Annual report 2010 - Aquafin

Annual report 2010 - Aquafin

Annual report 2010 - Aquafin

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Green light for clear water<strong>Annual</strong> <strong>report</strong><strong>2010</strong>An integral vision on water treatment

<strong>Annual</strong> <strong>report</strong><strong>2010</strong>An integral vision on water treatment

2<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>Content12Report of the boardof directors on thefinancial year <strong>2010</strong>4<strong>Aquafin</strong> in brief8Foreword52Socially responsibleentrepreneurship70<strong>Annual</strong> acount

4<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>

<strong>Aquafin</strong>in briefA STRONG PARTNER FOR THE FLEMISHREGION<strong>Aquafin</strong> was established by the Flemish Region in 1990,for the purpose of expanding, operating and pre-financing thewastewater treatment infrastructure in Flanders.<strong>Aquafin</strong> collects household wastewater from the municipalsewers in collector sewers and transports it to wastewatertreatment plants, where it is treated in accordance withEuropean and Flemish standards.The costs of the infrastructure works that were carried out,and <strong>Aquafin</strong>’s operating costs, are passed on to the consumerof tap water via the water companies. By doing this,the Flemish Region is following the ‘polluter pays’ principle,which is encouraged by Europe. The balance is paid to thewater companies by means of an operating subsidy fromthe Minafonds.<strong>Aquafin</strong> stands for good management of the wastewatertreatment infrastructure and a strong capacity for innovation.This means that the methodologies of <strong>Aquafin</strong> are at thefoundation of the area-wide implementation plans, which clearlyindicate on which municipal terrain, what infrastructureand when will be provided by the Flemish Region or by themunicipality. Due to the know-how that it has built up overthe years, <strong>Aquafin</strong> is also a much sought after partner inresearch projects, both in Belgium and abroad, which areaimed at implementing the European Water frameworkdirective. The knowledge that <strong>Aquafin</strong> acquires in this wayis for the benefit of the Flemish Regionand the municipalities.5

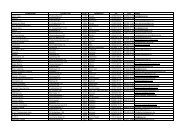

6<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>n Infrastructure under managementnFor industry in Flanders and foreign partnersAt the end of <strong>2010</strong>, <strong>Aquafin</strong> was responsible for theoperation of 247 wastewater treatment plants. To transportthe wastewater to the treatment plants, <strong>Aquafin</strong> wasresponsible for the management of 4,735 km of regionalcollector sewers. That is an increase of 113 km compared with2009. Since its establishment <strong>Aquafin</strong> has laid 3,555 km ofsewers. The remaining 1,180 km of sewer infrastructure wastaken over. <strong>Aquafin</strong> manages 1,174 regional pumping stationsand storage basins, of which 956 pumping stations wereconstructed by the company itself.PRODUCTS AND SERVICES OUTSIDE OFTHE AGREEMENT WITH THE FLEMISH REGION<strong>Aquafin</strong>’s subsidiary, Aquaplus NV, focuses domestically onthe requirements made on industry to comply with applicableEuropean directives. The company primarily carries outconsulting, design, building and operation assignments.On international markets, Aquaplus participates as aconsultant in open international tendering procedures. In mostinstances, the company acts as a sub-contractor. The focuslies on the new member states of the European Union, includingassignments for the European Commission, for nationalgovernments, cities, municipalities and utility companies,covering all of the stages of the wastewater treatment cycle.Outside of Europe, <strong>Aquafin</strong> is mainly active in the Middle Eastand in China.nFor Flemish municipalities<strong>Aquafin</strong> provides services for the expansion and managementof the municipal sewage system. A city or municipality maychoose to have a long-term partnership by means of aconcession, or it can allocate ad-hoc tasks to <strong>Aquafin</strong>.Besides this there is the possibility of joining in with the jointventures that <strong>Aquafin</strong> has concluded with the water companiesAWW and TMVW (rio-link), VMW (RioAct and RioP) and Vivaqua.CORE FIGURESAmounts in 000 euro 2006 2007 2008 2009 <strong>2010</strong>Operating income 289,539 324,730 326,340 352,047 362,540Profit for appropriation 11,917 10,339 6,289 6,531 7,084Balance sheet total 2,330,447 2,398,467 2,280,359 2,429,354 2,671,015Equity capital 116,071 166,592 169,908 170,230 216,561Short-term financing 217,270 204,800 82,994 30,500 140,600Long-term financing 1,331,128 1,269,125 1,192,967 1,303,608 1,355,481Number of <strong>Aquafin</strong> employees 737 777 820 854 882Number of VMM employees 105 98 95 92 89Total number of employees 842 875 915 946 971PROJECTS IN PORTFOLIO FOR THE FLEMISH REGIONNo. of projectsValue (million euros)Delivered 2,153 2,817.13Awarded and contracted out 294 384.65In design phase 1,077 1,074.67Total 3,524 4,276.44

Mission<strong>Aquafin</strong> develops and implementseffective solutions that provide cleanerwatercourses and sustainable water(re)use. We respond pro-actively toexpected developments in the watersector. As a result, and in a closerelationship with our customers,we bring a customised realisation ofEuropean objectives nearer every day.<strong>Aquafin</strong> in brief7

8<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>ForewordAN INTEGRAL VISION ON WATER TREATMENTIn recent years, <strong>Aquafin</strong> has become strongly rooted inthe water sector. Our knowledge of the development andmanagement of the treatment infrastructure, combined withour insight into the working of sewerage systems make <strong>Aquafin</strong>unique in Flanders. This strength has been acknowledged bythe region, the municipalities and the drinking water companies.The Flemish Government has provided a budget of€150 million for each of the five most recent programmes forthe development and optimisation of the supramunicipalwastewater treatment infrastructure. The last threeprogrammes received an additional €100 million for theimplementation of municipal works that the region hasundertaken within the framework of the Local Pact. This activeassignment portfolio of investment projects demonstratesthe trust that the Flemish Region has in <strong>Aquafin</strong>. At the endof <strong>2010</strong>, the portfolio contained over €1.4 billion for 1,371 projects,the highest amount ever.For the implementation of the European Urban Waste -water directive, wastewater from all conurbations in Flandersmust be treated in accordance with the applying standardsas quickly as possible. 99% of the projects that the regionassigned to <strong>Aquafin</strong> for this purpose have since beencompleted. The projects that the company is currentlyimplementing for the region fall within the implementation ofthe Water framework directive, which requires high-qualitysurface and ground water by 2015.

10<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>Replacement investments have also moved to theforeground in the meantime. Part of the collection andtreatment infrastructure in Flanders dates from long before<strong>Aquafin</strong> was founded. In order to continue pre-financing allthese investments for the region, a good relationship withthe banking world is crucial. Despite the difficult economiccircumstances in recent years, <strong>Aquafin</strong> continues to enjoythe trust of the banks.More synergies are being formed within the water sector,which contribute to implementing the integral water policy ofthe Flemish authorities. <strong>Aquafin</strong> collaborates intensively withvarious Flemish drinking water companies to implementmunicipal projects. In <strong>2010</strong>, <strong>Aquafin</strong> became a partner of RioP,a collaboration between the Flemish Water Supply Company(VMW) and <strong>Aquafin</strong>. This is a follow-up to RioAct, which wasinitiated by both parties in 2006. Last March, <strong>Aquafin</strong> joinedrio-link NV, the sanitation division of water-link cbva,established by drinking water companies AWW and TMVW.This new collaboration has enabled three major players in thewater sector to bundle their forces in order to provide anefficient service to inhabitants and the Flemish municipalities.The knowhow that <strong>Aquafin</strong> has acquired the past twentyyears can provide even more benefits for the Flemish Region.With the support of the Flemish authorities, we wish tovalorise our knowledge and experience more intensively forcompanies both at home and abroad and throughassignments for foreign governments. We intend to expandour commercial activities further, without losing sight of ourmain assignment for the region.<strong>Aquafin</strong> is a confident company with a clear vision onthe future and enough flexibility to react to changingcircumstances. We are also well aware of the fact that acompany is made by the people who work in it. Our companyis in its present position thanks to the enthusiasm andcreativity of our employees. We are convinced that we canfulfil our ambitions for the future with the same élan.Luc BossynsManaging directorMarc van den AbeelenChairman

Foreword11

12<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>

Report of the boardof directors on thefinancial year <strong>2010</strong>following the applicable articlesof the Belgian Companies ActCorporate Governance Statement 14Report of the board of directors 23Most important developments during the financial year 24Expansion of the wastewater treatment infrastructure for the Flemish Region 29Construction activity per water basin in <strong>2010</strong> 32Management of the wastewater treatment infrastructure for the Flemish Region 36Services beyond the scope of the agreement with the Flemish Region 41Research and product development 43Major risk factors 45The most important evolutions after the close of the financial year 47Comments with regard to the balance sheet 48Commentary on the profit-and-loss statement 50Proposal to the General Meeting 5113

14<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>CorporateGovernanceStatementGENERAL<strong>Aquafin</strong>'s first corporate governance charter was approvedby the Board of Directors on 26 January 2006. That charter wasprepared in accordance with the provisions of the Belgiancorporate governance code of 9 December 2004. With thepromulgation of the new version of the code in March 2009and because of the issue of an obligation loan, the charter hadto be amended. On 14 January <strong>2010</strong>, the Board of Directorsapproved the new version of the charter. The most recent versionis available for review on the website (www.aquafin.be).

