BETE Nozzles for Fire Protection - BETE Fog Nozzle, Inc.

BETE Nozzles for Fire Protection - BETE Fog Nozzle, Inc.

BETE Nozzles for Fire Protection - BETE Fog Nozzle, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>BETE</strong> <strong>Fire</strong> <strong>Protection</strong> <strong>Nozzle</strong> ExperienceWater DelugeA customer was designing awater deluge system to protect an11' x 40' x 8' high chemical tank.They needed complete coveragefrom 2 headers running parallelto the 40' long side.<strong>BETE</strong> Applications Engineersprovided several spraytrajectories and the N serieswas recommended because itoffered the proper combination ofcoverage and droplet size, as wellas industry approvals, such asFactory Mutual and UL.<strong>BETE</strong> N series fire protectionnozzles are recognized acrossthe petroleum and chemicalprocessing industries as thefirst choice in dry, fixed firesuppression systems. <strong>BETE</strong> Nseries nozzles are used routinelyin dry fire protection systemsprotecting offshore drilling rigs,LPG tanks, and LNG tanks, aswell as other types of vesselscontaining flammable liquids.Marine<strong>BETE</strong> N series nozzles are FactoryMutual and Lloyd’s Registerapproved <strong>for</strong> fire protection, arequirement <strong>for</strong> operation outof U.S. ports. These nozzlesare used on ships with watersystems, often replacing olderCO 2 based systems.N series nozzles are also usedto protect outdoor escape routesonboard tankers and offshoreoil-drilling plat<strong>for</strong>ms. Predictedspray patterns and trajectoriesprovide estimated nozzlecoverage under various windconditions. Using this data, ourcustomers are able to determineTunnel <strong>Fire</strong> <strong>Protection</strong><strong>BETE</strong> Applications Engineerssupplied spray pattern trajectorydata <strong>for</strong> the fire suppression systemin the 1.8 mile long BurnleyHighway Tunnel in Melbourne,Australia. The data includeddifferent wind velocities toensure that the nozzles specifiedthe correct nozzle mountinglocations.<strong>BETE</strong> has supplied “Deck Edge”nozzles <strong>for</strong> U.S. Navy applications.The 3/4" NF300-80X and the3/4" NF300-80 have been used inspraying Aqueous Film FormingFoam on the decks of aircraftcarriers.The 1/ 2" TF29-180 was developed<strong>for</strong> Navy magazine sprinklingon ships; it meets MilitarySpecification MIL-S-24660 (SH).The 180° full cone pattern reducesthe vertical clearance requiredbetween sprinklers and ordinancefrom 18" to 4".would offer sufficient coverageover a number of different windvelocities in the tunnel to controla fire. The system uses a combinationof <strong>BETE</strong> N7W and N8Wnozzles constructed in type 316stainless steel.Requirements <strong>for</strong> thermalradiation screening <strong>for</strong> personnelprotection on ships have been metmost effectively with the TF170or TF150 series nozzles. The TFnozzles provide better absorptionof thermal energy and dissipatesthe heat and energy from the fire.The multiple concentric conesprovide a barrier to air reenteringthe fire while also minimizingspray wind drift.In March of 2007, a serious autoaccident occurred that resulted ina fire in the tunnel. The sprinklersystem was activated and <strong>BETE</strong>N series nozzles succeeded incontrolling the fire.Water WallA customer was developing anew water wall protection systemon an oil rig to protect equipmentand personnel from the extremeheat generated by the naturalgas flare. The current systemconsisted of a few nozzles on theflare boom, but was inadequate<strong>for</strong> the amount of heat generated.<strong>BETE</strong> Applications Engineerssuggested a wide angle spiralwould be appropriate, specifically,the N5W to match thespecified flow rate. To confirmspacing, <strong>BETE</strong> modeling softwarewas used to determine spraycoverage trajectories from eachnozzle when sprayed horizontallyoutward. These trajectoriesprovided the customer theconfidence that the new designwould be more than sufficientto protect the rig.

