BUILDING MANAGEMENT SYSTEMS

BUILDING MANAGEMENT SYSTEMS

BUILDING MANAGEMENT SYSTEMS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>BUILDING</strong> <strong>MANAGEMENT</strong> <strong>SYSTEMS</strong>6PROD-PRC013-E4

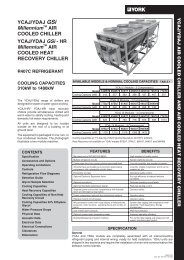

▲InteroperabilityWWW▲ ▲Managementlevel▲Web ServerTracer Summit TM LCD Touch ScreenBCUField ServerOperatorInterfaceBuildingControls▲AutomationlevelMP581Site installedUnit Controls▲FieldlevelPower panelcontrolLightingcontrolMP501/MP503EnergymeteringAlarm controlandmonitoringEX23rd partyequipmentcontrolBuildinginformationmonitoringField devicesControl,measure, monitoringIntegrationRTHD HFO/HFR VariTrac TM CGAN/CXAN CLCP Voyager TMHVACEquipmentwith Factory-MountedControls▲▲Trane Building Management SystemsFull BMS offer: Trane has developed a full range ofcommunicating controllers and components that canaddress all the needs of customers looking forcomfortable, and efficient environments related to HVACBuilding Management Systems. Trane also has taken carethat the teams serving this activity are structured so thatcustomer can get the right support at the right time,wherever in Europe.Open Systems: Trane has adopted the latest openprotocols standard and built them as native services intoits BMS offer. BACnet TM and LonTalk® are native withinTrane BMS panels. Thus several ways of integration andinteroperability are offered to users as to free them upfrom brands.Factory-mounted Controls: Every piece ofequipment leaving the factory is equipped with acontroller which is mounted, wired up, configured andtested before the unit ships to the site. This ensures thatequipment is easy to commission and ready to run.Domains:Functions:Applications:Products:IndustryLarge buildingsMedium buildingsLight commercial buildingsWater plant systemsVariable air systemsWater terminal systemsPackaged unit systemsWater terminal unit controlVAV unitsAHUTechnical lotsBuilding Management SystemsCommunication gatewayZN familyAHU controllerFreely programmable controllerI/O controllersNetwork controllerWeb serverVAV controllerBMS software<strong>BUILDING</strong> <strong>MANAGEMENT</strong> <strong>SYSTEMS</strong>7PROD-PRC013-E4

Domain: IndustryUtilities and HVAC process controlTrane already has a wide experience of industrial controlapplications, starting from simple chiller plantmanagement, up to highly technical systems, such asunderground water source heat pumps, or condenseroptimization for improving chillers efficiency.Reliability: One of the highest priority of Traneengineers when designing an industrial application is toensure a system that is reliable. As an exampleinstallation operation continuity is being focused on atdesign and commissioning stages. Trane proposessystems that can revert to a safe stand alone runningmode should any issue such as communication troublesarise, offering cooling capacity until the issue has beenanalyzed and fixed.Ease of use: On top of that reliability, Trane systemallows for ease of system operation. Whatever theproposed solution is, Trane always proposes simple touse user interfaces. These ones always offer pertinentinformation about system status and running conditions.Since every piece of equipment is hooked up to anetwork, the user can access at any time many systemand units information, allowing for easy diagnosis, andeasy understanding of system reactions.Optimization: Trane also focuses on savings. Thisobjective is focused on since the beginning of the project.Piping arrangement, chiller technology, unit sizesarrangement are being studied so that customer can getthe best result of their installation, according to theirsystem load profile. Chiller Plant sequencing is apowerful pre-engineered function that only requiresparameters for being able to drive the installation withhigh level of optimization.Dedicated BMS teams: From here, Trane isable to propose the BMS products adapted to the solutionthat the customer has chosen. At this point of time, BMSproject fulfillment teams take over the project. BMSproject fulfillment teams follow a complete process:building clear and fully detailed project specifications,proposing clear project development and fulfillmentschedule, and project management.Ease of commissioning: Pre-engineeredchiller plant management function are implemented onthe system so that commissioning time can be asreduced as possible.8PROD-PRC013-E4

Consulting services: Trane also has developedthe capacity of offering full support to its customers,beginning with customer's technical service. Traneproposes its simulation and solution evaluation software.Using this tool, customers can easily evaluate the bestalternative for solving their problem, by being able toview the solutions from different angles, such aseconomical aspects, technical aspects, safety andreliability etc…Single source responsibility: Customerscan have access to project info from a single sourcewithin the Trane organization. After the project has beenfulfilled, it is also easy for customers to get assistancefrom Trane in concluding a maintenance and servicecontract including HVAC and BMS equipment / softwares.This way, system fluctuations, fine tuning etc … can bedone by people working in sync with those teams thathave developed originally the application. This by essenceensures service continuity as well as efficiency inanswering any request of system improvement oradaptation.152431 = Critical Systems monitoring:Electrical Power: MP 5812 = System Water Flow Control:Variable frequency pump Control:VarioTrane VFD3 = Chiller condenser operation:Cooling towers control: MP 5814 = Chiller Plant Control:3 RTHD with factory mounted CH530Twin pump control for each chiller: BCU5 = System monitoring and Control:Supervision: Tracer SummitBMS: Domains Industry9PROD-PRC013-E4

Domain: Small/medium size officeBuilding controlThe know-how gained while sharing experiences with itscomfort process customer has led Trane to develop BMSsolutions dedicated to these applications.Comfort is a key in these projects, but not the only one.Having a look at the entire project process, as well asoffering a system capable of handling the overall buildingcontrol functions has also been taken into account inorder to offer packaged solutions.The packages Trane offers allow for several advantages:Comfort: All Trane HVAC equipment are shipped withfactory-mounted/factory-programmed controls, offeringeasy-to-install equipment, and reduced commissioningtime. All building equipment is fully compatible with eachother thanks to use of LonTalk® protocol. All comfortcontrol functions, such as scheduling, heating/coolingchange over management, timed overrides, chiller plantmanagement, boiler plant management, indoor air qualitycontrol are built in the system. The system also ensuresacoustic performance, by having FCU using the lowestfan speed possible.Energy savings: Trane's package includes severalfunctions dedicated to energy savings, such aschiller/boiler plant optimization, allowing for pumpingenergy savings, as well as equipment starts and stopsoptimization. It also includes automatic watertemperature compensation, occupied / stand by /unoccupied modes for FCU etc…Ease of use: Trane's solution offers a VGA display,presenting data as graphics. The entire system can beaccessed by an intuitive navigation tree system. Dailyoperators can easily access information such as ambienttemperatures, setpoint settings, timed override on anyzone, not being forced to understand HOW comfort isbeing maintained. For more advanced users or technicalpersonnel, the system also offers capability to access todetails about equipment such as various runningconditions for chillers, boilers, and AHU, or optimizationparameters for Plant controls. System howeverintegrates advanced event logging and trending, and verypowerful system access protection through passwordstrategies.10PROD-PRC013-E4