BOARD OF DIRECTORSnCompositionThe Board of Directors has been composed as shown in the table below since 3 August <strong>2010</strong>.Name Type of mandate / Independent / (non-) executive End of mandateVOF Thedes, represented by Marc van den Abeelen Chairman, independent, non-executive 2014Luc Bossyns Managing Director, executive 2014Alain Bernard Non-executive 2014Pol Cools Non-executive 2014Marijke Mahieu Independent, non-executive 2014VOF Materie, represented by Erik Matthijs Independent, non-executive 2014Francine Swiggers Non-executive 2014Jhony Van Steen Independent, non-executive 2014Ivo Van Vaerenbergh Non-executive 2014Flemish Environmental Holding Company NV Non-executive 2014(Vlaamse Milieuholding NV), represented by Matrix NV,represented by Roland Van DierdonckMr P. Cools no longer meets the criteria requirements for the status of an independent director. More information in thatregard is available in the description of the conflicts of interest - application of Section 523 of the Companies Code, further inthis statement.The Board of Directors is assisted by its secretary, Mr Alain Vanden Bon.Report of the board of directors15

16<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>nPresentation of the directorsMarc van den AbeelenMarc van den Abeelen has a doctor'sdegree in Law from the University ofBrussels. He became a professor of taxlaw and he was the Director-General ofthe High Diamond Council. He was amunicipal councillor in Aartselaar as of1976, an alderman from 1988 to 1993 andas of 1993 the mayor. Between 1995 and 2009, he was amember of parliament. From 1999 to 2004, he was thechairman of the Finance committee and from 2004 to 2009,chairman of the committee for Public Works, Mobility andEnergy of the Flemish parliament. In addition, he wasChairman of the Antwerp World Trade Centre. He becamethe Chairman of <strong>Aquafin</strong> in 2009.Luc BossynsLuc Bossyns holds a degree in CivilMarine Engineering from the University ofGhent. He was awarded a postgraduatediploma in Business Administration byUFSIA University (Antwerp). He began hisprofessional career with the Cockerill YardsHoboken in 1977. He subsequently workedfor CMB (head of the environmental construction division)and Boelwerf (technical director). From 1993 to 1995 he wasgeneral manager and director of Boelwerf Vlaanderen. He thenmoved to Stork MEC, where he was appointed managingdirector. From 1995 to 2006 he was also liquidator of allmedium-sized shipyards in Flanders. In addition, he has alsobeen the director of Bamboss BVBA since 1995 and, since 2003,a director of Etap NV. He was appointed managing director of<strong>Aquafin</strong> NV in May 2000.Alain BernardAlain Bernard studied Civil Engineeringand Civil Engineering Industrial Policy atthe University of Louvain. He started hiscareer at T.V. Zeezand with the expansionof the outer port of Zeebrugge. Between1982 and 1985 he worked as a projectmanager for NV Dredging International.He then was appointed as general manager at NV Hydro SoilServices. In 1990, he returned to work for NV DredgingInternational, initially as director of the Benelux division andfrom 1995 to 2006 as director-general. From 1997 to 2006 hewas also active as the chief operating officer of the D.E.M.E.Group (Dredging Environmental & Marine Engineering). In 2006,he was appointed as the Chief Executive Officer of D.E.M.E.Group and director of various subsidiary companies in theD.E.M.E. Group: DEC, C-POWER, Scaldis, GEOSEA… He has alsobeen chairman of the Belgian Dredging Federation since 2004.In 2007 he was appointed as a director of <strong>Aquafin</strong> NV.Pol CoolsPol Cools graduated from the Universityof Ghent as a Civil Engineer-Architect andEngineer in Environmental Sanitation.He started his career in 1972 with theBelgian Roads Fund, and in 1976 he wasan attaché to the personal office ofthe Minister of Public Works, Mr Defraigne.In 1977, he set up his own architect’s practice, initially asBureau ir Pol Cools, and from 1990 with the co-partnershipArch & Teco NV, of which he was a director. He expandedthe original architectural office into the Arch & Teco Group.That multidisciplinary study and consulting group compriseseight autonomous business units that were established byPol Cools between 1977 and 2005. Its activities include:architecture, restoration and spatial planning; stabilitystudies, civil engineering and hydraulic engineering; design ofgeneral infrastructure, road and sewer infrastructure projects;equipment techniques; energy performance calculation andcertificate; safety co-ordination and expertise, environmentaltechnologies; telecom networks and GIS projects; changemanagement; facility management; consulting; projectmanagement and coordination. Pol Cools expanded hisactivities at an international level as of 2005, with theestablishment of the joint venture Ase Structure Design PvtLtd in Chennai, India, of which he is a director. Since 2006,he has also been a member of the board of liquidators atBerlaymont NV 2000. He was appointed as a director of<strong>Aquafin</strong> in 2007.Marijke MahieuMarijke Mahieu holds a Licentiate inLaw from the University of Ghent.From 1975 to 1981 she worked as a lawyerin Ghent. Since 1981 she has worked as anofficial for the City of Ghent. Until 1995she worked in the legal department invarious posts. She was later promoted tothe position of manager of the Technical Services Department.In 1999 she became the director-manager of the Environmentand Nature Development Department, and in 2001 shebecame the acting director-general of the Economics,Environment and Public Health Department. Since 2003 shehas been head of the department of Work and Economy anda member of the management team of the City of Ghent.On the basis of her function, she is also a member of themanagement committee of the Innovation and IncubationCentre NV of the University of Ghent, a member of themanagement committee and a director of the NV De PuntGent, a member of the board of directors of VZW StartpuntGent, chairman of the Board of Directors of VZW Labeur Gentand a member of the board of directors of Max Mobiel Gent.She was appointed as a director of <strong>Aquafin</strong> NV in 2007.

Erik MatthijsErik Matthijs is a doctor in veterinarymedicine from the University of Ghent.He was a practising veterinarian untilOctober 1992. In 1986 he became thealderman responsible for finances in thecity of Eeklo. In October 1992, he wasco-opted as a senator in the NationalParliament. He sat in the Belgian Senate until June 1995.On 1 January 1995, he also became the mayor of the city ofEeklo, an office that he held until the end of December 2006.During that period he was also a member of the board ofDirectors of KAHOG (the Catholic University for healthcare) inGhent. In 1995 and 1999, he was directly elected as a member ofthe Flemish Parliament for the district Ghent-Eeklo. In June2004, he was once more elected as a member of the FlemishParliament, this time however for the province of East-Flanders.In the Senate, he was a member of the Education and ScienceCommission, and of the advisory committee for EuropeanAffairs. In the Flemish Parliament, he was a permanent memberof the Environment, Nature and Urban Planning Commissionfor more than 10 years. From 2004 until 2009, he was vicechairmanof the General Policy, Finances and BudgetingCommission of the Flemish Parliament. He is the co-author ofthe innovative land reclamation decree, and, at the end of 2004,he also participated in the reorganisation of the water sectorin Flanders. In May 2009, he was appointed as a director of<strong>Aquafin</strong> NV and as the chairman of the Audit Committee.Francine SwiggersFrancine Swiggers holds a licentiate inApplied Economics and a Master ofBusiness Administration from the CatholicUniversity of Louvain. Her professionalcareer started with the National Fund forScientific Research. In 1977 she moved toBacob Bank. Since 1997, she has been activewith the ARCO Group, where she is responsible for the followupof the financial participations. She was appointed chairmanof the management committee in 2007. In addition to severaldirectors’ mandates in the financing companies of the ARCOGroup, she also sits on the board of directors of Dexia SA,Dexia Bank Belgium, Dexia Crédit Local (France), VDK and isChairman of Procura VZW. She was appointed as a director of<strong>Aquafin</strong> in 1998.Roland Van DierdonckProf. Dr. Roland Van Dierdonck holdsa Civil Mechanical & ElectrotechnicalEngineering degree from the Universityof Ghent and a Ph.D. in BusinessAdministration from Harvard University.From 1978 to 1980 he lectured at IMD inLausanne. In 1980 he returned to Belgiumto teach at the University of Ghent. From 1987 to 1990 andfrom 1996 to 1998 he was chairman of the School forManagement of the University of Ghent. In the period1985-1992, he was visiting professor at Insead, Ecole Nationaldes Ponts et Chaussées in Paris and the University of NorthCarolina in Chapel Hill. From 1995 to 2001 he was guest lecturerat the Rotterdam School of Management of the ErasmusUniversity. From 1998 to 2007 he was dean of the independentVlerick Leuven Gent Management School. On 1 October 2007he became an emeritus professor of the University of Ghent.He was a member of the boards of directors of several profitand not-for-profit organisations. He has been associatedirector of the European Foundation for ManagementDevelopment since September <strong>2010</strong>. At this moment, he isthe Chairman of the Board of Directors of the VlaamseMilieuholding NV and member of the board of directors ofIndaver NV and <strong>Aquafin</strong> NV.Jhony Van SteenAfter completing his Economics studiesat the Free University of Brussels,Jhony Van Steen was employed by thatuniversity as a research assistant until1978. In 1978, he moved to the ASLK,where he was responsible for youth policyand introduced home banking in 1985.From 1989 to 1992, he was adviser, head of the cabinet, anddeputy head of cabinet at the PTT cabinet and the GovernmentAgencies cabinet. Between 1992 and 1993 he held the post ofexecutive director at ASLK Insurances. From January 1994 hewas Director Public and Social Profit Sector for Fortis. He helda variety of director’s mandates in insurance companies inBelgium and Luxembourg, including ES-finance, Belgacom,GIMV, PMV/ VPM, VIOM and the Dender schools group. He isstill active today in a variety of boards of directors in the publicand the social profit sector. He was appointed as a director of<strong>Aquafin</strong> NV in 2001 and is Chairman of the Appointments andRemuneration Committee.Report of the board of directors17