<strong>BETE</strong>...high per<strong>for</strong>mance nozzles<strong>for</strong> fire protection systems.<strong>Fire</strong> <strong>Protection</strong> <strong>Nozzle</strong> Experience:Since its inception in 1950, <strong>BETE</strong> <strong>Fog</strong> <strong>Nozzle</strong>, <strong>Inc</strong>. hasbeen recognized as an expert in the fire protectionindustry. <strong>BETE</strong>’s high-per<strong>for</strong>mance nozzles continue tobe the premier choice <strong>for</strong> offshore drilling and productionplat<strong>for</strong>ms; petroleum storage and transfer stations;LNG tanks; and in a wide variety of industrial andcommercial applications.Product Per<strong>for</strong>mance:<strong>BETE</strong>’s wide range of fire protection nozzles meet industryapprovals - U.S. Coast Guard, Factory Mutual System,Underwriters Laboratories and Lloyd’s Register - and areconsidered to be the standard <strong>for</strong> critical spraying applications.We take advantage of the latest developments in materialstechnology and continue to work with companies to createthe most efficient fire protection nozzles.U.S. Coast GuardApprovedEngineering Expertise:Our proven success is a result of our ability to find creativesolutions to difficult spraying challenges. <strong>BETE</strong> ApplicationsEngineers can apply their years of expertise to recommenda nozzle design to deliver the specific spray per<strong>for</strong>mancenecessary <strong>for</strong> your fire protection requirements. Our state-ofthe-artspray laboratory is designed to provide a wide range oftesting capabilities to accommodate emerging industry trends.

<strong>BETE</strong> Product Per<strong>for</strong>manceWater Wall – Water is used as a barrierto shield against radiant heat, harmfulgases, and flames to provide protection <strong>for</strong>personnel and equipment.<strong><strong>Nozzle</strong>s</strong>: TF150/170, N, FF, NFTF150/170 – spiral nozzles with high flowrates, wide coverage in close proximity,multiple concentric cones; more effectivethan a fanN – spiral with narrower angles than theTF150/170; regulatory approvals <strong>for</strong> fireprotection applicationsFF – provides a wide, single sheet spraywith a 145°angle. Less effective coolingand barrier protection than spiral-type (TF,N) nozzlesNF – greater choice of angles than FF (15°up to 120°)Water Deluge – There are two generalcategories <strong>for</strong> water deluge fire protectionsystems.1 Direct Extinguish - Large quantities ofwater are sprayed over the flames to controlthe blaze and extinguish the fire.2 Cooling - Water is sprayed onto the exteriorsurface of vessels that are underpressure and/or contain volatile materials,cooling the vessel and preventing explosion.<strong><strong>Nozzle</strong>s</strong>: N, MaxiPass, TFXP, TF150, TFXPW, FFN, TFXP, TF150, TFXPW – all spirals providea spectrum of drop sizes with concentricrings of larger droplet, high momentumspray containing fine droplets between therings. The high momentum, large droprings punch through the flame while thesmaller drops vaporize quickly, combiningmaximum flame penetration and heattransfer. This multiple cone strategy minimizeswind drift and prevents oxygenfrom reentering the spray areaN – spiral nozzle with advantages listedabove plus tighter tolerances to meet insuranceapprovals. Protective blow-off coversavailableMaxiPass – used when coverage diameteris more important than atomization andheadroom is adequate. The MaxiPass produceslarger droplets than an equivalentflow rate spiral causing improved wind resistance.High-pressure operation narrowsthe spray angle <strong>for</strong> greater penetration andresistance to crosswindsTFXP – spiral nozzle with advantages listedabove but with maximum free passageFF – used <strong>for</strong> surface or equipment protectionwhen relying on rundown <strong>for</strong> protectionis acceptableMarine – Marine applications includedeluge, foam, and water wall systemswhere the nozzles are subject to extremeweather conditions and exposure toseawater.