8Ease of installation: Trane's delivered packagecan come as a predefined kit including all components,control panels and so on, so that very little amount ofcoordination is requested for on site installation, wiringand commissioning. It is also possible to get the parts asindividual pieces, would the contractor, or wouldtechnical constraints such as clearance etc … not allowfor using the full 'kit'.Flexibility: Trane's system is capable not only ofhandling Trane equipment, but also extending its domainto integration of non-HVAC functions, such as externallighting systems, grass watering, intrusion system oreven alarms from ancillaries such as power systems,circuit breakers etc…Ease of doing business with: Choosing thissolution means having only one company handling theoverall comfort process. Trane is the contact for anyadvice concerning either the HVAC equipment or theassociated BMS. System optimization will be done bypeople who perfectly understand the HVAC equipment,and BMS components.971652431 = Chilled Water Plant: 2 RTAD with factory mountedCH530: BCU2 = Fresh air control: AHU: MP5813 = Lighting control: MP 5254 = Open Space comfort: HFO with factory mounted ZNcontroller5 = Tenant interface: Setpoint and room conditionsinformation: Web Server6 = System monitoring and Control: Supervision: TracerSummit7 = Intrusion system: Access Control system monitoring:BACnet TM8 = Critical Systems monitoring: Electrical Power: MP 5819 = Hot water plant: Boiler Plant Control: BCUThus Trane's offer is a solution that allows for betterbuilding performances and optimized projectmanagement, answering all concerns.BMS: Domains Offices11PROD-PRC013-E4

Domain: Large office buildingBuilding management controlIn addition to HVAC application solutions for large scalebuilding projects, Trane has developed one of the mostopen Building Management System solutions availableon the market. This range of solutions, completelydeveloped and manufactured by Trane, is the sum ofdecades of expertise, hundreds of HVAC system designs,thousands of operating and maintenance experts. It is theway a reliable and renowned manufacturer helps hiscustomer get the best out of his products.Large building comfort application have been carefullystudied by Trane and fully optimized functions have beenimplemented within Trane's BMS. These functions offerseveral unique advantages to Trane's contacts along theproject cycle.Flexibility: Trane's BMS is a highly flexible systemthat offers ease of (re) configuration. This allows thesystem to be adapted at every step of a project. It hasalso been considered that large buildings require changesquite regularly in the levels layout (open space) andTrane's system is fully organized as to allow for spacereconfiguration, thanks to advanced master/slavecapabilities of terminal units controller, perfectly fitted inthe global BMS.Flexibility is also at first priority when consideringBuilding Operations. Trane's BMS integrates graphicaluser interfaces, either based on HTML pages handled in adedicated environment, called Tracer Summit, or from asimple and standard PC Web browser for dailyoperations.Another important point is about the ability of Trane'ssolution to offer equipment integration and systeminteroperability. Since 1995, Trane has adopted the mostadvanced standard protocols, such as BACnet TM , LonTalk®or MODBUS, and has implemented them as nativefeatures of its BMS.Reliability: Trane's BMS takes advantage of Trane'sexperience in HVAC equipment, as well as in BMS, asTrane has been active in this domain for the last 25 years.Building its own electronic component was a choice thatTrane made as to perfectly master the complete productlife cycle, from development, engineering, manufacturing,up to maintenance, support and upgrade. This means thatevery piece of BMS component is well-known by Trane'sBMS personnel, and, would the project engineer require aspecific piece of information for assisting his customer,he can find it easily within Trane's organization.12PROD-PRC013-E4

Efficiency: Trane has developed pre-engineeredfunction within Tracer Summit that allow a high level ofsystem efficiency which can be seen from differentangles.Efficiency of commissioning: Minimum programmingis required to set up these functions and the BASproject engineers can spend more time in fine-tuningthe system rather than developing the applicationsfrom scratch.Perfect equipment coordination:Trane's HVACequipment comes with its factory-mounted controller.All these controllers have been developed keeping inmind their possible association within a system andthus, their interactions have been envisaged andimplemented within Trane's BMS. This way, it is quiteeasy for Trane's BAS engineers to associate thecontrollers and get the best of the equipment, simplyby telling the system how these controllers are linkedtogether.Fine-tuning: Trane's BMS integrates a unique reportgeneration system that allows operations managersto get a report of the current system status, by thesimple click of a mouse. This operation can be doneon ANY equipment integrated in the system, and doesnot require any programming. Should the operationmanager want a specific report, a specific layout, aspecific trend, Trane's BMS integrates a very simplereport template editor that allows creation of any7161152810 9431 = Weather information: MP 5032 = Chilled water plant: 2 RTAD with factorymounted CH530: BCU3 = Fresh air control: AHU with factorymounted MP 5814 = Open Space comfort: HFO with factorymounted ZN controller5 = Environmental comfort: Lighting control:MP 5256 = Tenant interface: Setpoint androom conditions information: WebServer7 = Workstation: Building SystemsManagement, operation and diagnosis:Tracer Summit8 = Variable Air flow control AHU + VAVvalves: MP 581 + VV 5509 = Hot water plant: Boiler Plant Control: BCU10 = Electrical Power monitoring: MP 58111 = Interoperability: Access Control systemmonitoring: BACnet TM + LonTalk®report, just by dragging/dropping any piece ofinformation available in the BMS database.Comfort: Trane's core business is about developingHVAC equipment. As to reach the unquestionable level ofequipment quality, reliability and efficiency, Trane'sengineers have had to consider the equipment in theirglobal environment. This means that on top of ensuringequipment safeties and running condition efficiency carehas been taken ensure performance around acoustics,energy savings, etc. Through the use of Trane's BMS,these aspects of equipment running conditions are evenimproved. As an example, a VAV box can be drivenaccording to pressures and running conditions of theAHU that is serving it. The equipment exchanges data inorder to align the respective working conditions to deliverthe optimum service to the end user.BMS: Domains Large Offices13PROD-PRC013-E4

Domain: Light commercialBuilding controlTrane has developed a Building Management Systemwhose capabilities perfectly match context of rooftop/airdistribution applications. Trane's BMS, for lightcommercial applications presents many advantages:Delivered System: Trane's light commercial BMSonly requires a few settings to be implemented on anapplication. Thanks to the capability of any Trane HVACequipment to communicate over a network, the BMSmanages to identify these equipment linked together,builds the corresponding database and automaticallyoffers to the end user predefined functions such as timeof-dayschedule, automatic setpoint reset, zonemanagement or alarming menu, with almost no laborrequired. If the customer wants to customize his interface,a convenient software interface is available to changezones that have been automatically created, changingalarms menus, and so on.The system is compact and very convenient to install andwire up. Trane's equipment uses an open standardprotocol, called LonTalk®, which is often present in thistype of building, and contractors perfectly master thiskind of bus topology installation.Trane's delivered system offers an additional perspective,since every piece of the puzzle comes from the samemanufacturer. It is far easier to have coordination onequipment delivery, commissioning and fine tuning, sinceonly one contact is involved for this. On top of this, Tranepersonnel are well trained for the entire systemcomponents, ensuring efficiency in commissioning, andfast response should the customer require anyinformation.14PROD-PRC013-E4

