BASCO ENGINEERED SHELL & TUBE HEAT EXCHANGERS

BASCO ENGINEERED SHELL & TUBE HEAT EXCHANGERS

BASCO ENGINEERED SHELL & TUBE HEAT EXCHANGERS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

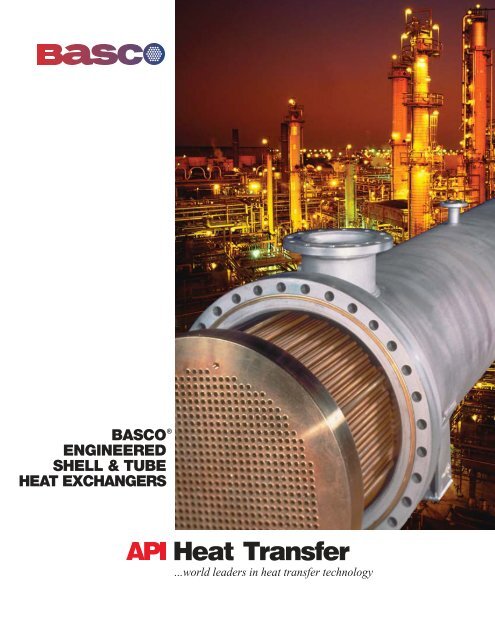

®<strong>BASCO</strong><strong>ENGINEERED</strong><strong>SHELL</strong> & <strong>TUBE</strong><strong>HEAT</strong> <strong>EXCHANGERS</strong>...world leaders in heat transfer technology

API Heat Transfer is your one source for custom engineeredshell & tube heat exchangers. With sizes ranging from 3” to 60” indiameter, and 12” to 40’ in length, our API Basco division is a fullservice manufacturer. Combining our human talent with ourstate-of-the-art manufacturing facility, our applications expertisewith our mechanical design know-how, and our drive to be thebest means our customers get what they pay for and more....a name synonymouswith high quality,cost effectiveshell & tube heatexchangers for over60 years.With a proud tradition ofservice to both OEM andEnd User customers, APIHeat Transfer’s Bascodivision has successfullymet industry’s mostchallenging heat transferapplications with robust,cost effective designs thatendure the test of time.Application EngineeringOur highly knowledgeable and experienced staff of applicationengineers use state-of-the-art software technology includingHYSIM, B-JAC and HTRI aswell as proprietary ratingsystems developed in-house.Combining API Basco’sengineering know-howwith sophisticated softwaretools ensures the bestsolution for each application.Heat loads, pressure droprestrictions, phase change,materials of construction,numerous international coderequirements, and customerspecifications are only someof the criteria our engineersassess on every project.After thorough review of allthe parameters, a complete professional proposal is generated forthe appropriate Basco/Whitlock Shell & Tube design.Mechanical EngineeringAPI Basco employs a full mechanical design team to handle allcontract work. Well versed in ASME, PED, and Chinese CMLCodes, as well as other regional pressure vessel regulations, ourdesigners ensure accuracy of drawings using the latest 2-D and3-D modeling software. Developing accurate bills of material,producing all necessary code calculations, and ensuring propercompletion of all required code paperwork and inspectionreports are all part of the daily activities for this team of designprofessionals.AdvancedPressureAutocadCosmosworksFEAANSYS FEASTXWin B-JAC HTRISolid Works

ManufacturingAPI Basco is located in Buffalo, NY within a few miles ofmajor highway, air and rail transportation. Our 80,000 sq. ft.manufacturing spaceis ISO 9001 certifiedand houses extensivefabrication resourcesincluding various CNCdrilling and machiningcenters, turning centers,and CNC punch presses.Multiple bridge and jibcranes, a multi-mediablast facility, burningtable, tube bending equipment, and a vast array of other supportequipment are employed to manufacture high quality, custom shell& tube heat exchangers.Inspection and TestEach stage of manufacturing is subjected torigorous inspection and test scrutiny – fromincoming material to completed assembly.A resident ASME authorized inspector oversees the completemanufacturing operation. Our in-house quality team ensures thatthe proper procedures are in-place, that our employees are welltrained, and that all the required inspections occur at the criticalstages of assembly. API Basco is well versed in all major pressurevessel codes, invests regularly in maintaining our various codecertifications and can offer a wide range of testing typical withinthe shell & tube industry.Product DevelopmentAPI Heat Transfer invests continuously to stay at the forefront oftechnology. Our product development staff and on-site test facilitydistinguishes API Heat Transfer from many of our peers. We believea strong focus on new products adds real value for our customers.By working closely with our customers during their new productdevelopment or product redesign cycle, API Heat Transfer canprovide a solution that optimizes thermal efficiency, pressure loss,size, weight and price to provide the best overall value.Markets ServedInclude:Air SeparationChemicalCompressorElectronicsFluid PowerIndustrialMarineNuclearPharmaceuticalPlasticsPower GenerationPulp & PaperRefrigeration