18<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>Ivo Van VaerenberghIvo Van Vaerenbergh holds degrees inCivil Mechanical Engineering and Environ -mental Sanitation from the University ofGhent. He has a postgraduate diploma inBusiness Management and a Master’s inBusiness Administration from the Universityof Louvain. He started his career within theservice departments of the Prime Minister with responsibilityfor Science Policy Programming. As operational director hewas responsible for the national R&D programmes Energy,Environment and Secondary Raw Materials. From 1979 to the90s he was the managing director of Metallo Chimique NV.He was the chairman of the board of directors of the StudyCentre for Nuclear Energy in Mol (1986-1989) and of theFlemish Environmental Holding (1994-2002). As an entrepreneur,he has been the chairman-managing director of the REM.B/Morssinkhof Hydraulics Group (Beerse, Rotterdam) since 1986and is a director of ENERGIUS NV, Thenergo NV and W-KrachtNV. He also holds director’s mandates on the boards of thefollowing companies/organisations: Reynaers Aluminium NV,Ziekenhuis Netwerk Antwerp vzw and Lanbokas and EdanBusiness Systems NV. He is also chairman of the board ofdirectors of Sustainable Energy Ventures (VMH). For twentyyears he was the chairman of the Voka-Kempen Chamberof Commerce, and he still chairs the Regional NuclearCoordination Cell (RNC). In 1995 he was appointed as a directorat <strong>Aquafin</strong> NV. Here he was the chairman of the board ofdirectors between 1999 and 2009.During <strong>2010</strong>, the Board of Directors met seven times.Until August, the board consisted of nine members. The boardof directors met in that composition four times. During onemeeting, all of the directors were present. One director wasabsent with reasons on two occasions. One meeting hadto be organised at short notice. Five directors attendedthat meeting, the other directors were validly represented.Since August, the board consists of ten members. In thecurrent composition, the board of directors has met threetimes. During two of those meetings, one director was absent.Seven directors attended the most recent meeting.nConflicts of interest - Application of Article 523 of theBelgian Companies ActDuring the meeting of 11 March <strong>2010</strong>, the meeting wasdue to decide on the matter of granting a disconnectionassignment to a Hydroscan Temporary Trading Association- Arch&Teco Networks - AB Infra-Asset, in which severalcompanies in which a director is a shareholder are members.Below follows a complete account of this part of the minutesof meeting of the above-mentioned meeting of the Boardof Directors."One director, Mr P. Cools, <strong>report</strong>s to the Board of Directors,with all members in attendance or represented, that a conflictof interests exists in this matter with regard to his person.He thereupon does not participate in the further discussion ofthis point of the agenda and leaves the meeting room.In accordance with the requirements of the law, the auditorwill be informed about this matter, and all necessary actionswill be taken for a correct <strong>report</strong>ing of this matter in the<strong>Annual</strong> Report.This conflict of interests consists of taking a decision,which represents a direct proprietary interest of this director.This proposal covers, after all, the possible granting of thisassignment to a Hydroscan Temporary Trading Association- Arch&Teco Netwerken - AB Infra-Asset (hereinafter: THV) inwhich several companies in which the director is a shareholderare members.nReport of activities and attendanceIn addition to exercising the competencies that are describedin the Charter, the Board of Directors gave considerationduring the past financial year to the further expansion of itsstrategic vision, the further setup and expansion of co-operativeassociations in the sector and the modification of themanagement contract with the Flemish Region.Mr L. Bossyns presented an overview of the order, which consistsof studies - in 14 lots and based on the capacity offered -concerning how the disconnection of the (rainwater drainage) ofconsumers can be done. This dossier was brought to the boardof directors because the total contract value is €3.5 million over aperiod of three years. For 13 of the 14 lots, the aforementionedTHV was the most favourable bidder at this time (contract value€2.5 million).He then reviewed the <strong>report</strong> of the tender briefly.

Conclusion: The board of directors approves the proposal ofgranting the order for 13 of the 14 lots to THV Hydroscan- Arch&Teco Netwerken - AB Infra - Asset (… ).Mr P. Cools then rejoined the meeting.The Compliance Officer <strong>report</strong>s that, in view of theagreement just granted, Mr P. Cools can no longer be designatedas an 'independent director'.”AUDIT COMMITTEEnCompositionnChairmanVOF Materie, represented by Erik MatthijsPol CoolsMarijke MahieuFrancine SwiggersFlemish Environmental Holding Company NV,represented by Matrix NV, represented byRoland Van Dierdonck (since 21 October <strong>2010</strong>)Report of activities and attendanceIn addition to the areas of activity that have beenspecifically assigned to the audit committee, attention hasalso been devoted to the memorandum of La CompagnieBenjamin de Rothschild concerning the interest analysis.The committee was also informed concerning the differencesbetween the bookkeeping rules according to the Belgianbookkeeping law and the rules of the IFRS. Those areas onwhich the conversion represents a substantial impact werediscussed at length. The committee also gave advice concerninga number of points with respect of the relationship withthe economic oversight authority.In <strong>2010</strong>, the Audit Committee met four times. The committeemet three times in the previous configuration. At one meeting,two members were absent; during the other meetings, allmembers of the committee were in attendance. In the newcomposition, the audit committee met once. One memberwas not in attendance at that meeting.APPOINTMENTS AND REMUNERATIONCOMMITTEEnnCompositionChairmanJhony Van SteenAlain BernardIvo Van VaerenberghReport of activities and attendanceIn addition to the normal areas of discussion related to theremuneration policy, extra-legal benefits, collective bargainingnegotiations and the formulation and evaluation of objectives,the committee advised the board of directors concerning theadjustment of the reorganisation resulting from the <strong>Aquafin</strong>strategic plan the management had proposed. The committeealso gave advice concerning the relationship with the economicoversight authority with respect to personnel matters.The Appointments and Remuneration Committee met fourtimes during the past financial year. All of the members werepresent at all of the meetings.MANAGEMENT COMMITTEEnCompositionManaging DirectorLuc BossynsOperations managerErik PoppeInfrastructure manager Dirk De WaeleCommercial manager Boudewijn Van De SteeneProcess Innovation and Danny BaetenInformation Systems managerReport of the board of directors19