Energy savings: Various pre-engineered tactics,such as setpoint reset, time-of-day scheduling, duty cycle,have been implemented in the system and can beassociated together to improve system energy efficiency,and almost not touch system comfort managementcapability.Trane's system is easy to install, set up and use. Thismeans that system updates, system daily operations andsystem maintenance can be done by operation personnelvery easily, requiring almost no specific training.Trane's system also has the capability to control ancillaryequipment, such as lights, parking lots, energy meters,and any equipment that must be controlled according toa time-of-day schedule, through simple interface such asrelay contacts.131 = Space temperature and humidity control: Rooftopunits with factory mounted control: ReliaTel TM2 = Lighting control: MP 5253 = Tenant interface: Setpoint and room conditionsinformation: Zone Sensor2Saying this, Trane's delivered BMS for commercialapplications is a powerful answer to customers who wanta very easy-to-use system, capable of simplifying their lifeall along the project life cycle.BMS: Domains CommercialPROD-PRC013-E415

FunctionWater plant systemsChillers are one of the main focuses for Trane. Theirenvironment is perfectly known by Trane engineers. Thishas led up Trane developing advanced Chiller PlantControl applications within its Building ManagementSystem. Trane also has taken this opportunity to make itssystem fully capable of handling boiler plants.Various aspects of boiler/chiller plant operations havebeen studied and very smart functions have beenimplemented within Trane's Water System Management.Trane's systems are able to handle many hydrauliclayouts.Most efficient results can be achieved with well-preparedpiping arrangement. However, Trane always studiespiping arrangement that is either existing or consideredfor the installation. Trane specialists in hydraulics andchillers application always review the system drawingsbefore any proposal is made. This helps Trane to clearlypoint out what the installation is really capable ofdelivering, and to position these capabilities regardingwhat is expected.Once this is clear, Water System Management addsadvanced capabilities to the customer's installation:Flexibility: Water System Management offersflexible interfaces to operate chiller plant. By a few mouseclicks, chillers can be turned into maintenance, sequencenumbers can be adjusted and rotation can be initiated.The same interface also helps operation personnelexactly know what the installation has been doing, iscurrently doing and will be doing in the near future. Atany time, the operator can anticipate system reactions.System graphics for plant operation can be monitoredfrom an Intranet, using a web browser.Energy savings: Water System Managementalways ensures that chillers are used in their mostefficient operation conditions. Unit technology andenvironment conditions are monitored by Water SystemManagement, which adjusts parameters according tochanges in the system running conditions. Parameterssuch as unit size, compressor technology, condensertemperatures are controlled. The number of chillers isautomatically adapted according to the system load.Should there be a change, the system anticipates andadds/removes chillers accordingly. The system alsocontrols all ancillaries such as pumps, cooling towers, drycoolers etc.16PROD-PRC013-E4

12345Reliability: It is obvious that chilled water productionis crucial for customer's process and the Trane systemmaintains a high level of reliability so that chilled watercan be maintained at all times.Every chiller is equipped with its own electroniccontroller, and each controller embeds an adaptivecontrol algorithm. Each controller is fully compatible withthe Building Management System, It communicates withit over a standard protocol, sharing all its runningconditions. This allows the management system to notonly turn on/off chillers according to temperatures ortemperatures differences, but also consider currentrunning conditions of chillers, such as maximum capacityreached, limit conditions, and so on, in order to knowsystem capacity at all times.Interoperability/integration: Trane systemsare fully capable of communicating with any equipmentand/or management system through the use of openstandard protocols, such as BACnet TM , or LonTalk®.Modbus is also supported allowing for a wide range ofintegration and data sharing with ancillaries, such aspumps, sensors or PLC's. Trane systems are capable ofintegrating either standard LonTalk® profiles (SCC, DAC)or Generic Lon Devices (GLD).1 = Network Management: BCU2 = Ancillaries control (Pumps): MP 5813 = Power control panel monitoring: MP581 + EX24 = Variable Flow control: Vario Trane VFD5 = Workstation: Tracer summit6 = Chiller: RTHD with factory mounted CH5306Protection: Trane systems offer a high security levelthat protects against any unexpected system operation.Operators can be authorized to monitor data only, writesetpoint and other parameters, create graphics or justview them, modify system layout, and so on. Every actionon the system is recorded in an event log. Events canthen be monitored, filtered by date/operator/device, etc.Events can be seen either at the PC level, or from a localtouch screen available in the plant room.Assistance: Trane systems allow for system remotemonitoring. After commissioning, Trane personnel canget connected to the system and monitor/fine tuneparameters to adapt the overall system performance.Alarms can also be forwarded to that remote workstation.If an IP address is available, a web server can be installedand allow for remote access to the system through asimple web browser. Trends, event log, system status canbe accessed this way from any location where an accessto the Internet/intranet is possible.BMS: Functions ChillerPROD-PRC013-E417

FunctionVariable air systemsIn buildings where environmental comfort is a key,variable air systems are the best alternative. Trane BMSintegrates the capability of driving such systems througha pre-defined engineered function called Variable AirSystems. By the use of VAS, building owners get a stateof-the-artsystem capable of offering many differentadvantages.System approach: Every piece of equipment of aTrane air system is equipped with an optimised controller,which locally ensures that the equipment is used the bestway. Trane air system management uses controllercommunication capability to handle all the equipmentfrom a global standpoint. Every running condition hasbeen modelled in a global function. Ancillaries, such aslights, power supply, shadows can be associated with theair system and all these components can be coordinatedtogether.Comfort: Thanks to a common communicationstandard protocol, all equipment serving the system isexchanging data with an application server which takesdecisions. If most VAV boxes are fed with too much air, itwill reset static pressure setpoint as to avoid unnecessarynoise. If boxes are fully opened and call for more air, thesetpoint is adjusted upward.Since VAV boxes are equipped with communicatingcontrollers, master/slaving can easily be used forhandling large zones avoiding fights between cooling andheating areas, as well as allowing for optimumtemperature control. Indoor Air Quality (IAQ) is alsoperfectly managed by such a system. Trane equipmentcan monitor indoor air conditions and drive the AHUfresh air dampers dynamically, by measuring the fresh airvolume sent into the building.18PROD-PRC013-E4