Engineering CapabilitiesStaff EngineerIn-HouseResources• Degreed staffengineers• Applications expertise• Mechanical designknow-how• Product developmentcapabilitiesMachine Tube Cutter OperatorCode Capabilities• ASME Section VIII• PED• TUV• Chinese CML• ASME Section I• TEMA C, B & R• Canadian Registration• Australian AS-1210• Polish UDT• Korean FactoryRegistrationAPI BascoBuffalo, NYSoftware• HTRI• B-JAC• FEA• 3-D Modeling• CFD - ComputationalFluid Dynamics• HYSIM ProcessModeling• In-house engineeringsoftware development3D ModelProductDevelopment• Performance testing• Fatigue testing• Thermal cycling• Prototype development• Thermal softwaredevelopmentFEA

Manufacturing CapabilitiesIntegrexManufacturing Skills• Torque control rolling• Seal and strengthwelding• Polishing, Sanitary 3A• TIG, MIG, GMAW, GTAW,SAW and SMAWwelding techniques• TEMA tight drillingtolerancesAutomated Drill PressQuality Assurance• X-ray• Magnetic particle• Heat treatment• ISO 9001• Resident ASMEcode inspector• Helium leak testing• Impact testing• PMIBasco Main FloorMajor Equipment• CNC drilling centers• CNC machining centers• CNC turning centers• CNC punch press• (2) 20-ton bridge cranes• Burning table• Tube bender• Multi-media blast facility• High capacity air dryer• Plate fin pressWelder Inside ShellSpecial Services• Oil flushing• Hydro testing• Pneumatic testing• Oxygen cleaning• Drying• Special paintOil Flush SystemOil Flush

Basco People & SolutionsAPI Basco ShopBundle Assembly AreaAPI Basco ShopType OP Assembly AreaTeam BascoEvaporator withDisengagement DrumGland CondenserPackageStacked TEMA AEW’swith Transfer ValuesTEMA BEU Exchanger forWastewater TreatmentTYPE ES Intercoolers ona Compressor PackageHigh Pressure TEMA BEPProviding Custom Thermal Solutions!

TEMA Shell & Tube NomenclatureAPI Basco is a proud member of TEMA - Tubular Exchanger Manufacturer’sAssociation. TEMA members set the standards by which virtually all customshell & tube heat exchangers are specified and built. Basco has been a membersince the 1950’s, and consequently we have a complete and comprehensiveunderstanding of the engineering, manufacturing and testing requirements to meetthis world-recognized standard. While other manufacturers may simply interpret theregulations, API Basco has the requisite member design and fabrication capabilitiesto lead the industry by helping to shape and define those standards for the longtermbenefit of all users.