<strong><strong>Nozzle</strong>s</strong>: TF29-180, SRWM, in addition towater wall and water deluge nozzlesTF29-180 – very wide coverage <strong>for</strong> limitedheadspace areas (such as storage rooms onships)SRWM – pop-up operation <strong>for</strong> deck cooling/protection/decontamination;usedwhere a permanently exposed nozzlewould be an obstructionHalon Replacement – Professionalsare turning to fine water mist systems inlieu of environment-damaging Halon systems.Exceptionally fine water droplets aresprayed over the fire where they evaporateand displace the oxygen, extinguishingthe fire. The low volume flow and highevaporation rate minimize water damageto sensitive equipment.<strong><strong>Nozzle</strong>s</strong>: MicroWhirl, L, PJ, P, MicroWhirl HeadMicroWhirl - high-pressure nozzle producingvery low flow, extremely fine, mistingprotectionP, PJ – higher flows than the MicroWhirl;produces a very fine mist by means of anexternal impingement pinL - higher flows than the PJ with fineatomizationMicroWhirl Head – standard, stockmanifold <strong>for</strong> up to seven (7) individualMicroWhirl nozzlesFoam – The nozzles are used to spraylow-expansion foam, such as AFFF, ontoship decks and in smaller enclosed areas tohelp subdue the fire.<strong><strong>Nozzle</strong>s</strong>: TF, N, NF, NFXTF, N – spiral nozzles are placed so that thespray is perpendicular to the surface to becoveredNF, NFX – flat fan nozzles are oriented tospray parallel and very close to the surfaceto be protectedTunnel <strong>Fire</strong> <strong>Protection</strong> – A welldesignedfixed fire suppression system ina traffic tunnel protects against loss ofhuman life and minimizes structural damagein the case of a fire or explosion. Spiralnozzles can be more effective than traditionalsprinkler systems due to higherflame penetration by the multiple cones.<strong><strong>Nozzle</strong>s</strong>: N, TFXP, TF150, TFXPWN, TFXP, TF150, TFXPW – all spirals providea spectrum of drop sizes with concentricrings of larger droplet, high momentumspray containing fine droplets between therings. The high momentum, large droprings punch through the flame while thesmaller drops vaporize quickly, combiningmaximum flame penetration and heattransfer. This multiple cone strategy minimizeswind drift and prevents oxygenfrom reentering the spray areaN – spiral nozzle with advantages listedabove plus tighter tolerances to meetinsurance approvals. Protective blow-offcovers availableTFXP – spiral nozzle with advantages listedabove but with maximum free passageWater Mist – Water mist systems usea finely atomized, low flow water sprayto extinguish fire. They are ideal <strong>for</strong>protecting assets that would otherwisebe destroyed by water damage in delugesystems.<strong><strong>Nozzle</strong>s</strong>: MicroWhirl, L, PJ, P, MicroWhirl HeadMicroWhirl - high-pressure nozzle producingvery low flow, extremely fine, mistingprotectionP, PJ – higher flows than the MicroWhirl;produces a very fine mist by means of anexternal impingement pinL - higher flows than the PJ with fineatomizationMicroWhirl Head – standard, stock manifold<strong>for</strong> up to (7) individual MicroWhirlnozzlesToxic Gas Mitigation – Water spraysystems are used to remove water soluble,toxic gases from the air in the event of anaccidental leak. These systems prevent thespread of hazardous vapor clouds. <strong>BETE</strong>TF16FCN and TF20FCN nozzles werechosen <strong>for</strong> mitigation systems of accidentalreleases of hydrofluoric acid (HF) by theIndustry Cooperative Hydrogen FluorideMitigation Assessment Program.