Savings: Dynamically adjusting airflow in the ductsystem leads to energy savings by the reduction of fanconsumption. Occupancy schedules also participate inenergy savings.Start/stop optimisation, done through the monitoring ofoutdoor air conditions, building inertia and occupancyprofiles are also a very powerful tool. Control of IAQ alsois an important asset for energy savings. Only the rightamount of fresh air is handled by the system reducingunnecessary ventilation.121 = Open space Comfort: AHU with factorymountedcontrol MP5812 = Variable air volume damper: VariTrane TM+ VV 550Ease of use: Trane systems can be run through anintuitive web-style user interface, as well as from touchscreens displays at every level of the system. The use of anadvanced password system allows the use of filteringscreens so that users only have access to what they reallyneed. End users can also use their standard PC to operatethe system, by surfing on their dedicated web pages forsetpoint adjustment, for example. Alarms are alsomonitored by the system and can be forwarded to theappropriate recipient via e-mail. Reports are accessiblethrough couple of mouse clicks, no engineering, noprogramming being required. Time of day schedules,setpoints and system statuses can be accessed, for readingand reading/writing, depending on the password given.BMS: Functions Air SystemsPROD-PRC013-E419

FunctionWater terminal units systemsWater terminal units and chillers are Trane core products.Understanding how this equipment is being usedtogether, is part of Trane know-how that has beenconverted into a Management System. Other equipmentserving building comfort system is also under Tranesystem, control such as air handling units, exhaust fans,water treatment, but also ancillaries such as lights, powerdistribution panels, and so on.The system that Trane offers covers key points for aproject to be successful.Comfort: Trane has developed advanced electroniccontrollers that offer individual comfort at each terminalunit level. This comfort is offered several ways• Temperatures are being monitored and controlled tostay within limits each user can adjust, either byindividual wall sensors, or by the use of web pages.• Sound level is maintained at its minimum value and airmovement reduced as much as possible by the controlof fan speed, which is maintained at the lowest value aspossible.• Comfort is maintained year-round, cooling/heating modeis controlled automatically and intelligently, change overbeing totally transparent to the occupant.• Comfort for the operation manager is also ensured.Master/Slaving is now very easy to set up andreconfigure. Open space re-design can be done in veryshort period of time.• Indoor Air Quality (IAQ) is also one of the advantages ofa Trane system which is capable of monitoring andmaintaining IAQ within optimum limits, by collectingIAQ data from terminal units and givingrecommendation to the AHU, thanks to communicationbuses.Ease of use: Trane systems communicate throughopen protocols (LonTalk® BACnet TM ) as a core means ofdata sharing. In addition to this data sharing, the systemhandles several types of user interfaces, so that everyuser can have access to the information he needs, whilenot being overwhelmed with inappropriate data.• Terminal units can be equipped with wall sensorsembedding indications such as setpoint, timed override,and temperature values. This information can beadjusted within pre-determined limits.• Operation managers can have access to system statusby using an advanced graphical interface running on aPC. This status can be filtered and organized accordingto the use. Software interfaces integrate a user-friendlygraphical interface allowing authorized users tochange/create graphics to optimized them for theirown use.20PROD-PRC013-E4

43• Operation engineers can have access to systeminformation in the different technical locations in thebuilding by the use of VGA touch screens, on which localdata are presented.• Time-of-day (TOD) scheduling is integrated in thesystem and offers a very convenient interface for TODadjustment, group/zone creation or modifications.• Every single piece of equipment in the system can befocused on. It can be overridden in any state as formaintenance or test purposes. A trend can also begenerated for it, and automatic reporting is available,not requiring any specific programming.• Equipment or system alarms can be monitored andbroadcasted on the system so that the best recipient canget a notice for this particular event and react in themost efficient manner. If a recipient does not reactwithin a pre-defined period of time, the alarm isforwarded to another level of recipients until the alarmis acknowledged.• The addition of a web server allows for systemperformances monitoring from a PC equipped with asimple browser. Graphics and trends are converted toHTML pages and are available from any location on theintranet/internet, through the use of an IP address.121 = Open Space comfort:HFO with factory mounted ZN controller2 = Ancillaries control:Lighting control: MP 5253 = Open Space comfort:UniTrane TM II with factory-mounted ZN controller4 = Tenant interface: Setpoint and room conditionsinformation: Zone SensorSavings: Through the coordination of all equipmentwithin the building, it is quite simple for the managementsystem to optimize energy consumption. Savings also areavailable at system design and system commissioningphases.• Water system management can be organized, so thateither chilled water or hot water production is handledin the most efficient way. Hot water can be generatedeither by boilers, reversible units or a combination ofthe two.• Equipment schedules integrate an optimization function,which determines building inertia and adjusts start/stoptime according to temperatures/relative humidity andbuilding occupancy.• Each Trane piece of equipment is delivered with factorymountedcontrols which are ready to work when theequipment leaves the factory. No extra work on site isrequired for it to control the equipment it is associatedwith.Coordination of production (cooling/heating) and use(FCU, AHU…) is one of the best approaches to optimizesystem operation. Communication is the key factor forthis to be efficient and Trane equipment all integrate astandard protocol interface.BMS: Functions Water SystemsPROD-PRC013-E421

ApplicationPackaged unit systemsPackaged units such as rooftop equipment are often usedin more than one unit application. Trane has developed adelivered system allowing for ease of operation, ease ofinstallation of such systems. To serve concerns for suchinstallations, Trane has developed a dedicatedmanagement system that offers the following services:Easy to install: Trane system consists in a modulethat only needs 4 screws to be mounted on the wall. Thismodule is divided into 3 pieces, one being a mountedplate that can be installed before the electronic andscreen plates are being delivered, reducing risks ofdamage.Ease of operation: Trane system comes with atouch screen. One hour is needed at the most to trainusers, either daily operators, or operation people, thanksto the use of graphics. Should a more advanced interfacebe required, a PC can be connected to the panel and offera Windows-based HTML interface with enhancedfunctions.Easy to do business with: Thanks to Trane'sapproach to packaged systems, customers only have onecontact point for the whole installation. For explanations,project status, or advice on system expansion, only onephone number is necessary.Easy to commission: All Trane equipment isLonTalk® compatible. This means that polarity is nolonger an issue, and bus layout is simplified. Tranesystem automatically discovers all equipment hooked upto the network and builds a default database in fewminutes after first power-up. This ensures that thebuilding is managed automatically with default valuessuch as setpoint, zone names, and schedules. Thesevalues can be adjusted at a later stage, after the endusers have entered the building.22PROD-PRC013-E4

More than just air conditioning:Ancillaries such as pumps, lights, variable air systems canbe under its control. The system applies time-of-dayschedules and setpoint global changes to all devicesconnected to the network.Trane systems offer a centralized control for theequipment serving building comfort. From this centrallocation, all equipment can be operated and monitored. Ifa remote connection is required, the system integratescapability of forwarding alarms and trends to a remotelocation either through Ethernet network and appropriateWindows application running on a customer-supplied PC,or through phone lines.Savings: Trane system allows for reduced installationcosts. Only thermistors need to be wired up to DX units,requiring only 2 wires instead of many for complete wallsensors. Energy is better handled by the use of time-ofdayschedules and optimal start/stop function.Heating/cooling coordination makes sure that equipmentis not competing against each other and wasting energy.121 = Space temperature and humidity control:Rooftop units with factory mountedcontrol: ReliaTel TM2 = Tenant interface: Setpoint and roomconditions information: Zone SensorBMS: Functions Packaged unitsPROD-PRC013-E423