TEMA Shell & Tube SpecificationsTEMA BETDescription: Pull through tube bundle q studded internalfloating head to tubesheet joint q multi-pass tubeside orsingle pass with Slip Tube design q channel or bonnettubeside connection q pressure range – 75 psi to 300 psi.Applications: Liquid heaters with low pressure steamon the shell side q single and double shell (gas in shell)compressor intercoolers on refinery applications q shellsidegas or oil coolersGASKETFLOATING <strong>TUBE</strong>SHEETGASKETGASKETSTATIONARY<strong>TUBE</strong>SHEETBONNETASSEMBLYFLOATING HEADCOVER<strong>SHELL</strong> COVER(Optional)FULL FACEMETAL GASKET WITHBOLT HOLES<strong>SHELL</strong> COVERGASKETAdvantages:1. Relatively large annulus around outer tube limit (O.T.L.)and shell I.D. permits entrance to the tube bundle withlittle resistance. The results are low entrance-exitvelocities and pressure loss.2. Easily removable tube bundle.3. Tube bundle expands freely with no special provisions forexpansion.TEMA AESDescription: Removable tube bundle, split clamp-ringfloating head q multi-pass tubeside or single pass withSlip Tube design q floating head bolted to split clamp-ring(requires shell cover larger than shell to accommodatefloating head) q pressure range – 75 psi to 600 psi.CONFINED GASKETSFLOATING<strong>TUBE</strong>SHEETFLOATING END DETAILFLOATING HEAD COVERLimitations:1. No gasket leak detection at floating head and tubesheet.2. Relatively low thermal efficiency due to large annulusbetween outer tube limit (O.T.L.) and shell I.D. (results inlow shell side heat transfer coefficient).3. Less tubes for any given shell size compared to other types.Applications: Often used in refineries q gas in shell units upto 600 psi q high pressure seal oil coolers up to 600 psiq API 660 oil coolersCLAMP RING (SPLIT)CHANNEL COVERCONFINED GASKETSTATIONARY <strong>TUBE</strong>SHEETCONFINEDGASKETFLOATING <strong>TUBE</strong>SHEETFLOATINGHEAD COVERASSEMBLY<strong>SHELL</strong> COVER ASSEMBLY<strong>SHELL</strong>FLANGECONFINEDGASKET<strong>SHELL</strong> PIPEFLOATING <strong>TUBE</strong>SHEETFLOATING END DETAIL<strong>SHELL</strong> COVER ASSEMBLYCHANNEL ASSEMBLYCONFINED GASKETFLOATING HEAD COVER ASSEMBLYAdvantages:1. Higher efficiency compared to Type BET units because ofsmaller annulus and more tubes per shell size.2. T ube bundle expands freely with no special provisionsfor expansion.Limitations:1. No gasket leak detection at floating head.2. Floating head and fixed end connection must be unboltedto remove tube bundle.

TEMA Shell & Tube SpecificationsTEMA BEPDescription: Removable tube bundle, outside packed floating tubesheet design.Tubesheet assembly may be of fabricated or forged steel to satisfy designpressure requirements q tubeside fluid is fully gasketed; shellside packingavailable in various materials q tubeside pressure range – to 3000 psi. Max 150psi shellside.Applications: Where lethal or explosivegasses are involved q where highpressure is applied only on the tubesideq where gasket malfunction must bedetectable.STATIONARY <strong>TUBE</strong>SHEETPACKING RINGSGASKETSPACKING GLANDGASKETPACKING GLANDPACKING RINGSFLOATING<strong>TUBE</strong>SHEETFLOATING <strong>TUBE</strong>SHEET ASSEMBLY<strong>SHELL</strong>ASSEMBLYGASKETSAdvantages:1. No packing exposed to tubeside fluid.2. Compared to BET and BES, outer tube limit (O.T.L.) relatively close to shell I.D.resulting in increased heat transfer efficiency.3. No possibility of shell and tubeside fluids intermixing through packing orgaskets.Limitations:1. One or two pass configurations only.2. Shellside pressure up to 150 psibecause of packing rings at floatingtubesheet head.3. Bundle expands into customer’spiping.TEMA BEMDescription: Fixed tubesheet, non-removable bundle q tubesheet welded directlyto shell q single or multi-pass designApplications: Chemical processesq high pressure air and nitrogenchillers (gas in tubes, freon shellside).<strong>TUBE</strong>SHEET<strong>TUBE</strong>SHEETGASKETGASKETBONNET ASSEMBLYBONNET FLANGE<strong>SHELL</strong> PIPEGASKET<strong>TUBE</strong>SHEETELLIPTICAL HEADGASKET JOINT DETAILAdvantages:1. Economical design.2. No possibility of contamination compared to designs with floating head gaskets(except in tube failures).3. High pressure shellside designs more easily accomplished than in floating head types.4. Extremely efficient shellside heat transfer due to small annulus between outertube limit (O.T.I.) and shell I.D.5. Shell design can be modified for large expansion area where partial vaporizationof liquid occurs.6. No gasketed joints on shellside.Limitations:1. No provisions for differential.expansion of tubes and shell withoutexpansion joint.2. Shell and tubesheet material mustbe weldable.3. Tube bundle is not removable forcleaning.