<strong><strong>Nozzle</strong>s</strong>: TF, TFXP, NTF/TFXP - finer spray nozzles with standardflow rates; good <strong>for</strong> scrubbing chemicalsN - spiral nozzle with advantages listedabove plus tighter tolerances to meetinsurance approvals. Protective blow-offcovers availableDust explosion protection – Waterspray systems are used to prevent explosivecombustion triggered by dust buildup or static electricity in storage tanks andtransfer conveyors <strong>for</strong> items such as coaland grain.<strong><strong>Nozzle</strong>s</strong>: MicroWhirl, L, PJ, TF, SRWMMicroWhirl, L, and PJ – fine mist with nowetting. <strong>Inc</strong>reases humidity and lowersstatic discharge riskTF – adding enough moisture to prevent/knock down dustSRWM – installs flush to the vessel walland extends when activated; used inextremely dirty or dangerous areas wherean exposed nozzle would be destroyed

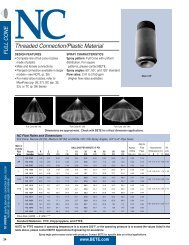

<strong>BETE</strong> Product SpecificationsNSpray Characteristics• Two spray cones—an outer, wide anglecone and a narrower inner cone—combineto give full cone effect• Fine atomizationSpray Patterns: Full ConeSpray angles: 90° and 120° standardFlow rates: 3.0 to 534 gpm (9.67 to 1720L/min) Full Cone 90°TF29 – 180Spray Characteristics• Wide spray coverage• Fine atomizationSpray Patterns: Circular sheet with maximumcoverage and excellent atomizationSpray Angles: 180° extra-wide angleFull Cone 180°MicroWhirl /MWHSpray Characteristics• Mist at low pressure; fog at high pressureSpray pattern: Cone-shaped <strong>Fog</strong>Flow rates: 0.009 to 0.151 gpm (0.032 to0.517 L/min) per nozzleFull Cone 120°MicroWhirlMWH - manifold of 7<strong>Fog</strong>TFXPSpray Characteristics• Wide range of flow rates• Fine atomization • Clog resistantSpray Patterns: Full Cone (Hollow Coneavailable by special order)Spray Angles: 90° and 120°Flow rates: 3.0 to 3320 gpm (9.67 to 10700L/min)Full Cone 90° (XPN)TF 150/170Spray Characteristics• Wide spray angles• Fine atomizationSpray Patterns: Full Cone and Hollow ConeSpray Angles: 50° to 180°Flow rates: 0.5 to 3320 gpm (2.26 to 10700L/min) (Higher flow rates available)Full Cone 150/170°PJSpray Characteristics• Finest mist of any direct pressure nozzle• Produces high percentage of dropletsunder 50 micronsSpray pattern: Cone-shaped <strong>Fog</strong>Spray angles: 90°. For best 90° pattern, operatenozzle at or above 60 psi (4 bar)Flow rates: 0.013 to 1.4 gpm (0.043 to5.34 L/min)<strong>Fog</strong>Full Cone 120° (XP)TFXPWSpray Characteristics• Wide coverage• Fine atomizationSpray Patterns: Full ConeSpray Angles: 150°Flow rates: 33.6 to 534 gpm (181 to 1720L/min)Full Cone 150°LSpray Characteristics• High flow misting per<strong>for</strong>mance atlow pressureSpray Pattern: Hollow Cone <strong>Fog</strong>, nearly asfine as P seriesSpray Angles: 90° standard (120° by specialorder)Flow rates: 0.14 to 3.84 gpm (0.534 to14.7 L/min)<strong>Fog</strong>PSpray Characteristics• Finest mist of any direct pressure nozzle• Produces high percentage of dropletsin the 25-400 micron range; ideal <strong>for</strong>dust suppressionSpray pattern: Cone-shaped <strong>Fog</strong>Spray angles: 90°. For best 90° pattern, operatenozzle at or above 60 psi (4 bar)Flow rates: 0.034 to 7.68 gpm (0.153 to 30.3L/min)<strong>Fog</strong>