Application Selection InformationWater Terminal unit controllerDescriptionOptimized controller for water terminal unit control application. Can drive 3 wires or hot wax valvesactuators, supports most common unit configuration and drive a solid state relay for sound levelcomfort.Customer benefitsReduced commissioning time:• Compact, quick connection, embedded power supply• Master / slave direct binding• Advanced comfort: Cascade zone / supply air temperature algorithm for precise temperature controlApplicationZN523Factory-mountedYesCommunicationLonTalk®2-pipe cooling-onlyx2-pipe cooling-only + electric heaterx2-pipe heating onlyx2-pipe changeoverx2-pipe changeover + electric heaterx4-pipexFunctionFan speed control (3 speeds)AutoThermal valve actuator controlYes3 wires valve actuator control YesAutomatic changeoverYesOccupied/unoccupied modeYesWall sensor (fan speed: low/medium/high/auto/off,setpoint knob, override/cancel)YesAutomatic fan speed optimizationAutoSupply air measure and controlYesEntering water temperature measureYesAuto changeover (2-pipe mode)YesAuto changeover (4-pipe mode)YesDirty filter timerYesMaster/SlaveYesOccupied stand-byYesTimed overrideYesDuty cyclingYesFrost protectionYesPower up functionYesDiagnosisYesChilled beam controllers24ApplicationZN523Factory-mountedYesCommunicationLonTalk®2-pipe cooling-onlyYes2-pipe cooling-only + electric heaterYesFunctionThermal valve actuatorYes3 wires valve actuator control YesOccupied/unoccupied modeYesWall sensor(setpoint knob, override/cancel)YesSupply air measureYesEntering water temperature measureYesMaster/SlaveYesOccupied stand-byYesThis is a short list of what can be done with these controllers. For information on other applications, contact your local sales office.PROD-PRC013-E4

VAV Terminal units controllersDescriptionDedicated to variable air volume valves control, these controllers handle multiple application type,and integrate several diagnostic features for easy commissioning and facility management.Customer benefits• Application flexibility: same controller whatever the application is• Reduced communication time: multiple diagnosis at controller level• Freedom of choice: can either be tied in Trane BMS or in any LonTalk compatible BMSUCM VAV III/IV VV 550ApplicationFactory-mounted Yes YesCommunication Proprietary LonTalk®1 duct Yes Yes1 duct + heating water coil Yes Yes1 duct + heating electric coil Yes Yes1 duct with parallel fan Yes Yes1 duct with series fan Yes Yes1 duct with parallel fan and water coil Yes Yes1 duct with parallel fan and electric coil Yes Yes1 duct with series fan and water coil Yes Yes1 duct with series fan and electric coil Yes YesFunctionIntegrated airflow control Yes YesIntegrated supply/extract flow differential control No YesGeneric output No YesGeneric binary input or occupancy sensor input Yes YesCO 2 sensor input or auxiliary temperature sensor Yes YesRemote communication pins on wall sensor Yes YesAutomatic calibration Yes YesAir/water balancing application No YesManual test function Yes YesDamper position for pressure optimization Yes YesCO 2 base demand control ventilation No YesVentilation ratio to control outdoor air damper Yes YesThis is a short list of what can be done with these controllers. For information on other applications, contact your local sales office.Building Management Systems Applications25PROD-PRC013-E4

Air Handling Units - AHU controllersDescriptionPre-engineered or fully programmable controller for AHU applications. Support LonMark SpaceComfort Controller (SCC 8500) or Discharge Air Controller (DAC 8610) profiles.Customer benefits• Reduced commissioning by the use of application libraries for AH541• Reduced programming time by use of Trane Graphical Programming and re-use of existingapplication library of AH541Air Handling Units - AHU controller AH 541 MP 581Factory-mounted Yes YesCommunication LonTalk® LonTalk®Analog inputsReturn / supply / outdoor air temperature sensor X / X / X X / X / XAmbient / mixed air temperature sensor X / X X / XTemperature setpoint adjustment X XDuct static pressure X XDifferential pressure X XReturn / supply / outdoor air humidity sensor X / - / - X / X / XAmbient air humidity sensor - XHumidity setpoint adjustment - XCO2 sensor / CO2 setpoint - / X X / XAir quality / IAQ setpoint - / X X / XBinary inputsFrost thermostat X XDifferential filter pressure switch X XLow air pressure switch X XMotor(s) default(s) X XElectrical heater default X XDamper end switch X XOn/off contact X XOccupancy mode X XTimed override X XCommunication bus terminals 2 2Analog OutputPre-heating / cooling / heating valves X / 0-10 V/3 wires X / 0-10 V/3 wiresSignal damper X / 0-10 V/3 wires X / 0-10 V/3 wiresElectrical heater X / 0-10 V/3 wires X / 0-10 V/3 wiresVariable speed supply air / return air motor X / 0-10 V/3 wires X / 0-10 V/3 wiresSignal humidifier X / 0-10 V/3 wires X / 0-10 V/3 wiresTemperature * *Humidity * *Pressure * *Position damper * *Binary outputSupply air motor command X XExtract air motor command X XDamper command X XHumidifier command X XDefault Signal X X- Not Available * Screen Display point X Hardware point26PROD-PRC013-E4

Technical lots - Input/Output controllersDescriptionField installed controllers dedicated to monitoring and control of any technical lots, such as boilerplant, point monitoring, specific algorithm control.Customer benefits• Open systems: Lontalk® compatibility• Adapted range of product to real use: small / medium / large point count• Flexibility for programming panelsMP 501 MP 503 MP 523 MP 525 MP 581Factory-mounted No No No No NoCommunication LonTalk® LonTalk® LonTalk® LonTalk® LonTalk®I/O capacity 4 8 12 Expandable > 20ApplicationSingle loop controller X - - - XMonitoring temperature - X X X XMonitoring humidity - X X X XMonitoring pressure - X X X XControl mechanical equipment - X X X XControl water pumps - - - - XControl boilers - - - - XControl cooling towers - - - - XControl heat exchangers - - - - XDisplay screen option - - - - XFreely programmable - - - - XLocal overrides (software) - - - - XLocal overrides (LCD) - - - - XLocal language - - - - X- Not Available X Hardware pointThis is a short list of what can be done with these controllers. For informations on other applications, contact your local sales office.Building Management Systems ApplicationsPROD-PRC013-E427