TEMA Shell & Tube SpecificationsTEMA BEUDescription: U-tube design with pull through, removable ornon-removable tube bundle q furnished in multi-pass designonly q pressure range – 75 psi to 3000 psi tubeside and75 psi to 1500 psi shellside.Applications: Chemical processes q tank suction heaterq liquid heaters q vaporizers (where partial vaporization ofliquid occurs).<strong>TUBE</strong>SHEETCONFINEDGASKETS“U” <strong>TUBE</strong>SBONNETASSEMBLYBONNET ASSEMBLYCONFINED GASKETS<strong>SHELL</strong> ASSEMBLY<strong>TUBE</strong>SHEETAdvantages:1. Tubes expand freely without special provisions.2. Single tubesheet minimizes number of tubeside joints.3. Economical construction.4. Highly efficient heat transfer – small annulus betweenouter tube limit (O.T.L.) and shell I.D.5. Tube bundle easily removable.<strong>TUBE</strong>SHEET GASKET DETAILLimitations:1. Outer tube rows must be removed before replacinginner rows.2. Requires chemical cleaning.3. May not be advisable for use where tubeside fouling isanticipated.TEMA AEWDescription: Removable tube bundle, one or two-pass designq double packed floating tubesheet with “O” rings andthreaded retainer with telltale holes for leak detection q shellsizes from 6” to 42” q pressure range – 75 psi to 600 psi.GASKETApplications: Lube oil coolers q jacket water coolersq aftercoolers.TELLTALE HOLES “O”RING RETAINERSTATIONARY <strong>TUBE</strong>SHEETCHANNEL COVERGASKET“O” RING PACKINGFLOATING <strong>TUBE</strong>SHEETAdvantages:1. Highly efficient heat transfer – small annulus betweenouter tube limit (O.T.L.) and shell I.D.2. Threaded “O” ring retainer permits tube inspection andcleaning without releasing shellside pressure.3. Leaks easily detected – mixing or contamination of fluidseliminated.4. Channel covers and return heads are easily removable forbundle inspection and cleaning.5. Because of full thickness metal of “O” ring retainer,possibility of overtightening bolts and resultant “O” ringdamage is eliminated.<strong>SHELL</strong> FLANGE<strong>SHELL</strong> PIPEFLOATING <strong>TUBE</strong>SHEETTELLTALE HOLES“O”RING RETAINERPACKED END DETAILCHANNEL“O” RING PACKINGLimitations:1. Should not be used for explosive or lethal fluids wherepacking leak cannot be tolerated.2. One or two-pass configuration only.

Custom DesignsDescription: Removable pull through bundle, high pressure closure, double shell,hairpin design q Siller floating ring closure q “O” ring packing, retainer and splitring seal shell and tubesheet assembly – permits bundle removal from reversingbonnet end q pressure range – 1200 psi to 6000 psi tubeside and 150 psi shellside.Applications: High pressuregas-in-the-tube.“O” RING RETAINERSPLIT RING“O” RING PACKINGCLOSURECOVERMETALCLOSURE<strong>SHELL</strong> FLANGEGASKET<strong>SHELL</strong> PIPE<strong>TUBE</strong>SHEETASSEMBLYRUPTURE DISC(S)“U” <strong>TUBE</strong>SREVERSINGBONNETDETAIL “A”SEEDETAIL“A”<strong>TUBE</strong>SHEET ASSEMBLYRUPTURE DISC(S)GASKET“U” <strong>TUBE</strong>SREVERSINGBONNETAdvantages:1. Replaces several “double pipe” sections in high pressure appications.2. High heat transfer efficiency due to small annulus between outer tube limit(O.T.L.) and shell I.D.3. Maximizes tube count and heat transfer service in given shell size.4. Water and gas sealed off with two separate gaskets and two sets of bolts.5. Desirable for applications which impose shell length limitations.6. Tube bundle easily removable for cleaning or inspection.Limitations:1. Outer tube rows must be removedbefore replacing inner rows.2. Requires chemical cleaning.3. May not be advisable for use wheretubeside fouling is anticipated.Description: Custom Basco high pressure exchanger q removable pull throughtube bundle, high pressure closure, floating head, outside packed q special Sillerfloating ring closure q standard square neoprene packing used between floatingtubesheet and shell flange.Applications: High pressuregas-in-the-tube.<strong>TUBE</strong> BUNDLE REMOVED FROM THIS ENDSTATIONARY <strong>TUBE</strong>SHEETRUPTURE DISC(S)PACKING RINGGASKETSCOVERCOVERGASKET<strong>SHELL</strong>FLANGE<strong>SHELL</strong> PIPEFLOATING<strong>TUBE</strong>SHEETPACKINGGLANDPACKINGRINGSPACKED END DETAIL(OUTSIDE PACKED FLOATING HEAD TYPE)Advantages:1. Replaces several “double pipe sections” in high pressure applications.2. High heat transfer efficiency due to small annulus between outer tube limit(O.T.L.) and shell I.D.3. Maximizes tube count and transfer surface in given shell size.Limitations:1. Single pass configuration.