<strong>BETE</strong> Product Certifications<strong>BETE</strong> N series nozzles are the onlyspiral design nozzles in the industrythat are U.S. Coast Guard andFactory Mutual approved.All N series nozzles are alsoUnderwriters Laboratories andLloyd’s Register approved. Theseindependent agency approvalsare recognized worldwide by lossprevention system designers as importantcriteria <strong>for</strong> selectingnozzles that con<strong>for</strong>m to stringentinstallation and per<strong>for</strong>mancestandards.MaxiPass (MP)Spray Characteristics• High reliability spray per<strong>for</strong>mance underthe most difficult conditionsSpray pattern: Full Cone* (Square patternsto special order)Spray Angles: 30°, 60°, 90° and 120°Flow rates: 0.7 to 978 gpm (2.6 to 3540L/min). Flow rates up to 4500 gpm (17,000L/min) available.Full Cone 90° (M)SRWMU.S. Coast GuardApprovedSelf-retracting Wall MountSpray Characteristics• Relatively large free passage• Self-draining• Pops up to spray when activatedSpray Pattern: Flat circular sheet with maximumcoverage and excellent atomizationSpray Angle: 180° extra wide coverageHollow Cone 180°The entire N series is certified<strong>for</strong> use on ships and offshoreinstallations by Lloyd’s Registerand complies with the InternationalConvention <strong>for</strong> the Safety of Life atSea (SOLAS). The N3, N4, N5,N3W, N4W, and N5W models arealso approved by the U.S. CoastGuard <strong>for</strong> tank vessel pumprooms. The <strong>BETE</strong> N9 nozzle isdesigned to meet FM requirements<strong>for</strong> use in fixed deluge installationsprotecting industrial trans<strong>for</strong>mers.The N6 with dust cover option isalso Factory Mutual approved. Theentire N series has UL approval inboth stainless steel (ASTM A743)& brass (ASTM B30).The TF24-150 nozzle is FactoryMutual approved. This wide sprayangle design provides maximumcoverage in low clearance installations.The TF29-180 series wasdeveloped by <strong>BETE</strong> <strong>for</strong> Naval SeaSystems Command to con<strong>for</strong>m toMilitary Specification MIL-S-24660(SH), <strong>for</strong> fire protectionwithin tight quarters of denselypacked ship-board magazines.FFSpray Characteristics• Extra-wide 145° spray angle• Medium-impact spray• Spray discharge deflected 75° from inlet axis• Coarse atomizationSpray Pattern: Flat FanSpray Angles: 105° to 145°Flow rates: 0.014 to 235 gpm (0.510 to 757L/min)Fan 145°NFSpray Characteristics• High impact• Uni<strong>for</strong>m distribution with tapered edges<strong>for</strong> overlapping spraysSpray pattern: Fan and Straight JetSpray angles: 0° to 120°Flow rates: 0.103 to 1380 gpm (0.161 to3430 L/min)Fan 50°Other UL approved nozzles arethe 3/8” FF 145° fan and theNCM1012 K-30° full cone (NCKseries) in Brass (ASTM B30).The 3/8” FF 187 is also FactoryMutual approved.■ Spiral ■ Misting ■ Whirl ■ Fan ■ Special Purpose

<strong>BETE</strong> Engineering Expertise<strong>BETE</strong> ENGINEERINGAt <strong>BETE</strong> <strong>Fog</strong> <strong>Nozzle</strong>, <strong>Inc</strong>., oursuccess has always been focusedon understanding our customers’business and providing effectiveengineered solutions to their mostdifficult fluid process challenges.With more than 55 years of experiencedesigning and fabricatingspray nozzles, <strong>BETE</strong> has theengineering expertise customerscan count on.<strong>BETE</strong> Applications Engineersuse their expertise to assist fireprotection system designersselect the best nozzle <strong>for</strong> theirapplication. Our experiencedApplications Engineers are readyto analyze your conditions of supplyflow rate, operating pressure,nozzle orientation, wind drift,spray coverage, and spray density.<strong>BETE</strong> has developed proprietarysoftware models to provideestimates of critical nozzle per<strong>for</strong>mancedata like spray coveragetrajectories. This software, basedon our years of experience withspray nozzles, allows us toestimate spray coverage <strong>for</strong>various wind speeds, directionsand nozzle orientations.Spray Coverage Trajectories<strong>BETE</strong> SPRAY LABORATORYThe <strong>BETE</strong> Spray Laboratory isequipped to provide spray testdata <strong>for</strong> a wide range of nozzlesover an array of operating conditions.Our state