Building Management Systems - User InterfaceDescriptionDifferent interfaces that adapt to the right application: From local display for controlling a processfrom its location, to PC workstation software allowing for total building management, and to Webserver for serving pages to remote connected end users.Customer benefits• Consistency in function provided: scheduling, alarming, reporting, timed override, systemmonitoring, event logging• Easy operation: custom graphics, view / control of any system pointApplicationBCU Display Tracer Summit Web ServerPassword protected X X XTouch screen interface X X -Windows type navigation - X XTime of day scheduling X X XEvent logging X X XTrending/event graphing - X XPre-engineered reports - X XCustom reports - X -Personal computer support - X XUser friendly alarm log interface X X XAlarms acknowledge X X -Remote RS 232 connection X X -Remote IP connection X X X- Not Available X CompatibleThis is a short list of what can be done with these controllers. For informations on other applications, contact your local sales office.28PROD-PRC013-E4

Protocol gatewayDescriptionDedicated to MODBUS interfacing between Trane and non Trane devices, this compact interfacesoffer straight commissioning and low risk of technical issues.Customer benefits• Open systems: supports reliable and highly supported MODBUS RTU protocol• Straight commissioning: auto binding with LonTalk compatible unitsProtocolInterfaceController (PIC)BCU+PICBCU+Field ServerChiller controllersNumber of unit per interfaceSMM 1 4 10 MaxTRACER CH.532- 1 4 10 MaxUCM-CLD + CSR 1 4 10 MaxUCP2 + TCI3-com3 1 - -UCP2 + TCI3-com4 1 4 10 MaxTRACER CH.530 1 4 10 MaxRooftop controllersRooftop + UCP2 + TCI-3 com3 - 4 16 MaxRooftop + Reliatel + LCI-r - 4 16 MaxTerminal unit controllersZN 523 - 25 100 MaxGeneric PLC'sAH 541 - 4 10 MaxMP 581 - 4 10 MaxMP 501-503 - 4 120 MaxGeneric data point - 50 500 Max- Not AvailableThis is a short list of what can be done with these controllers. For informations on other applications, contact your local sales office.Building Management Systems Applications29PROD-PRC013-E4

Technical characteristicsTerminal Unit controller - ZN 523DescriptionAdvanced compact water terminal unit controller. Flexible and optimized for comfort and energysaving control.Customer benefits• Optimized commissioning : compact, can come as factory-mounted option, pre-commissioned• Flexibility: same controller for several application types (hot wax / 3 wires applications, …)• Error less wall interface wiring: RJ9 connector for quick and reliable communication with wallinterfaceZN 523I/O Type Index Signal type I/O UseBinary inputs BI 1 Dry contact OccupancyBI 2 Dry contact Window contactAI 1 thermistor Return air temperatureAnalog inputs AI 2 thermistor Entering water temperatureAI 3 thermistor Discharge air temperatureBO 1 relay 230 Vac / 3A NO High fan speedBO 2 relay 230 Vac / 3A NO Medium fan speedBO 3 relay 230 Vac / 3A NO Low fan speedBinary outputs BO 4 triac 230 Vac, 5 A Heat valve open, electric heat (solid state relay)BO 5 triac 230 Vac, 5 A Heat valve closeBO 6 triac 230 Vac, 5 A Cool valve openBO 7 triac 230 Vac, 5 A Cool valve closeBO 8 relay 230 Vac / 10A NO Electric heat (relay)Main featuresPower230 Vac 50/60 Hz 1phaseOperating environment0 to +60°C5 - 95% humidity non-condensingStorage environment- 40 to +85°C5 - 95% humidity non-condensingProtection class IP 20Dimensions (mm) 132 x 120 x 44Agency listing / complianceImmunity (directive 89/336/EEC)EN 50082-1: 1997 - EN 50082-2: 1995Emissions EN 50081-1: 1992CommunicationLonTalk® protocol SCC 8501 profileNetwork type : FTT10-ADiagnosis interface3 LED / "Service pin" 1 push button30PROD-PRC013-E4

Zone Sensor for water terminal unitsDescriptionInnovative in its design and function set, this interface offers user friendly comfort control, as wellas occupant unique features, such as occupant call, or maintenance request.Customer benefits• Ease of use: clear large Liquid Crystal Display and large push buttons• Reduced commissioning time: use of RJ9 type connection to the controller• Short commissioning: menu driven setupMain FeaturesSupported signal typePush buttonsLarge push buttons: Setpoint adjustment(increase / decrease), fan speed, timed override,+ various combinationsLCD displayAt the center of the interface, 42 mm diameterForeground color: red / Background color: light grayLogos: fan, occupancy, temperature, window open, faultAbsolute temperature, current absolute or relativesetpoint, ocupancy status, controller fault status, activeoccupant call status, window open status, maintenance callZone sensorIncluded in the wall interfaceMeasures temperature between +5°C and 30 °C, accuracy of 0.2 °CSensor is automatically disabled when remote controller uses'return air'Dimensions (mm)120 mm (diameter), 30 mm (thickness)Connexion to controller RJ 9Agency listing / complianceEmission (directive 89/336/EEC)EN 50081-1: 1992Protection class IP 30Electric insulation classClass IIBuilding Management Systems Products31PROD-PRC013-E4

AHU Controller - AH 541DescriptionField installed controller on Air Handler Units. AH 541 comes with pre-engineered functions for fastcommissioning of most common units.Customer benefits• Flexibility: expandable controller through the use of EX2 panels• Easy operation: user-friendly optional touch screen for unit monitoring, overrides and control• Open systems: supports SCC / DAC LonTalk® profileAH 541I/O Features Number Supported signal typeUniversal input 12 Dry contact (included pulses)0-10 Vdc - 0-20 mALinear variable resistor - ThermistorSpecific Pressure Input 1 Specific Input for Trane pressure sensorBinary outputs 2 24 Vac powered contact (12 Vac 0,5A)Analog Outputs 5 0-10 Vdc - 0-20 mAMain FeaturesPower Supply24 Vac 50/60 Hz 1 phase - 10 VA under 24 VacOperating environment- 40 to +70°C (0 to +50°C operator display)10 to 90% humidity non-condensingStorage environment- 50 to +95°C (-25 to +75°C operator display)10 to 90% humidity non-condensingProtection Class IP 20Dimensions (mm)215x385x127Weight (kg) 1MemoryRAM 512 K ROM 2 MB flash EEPROM 256 KOperator display (option)Touch screen resolution 320x240 pixelsTimerIncluded in the operator displayBatteryDynamic data/time: high capacity backup (7 days)Agency listing / complianceImmunity (directive 89/336/EEC)EN 50090-2-2: 1996Emissions (directive 89/336/EEC)EN 50090-2-2: 1996 - EN 61000-3-2: 1996 - EN 61000-3-3: 1995CommunicationLonTalk® Protocol SCC or DAC profileNetwork type : FTT10-AExtension Capability4 EX2 modules maximumDiagnosis Assistance9 LED - 1 "service pin"32PROD-PRC013-E4