20<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>IMPORTANT ELEMENTS OF THE EVALUATIONPROCESS OF THE BOARD OF DIRECTORS,THE COMMITTEES AND THE INDIVIDUALDIRECTORSThe members of the Board of Directors regularly evaluatethe operations of this corporate organ on the basis of size,composition and functioning. The current composition isevaluated against the desired composition. The relationshipand interaction with the Management Committee will also bereviewed. The Appointments and Remuneration Committeeprovides an analysis on this matter to the directors. For thepurpose of evaluating this interaction, the non-executivedirectors will meet at least once every year without theManaging Director being present.As part of the evaluation process by the Audit Committee,the following elements are assessed: internal regulations,composition and appointments, meetings, training of membersand funds available for such training, the whistleblowerprocedure and relations with the Board of Directors. An evaluationis also prepared of the responsibilities with regard to financial<strong>report</strong>ing of the company, internal control and risk managementsystems, as well as the internal and external audits.The Appointments and Remuneration Committee drawsup an evaluation of its own effectiveness and efficiency everytwo years. For this self-evaluation, an individual questionnaireis submitted to the members of the committee. The resultsof this will be discussed during a committee meeting andsubsequently submitted to the Board of Directors. An analysiswill also be made of the interaction between the ManagementCommittee and the Board of Directors. The committee alsogives advice concerning the performance of the individualdirectors, especially with a view to their eventual reappointmentand with special attention to an evaluation of the variouschairmen.REMUNERATION REPORTnNon-executive directorsThe General Meeting decided in 2005 to pay a fixed stipendper year, supplemented with a variable sum per meeting ofthe board or committees attended. These amounts areincreased by 20% for the Chairman of the Board of Directorsand for the chairmen of the various committees. If thedirectors carry out a task that is separate from their normaltasks as directors, compensation will be granted in accordancewith the decision of 2009. This is solely related to assignmentsgiven from time to time to individual directors by the boardof directors or the management committee. The stipends arecharged against general costs.NameTotal amount receivedMarc van den Abeelen (C) (to 20/04/<strong>2010</strong>) € 10,637.45VOF Thedes, represented by € 26,262.54Marc van den Abeelen (from 20/04/<strong>2010</strong>) (C)Alain Bernard € 11,412.38Pol Cools € 12,786.10Marijke Mahieu € 12,469.09Erik Matthijs (C) (to 20/04/<strong>2010</strong>) € 5,652.19VOF Materie, represented by € 11,561.49Eric Matthijs (from 20/04/<strong>2010</strong>) (C)Francine Swiggers € 11,095.37Jhony Van Steen (C) € 14,677.60Ivo Van Vaerenbergh € 13,472.96Flemish Environmental Holding Company NV € 4,455.76(VMH NV), represented by Matrix NV,represented by Roland Van Dierdonck((C) = Chairman)nUitvoerend bestuurderThe total gross compensation that was invoiced over <strong>2010</strong>by Bamboss BVBA, whose Managing Director is the Executive(Managing) Director of <strong>Aquafin</strong>, is composed as follows:• basic compensation: € 372,041.04• variable portion: € 141,325.87• pensions scheme contributions:none• other compensation components: € 1,382.94He receives no compensation as a director within the Boardof Directors.n Management committeeThe total gross compensation that was paid to the membersof the Management Committee over <strong>2010</strong>, with exception ofthe Managing Director, amounts to:n• base salary: € 595,161.39• variable portion 1 : € 58,643.72• pensions scheme contributions: € 110,674.54• other compensation components: € 97,027.62GeneralThe salary policy with regard to the executive management,including the Managing Director, is specified by the Board ofDirectors, after it has received an advice from the Appointmentsand Remuneration Committee. The remuneration policy isdirected towards attracting, retaining and motivatingcompetent and skilled persons. The size of the compensationtakes the individual tasks and responsibilities of the membersof the Management Committee into account.1 The total amount of this income component is divided into one amount that is paid out as a gross bonus and is included under this heading,and another amount is part of the pension scheme entitlements, which are included under a heading of that name.

Once per year, the performance of the management teamis evaluated in the presence of the Managing Director.The evaluation of the Managing Director is carried out in hisabsence, of course. The entire process is closely monitored bythe Appointments and Remuneration Committee, and it isapproved by the Board of Directors. The operational, personaland commercial objectives are formulated each year on thebasis of a set of regulations. Each of the objectives is weightedin advance for the evaluation. In <strong>2010</strong>, the components of theevaluation made reference amongst others to organisational,budgetary, economic and environmental aspects and/orresults. In addition to the evaluation on the basis of objectives,the entire functioning of the involved person is also evaluated.The period during which these performances were evaluatedcovers 1 January <strong>2010</strong> up to and including 31 December <strong>2010</strong>.No shares (options) and/or rights for the acquisition ofshares were granted to the members of the executivemanagement (including the Managing Director).Up to or after 1 July 2009, no employment contracts wereconcluded with the Managing Director or any other memberof the Management Committee.IMPORTANT CHARACTERISTICS OF THEINTERNAL CONTROL AND RISK MANAGEMENTSYSTEMS OF THE COMPANYThe Board of Directors is aware of its responsibilities andtakes all possible risks into account in the determination ofthe strategic direction of the company. The risk-relatedsubjects are discussed at its meetings. The ManagementCommittee is also aware of the importance of good internalcontrol and risk management. Risk-related subjects arediscussed at the weekly gatherings.A risk-management policy, for which policy lines, procedures,signature authorities, built-in alarms and checklists weredefined, has been implemented in all departments. Changesin legislation are also followed up on. The necessary measureswere taken for ensuring information security. Several specificdepartments concentrate heavily on risks: Prevention & Safety,Environment and Quality, Compliance Management, the LessNuisance Manager, the ombudsman and the internal auditor.In addition, the company devotes attention to monitoringand <strong>report</strong>ing risks. In that respect, use is made of a reliableinformation system and the Balanced Scorecard, both asa measurement instrument and as a <strong>report</strong>ing system.Internal quality audits are carried out on the implementedprocedures. The internal auditor, external auditor and theEconomic Oversight Authority of the Flemish Region provideeffective oversight of the company.CONTROL OF THE COMPANYErnst & Young Bedrijfsrevisoren BCVBA, J. Englishstraat 52in Borgerhout, represented by Ronald Van den Ecker, have beenappointed as auditors of the company.The auditor's mandate lapses at the close of the annualmeeting in 2011.The annual compensation of the auditor, for the statutoryaudit of the annual financial statements of the company,amounts to € 58,350 (exclusive of VAT), which is paid to Ernst& Young.An additional amount of €50,000 (ex VAT) for managingthe conversion to IFRS was paid to the external auditor forspecial assignments and to persons with whom the auditorcollaborates on a professional basis. Further information onthis can be found in the explanations to the annual financialstatements.Report of the board of directors21

22<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>SHAREHOLDER STRUCTURE ANDCROSS-PARTICIPATIONSThe Vlaamse Milieuholding is the owner of all shares of<strong>Aquafin</strong> NV. No cross-participations exist.• Article 5.4/1: majority of independent directors in theAppointments and Remuneration CommitteeFor the purpose of maintaining the continuity withinthis committee, it was decided to appoint Mr Van Vaerenberghas a member. He is not an independent director but he knowsthe company and the specific context that it has to workin thoroughly.INSIDER TRADING AND MARKETMANIPULATIONWhen the new Charter was created, measures wereincluded to be in compliance with the provisions of theEuropean Directive 2003/6/EC concerning insider trading andmarket manipulation, since these provisions are applicable tothe company since the emission of the 2009 debenture loan.The role of the Compliance Officer was described with regardto the observance of applicable regulations and the provisionof required information. That Board of Directors will, if necessary,draft a so-called trading regulation.EXPLANATION REGARDING DEVIATIONSWITH REGARD TO THE CODE<strong>Aquafin</strong> applies the provisions that have been defined inthe “Belgian Corporate Governance Code”, which applies topublicly listed companies. Deviations from the Code arepossible in certain instances, due to the individual characterof the shareholding in the company.Mr A. Vanden Bon, secretary of the Board of Directors,has been appointed as the Compliance Officer.No <strong>report</strong>s were made during <strong>2010</strong>, to which theseprovisions would be applicable.The Code provisions that the company does not complywith are explained in more detail below.• Stipulation 8.9: Convocation of General MeetingsThe articles of association include a legal threshold of 20%for the convocation of a General Meeting. Given the nature ofthe shareholders of the company, lowering this threshold ispointless at this point.• Article 5.2/4: majority of independent directors in theAudit Committee.To ensure the continuity of the functioning of thiscommittee, it has been decided to retain Mr P. Cools as amember, in spite of Mr Cools unexpectedly having lost hisstatus an independent director in the course of this financialyear. The committee has a composition that still meetsthe requirements of the law (Sect. 526bis, Companies Code).

Report ofthe boardof directorsOver a period of twenty years, <strong>Aquafin</strong> has become a strongpartner in the water sector. Our strength is unmistakeablyin the combination of vision, expansion and management ofthe wastewater treatment infrastructure. The feedback betweeneach of the steps makes it possible to have an integratedvision with respect to water treatment. The Flemish Region,the municipalities and the drinking water companiesappreciate our technical expertise, our knowledge of the area,and our innovative attitude. All of those characteristics make<strong>Aquafin</strong> a unique player in the sector.Report of the board of directors23

24<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>Most importantdevelopmentsduring thefinancial yearCOMPANY IN MOTION<strong>Aquafin</strong> has made the strategic choice for a client-focusedmodel, in which we expand and deepen our core activities inFlanders. We focus on delivering added value to the FlemishRegion, the municipalities and our stakeholders. At the same time,we create space for new opportunities. For example, we want toleverage the valorisation of our expertise with the Flemish industryand abroad.To achieve that ambitious plan for the future, the companymust be manoeuvrable and able to respond quickly to trends andchanges within and outside the sector. That means, in the firstplace, a culture change with every member of personnel improvinghis or her client orientation. The organisation is being redrawn aroundour four core processes: vision development, accelerated executionof projects, network operations and financing. The managementand control processes were redefined with a clear objective.We want to give our clients a pleasant experience and deliver rapidtransactions, with budgets and cost prices that are transparent andwhere a commitment is a commitment. Those objectives requiregood information management and a flexible IT architecture thatis aligned with our processes. For that reason, the requirements inthat area were identified in <strong>2010</strong>.