Other Products Available from API Heat TransferAPI Heat Transfer, Inc.2777 Walden AvenueBuffalo, New York 14225(716) 684-6700www.apiheattransfer.comGasketed Plate Heat ExchangersWelded Plate Heat ExchangersDivisions:API Airtech ISO-9001 CertifiedAir Cooled Aluminum Heat Exchangers91 North Street • P.O. Box 68Arcade, New York 14009-0068(585) 496-5755 • Fax: (585) 496-5776The Schmidt line of gasketed plate & frameheat exchangers provide excellent heat transferin a compact space. Plates are pressed fromstainless steel, titanium and other alloys.Gaskets of nitrile, EPDM, Viton ® , compressedfi ber and Tefl on ® are used. Capacities rangefrom 0.5 to 10,000 GPM.Semi-Welded Plate Heat ExchangersThe Sigmawig all-welded plate heat exchangerhas operating temperatures as high as 750º Fand as low as -320º F, and operating pressuresas high as 360 PSI. The unique concept ofthis rugged heat exchanger makes it a viablesolution for many heat transfer needs previouslythought only suitable for shell & tube designs.Extended SurfaceAPI Basco ISO-9001 CertifiedBasco®/Whitlock® Shell & Tube Heat Exchangers2777 Walden AvenueBuffalo, New York 14225(716) 684-6700 • Fax: (716) 684-2129API Schmidt-Bretten AmericasPlate Heat Exchangers and Thermal Systems2777 Walden AvenueBuffalo, New York 14225(716) 684-6700 • Fax: (716) 684-2129Combines the high thermal effi ciency, compactdesign, and low volumetric liquid hold-up of aplate heat exchanger with the leak preventionof a shell & tube. Ideal for ammonia applications.Air-Cooled Heat ExchangersUnique, patented plate-fi n design for centrifugalor axial compressor intercooler and aftercoolerapplications and minimal pressure loss. Designeliminates separators. ASME code design isstandard. Diameters from 20” (50.8 cm) to120” (30.38 cm).Hubbed Shell and Tube Heat ExchangersAPI Schmidt-Bretten GmbH. & Co. KGISO-9001 CertifiedPlate Heat Exchangers and Thermal SystemsLangenmorgen 4D-75015 Bretten, Germany(49)725253-0 • Fax: (49)725253-200API Heat Transfer (Suzhou) Co. Ltd.Air Cooled Aluminum Heat ExchangersShell & Tube Heat ExchangersPlate Heat Exchangers156 Qingqiu Street, 3rd DistrictSuzhou Industrial ParkSuzhou, Jiangsu 215126 China(86)512-88168000 • Fax: (86)512-88168003High effi ciency, brazed aluminum coolers forcooling a wide variety of liquids and gases withambient air. Lightweight, yet rugged. Capableof cooling multiple fl uids in single unit. Modelscan be supplied with cooling fan and a varietyof drives.SigmaStar ® Evaporator SystemsStraight or U-tube, fi xed or removable tubesheetgeneral purpose exchangers designed to cooloil, water, compressed air and other industrialfl uids. A variety of port confi gurations andmaterials are available. Diameters from3’’ (7.62 cm) to 12’’ (30.48 cm).Genuine Manufactured PartsContact your local API Sales Representativeor API Heat Transfer directlytoll-free @ 1-877-API-<strong>HEAT</strong>e-mail @ sales@apiheattransfer.comUtilizing the SigmaStar® plate, this evaporatorsystem is designed to remove water or othersolvents, while concentrating solutions.SigmaStar® Systems can be pre-assembledand pre-tested prior to shipment for quickand easy start up.Contact API Heat Transfer to order all yourreplacement parts. Only genuine partsmanufactured to the original specifi cationsof your heat exchanger will ensure properperformance. Many items such as gaskets,bonnets, and PHE thermal plates are availablefrom stock.Form ENG-420 11/06 © 2003 API Heat Transfer Printed in USA