Freely programmable I/O controller - AHU controller - MP 581DescriptionThis freely programmable controller uses a graphical programming tool that allows control softwareeasy development, applied on any HVAC and building management applications. Its use is userfriendly thanks to its local LCD touch screen.Customer benefits• Easy operation: user-friendly touch screen, driven by icons; expandable through the use of EX2panels• Ease of programming: graphical interface TGP (Tracer Graphical Programming) for efficientprogramming• Open systems: supports LonTalk® communication protocol, as a DAC, SCC or generic profileMP 581I/O Features Number Supported signal typeUniversal input 12 Dry contact (included pulses)0-10 Vdc - 0-20 mALinear variable resistorThermistorSpecific Pressure Input 1 Specific Input for Trane pressure sensorBinary outputs 6 24 Vac powered contact (12 Vac 0,5A)Analog Outputs 6 0-10 Vdc - 0-20 mAMain FeaturesPower Supply24 Vac 50/60 Hz 1 phase - 10 VA under 24 VacOperating environment- 40 to +70°C (0 to +50°C operator display)10 to 90% humidity non-condensingStorage environment- 50 to +95°C (-25 to +75°C operator display)10 to 90% humidity non-condensingProtection Class IP 20Dimensions (mm)215x385x127Weight (kg) 1MemoryRAM 512 K ROM 2 MB flash EEPROM 256 KOperator display (option)Touch screen resolution 320x240 pixels - Local languageTimerIncluded in the operator displayBatteryDynamic data/time: high capacity backup (7 days)Agency listing / complianceImmunity (directive 89/336/EEC)EN 50090-2-2/96: 1996Emission (directive 89/336/EEC)EN 50090-2-2: 1996 - EN 61000-3-2: 1996 - EN 61000-3-3: 1995CommunicationLonTalk® Protocol SCC or DAC profileNetwork type : FTT10-AExtension Capability4 EX2 modules maximumDiagnosis Assistance9 LED - 1"service pin"Building Management Systems Products33PROD-PRC013-E4

MP 581 I/O Expansion Module - EX2DescriptionThe EX2 is a field-installed expansion module for MP 581 freely programmable controller. It allowsMP581 to monitor and control I/O point at remote locations, by driving these expansion panels overa simple RS485 communication bus.Customer benefits• Low cost expansion panels: offers 6 universal inputs, 4 binary outputs, 4 analog outputs per panel• Ease of installation: compact enclosure• Flexibility: EX2 is linked to the master panel over a communication bus for remote installationI/O Features Number Supported signal typeUniversal input 6 Dry contact binary - 0-20 mA - 0-10 Vdc - RTD - ThermistorBinary outputs 4 24 Vac powered contact (12 Vac 0,5A)Analog Outputs 4 0-10 Vdc - 0-20 mAMain FeaturesPower Supply24 Vac 50/60 Hz - 60 VA maximumOperating environment- 40 to +70°C5 to 90% humidity non-condensingStorage environment- 40 to +85°C5 to 95% humidity non-condensingDimensions (mm) 175 x 137 x 51Weight (kg) 1Agency listing / complianceEmission (directive 89/336/EEC)EN 50081-1: 1992 - EN 50090-2-2: 1996 - EN 61326-1: 1997Immunity (directive 89/336/EEC)EN 50082-1: 1997 - EN 50082-2: 1995 - EN 50090-2-2: 1996- EN 61326-1: 1997CommunicationCommunicates with MP 581 on an IEEE-485 linkMP 581 Operator DisplayDescriptionThis is an intuitive LCD operator interface allowing for easy point monitoring, overriding, schedulingand troubleshooting. It consists in a high resolution graphical touch screen enclosed in a nicelooking casing for convenient installation.Customer benefits• Convenient interface: can be installed directly in building tenant spaces for being an interface withthem• Ease of use: supports local languages• Ease of diagnosis: shows point overrides, in alarms, ...Main FeaturesSupported signal typePower SupplyNo power supply : gets its power from the panel it is connected toOperating environment0 to +50°C10 to 90% humidity non-condensingDimensions (mm) 260 x 222 x 58Touch screenVGA backlit crystal display with touch-screenViewable area : 115 mm x 86 mmResolution of 320 x 240 pixels34PROD-PRC013-E4

Generic I/O controllers - MP 501/503/523/525DescriptionRange of I/O controllers with various capacities and built in functions, adapted to different functionssuch as point monitoring, point scheduling, simple loop control, HVAC process control orexpandable controller for flexible I/O count support.Customer benefits• Open systems: LonTalk® communication protocol• Application flexibility: output status feedback on MP 525• Optimized cost: several panel sizes for perfect adaptation to the needI/O Panel FeaturesMP 501 MP 503 MP 523 MP 525I/O Features Number Number Number NumberAnalog input 1Binary input 1Universal input 4 8 5 modules of 4Binary outputs 1 4 4 6 modules of 4Analog Outputs 1 7 modules of 4Main FeaturesPower Supply A(*) A(*) A(*) B(*)Operating environment0 to +70°C5 - 95% humidity non-condensingStorage environment-40 to +85°C5 - 95% humidity non-condensingAnalog inputThermistor or 4-20 mABinary inputPowered input 24Vac 0,25VAUniversal inputDry contact or 0-20mA or 0-10Vdc or 10 kohm thermistorBinary outputs 24 Vac 12 VA powered relay 230 Vac relay/3AAnalog Outputs0-20mA or 0-10 VdcProtection class IP 20Dimensions (mm) 175 x 137 x 51Weight (kg) 0.22 0.35Agency listing Immunity: EN 50082: 1997compliance Emissions: EN 50081-1: 1992, EN 61000-3-2: 1996CommunicationLonTalk® protocol generic modeNetworkFTT10-A(*) A: 24 Vac 50/60 Hz 1 phase 60 VA max power(*) B: 230 Vac 50/60 Hz 1 phase 1A max powerBuilding Management Systems Products35PROD-PRC013-E4