A flexible company also requires a flexible organisationof work and workstations. When the <strong>Aquafin</strong> main buildingwas renovated in <strong>2010</strong>, that is the philosophy that was used.There are no permanent workstations anymore; there are nowclean desks that can be used for concentrated work, projectwork or meetings, depending on the need. That philosophywill be expanded throughout the company as soon as all ofthe necessary steps have been taken to organise and digitisethe information and paper flows.With the budget for the optimisation programme 2012,133 projects will be carried out. Projects valued at €200 millionwere defined, with €100 million again being allocated toinvestments related to the Local Pact with the municipalities.In this programme, the remaining €50 million is beingexplicitly allocated for the overrun of the investment andrenovation programme from previous programme years.EXERCISE SHOWS THAT AQUAFIN IS'CRISIS-READY'In December, <strong>Aquafin</strong>, a crisis-communication firm andthe Federal Nuclear Control Agency held an extensive crisissimulation that tested our communications skills and ouroperational readiness. The exercise was assessed as 'good',and some points with room for improvement were identified.The general view was that <strong>Aquafin</strong> was among the top inBelgium when it comes to preparation for and communicationduring crises. Of course, we are not going to rest on our laurels.Regular exercises are crucial to be able to respond adequatelyif a real problem arises.APPROVAL OF OPTIMISATION PROGRAMMES2011 AND 2012On 6 April and 19 November, the Flemish Region set thebudget for the expansion of the supra-municipal watertreatmentinfrastructure for the programme years 2011 and2012 at €250 million each.As part of the Local Pact with the municipalities, in 2008,the Flemish Government decided to make an annualcontribution of €100 million over seven years to improvethe municipal sewer system via the investment programmemandated to <strong>Aquafin</strong>.With the budget for programme year 2011, 192 projectswill be carried out. The basic budget of €100 million is beingaugmented with €100 million for projects that have beendefined as a part of the Local Pact. The remaining €50 millionare intended for dealing with budgetary shortfalls on projectsthat had been mandated in the past.The optimisation programmes are being drawn up bythe VMM (Flemish Environment Agency), in consultationwith <strong>Aquafin</strong>, the provinces and the basin administrators.They include projects that focus on the additional sanitationof various discharge locations, the construction of small-scalewastewater treatment plants and the construction of strategicrainwater piping to improve the existing infrastructure.When choosing the projects, attention is given to theirecological and economical profitability.FIRST PART OF THE PLANTS AND PROPERTYOF THE FLEMISH ENVIRONMENTAL COMPANYPURCHASEDIn 1994, under the terms of the management agreementbetween the Flemish Region and <strong>Aquafin</strong>, the companyacquired the user rights for the treatment plants that hadalready been established before the company was operating.Those treatment plants are not carried on the <strong>Aquafin</strong> balancesheets. The investments for the renovations and expansion ofthose plants, which <strong>Aquafin</strong> had done over the past few years,are carried on our balance sheets.Report of the board of directors25

26<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>It has become clear in the meantime that it is not efficientto have two entities with responsibility for a single piece ofproperty. For that reason, the Flemish government decidedto have <strong>Aquafin</strong> purchase, operate and finance the plantsowned by the Flemish Environment Company.To make the financing of the purchase possible, themanagement agreement and the allocation agreement wereexpanded by addendum no. 7 and addendum no. 2, respectively.The first phase of that purchase took place at the end of<strong>2010</strong> for a purchase amount of €157.9 million (incl. registrationrights). Part of that purchase was financed with equity.For that purpose, the shareholder Flemish EnvironmentalHolding made a capital payment of nearly €49 million.The remainder of the purchase was financed with the existingcommercial paper programme.The second phase of the purchase has a value of approx.€200 million and will be done in 2011. The remaining amountof the purchase, for the first and second phases combined,will be financed by borrowed capital in a single package.The part of the purchase that was financed with equity willnot be passed on in the drinking water charges to customers.However, the matching amount may be charged if themanagement agreement were to come to an end. The partthat is being financed with borrowed capital will be chargedover a period of 20 years.The graph shows the impact of the purchase on theamount of the invoices to the drinking water company forthe next few years.APPROVAL OF THE FINANCIAL STATEMENTSFOR THE FINANCIAL YEARS 2005-2007On 2 April <strong>2010</strong>, the Flemish government decided toapprove the financial <strong>report</strong>s for financial years 2005,2006, and 2007. Those <strong>report</strong>s were prepared by <strong>Aquafin</strong> inaccordance with Article 5 bis-1 of the management agreement.They give a well-structured picture of the utilisation ofthe funds that were provided to <strong>Aquafin</strong> for the execution ofthe management agreement. The decision of the FlemishGovernment implies that no costs have been rejected andthat the created provisions do not have to be utilised.IMPACT PURCHASE VMM TREATMENT PLANTS ON THE AMOUNT OF THE INVOICESTO THE DRINKING WATER COMPANIES/THE FLEMISH REGION600,000,000 €500,000,000 €400,000,000 €300,000,000 €200,000,000 €100,000,000 €0 €<strong>2010</strong>201120122013201420152016201720182019202020212022202320242025202620272028202920302031n Current invoicesn Invoices after plants purchase

For the operating costs for the years 2008 and 2009, a totalprovision of €500,000 was reserved in the past. Inasmuch asthat provision is not based on actual payments, the auditcommittee advised in <strong>2010</strong> that the company should reclaimall of that provision.FIRST EU FINE LOOMS FOR BELGIUMWith Belgium still not complying with the EU UrbanWastewater directive, the country has been sent to theEuropean Court of Justice for the second time. That could leadto a lump-sum fine of more than €15 million and a dailypenalty of nearly €62,000 until Belgium complies with thedirective. In Belgium, environmental matters are a regionalresponsibility. None of the three regions is currently compliantwith the directive. Since the foundation of <strong>Aquafin</strong> in 1990,we have eliminated a large part of the arrears thatFlanders had vis-à-vis the neighbouring countries. As of today,there are no agreements concerning the allocation of theaforementioned fine and penalties among the three regions.<strong>Aquafin</strong> does not expect an EU fine for Belgium to haveimmediate consequences for the company.BOOKKEEPING SWITCHES TO INTERNATIONALSTANDARDStarting in 2011, <strong>Aquafin</strong> will <strong>report</strong> in accordance with theapplicable International Financial Reporting Standards (IFRS).A working group was established early in <strong>2010</strong> to managethe implementation of IFRS. A phased plan was developed ina joint project approach with a consultant.The emphasis is on the specific standards and interpretationsthat are important for <strong>Aquafin</strong>, especially IFRIC 12 – servicesbased on concession agreements. In order to publish thefinancial <strong>report</strong> for 2011 in accordance with IFRS rules,comparable figures had to be <strong>report</strong>ed for <strong>2010</strong>. Starting ontime was therefore a key aspect. The website of <strong>Aquafin</strong>was also modified to comply with all of the informationrequirements.FINANCIAL DEVELOPMENTSnContinued trust of our financiersOver the past few turbulent financial years, our financiershave continued to have trust in the company. In the currenteconomic situation, it is important to have financing in placeeven before it is needed. For both the short-term and longtermfinancing, <strong>Aquafin</strong> was able to extend its credit lines in<strong>2010</strong>, including the extension of the bilateral credit lines at thesame level. After the European Investment Bank (EIB) grantedthe first 30-year loan to <strong>Aquafin</strong> in 2009, the first 30-yearcommercial loan was finalised in <strong>2010</strong>.The EIB and <strong>Aquafin</strong> have been working together since1994. <strong>Aquafin</strong> is very grateful to that institution for the adviceand the support it has given for all that time. With a total ofseven loans, the EIB has supported the wastewater treatmentsector in Flanders with €1.2 billion.Report of the board of directors27

