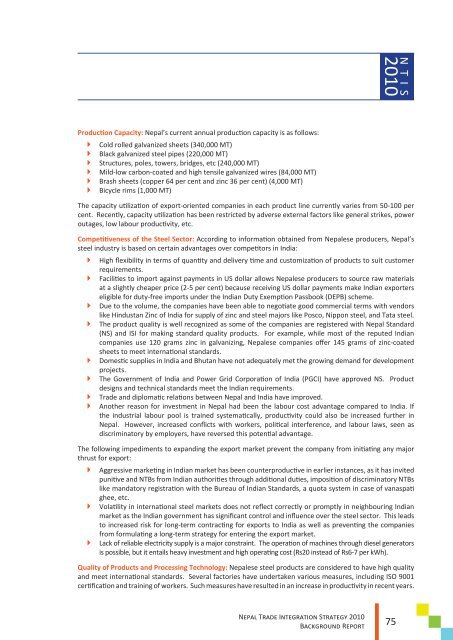

N T I S2010Production Capacity: Nepal’s current annual production capacity is as follows: Cold rolled galvanized sheets (340,000 MT) Black galvanized steel pipes (220,000 MT) Structures, poles, towers, bridges, etc (240,000 MT) Mild-low carbon-coated and high tensile galvanized wires (84,000 MT) Brash sheets (copper 64 per cent and zinc 36 per cent) (4,000 MT) Bicycle rims (1,000 MT)The capacity utilization <strong>of</strong> export-oriented companies in each product line currently varies from 50-100 percent. Recently, capacity utilization has been restricted by adverse external factors like general strikes, poweroutages, low labour productivity, etc.Competitiveness <strong>of</strong> the Steel Sector: According to information obtained from Nepalese producers, Nepal’ssteel industry is based on certain advantages over competitors in India: High flexibility in terms <strong>of</strong> quantity and delivery time and customization <strong>of</strong> products to suit customerrequirements. Facilities to import against payments in US dollar allows Nepalese producers to source raw materialsat a slightly cheaper price (2-5 per cent) because receiving US dollar payments make Indian exporterseligible for duty-free imports under the Indian Duty Exemption Passbook (DEPB) scheme. Due to the volume, the companies have been able to negotiate good commercial terms with vendorslike Hindustan Zinc <strong>of</strong> India for supply <strong>of</strong> zinc and steel majors like Posco, Nippon steel, and Tata steel. The product quality is well recognized as some <strong>of</strong> the companies are registered with Nepal Standard(NS) and ISI for making standard quality products. For example, while most <strong>of</strong> the reputed Indiancompanies use 120 grams zinc in galvanizing, Nepalese companies <strong>of</strong>fer 145 grams <strong>of</strong> zinc-coatedsheets to meet international standards. Domestic supplies in India and Bhutan have not adequately met the growing demand for developmentprojects. The Government <strong>of</strong> India and Power Grid Corporation <strong>of</strong> India (PGCI) have approved NS. Productdesigns and technical standards meet the Indian requirements. Trade and diplomatic relations between Nepal and India have improved. Another reason for investment in Nepal had been the labour cost advantage compared to India. Ifthe industrial labour pool is trained systematically, productivity could also be increased further inNepal. However, increased conflicts with workers, political interference, and labour laws, seen asdiscriminatory by employers, have reversed this potential advantage.The following impediments to expanding the export market prevent the company from initiating any majorthrust for export: Aggressive marketing in Indian market has been counterproductive in earlier instances, as it has invitedpunitive and NTBs from Indian authorities through additional duties, imposition <strong>of</strong> discriminatory NTBslike mandatory registration with the Bureau <strong>of</strong> Indian Standards, a quota system in case <strong>of</strong> vanaspatighee, etc. Volatility in international steel markets does not reflect correctly or promptly in neighbouring Indianmarket as the Indian government has significant control and influence over the steel sector. This leadsto increased risk for long-term contracting for exports to India as well as preventing the companiesfrom formulating a long-term strategy for entering the export market. Lack <strong>of</strong> reliable electricity supply is a major constraint. The operation <strong>of</strong> machines through diesel generatorsis possible, but it entails heavy investment and high operating cost (Rs20 instead <strong>of</strong> Rs6-7 per kWh).Quality <strong>of</strong> Products and Processing Technology: Nepalese steel products are considered to have high qualityand meet international standards. Several factories have undertaken various measures, including ISO 9001certification and training <strong>of</strong> workers. Such measures have resulted in an increase in productivity in recent years.NEPAL TRADE INTEGRATION STRATEGY 2010BACKGROUND REPORT75