BCU - BMTXDescriptionBCU is an intelligent panel that controls integration and networking capabilities of the TracerSummit product suite. It handles peer to peer data base management with pre-engineered functionssuch as Chiller Plant Control or data logging.Customer benefits• System that lasts: high reliability• Low risk in database management: peer to peer shared database• Open protocols, BACnet TM and Lontalk®I/O Features Number Supported signal typeBinary inputs 2 Pulse meter or standard status inputsMain FeaturesPowerNominal rating : 230 Vac; 50 or 60 Hz; 1 phaseOperating environment0 to +50°C10 - 90% humidity non-condensingStorage environment-46 to +66°C10 - 90% humidity non-condensingEnclosureNEMA-1Dimensions (mm) 418 x 373 x 140Weight (kg) 7Agency listing / compliance EN 61326: 1998 Class B - EN 61326: 1998 Commercial - EN 61010-1: 2001MemoryFLASH 16 MB - EEPROM 512 KB - SRAM 1 MB - SDRAM 8 MBBatteryPrograms backed up by non-volatile memoryCommunicationEthernet port EIA-232 BACnet TM portComm3, Comm4 : 2 links, and LonTalk®Operator display (option)Monochrome VGA touch screen - 320 x 240 pixelsModem (option)Internal 56 kbpsWeb ServerDescriptionTracer Summit Web Server allows users using a web browsing application to operate a buildingcontrolled by Trane Tracer Summit. Schedules, areas, setpoint adjustment or data logging andrending can be accomodated among other functions.Customer benefits• Two network part for separation between HVAC and office Ethernet• Flexibility: any PC with web browser can serve as entry point in the system• Ease of operation: graphic interface with user friendly interface (Calendar, ….)36Main FeaturesOperating environment0 to +50°C10 - 90% humidity non-condensingStorage environment-40 to +85°C10 - 90% humidity non-condensingProtection class IP 30Dimensions (mm)260x223x70Weight (kg) 1.1Agency listing / compliance CE EN 61326: 1998 - EN 61010-1: 1993MemoryRAM 32 MB ROM 256 Mo flashSecuritySecure Sockets layer (SSL) protocolSoftware requirementJava 2 plug in 1.4.0 or higher Web browser Internet Explorer 5.01 or higherNetscape navigator 6.2 or higherNetworkTwo RJ 45 Ethernet 10/100 BaseT ports with rate auto detectionPROD-PRC013-E4

VAV UCM III/IVDescriptionVAV UCM II/IV are dedicated controllers for any VAV application type. It measures air flow andtemperature for a cascade control process allowing for accurate and precise room comfortmanagement.Customer benefits• Easy commissioning: factory installed control: flow (min / max / nominal) are preset at the factory• Reliable system application: perfectly integrated within Tracer Summit Variable Air Systempre-engineered functionI/O characteristics Number Supported signal typeBinary inputs 1 Occupancy or generic binary inputAnalog inputs 8 Zone temperature Zone sensor common groundLocal setpoint CO2 sensor Pressure transducerAuxiliary temperature or CO2 sensorOutdoor air temperature orGeneric temperature universal 4-20 mABinary outputs 5 Open damper Close damperModulating heating valve openModulating heating valve closeMain FeaturesPower24 Vac 50/60 Hz 1 phase - 50 VA maxConsumption 50 VA max at 24 VacOperating environment0 to +60°C10 - 90% humidity non-condensingStorage environment-40 to +65°C10 - 90% humidity non-condensingCommunication Protocol TRANE proprietary (SCC 8500)Building Management Systems Products37PROD-PRC013-E4

VV 550DescriptionVV 550 are dedicated controllers for any VAV application type. It measures air flow and temperaturefor a cascade control process allowing for accurate and precise room comfort management.It supports LonTalk open protocol.Customer benefits• Easy commissioning: factory installed control: flow (min / max / nominal) is preset at the factory• Reliable system application: perfectly integrated within Tracer Summit Variable Air Systempre-engineered functionI/O characteristics Number Supported signal typeBinary inputs 1 Occupancy or generic binary inputAnalog inputs 4 Space temperature, space setpoint, primary/discharge airtemperature, primary air flowBinary outputs 5 Air valve close, air valve open, heat stage 1, heat stage 2,heat stage 3/Fan on/offMain FeaturesPower18-32 Vac (24 Vac nominal) at 50/60 HzOperating environment0 to +60°C5 - 95% humidity non-condensingStorage environment-40 to +65°C5 - 95% humidity non-condensingCommunicationLonTalk® protocolLonMark® Space Comfort Controller profile (SCC 8500)38PROD-PRC013-E4

Field ServerDescriptionBACnet TM to MODBUS gateway, dedicated to Tracer Summit applications.Customer benefits• Easy commissioning: easy to set up MODBUS data table• Easy operation and diagnosis: compact device with diagnosis indicator (Leds)ProductsI/O FeaturesSupported signal typeConnection1 RJ 45 IEA-2321 screw terminal EIA-4851 10 BaseT RJ 45 EthernetMain featuresPower24 Vac 50/60 Hz 1phaseOperating environment0 to +60°C10 - 90% humidity non-condensingStorage environment-46 to +66°C10 - 90% humidity non-condensingProtection class IP 30Dimensions (mm) 110 x 90 x 45Agency listing / complianceCE EN 55022 Class BLED9 active LED for: Transmit, receive, Ethernet link, power OK,bridge running, configuration error, node offline, comm error,system errorSoftwareSoftware and driver compatibility: BACnet TM (Ethernet or IP)MODBUS RTUBuilding Management Systems39PROD-PRC013-E4

PICDescriptionGateway for converting Trane proprietary protocols to MODBUS/RTU, or between Trane equipmentLonTalk controllers and MODBUS/RTU.Customer benefits• Easy commissioning: auto commissioning / auto binding supported• Flexibility: compatible with all Trane equipment• Easy operation and diagnosis: terminal port + status light indicatorsI/O FeaturesSupported signal typeConnection1 IEA-2321 EIA-485Main featuresPower230 Vac, 50/60 Hz, 1phaseOperating environment0 to +60°C10 - 90% humidity non condensingStorage environment-46 to +66°C10 - 90% humidity non condensingProtection class IP 30Agency listing / complianceCE 89/336/EECLEDActive LED for : Transmit , receive, power OK,configuration error, comm error, system error.SoftwareMODBUS RTU, slave mode1200 to 57600 bps40PROD-PRC013-E4

BMS Software: Tracer Summit V16DescriptionHuman interface between building manager and control system. Integrates graphical browsing ofthe application, user friendly interface for scheduling, reporting, alarms tracking and forwarding.Customer benefits• User friendliness: reduced training need• Reduced commissioning time: advanced LonTalk® capability allowing easy integration of nonTrane devices• Efficient building operation: auto reportingI/O characteristics NumberOperating system Windows 95b, 95c, 98, 98SE, ME, NT4.0, 2000, XPHardware requirement Windows 95b, 95c, 98, 98SE, ME Processor 233 MHz 64 MB RAM300 MB hard drive free space32x CDROM15" SVGA display, 800x600 resolution minimumHardware requirement Windows XP, Processor 233 MHz 64 MB RAMWindows 2000,300 MB hard drive free spaceWindows NT4.0 (> SP3.0)32x CDROM15" SVGA display, 800x600 resolution minimumCommunication BACnet TM BACnet TM ASHRAE/ANSI 135 standard10BASE-T/ 100BASE-TX dedicated Ethernet orTCP/IP compatible networkCommunication LonTalk® Based on EIA-709.1 LonTalk® standardLonTalk® Standard Network Variable TypesFTT-10A transceiversTwisted-pair physical mediaCommunication MODBUS Tracer Summit communicates with devices that support theMODBUS Remote Terminal Unit (RTU) protocol using theField ServerBuilding Management Systems Products41PROD-PRC013-E4