28<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>nConfirmation of credit-worthiness of <strong>Aquafin</strong>In September <strong>2010</strong>, <strong>Aquafin</strong> again received an excellent<strong>report</strong> from the independent rating service Moody’s. For bothshort-term and long-term credit, <strong>Aquafin</strong> was granted thebest possible ratings - AAA and P-1, respectively. With thoseratings, <strong>Aquafin</strong> is still able to borrow today from the banks atextremely favourable rates.n Meeting the financial needs for 2011The financial requirements for 2011 amount to approximately€400 million. That amount is needed in order to carry outthe investment programme that has been imposed and forthe further purchase of the remaining treatment plants fromthe Flemish Environment Company (addendum No. 7). We willconsult the banks to develop proposals for specific products,with due regard for the possibilities of the market. There isanother line of €125 million available from the EuropeanInvestment Bank. We have different bilateral short-term linesof credit, including a revolving credit facility in the amountof €210 million. There is also a great deal of room underthe commercial paper programme of €400 million, which has€300 million in back-up lines.The financial results of the interest management arecalculated against individual benchmarks (the result of anindividual strategy in comparison with the applicable interestswap at the moment of the establishment/execution ofthe structure). The interest cost of the underlying loan mustbe taken together with the results of the structure builton top of it, in order to see <strong>Aquafin</strong>'s ultimate debt burden.The financial results are offset with the drinking-watercompanies. The market value of the derived financial instrumentsis stated in the explanation of the annual accounts.nInterest management is a successThrough active management of the interest risk <strong>Aquafin</strong>wishes to optimize the financing costs. In 2006, the <strong>Aquafin</strong>Board of Directors approved the outlines of a dynamicmanagement procedure for interest-rate risks. The interestpolicy was modified in 2008. In 2009, primarily the descriptionsand definitions were modified. No changes were made tothe principles themselves.For the existing credit portfolio the active interest ratemanagement became tangible in the form of “fixed interestdebt variabilisation”, whereby a safeguard is built in againstincreasing interest rates and at the same time the possibility iscreated of benefiting from stabilizing or falling interest rates.Active interest management can be applied to maximally 35%of the underlying debt of <strong>Aquafin</strong>’s total debts in the long term,increased by the bonds issue of 30 May 2006. That strategywas finalised in 2008. To cover future financing requirements,the interest policy provides a dynamic programme for interestmanagement, up to a maximum of 50% of the future longtermdebt, which could be up to five years in the future.New structures were established in <strong>2010</strong> for our futurefinancing requirements. Existing strategies were also optimised.In <strong>2010</strong>, savings of €1,068,000 were achieved vis-à-vis thebenchmark. Half of that was immediately deducted fromthe invoice to the drinking-water companies. The other half wasretained in the company as an interest buffer for optimisingstructures. As of 31 December, that buffer amounted to€1.6 million. That amount is made up of the reserve fromprevious years plus the amount from <strong>2010</strong>. According tothe agreements made with the economic oversight authority,that amount may never be higher than €2 million.

Expansion ofthe wastewatertreatment infrastructurefor theFlemish RegionThe emphasis for both the Flemish government and <strong>Aquafin</strong>is on the effective achievement of the European directives.The expansion of the wastewater treatment structure in Flandersis preceded by careful vision development. In <strong>2010</strong>, <strong>Aquafin</strong> onceagain achieved the set objectives. We continue to examine ourprocedures, however, to be able to work more client-focused andmore efficiently.In order to keep the timeframe from design to delivery as shortas possible, we examined our project-procedures in <strong>2010</strong> andmodified them. Before the first steps to implementation are taken,we precisely identify the risks associated with a project. That wasdone in the past as well, of course, but less explicitly. We also wantto be able to anticipate possible delay factors more quickly.These may be found in the social context, or may be related toconstructional aspects such as ground quality and the location ofthe utilities pipelines. Accurate estimates and good investmentcostmanagement are also important. We are already monitoringthe legal administrative framework, such as the application forpermits, very closely, but there, too, it is important to be proactive.Report of the board of directors29

30<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>PROJECT PORTFOLIO GROWS FURTHEROn 31 December <strong>2010</strong>, the active investment-project orderportfolio for the Flemish Region amounted to more than€1.4 billion for 1,371 projects. By that date, <strong>Aquafin</strong> haddelivered 2,153 investment and renovation projects worth€2.8 billion.VALUE PROJECT PORTFOLIOnnIn design phase:€1,074.67 mioAwarded andcontracted out:€384.65 mionDelivered€2,817.13 mioTENDERSIn <strong>2010</strong>, <strong>Aquafin</strong> put projects worth €151 million out totender. That is €5 million more than in 2009. By collaboratingwith municipalities and supra-municipal utilities, the amountrose to €230.4 million. For 2011, we are aiming for €160 million.For all agglomerations, a determination has been made ofthe wastewater treatment infrastructure that is a priority inorder to comply with the European Urban Wastewaterdirective. Since the start of <strong>2010</strong>, all wastewater treatmentplants in agglomerations of more than 10,000 peopleequivalentswere operational and only 9 collector sewers werestill being worked on by the end of <strong>2010</strong>.In agglomerations of between 2,000 and 10,000 peopleequivalents,there were 4 wastewater treatment plantsmissing at the beginning of 2011. The plants in Bavegem,Oplinter, Hoepertingen and Melsbroek were all in progress.The remaining 20 priority collector sewers have been put outto tender or are in progress.DELIVERIESIn <strong>2010</strong>, <strong>Aquafin</strong> delivered projects worth a total of€157.73 million. The amount for wastewater treatment plantswas €33.9 million. For the expansion of the sewer system,€123.82 million was spent. The target for 2011 is €158 million.CONTRACTING RHYTHM (in million Euros)DELIVERY RHYTHM (in million Euros)300250200150100503002502001501005002003 2004 2005 2006 2007 2008 2009 <strong>2010</strong>02004 2005 2006 2007 2008 2009 <strong>2010</strong>n <strong>Aquafin</strong>n Other partiesn Budgetn Total

32<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>Construction activity per water basin in <strong>2010</strong>YSER - BRUGES POLDERS - GHENT CANALS - LEIE●HEISTKNOKKE●●BOEKHOUTEBRUGGE ●●MALDEGEMWATERVLIETMOERBEKE -●●● BRUGES POLDERSEEKLO● STEKENEOOSTENDE●KRUISSTRAAT●ZELZATE ●JABBEKEERTVELDE ●MOERBEKE ●●● SINT-NIKLAASYSERBEERNEMSINAAI SINT-NIKLAAS -●●ZOMERGEMGHENT CANALSWULPENKOEKELAREAALTERHEIMOLEN●●RUDDERVOORDE●●● EVERGEM●●● PERVIJZEBALIEBRUGGE ●● SINT-PIETERSVELDADINKERKELOKEREN●KORTEMARKWINGENENEVELE●●GENT●WOUMEN●LATEMLO ●●●TIELTSTADEN● DEURLE●●DEINZEPITTEM● VLETERENROESELAREROESBRUGGE ●●● OLSENE● INGELMUNSTERWATOU●IEPERMOORSLEDE● WAREGEM●ZONNEBEKELEIE●●● BEVEREN-LEIEPOPERINGE ● VLAMERTINGE●●● HARELBEKEIEPER - HOLLEBEKELEDEGEMHEULEWESTOUTER ●●●● ●WESTOUTER_OUDMENENLOKER●●●l taken into operation in <strong>2010</strong>YSERTreatment level: 75.6% (75.3% in 2009)Supramunicipal infrastructure under management:l 18 wastewater treatment plantsl 85 pumping stationsl 380 km of pipingNUMBERTENDER SUMProjects in progress 10 6,804,921 €NUMBERDELIVERY SUMDelivered projects 8 8,031,418 €GHENT CANALSTreatment level: 80.2% (79.9% in 2009)Supramunicipal infrastructure under management:l 16 wastewater treatment plantsl 90 pumping stationsl 356 km of pipingNUMBERTENDER SUMProjects in progress 8 4,075,961 €NUMBERDELIVERY SUMDelivered projects 6 12,255,572 €BRUGES POLDERSTreatment level: 84.4% (80.9% in 2009)Supramunicipal infrastructure under management:l 12 wastewater treatment plantsl 101 pumping stationsl 338 km of pipingNUMBERTENDER SUMProjects in progress 10 12,889,389 €NUMBERDELIVERY SUMDelivered projects 3 2,421,894 €LEIETreatment level: 69.4% (66.5% in 2009)Supramunicipal infrastructure under management:l 16 wastewater treatment plantsl 70 pumping stationsl 344 km of pipingNUMBERTENDER SUMProjects in progress 12 16,587,851 €NUMBERDELIVERY SUMDelivered projects 10 10,447,820 €

LOWER SCHELDT - UPPER SCHELDT - DENDERANTWERPEN - NOORDBERENDRECHTLOWER SCHELDT●BRASSCHAATKIELDRECHT ●KALLOSCHOTENDE KLINGE●MERKSEM ● ●●●●BEVERENDEURNESCHILDEBURCHT ●●WOMMELGEMANTWERPEN - ZUID ●● BOECHOUT●●●AALBEKE -TOLPENHOEK● ●ROLLEGEMTEMSE●● ●HAMME BORNEM● ●EDEGEMAARTSELAAR● BOOMDESTELBERGENSINT-AMANDS ● ●BLAASVELDZELE●●●RUISBROEKBERLARE●●DENDERMONDEOVERSCHELDEMERELBEKE●●●● ●WICHELENLONDERZEELMELLE ●WETTERENDE PINTE - ZEVERGEM ●●LEDE ●LEBBEKE - ROOIEN●EKE ●OOSTERZELEAALST●MERCHTEM●GAVERE ●●●●KRUISHOUTEMBAMBRUGGE● ASSE - BOLLEBEEKDIKKELVENNELIEDEKERKE●ASSE - BEKKERZEELUPPER SCHELDT● ZWALM●SINT-ANTELINKS DENDEROUDENAARDESINT-MARIA-LIERDE● NINOVE● ELSEGEM BRAKEL ● ●SCHORISSE ●● ZANDBERGEN● KLUISBERGENPARIKE● GERAARDSBERGEN●AVELGEM●●RONSE● GALMAARDENHELKIJN●●●l taken into operation in <strong>2010</strong>LOWER SCHELDTTreatment level: 87.6% (84.7% in 2009)Supramunicipal infrastructure under management:l 39 wastewater treatment plantsl 156 pumping stationsl 717 km of pipingNUMBERTENDER SUMProjects in progress 37 65,989,858 €NUMBERDELIVERY SUMDelivered projects 24 57,883,371 €DENDERTreatment level: 78.6% (78.1% in 2009)Supramunicipal infrastructure under management:l 11 wastewater treatment plantsl 128 pumping stationsl 426 km of pipingNUMBERTENDER SUMProjects in progress 16 20,188,586 €NUMBERDELIVERY SUMDelivered projects 7 3,410,870 €UPPER SCHELDTTreatment level: 65.1% (63.9% in 2009)Supramunicipal infrastructure under management:l 16 wastewater treatment plantsl 34 pumping stationsl 185 km of pipingNUMBERTENDER SUMProjects in progress 9 6,721,101 €NUMBERDELIVERY SUMDelivered projects 6 6,464,767 €Report of the board of directors33