of the art spraylaboratory is used to test nozzleper<strong>for</strong>mance characteristics likespray pattern, coverage, sprayangle and drop size distribution.Customers have also used ourspray laboratory and nozzleexpertise <strong>for</strong> special test programs.Whether you're working on anew application or a systemmodification, <strong>BETE</strong> spray testingexpertise can provide an effectivesolution.THE <strong>BETE</strong> DIFFERENCE<strong>BETE</strong>’s mission goes beyondjust selling spray nozzles: it isto provide engineered sprayingsolutions that exceed customerexpectations in every detail.Extensive in-house capabilities,including integrated 3DCAD/CAM design, rapidprototyping, investment casting,CNC machining, welded fabrication,and spray testing, make itpossible to offer the highest levelof quality throughout every phaseof production.The <strong>BETE</strong> Difference is ourunparalleled ability to respondquickly and effectively to anykind of spraying challengeanywhere in the world with themost knowledgeable customerservice in the industry.Ask <strong>BETE</strong>. We know <strong>Fire</strong><strong>Protection</strong> <strong><strong>Nozzle</strong>s</strong>.Our success in fire protectionis built on our ability to carefullyengineer our nozzle designsto deliver the specific sprayper<strong>for</strong>mance required by firesuppression system designers toefficiently suppress and extinguishmany different types of fires.Call <strong>BETE</strong> and put our years ofexperience to work to selectthe best spray nozzle <strong>for</strong> yourfire protection needs.<strong>BETE</strong> <strong>Fog</strong> <strong>Nozzle</strong>,<strong>Inc</strong>.Comparison of spray wind resistance <strong>for</strong> the <strong>BETE</strong> N6 and N9 Deluge <strong><strong>Nozzle</strong>s</strong>.Operating Pressure 60 psi, spraying downward,modeled in 10 & 20 mph crosswindN6 DV0.9 = 990 microns N9 DV0.9 = 1411 microns50 Greenfield St.Greenfield, MA 01301T (413) 772-0846F (413) 772-6729www.bete.comPERFORMANCE THROUGH ENGINEERING

Since 1950, <strong>BETE</strong>’s per<strong>for</strong>mancein designing innovative spraynozzles has earned us anenviable reputation as a worldleader through its engineeringand manufacturing capabilities.<strong>BETE</strong> makes over 20,000 differentnozzles and over 60% of the spraynozzles shipped are customizedsolutions to solve the needsof our customers’ sprayingsystem challenges.<strong>BETE</strong> is the only nozzle manufacturerwith a complete in-house investmentcasting foundry, allowing <strong>for</strong> preciseand economical ways to producecomplex shapes in alloys that aredifficult or too expensive to machine.In addition, <strong>BETE</strong> offers manyspecialized processes such as customwelded fabrication, plasma spraycoating, plating, heat treating,grinding, ceramic fabrication andfilament winding of FRP.<strong>BETE</strong>’s advanced CIM (ComputerIntegrated Manufacturing)environment links CAD workstations,a CAM part programming systemand CNC machine tools. This makesit possible to manufacture any oneof thousands of products within ashort time, while providing reliabledelivery <strong>for</strong>ecasts.www.bete.com<strong>BETE</strong> <strong>Fog</strong> <strong>Nozzle</strong>,<strong>Inc</strong>.PERFORMANCETHROUGH ENGINEERING50 Greenfield StreetGreenfield, MA 01301T (413) 772-0846 F (413) 772-6729Email: sales@bete.comwww.bete.comManual No. 105.1FF0608 2.5K©2008 <strong>BETE</strong> <strong>Fog</strong> <strong>Nozzle</strong>, <strong>Inc</strong>. All rights reserved.In 2003, <strong>BETE</strong> <strong>Fog</strong> <strong>Nozzle</strong>, <strong>Inc</strong>. became the first spray nozzlecompany in the world with a quality management systemadhering to the demanding ISO 9001:2000 standard.