DEMER - MAASESSEN●KALMTHOUT●MEER●HOOGSTRATEN● POPPEL●●● ZONDEREIGENMAASLOENHOUT●MERKSPLAS●BRECHTACHEL●● HAMONTLOMMEL● ●OVERPELT● LOZEN●BOCHOLTEKSEL ●KINROOI●● ● KESSENICH●BREEPEERBEVERLOMAAS● NEEROETEREN●TESSENDERLO●● KOERSEL● DILSENHEUSDENLUMMEN - GENEIKENHOUTHALEN - CENTRUM●ZICHEM●●MESSELBROEK●●ZONHOVENHOUTHALEN - OOST● ●ZOLDER ●AARSCHOT●DIEST●● HASSELT - KIEWIT● EISDENRILLAAR●●●● ●●HALENKERMTBOORSEM ●●HASSELT BOKRIJK GENKROTSELAAR● LANAKENDEMERALKEN ●●● BILZENROOSBEEKSINT-TRUIDEN WIMMERTINGEN●● HOESELT● RIEMSTNEERVELPZOUTLEEUW ●BIERBEEK - KLEINBEEK●●BORGLOON - TIVOLI ●TIENEN ●BORGLOON - NEREM ●● RIKSINGEN● ZICHEN●●●●HOEGAARDENGELMENTONGERENLANDEN -●VOEREN - VEURSRUMSDORP●l taken into operation in <strong>2010</strong>DEMERTreatment level: 69.8% (69.1% in 2009)Supramunicipal infrastructure under management:l 36 wastewater treatment plantsl 135 pumping stationsl 578 km of pipingNUMBERTENDER SUMProjects in progress 25 40,820,922 €NUMBERDELIVERY SUMDelivered projects 17 12,718,716 €MAASTreatment level: 84.0% (83.8% in 2009)Supramunicipal infrastructure under management:l 29 wastewater treatment plantsl 97 pumping stationsl 437 km of pipingNUMBERTENDER SUMProjects in progress 11 32,172,107 €NUMBERDELIVERY SUMDelivered projects 3 5,861,426 €Report of the board of directors35

36<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>Management ofthe wastewatertreatmentinfrastructure forthe Flemish RegionThe wastewater treatment infrastructure that <strong>Aquafin</strong> managesfor the region has become very extensive over the course of years.The standards that the treated water must comply with arebecoming increasingly strict. Nevertheless, we continue to delivergood results. That is due to the fact that <strong>Aquafin</strong> is constantlysearching for efficiency improvements and innovative solutions.The effluent results of <strong>2010</strong> were evaluated for 245 wastewatertreatment plants (WWTPs). Those are the treatment plans thatthe Flemish Region entrusted <strong>Aquafin</strong> with the operations ofin 1994 and the plants that <strong>Aquafin</strong> built itself and delivered tothe Flemish Region and for which the VMM (Flemish EnvironmentAgency) currently has an inspection programme.

IN ABSOLUTE FIGURES, A RECORD NUMBEROF PLANTS MET ALL THE STANDARDSIn <strong>2010</strong>, 232 plants (94.7%) were in compliance with all ofthe emission standards imposed. That is one per cent less thanin the previous year, but in absolute figures, there were anadditional nine plants that met all of the standards. The graphshown below begins in 1999, the year in which Europeimposed nutrient removal in large agglomerations.Four wastewater treatment plants were not compliantwith the effluent standards of the EU's Urban Wastewaterdirective. Until April 2004, the same standards were also thesector standards for the Flemish Region. Nine other treatmentplants did comply with the standards of the UrbanWastewater directive, but not with the stricter Flemishstandards of the VLAREM 'small train' modification.EVALUATION OF THE TREATMENT PLANTS’ RESULTS100%90%80%70%60%50%40%30%20%10%0%1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 <strong>2010</strong>n Complying with all standardsn Non-compliant with the stricter Flemish standards of the “Vlarem Kleine Trein”n Non-compliant with the 2003 standardsThe small-scale treatment works in Vlezenbeek, Voeren-Veurs and Oud-Heverlee did not comply with the UrbanWastewater directive as a result of a single sampling day,which measured serious excesses of biological oxygendemand (BOD), and chemical oxygen demand (COD) andsuspended solids. The plant in Halle failed due to severalincidences of major sludge leaching. At the end of December<strong>2010</strong>, the aged small-scale works in Halle and Vlezenbeek weretaken out of service and replaced by pumping stations.Nine wastewater treatment plants did not satisfy thestricter Flemish standards. For most of the plants, the shortfallwas extremely small.The treatment plants in Zele, Diest, Malle, Wingene andZemst-Kesterbeek failed by only one per cent for only oneparameter measured against the mandatory eliminationpercentage. The treatment plants in Olsene, Rollegem andBurcht also had shortcomings with only one parameter.The treatment plant in Oud-Turnhout, on the other hand,failed in four out of five mandatory elimination percentages.It is important to note here that the different concentrationstandards were not exceeded on any measurement day foreight of the nine plants. Only the treatment plant at Rollegemshowed one instance of exceeding the standard slightly forthe concentration of suspended solids, an exceeding that iseven permitted under the Vlarem.Report of the board of directors37

38<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>LOW OPERATING COSTS IN COMPARISONWITH GERMAN BENCHMARKThe German Aquabench has compared <strong>Aquafin</strong>'sperformance in several areas with eight German wastewatertreatment operators of varying sizes. It was to be expectedthat <strong>Aquafin</strong> would show peaks and dips in comparison withthe German operators because we are a foreign company,which is, by definition, set up differently. That turned out notto be the case, however. The <strong>Aquafin</strong> performance was verygood against the global results. <strong>Aquafin</strong> scored very well inthe operational area, in our cost per treated people equivalent.The cost component of the supporting processes was also low.The costs for sludge processing were average.HIGHEST ELIMINATION RESULTS FORTHREE PARAMETERSPer measured parameter (BOD, COD, suspended solids,nitrogen and phosphorus) the difference is determinedbetween the biologically treated pollutant load and theresidual pollutant load that is discharged after biologicaltreatment. The difference is the removed pollutant load,expressed in 1,000 tonnes/year. In comparison with 2009,eliminated residual pollutant load rose in <strong>2010</strong> by 6% forBOD and 1% for nitrogen and phosphorus. The eliminatedresidual pollutant load for COD and suspended solidsdeclined, however. The increases and decreases primarilyfollowed the influent loads.The removal percentage of the pollutant load is equal tothe pollutant load removed during the biological treatment,divided by the total pollutant load that was treatedbiologically. The average removal percentage has been stablefor several years for BOD (97%), COD (89%) and suspendedsolids (95%). In 1995, the Flemish government adopted astandard of 75% for nitrogen and phosphorus for all of thepublic wastewater treatment plants combined. Those targetswere also achieved in <strong>2010</strong> with 79% for nitrogen and 83%for phosphorus.ONCE AGAIN MORE POLLUTANT LOADDELIVERED AND BIOLOGICALLY PROCESSEDThe measured pollutant loads that are delivered to thetreatment plants can be expressed in terms of the number ofinhabitants that are already connected to the wastewatertreatment infrastructure. Flanders Region has more than6.1 million inhabitants. In <strong>2010</strong>, the treatment percentage wasapproximately 78%. Without counting the Flemish householdswhose wastewater is treated in the two Brussels treatmentplants, and without the pollutant loads of the connectedcompanies, the pollutant load of approximately 4.5 millionresidents would be expected at the <strong>Aquafin</strong> treatment plants.If we calculate the pollutant loads that were delivered in<strong>2010</strong> on the basis of the daily theoretical pollutant load perresident of Flanders, it appears that that pollutant load ismore than achieved. Estimates on the basis of five measuredparameters indicate a pollutant load for 4.634 millionresidents. 1 The data on nutrients are overstated, the data onBOD and suspended solids are understated.1 For the design of waste water treatment plants, the calculations takeaccount of the theoretical daily pollutant load of each Flemish resident:54 g BOD, 135 g COD, 90 g suspended silids, 10 g nitrogen and 2 gphosphorus.

REMOVED WASTE LOAD AND TREATMENT EFFICACY OF WASTEWATER TREATMENT PLANTSnBiological oxygen demandnSuspended solids751001<strong>2010</strong>0Removed waste load(1,000 tonnes/year)706560959085Removal percentageRemoved waste load(1,000 tonnes/year)11010090959085Removal percentage55808080‘01 ‘02 ‘03 ‘04 ‘05 ‘06 ‘07 ‘08 ‘09 ‘10‘01 ‘02 ‘03 ‘04 ‘05 ‘06 ‘07 ‘08 ‘09 ‘10nChemical oxygen demandnNitrogen2001002080190951875Removed waste load(1,000 tonnes/year)1801701609085Removal percentageRemoved waste load(1,000 tonnes/year)161412706560Removal percentage150801055‘01 ‘02 ‘03 ‘04 ‘05 ‘06 ‘07 ‘08 ‘09 ‘10850nPhosphorus‘01 ‘02 ‘03 ‘04 ‘05 ‘06 ‘07 ‘08 ‘09 ‘10Removed waste load(1,000 tonnes/year)3,02,72,490858075Removal percentageThe graphs show the removed pollutant load of all of thewastewater treatment plants combined, as well as the removalpercentage. Per measured parameter (BOD, COD, suspendedsolids, nitrogen and phosphorus) the difference is determinedbetween the biologically treated pollutant load and the residualpollutant load that is discharged after biological treatment.The difference is the removed pollutant load, expressed in1,000 tonnes/year. The removal percentage is the equivalent tothe pollutant load removed during the biological treatment,divided by the total biologically treated pollutant load.2,1‘01 ‘02 ‘03 ‘04 ‘05 ‘06 ‘07 ‘08 ‘09 ‘1070nlRemoved waste loadRemoval percentageReport of the board of directors39

40<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>ECOLOGICAL PERFORMANCE OBJECTIVELYMEASURED VIA THE INDICATOR FRAMEWORKFor monitoring the performance of the wastewater treatmentinfrastructure in Flanders, the VMM (Flemish EnvironmentAgency) and <strong>Aquafin</strong> use an indicator framework that expressesthe quality of the management of the supra-municipal waste -water treatment infrastructure in figures. <strong>Aquafin</strong>’s assignmentwas expressed by five indicators: whether the major pumpingstations on the sewage system function as they should;whether the overflows on the sewage systems are notworking more than expected; whether the capacity of thepumps and screws of the sewage water treatment plants areutilised sufficiently; whether the water is sufficiently treatedthere; and whether <strong>Aquafin</strong> responds well to incidents thatoccur in the wastewater treatment infrastructure. At this time,the indicators are already being calculated for 72 treatmentzones. Combined, they comprise approximately 70% of theFlemish residents who will be connected to the central watertreatmentinfrastructure in the future. The indicator frameworkwill be applied to 129 treatment zones over time. From theresults of 2009, it appears that <strong>Aquafin</strong> has once againimproved its score in comparison with the previous year.That is primarily due to better wastewater treatment.The indicator that evaluates the overflow functioning hasdeteriorated slightly in comparison with last year. <strong>Aquafin</strong> ishowever not evaluated for the functioning of the overflows.That is often the result of factors that the company does nothave complete control over, such as the dilution of the sewagewith rain water in the sewage system.ENERGY RECOVERY FROM SEWAGE WATERIn addition to raw materials, we can also recover heat fromsewage water. Wastewater contains a high level of thermalenergy because households send a lot of hot water into thesewage system. Investigations into the feasibility of usinga heat pump on effluent have led to positive results and animplementation at the Aartselaar wastewater treatment plant.The laboratory in Aalst is being heated as well with a heatrecoveryinstallation. We are currently conducting feasibilitystudies for the use of heat pumps in the sewage system to,for example, heat swimming pools and public buildings.STANDARDS FOR TREATED DOMESTICWASTEWATERThe treated wastewater (effluent) must meetcertain standards, which depend on the size of theagglomeration for which the plant was built. Up to 2004these norms were a copy of the European standards,imposed via the European Urban Wastewater directive.At the Flemish level they were made stricter by a Vlaremamendment between 2004 and 2006. <strong>Aquafin</strong> monitorsfive parameters: biological oxygen demand (BOD),chemical oxygen demand (COD), total nitrogen, totalphosphorus and suspended solids. The biological oxygendemand indicates how much oxygen bacteria need todecompose the organic pollutant load in 5 days’ time at20° C in 1 litre of treated wastewater. When BOD valuesare high the bacteria develop so fast that there is a riskthat through their respiration all oxygen in the water willbe used. The chemical oxygen demand indicates howmuch oxygen is needed to fully oxidize the pollutant loadpresent. The parameter suspended solids provides ameasure for the suspended (non-dissolvable) solids thatmay remain in the treated wastewater. Too muchnitrogen and phosphorus in the water produces anexplosive algae growth. At night these algae removeoxygen from the water creating difficulties for fish,aquatic plants and other organisms.

Services beyondthe scope of theagreement withthe Flemish RegionAn increasing number of municipalities also use their ownresources to engage <strong>Aquafin</strong> because they can use the support ofa professional partner for the expansion and management oftheir sewage systems. The Minister of the Environment encourages<strong>Aquafin</strong> to valorise its expertise with the municipalities andindustry in Flanders as well as abroad.RELIABLE PARTNER FOR THE EXPANSIONAND MANAGEMENT OF THE MUNICIPALWASTEWATER TREATMENT INFRASTRUCTUREThe regional wastewater treatment infrastructure is in theoptimization phase, while the local sewerage network still has tobe expanded substantially. Since the end of 2004, <strong>Aquafin</strong> hasbeen permitted to compete with the other sewerage operators inthe municipal market. With our knowledge and experience, we arethe ideal partner to assist the municipalities in their efforts tocomply with the directive on Urban Wastewater and the WaterFramework directive.Report of the board of directors41

42<strong>Annual</strong> <strong>report</strong> <strong>2010</strong>The municipalities that decide to work with <strong>Aquafin</strong> forthe expansion and management of their system always do soon the basis of a tender call. In <strong>2010</strong> a municipality couldchoose for ad hoc assignments or a long-term collaborationwith <strong>Aquafin</strong>. That could be done by concluding a directconcession agreement or by joining the collaborativeventures that <strong>Aquafin</strong> has entered into with drinking watercompanies AWW (RI-ANT), VMW (RioAct and RioP) andVivaqua. <strong>Aquafin</strong>'s turnover outside the contract with theRegion however is not substantial compared to the totalturnover of <strong>Aquafin</strong>.In <strong>2010</strong>, <strong>Aquafin</strong> became a partner to RioP through theaddition of our databases for the connected municipalities.For <strong>Aquafin</strong>, that also means being embedded in the provincialand technical committees.Four new municipalities have joined RioAct, and one newmunicipality has joined RioP. Another four municipalities haveentered into extensive Rio-Totaal contracts for differentmodules. Our services for our existing clients were intensified,which is demonstrated by the project portfolio for themunicipalities connected to RI-ANT and the municipalitiesthat have entered into a concession with <strong>Aquafin</strong>. <strong>Aquafin</strong> hasentered into financing agreements with several newmunicipalities for the projects that are to be carried out.The municipalities that were already taking advantage of thatpossibility have had additional projects financed.Our client municipalities clearly appreciate our personalapproach to disconnecting rainwater and household waste -water on private property and the placement of individualtreatment installations. Our own disconnection experts arethe company's calling card for the neighbourhood residents.Over the next few years, we want to concentrate even more onpersonal contact with the residents by expanding a contactcentre. For the municipal administrations, we will expand ourextranet services further.SUPPORT FOR INDUSTRY AND FOREIGNPROJECTS VIA AQUAPLUSAquaplus NV, the commercial subsidiary of <strong>Aquafin</strong>,concentrates on industrial requirements in Belgium. AbroadAquaplus offers assistance to governments, administrationsand companies in achieving their environmental norms.Aquaplus offers customised solutions for all stages withinthe wastewater cycle. In <strong>2010</strong> in Belgium, the company signedinteresting contracts for the operation of industrial waste -water treatment facilities. There is a clear demand for technicaltraining provided by Aquaplus outside Belgium, as well.FLEMISH RESIDENTS PER SEWERAGE OPERATORn <strong>Aquafin</strong> 43%n AquaRio (TMVW) 23%n IWVA 0,5%n RioBra (PBE) 5%n Vivaqua (BIWM) 2%n Hidrorio/Hidrosan/Hidrogem (Pidpa) 7%n Infrax 20%n RioAct (VMW-<strong>Aquafin</strong>) 16%n RioP (VMW-<strong>Aquafin</strong>) 4%n <strong>Aquafin</strong> (concession) 6%n Extensive RioTotaal contracts 2%n RI-ANT (AWW-<strong>Aquafin</strong>) 15%